Our new-to-us J/109, like most production boats, came to us with an electrical system, installed in 2004, that is not even close to ABYC compliant. Said system also had some dangerous defects.

And on top of that, the system as installed by the builders, while adequate for the light usage they envisioned, is horribly inefficient, and will be very frustrating, not to speak of environmentally destructive, to live with once away from shore power for more than a few hours—think running the engine for hours, and often, to charge the batteries.

The same applied to our previous boat, a McCurdy and Rhodes 56 that we owned and mostly lived aboard for 30 years, and the one before that, a Fastnet 45.

The Way It Is

But here’s the thing, our experience is the norm, not an aberration, and the older the boat we buy is, the worse the system will be, so there’s no point in wasting time pissing and moaning, rather, we need to fix it.

Two Tips For Buyers

But before we get into that, two tips for those of us buying a secondhand boat, as we did:

- The boat will almost certainly require significant rewiring and electrical upgrades, so we better budget time and money to do that.

- The survey will probably not warn us of this impending expense and hassle, so even with a clean survey we need to leave money in the budget for this project.

A Survey Won’t Save Us

On the second point. Yes, I know, most surveyors claim to be ABYC trained and claim they survey to that standard. And maybe some do.

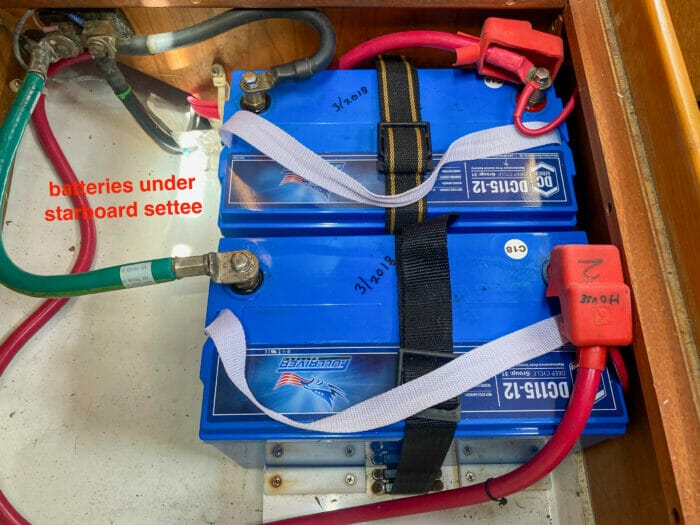

But the fact is that, during the process of buying our J/109, I read through three surveys on the class—two on the boat we bought, and one on another boat—and not one even pointed out that the batteries were not fused, a fundamental code violation and a potential boat-burner.

I also read through several other surveys on other types of boats, and not one had more than one or two trivial mentions of ABYC-compliance violations, and all completely missed problems and omissions that I could see at a glance in photos, like the one at the top of this article.

A North American Problem?

I’m guessing, but do not know, that the situation in Europe, and probably Australia and New Zealand, will be better, at least for boats built comparatively recently, both because in those countries regulations are backed up by the rule of law, rather than just being recommendations as ABYC’s are, and because it seems that surveyors in these countries are, as a rule, more thorough.

But even so, our experience and what we are doing about it will still be of use to those of you in countries other than North America who are buying boats that are over about 10-years old, or boats that have suffered from electrical system modifications from a series of owners equipped with a lot more enthusiasm than knowledge.

So what the heck are we supposed to do about this state of affairs?

Delegate?

What about hiring a boatyard to fix the problems and upgrade the system to ABYC? Generally a bad idea for three reasons:

- Most boatyard staff are woefully ignorant of basic electrical theory and the applicable standards; yes, including the ones that are ABYC certified—the courses they take are a joke.

- Even if the yard has a person who does understand ABYC or CE, the likelihood is that they will have absolutely no idea how to make the system more efficient for cruising away from shore power.

- High cost. More on that in a minute.

How bad are the first two issues? Really, really bad. For example, I know of only one guy here in Nova Scotia and one in Maine who I would trust to rewire my boat to be both compliant and efficient.

Gotta Take Responsibility

Given the deplorable state of training and knowledge among most boatyard “professionals” and even boatbuilders, particularly in North America, even if we can afford to delegate the actual work, we owners have to get at least a basic understanding so that we can check it’s being done right.

The other problem is that even if you can find someone competent (look for independent contractors, not boatyards), you will probably have to wait ages before they can help you. The good people are invariably snowed under.

Don’t believe it’s that bad? Well, read on for a couple of examples:

I’ll take the easy fault: no fuses at the battery. Fun sparks if the battery to switch line disconnects at the switch end especially on a metal boat

Oh, and yes please do a lithium chapter. I am particularly interested in whether we can trust the battery management system built in to many lithium packs to charge when supplied 14-odd volts from the alternator

Hi Adam,

Short answer to that: no

“Drop In” lithium on a cruising boat is in my top three list of the biggest scams I have seen perpetrated on us boat owners in the last 40 years.

I talked with our insurer about lithium and they gave me some requirements that I took to a reputable installer in Ft Lauderdale. They came back with a full Victron quote for 900ah that fully met charging, discharging, monitoring, and alarms. $35,000 was the quote.

I got a second quote, $30,000 but it didn’t include integrating the alternators (catamaran).

When it comes to work that we have done on our boat, we always approach it in the order of safety, reliability, redundancy, and cost.

At this point I just don’t see how the cost/benefit works out for lithium for /us/.

Hi Ray,

You make a very good point that as soon as we involve our insurance companies in the decision lithium gets very, very, expensive. I’m guessing that will change over time as good quality properly integrated lithium solutions get less expensive, but of course that will still leave us with a lot of expense for the professional installation that most underwriters are starting to insist on. Thanks for the realty wake up call and sharing your very sensible process.

Lithium’s not a chapter. It’s a textbook.

“Drop-in replacement” lithium batteries are, almost universally, meant for streetlights and traffic signals and the like. Cruising boat service absolutely requires a properly integrated system, otherwise you will end up with expensive failures (if not fires).

At the very least, anyone considering such a system needs to thoroughly read and understand ABYC A-4, E-10, E-11, E-30, and TE-13, and to understand exactly how the battery chemistry, cell balancing, BMS, charging & load buss architecture, charge/discharge characteristics, temperature management, fire suppression, etc. need to work. You also need a good relationship with your insurer, and for them to sign off on the design and the installation. The underwriters are starting to get wise to the risks of DIY lithium.

I’m thinking of doing another article or two on this, not from a “here’s how to build one” standpoint, but rather “here’s all the stuff you need to become an expert in before you can think about building one”.

Hi Matt, well said. And as probably most of us don’t have time and experience enough to become that expert, one needs to find one. And I am drop dead sure there are more self-assigned Lithium experts in the wild than good people having real know-how.

Agree 100%.

Hi Matt,

That’s a good summary, all I’m planning is to discuss why the system I’m planning for the J/109 would have to be radically changed for lithium. So, like you, no plans to get into the how-to-lithium game. Giving people just enough information to help them trash a bunch of expensive gear, or possibly burn their boats is not what we do here at AAC…there are already enough practitioners of that art out there, particularly on YouTube!

Hi Matt,

Nigel Calder has an interesting take on lithium and insurance companies in an endpaper essay in the Feb/March “Professional Boatbuilder”.

My best, Dick Stevenson

Hi Dick,

Is that online, if so, can you please link to it.

Hi John,

I get a paper copy. I could not find it on line, but that may reflect more my lack of skills in the computer realm.

My best, Dick

Hi John, yes, PB current and back issues are online, at least for subscribers. Subsription is free for “marine professionals”, I’m 100% sure that you qualify.

Hi Adam,

That’s one, for sure.

The biggest mistake we made with our rewire was to not add extra “fat” to the output calculations of our flexible solar panels. After a couple of years their output was down just enough to break the nice plan we had made, and mean we needed to start running the engine again more often than I’d liked.

+1 vote for a lithium chapter (although it is not in my immediate future).

Hi Alissa,

Sorry to hear that, but thanks for sharing, it’s a great tip.

Yes to the lithium discussion!

John will you put fuses on the batteries themselves?

If it’s not fused on the battery itself, it should be fused within 7 inches of the positive terminal. I’d be amazed, and dismayed, if a surveyor missed that.

Blue Sea’s on-terminal fuses are nice and compact, as long as you have some vertical clearance, but spares can be hard to find. (While taking delivery of Maverick V, we got stuck at the dock because someone had installed a 150 A fuse, the largest that the chandlery had in stock — but the starter drew 200-250 A.)

My own preference is for a 6-inch 0AWG or heavier pigtail to a marine MEGA-AMG or Class-T fuse block, for which spares in any rating up to 400 A are readily available. Add double-layer heat shrink insulation over any exposed metal on the terminals, plus a rubber cap to protect the lugs from shorting if someone drops a tool.

Also, am I badly mistaken, or did someone wire the battery switch on John’s boat to the negative terminals? (edit – or is that the shunt, in which case why are they on opposite ends?) And what’s with the gigantic spacers on the lugs?

Hi Matt,

All good ones, and yes the survey mis blew me away too, but I have 4 recent surveys that all missed the same thing. As to wiring on the shunt that you and Steve got…beats the hell out of me! Huge spacer on lugs are so one can use clamp on cables like in a car, but the “professional” who changed the batteries a couple of years ago did not remove then when using ordinary bolt on lugs…probably the same genius who wired the shunt.

I’m with Matt on MEGA/AMG fuses. Previously, I was favoring ANL fuses “because they are readily available”. What changed my mind was two things.

First, an odyssey to actually find one on a foreign city. What I got was either for M8 bolt not M10, or it wasn’t ignition protected (fuse was on battery compartment).

Second thing was finding this document on Bluesea whitepapers, that say:

“Blowing amperage for 40A ANL fuse is actually about 100 amps”…

https://www.bluesea.com/support/articles/Circuit_Protection/95/Choosing_Circuit_Protection

The only thing wrong with MEGA/AMG fuses is that they too have two bolt sizes, M6 and M8, and they can be tinned or plain copper. So, having a set of suitable spares is pretty much mandatory with them too.

Also, they are cheaper, and more compact than ANL’s, so it is quite easy to make a neat custom main bus with them where the other end is on common copper bar and output is on bolt with cable lug – provided that one can do a hot-dip-tinning for plain copper bar.

Good info Petri. I’m trying to sort out what to do on my own boat, as it too, did not come with circuit protection and was also missed by the surveyor. I’m using the blue sea circuit wizard to determine the protection. It asks for the CCA of the battery. I have no idea what that is for my house bank and can’t find it on the Trojan website (anyone know how to calculate this?). So I tried this exercise for the engine starting circuit. After entering the data for the wire size and getting 2/0, I’ve entered the load of the starter, which I estimate to be around 250A and the CCA of the battery which is 1375. It gives me a range of fuses to select from and it describes MEGA fuses as having inadequate AIC, even though it has fuses available at the same rating. I’ve tried different configurations and MEGA is always not recommended for the same reason. ANL and Class T are always on the list.

Am I missing something here regarding AIC and each fuse’s application? Or is that what the Blue Sea paper is trying to point out?

Your comment regarding international availability has me thinking. So maybe Class T is more widely available abroad…? Or I just carry more spares than originally planned for.

Hello Will, I remember that two T-105’s in series give about 650A CCA. What comes to MEGA/AMG AIC (Amperage Interrupt Capacity), I think that they got derated from 5000A to 2000A on Bluesea somewhere between 2010-2020. Though it reads on AMI/MIDI product page that it is 2000A on 32V and 5000A on 16V. It should apply also to MEGA/AMG.

Anyhow, T-fuse is the universally recommended main battery fuse because 20 000A AIC is always sufficient, and MEGA/AMG ‘s ans AMI/MIDI are good to fuse the main bus cabling, ie. input cables from alternator, mains charger, solar, wind etc. and outputs to main panel, inverter etc.

And yes, BUSS automatic breakers (40-150A) are more “offshore’y” for main bus, but sometimes not ok due to cost, size or amperage issues.

Hi Mike,

On one, not the other, more coming on why.

Another vote for what it takes to switch to lithium.

yes to more on lithium reality

Hi Brian,

Will do. Tentative title for first piece. “Don’t Let a Con Man Sell You Drop in Lithium”

Seriously, I totally get why very smart people get sucked in by this one…con men are convincing, that’s what they do.

Cables not secured every 18″

If either of these batteries are not used for starting then they lack OCP within 7″ (can’t tell for sure but that includes the small wire) of the positive terminals.

The straps and strap eyes, secured with all too common mild steel and now rusty screws, will almost certainly not pass the ABYC battery security test. ABYC standards do allow for 1″ of movement, a rule I’ve been fighting to change for years. Those wimpy strap kits have been a travesty to the marine industry for decades. light duty, hard to take apart and the screws, oh the mild steel screws, which are undersized in any event.

Why are the negative cables connected to opposite sides of the shunt?

Negative cables are the wrong color.

Hi Steve,

I think you got them all, although maybe add no drip tray, but that’s hard to see in the shot.

Hi Steve, and Matt,

it seems that the two batteries are not paralleled. If the above battery is the starter one, then the negative Side is wired correctly

With a new to me 80s cruising boat with original DC system, I’d love to see the lithium option. If I’m going lithium, I’m going all in with a bigger alternator an external regulator.

“Drop in” lithium batteries are readily available. How would one utilize one of these? Or are they all snake oil?

Also curious about what the comment on what makes a shore power charger dumb.

Hi Ben,

Yup, “Drop In” is snake oil…rubbish…a con…and bullshit. Sorry, but I have to say this issue has got me really upset about the number of my fellow voyagers who are getting ripped off.

More coming on that and you can read more now on the battery charger problem: https://www.morganscloud.com/2010/09/04/agm-battery-chargers/

Are you saying the concept of “drop in” is BS or are you saying “drop in” batteries, meaning internal integrated BMS, cannot be safely or effectively used? Curious as Rod C states on his site that there are 2 “drop in” designs he would use, one of which I selected. KiloVault. Well engineered BMS, high charge and discharge rates, UL 1973 certified (a Nigel must-have and almost impossible to find on LiFePO elsewhere and certainly not drop ins.) bluetooth monitoring…understanding I had to re-engineer everything: alternator (including protection), regulator, inverter, charging strategy.

Hi Jeffrey,

Both. The bottom line is that if we want to do lithium really right and be compliant with coming standards, the BMS must be capable of communicating with and controlling charging sources and “drop in” batteries can’t do that since the BMS is internal to the battery and has no way to communicate. (Both Lithionics and Victron have batteries they call “drop in” that have external comms ability, just to add to the confusion.)

More in a future article.

Cool custom lug on the left terminal of the shunt.

How much stacking is allowed on terminals?

I see the batteries are under the settee, so I assume below the waterline. Is there any containment required for this type of battery in this location? Our wet cell batteries are above the waterline and also contained so I’m not sure if requirements differ here. Also, it’s hard to tell in the photo, but what is there to know about battery (+ and -) cables being of equal length in this photo?

Pretty tough game to point out errors after Matt and Steve D had a go…

Hi Will,

I have never heard of any differences in containment requirement dependant on position relative the the waterline, and can’t really see a reason for one. Am I missing something? That said, ABYC does require a drip tray for any batteries.

As to the cable lengths. As a general rule, if batteries are in parallel the cables should be the same length from the charge source, otherwise they will charge unevenly . That said, the way it’s done in the pic is a lot less than optimal, and I will be changing that.

Regarding position relative to waterline, I honestly had no idea, I guess I was just curious. As I thought more I realized it doesn’t make sense. Thanks for the feedback

Hi Will,

As I remember the stack limit in ABYC is four (would need to check to be sure), although personally I think three is a better limit, and no more than two optimal.

4 terminals per stud is allowable.

”Boat Owner’s Mechanical and Electrical Handbook”, latest edition, Nigel Calder. Required Reading. Best $50 I ever spent on boating equipment.

Hi William,

I agree, anything by Nigel is a great resource.

One No vote on lithium batteries. Don’t care about right now. I’m more interested in what you plan to issue on your system. I need to improve and upgrade exactly as you outlined. I have a J Boats-type stock system. Many thanks. Brad.

Hi Brad,

You and I are on the same page, I suspect: just want to go sailing as soon as, and as much as, possible with a functional system. I will prioritize that.

What J boat do you have?

John

Hi John and all,

Your discoveries on your J are really disturbing, especially as I consider Js as one of the medium to higher end boats constructed in the US.

Manufacturing and design standards are not going to change by themselves.

I would like to suggest starting a list of questions (might make a good article) that can (and should) be asked whenever someone is considering a boat.

I would start with whether the boat was fully built to ABYC standards. Then ask (not in order of importance) questions such as:

1. Are all stainless-steel fasteners in aluminum coated with TefGel/Duralac or equivalent?

2. Are there high-water alarms?

3. Is there provision for a reasonably sized anchor?

4. Is there a place to sleep off-shore: a straight settee?

5. Are there smoke detectors?

I am showing a senior moment, because I know there are numerous other simple questions that would tell the boat seller the kinds of things that the designer/manufacturer should be including or give consideration to. This could be asked at boat shows etc. and that might get across to the designers and manufacturers (and surveyors) that they need to up their game.

Random thoughts, My best, Dick Stevenson, s/v Alchemy

Hi Dick,

We already cover most all of those subjects in articles here at AAC.

And, over the next year we will be publishing check lists that will act as an index to those articles. The key point being that there is no point in a check list if there is no underlying explanation of the reason for setting a standard available and linked.

We also have an online book on buying a boat that covers most all of those subjects and that is heavily linked to other articles: https://www.morganscloud.com/category/boat-design-selection/book-how-to-buy-a-cruising-boat/

Hi John,

My point was more along the lines of coming up with a list of questions to ask at boat shows and the like: if enough people start asking: “Are all stainless-steel fasteners in the aluminum mast coated with an anti-seize?”, the manufacturers will get the message. There are a whole list of simple things like this, inexpensively done at the factory, but more complicated later, which should be standard on boats, but are not.

The manufacturers are not going to change in these areas, it seems apparent. Perhaps the buyers asking pointed and pertinent questions might move the bar.

My best, Dick

Hi Dick,

Given that that exact issue is in our rigging inspection articles and will be on the rigging inspection check list, I really have trouble understanding the need for a separate pre buy check list. Given that the check lists I’m creating are designed to bring a boat up to, and keep her at, offshore standard, why would they not work unmodified to use during the process of buying an offshore boat?

Hi John,

I am sorry I was not clear.

I think the boating industry does not work well in taking care of boat owners and does not take good care in a multitude of ways (talk about killing the golden goose). My intention, probably naïve, was to generate some questions to prod manufacturers via boat sellers to do the right thing in putting together their boats (Ask about TefGel when dis-similar metals are in contact for ex.). It was not my intention to generate a list of questions to help people decide what boat to buy or what needs to be done to bring a boat into offshore readiness. I am aware you have been and are amply covering this challenge.

In one area, this boat-owner-concern being expressed has seemed to work: some boatyards, when they hear owners say that they do not wish, when over-wintering outside with hard-stands, to be placed next to a boat with their mast up and jib left on and furled, have changed policy to preclude sails being left on.

This is one example: it would be nice if others would follow.

My best, Dick

Hi Dick,

I guess I still think we are on the same page here. Surely if we have articles (nearly 1200 at the moment) specifying what a good boat should be, and we add check lists, that will substantially increase the chances that boat buyers will ask hard questions of the sellers?

Since Lithium is here to stay, an article on how to embrace it properly, would be a welcome addition.

Hi John,

Yes, I think it’s time to do more of that.

However, I think a better first approach, rather than assuming that we will embrace lithium, is learning enough about it to decide whether or not lithium is a good match for our needs.

In the words of Ray Dalio: never make a decision until we have deeply evaluated the current reality (what is) and the options.

To that end, we already have two articles that will tell you most of what you need to know:

https://www.morganscloud.com/2014/01/26/lithium-ion-batteries/

https://www.morganscloud.com/2014/01/26/lithium-ion-batteries/

Thanks for this John, we have a new-to-us Ericson with an electrical system that looks to have been modified by a couple of smart and well meaning PO’s but has me scratching my head on where to go next after handling the few items pointed out in our survey. I’m excited to follow this series! Also I agree with and appreciate your intent to focus on lead-acid before spending too much time delving into lithium. Since lead-acid is probably what most of us have right now it seems a better starting point to understand and design a safe and functional lead acid system, then perhaps explore lithium at some point down the road.

Hi Jim,

I hear you on the attractiveness of the step by step approach to lithium from lead acid, but it’s actually a not a great way to go if you really want lithium, since you will end up tearing a lot of the lead acid system out to build a good lithium system.

Hi Jim,

Having thought about it overnight, what I may be able to do is point out changes to my base design that will make it more “lithium ready”, for those who want to keep that option open. I will cogitate on that.

That would be a great way forward if possible, since it sounds from more recent posts that the interest in lithium is big. If it doesn’t get too complicated it will also increase potential learning by comparing and contrasting systems. Thx!

Hi Jim,

Will do, but keep in mind that lithium systems are intrinsically complicated, so no way I can fix that.

It has been our desire for simplicity (and internal ballast) that has kept us in the lead-acid battery camp. We know the shortcomings and pitfalls, but we have a boat with the internal space and access to pretty well do what we want. If we had a sporty racer-cruiser, I would have a different set of goals.

Just the restrictions in shipping lithium to wherever we might happen to be on the boat, never mind the complex management, charging and wiring consideration, are pretty much a deal-breaker for us in a way that lithium batteries in an EV car (which are quite close to “drop in” in terms of replacement after 8-10 years,as I understand) would not be.

Hi Marc,

Good point on the difficulty of shipping lithium in a hurry particularly to a remote place.

Hi Marc and John,

This is also an issue for batteries for electric outboards. A friend had bought a spare battery for his Torqeedo, but could not get it shipped to Iceland where his boat was. I ended up bringing it with me when I sailed to Iceland. With-in country there was no issue sending by mail.

My best, Dick Stevenson, s/v Alchemy

It may be for all I know an issue for certain lithium computer batteries. They are not all created equal, a point Rod Collins has (at some effort, as he reports) just made in his first post-stroke article and which has some bearing on the present discussion, which is “lithium-rich”. https://marinehowto.com/drop-in-lifepo4-be-an-educated-consumer/

Glad you posted the link to Rod’s article about drop in batteries. I read the article a week or so ago, and to say it is shocking, is an understatement.

Hi Dan and Marc,

Yes, I read it too, just confirmed for me that “drop in” lithium is a giant scam. That said, I was a bit confused by his article in that he started off asserting that “lead is dead” but then went on for maybe 10,000 words showing that drop in lithium was not a viable alternative and that anyone doing lithium had to either become an expert or buy an expensive fully integrated external BMS solution. I have been saying that for three years years: https://www.morganscloud.com/2018/05/05/battery-options-part-1-lithium/

But would add a third alternative: stick with lead acid and learn how to manage them (easy, particularly with solar) so as to get the >1500 cycles that Phyllis and I have been experiencing.

I’d appreciate a guide to the changes to the base design. We are starting from scratch.

Hi Dave,

I will talk about changes required for lithium, but I won’t be providing a turn key design since with all the variables and the impending regulation, there is no way to do that well and safely.

I look forward to seeing not just the design but the implementation of the design.

I’ve seen lots of photos not what look like great setups, but normally located in an area with great access and lots of space (like on your old boat). But unfortunately often not available on smaller boats.

I have also noticed in more than one manufacturers product installation instructions phrases along the lines of:

This should be connected directly to the battery terminals.

One even stated as a warning that no fuse, switch etc should be in the cable. In this instance to stop a wind turbine going out of control if power is lost.

Hi Dan,

This should work for you since a J/109 is a quite small boat, so I have had to come up with a design that’s space efficient.

On battery direct connections: I would never knowingly buy any piece of kit that demanded I attach it directly to the batteries without a fuse. And if I bought it without realizing that was a requirement, I would send it back.

A device that specifies “Connect this directly to the batteries and do not use a fuse or circuit breaker” should, in general, be returned to the store for refund, and also reported to the relevant product safety authority in your country. Explicitly telling the installer to violate electrical safety codes is a good sign that the product itself is likely in violation of those same codes.

A wind turbine that spins up out of control if it doesn’t have a battery to charge could not possibly meet CE (or UL, or ETL, or any other) standards.

John, EU and UK surveyors are not any better than USA surveyors in a general context. There’s no standard testing or qualifications for yacht surveyors. We get the same trust and reliability issues with surveyors on this side of the pond. You can’t even trust word of mouth as I have seen the same surveyor praised and criticised on forums. There are no legal requirements on leisure yachts for electrical installations, post new sale, and you will see a lot worse over here in the UK, as we have a long history of unskilled DIY. Yes, on construction, yachts must legally be compliant with EU or UK legislation to obtain the CE mark in the EU based on the Recreational Craft Directive (RCD), or the new system for the UK, post Brexit (I can’t remember the name, but similar to RCD). In the UK (or EU) if you buy a second hand boat, and if the electrical installation has been changed, it is likely it will not comply with any standard. For example, my new to me boat, second hand, had woefully undersized mains power battery charger wires to the batteries, one of those dangerous rectangular pin shore power sockets, complete with burnt out pins and melted terminals, all fitted by the last person who owned the boat. I agree that the lithium discussion should be ignored, at least for a few years, as most of us probably need to focus on the non lithium wiring systems that are currently ubiquitous.

Hi Alastair,

Yes, I’m aware that there is nothing in the EU to enforce regulation on older boats, still, I think there’s a benefit in the EU approach of requiring compliance on new boats. For example, there are many things on my J/109 that I have to change and fix that would not be my problem if ABYC compliance had been required when she was built. Don’t get me wrong, the CE/ISO is far from perfect, for example the keel scantling requirements are a joke.

And I also still think, based on extensive investigation when I was buying a boat, that surveying is better in Europe, although I’m sure there are charlatans there too. Even though I went to a huge amount of trouble to select a surveyor who was generally recognized as being among the best, the surveys received by three friends who bought boats in Europe were far more extensive and professional than any of the four surveys I have in my possession from North American surveyors.

Hi Alistair and John,

In my time in the EU and UK, I had 2 surveys done: regular insurance up-dates. I did my best to find the most well thought of surveyor. Both survey reports were quite disappointing.

My best, Dick Stevenson, s/v Alchemy

Hi John

I am curious to see what you come up with, you certainly couldn’t find a better group of people to work on it.

One thing that would be interesting to me would be how you would plan to set up charging for an electric outboard as I believe you said you were planning to go that way. Given that the capacity of those batteries represents a significant portion of the capacity of many house banks, just plugging in and charging without any thought or electronic nannies could be problematic.

Another thought is the actual energy budget you plan to work to from generation, storage and usage standpoints. I realize you already have some sizing calculators on this, I was thinking of using your implementation as an example. One of my pet peeves is the people who boast that their solar has them at full charge every single day by 10am, that means the boat is saddled with way too much solar and likely too big of a battery bank or their statement isn’t true. I know some are true, there is a local IP350 I know of with >1200W of hard panels, those boats were not great sailors to start with but it must be hopeless now. I think that I may have been overly conservative in installing 4X GC2’s on our boat and now lug around the extra weight. I have been tracking and I think if I had installed 2X GC2’s we would have only needed to run the engine just for charging purposes about once every 3 years and with the 4 batteries, we have never had to do it. I would think that the ideal system for me if you are at all weight and windage conscious would require you to use the engine just for an hour or two of charging something like 1-3 times a year to cope with the stretches of low generation and high usage.

Eric

Hello John.

I look forward to further installments on this issue as someone who is migrating more and more from the dock to the hook. One upgrade I am preparing for is to replace my manual windlass with 12V electric. With a 35 foot boat, my thinking is to power it from the existing (or improved!) battery bank. Any inclusion of proper planning for this circuitry in the system would be appreciated.

Hi Kevin,

Powering a windlass is really a subject in and of itself, so I’m not planning to put that in specifically. That said, you will find most of the information you need to figure it out already in our online book: https://www.morganscloud.com/category/electrical/online-book-electrical-systems/

Then if you have specific questions, I will try and answer them in a comment.

Hi Eric,

Since we already have three chapters on sizing a battery bank, and two on selecting battery type, I’m not planning to go there again, and just focus on the circuit design.

That said, of course I ran an energy budget, and, as you say, the electric outboard is a problem. In the end I decided to just charge it on shore power, which will work for our intended usage. Also, there are days around here where one ends up motoring all day, so we can charge it then, but we won’t run the engine just to charge the outboard.

I also ended up doing what I generally argue one should never do: starting with the batteries that we can fit in the boat (just 3x group 31s) and then cutting stuff until I made it work. The result is when cruising we will run the engine at least once a day to charge, assuming we don’t go anywhere. Given that we will probably spend no more than 2-3 weeks on the boat a year, and will often get that charge motoring in and out of anchorages, as well as be on shore power sometimes, this seems acceptable, particularly given that there is no good way to put a bunch of solar on a J/109 without ruining her as a sailboat—for example, an arch, or even a Bimini top on the boat would be a travesty, at least to me. (I’m putting on one small panel to charge at the mooring.)

My fairly well informed budget says less than 15 hours of charging run time a year, and that on a 28 hp engine, so a trivial amount of diesel and carbon, that’s just not worth worrying about. I think this even works well environmentally, although I have not worked it out, but my guess would be the impact of making the panels and extra batteries to save ever having to run the engine would be more than the fuel use impact for years and years.

Long way of saying, I agree with you that designing with the goal of never running the engine to charge is not always a good plan, and maybe not even the greenest way.

Hi John,

That all makes sense. And I totally agree on not ruining the sailing qualities of your boat, it would be extremely easy to do. That being said, I also agree with your plan for a small solar panel for the mooring, it makes the batteries last a ton longer and doesn’t leave you with a quandary of what to do at the end of a nice day of sailing when your batteries are a little discharged. I had selfishly been hoping that you would cave and try to figure out how to discreetly fit a moderate amount of solar without resorting to performance degrading solutions like arches and biminis as one way to make up for a small battery bank is increased solar. I can’t think of many boats I have seen that do this well and I also wonder about longevity of deck mounting panels so we haven’t ditched our single 140W rigid panel yet but I would like to.

Some very rough numbers on solar panels versus burning diesel are interesting. The actual numbers are very specific to how specific solar cells are manufactured but the average CO2 equivalent per kW is about 2500kg. With diesel being about 10kg CO2/gallon, you would need to burn about 1/4 gallon of diesel for every watt of solar installed until the diesel had higher GHG emissions (there are some other nasty emissions I am ignoring). Taking a wild guess that your usage would require a 200W solar panel and that panel would last 15 years in a marine environment, that would mean it would need to displace a bit over 3 gallons of diesel per year to break even. So for someone not cruising full time, while solar is probably a little better, it is not a huge difference and there are many other things you can do to lower your footprint much more such as avoiding a single plane flight.

Sounds like you reached a similar conclusion on charging an electric outboard as me. We almost never spend the night on a dock and don’t have a shore power system so for us, it would be charged at home or only when the engine is running. As we discussed, I think this will work from an energy standpoint but I haven’t given thought on how to make it idiot-proof. I also have been thinking recently that I maybe should put a bit of effort into improving our rowing instead, I have already installed a foot stretcher but the oar blade shape is not optimal and the oarlocks are slightly low.

Eric

Hi Eric,

That’s interesting on solar equivalent to diesel and confirms we will be very close to break even given that I can’t see us using more than 5 gallons a year for charging, and probably half that. The other point in all of this, which I know you get, is that by not screwing up the boat’s sailing abilities by hanging all kinds of stuff on her, we will sail more, and in turn save a bunch of fuel that way.

Your point about flying is and an important one too. People who crow about how green they are because they add a couple of solar panels to their boat and then arrive at the marina in a half ton truck they have no need for and fly off every couple of months to “get away” drive me nuts!

We just spent a bundle insulating our cottage which will save more carbon in a few years, I’m pretty sure, than decades of cruising with a diesel engine, particularly because we still generate a lot of our electricity here in Nova Scotia from coal.

Reminds me that I have been meaning to write a post about this “relative greenness” issue and the importance of concentrating, and spending, on real savings, not what I would call “virtue signalling savings”.

An area that I would like clarified in the upcoming articles, based on your design, is grounding (earthing) and why you choose to ground what you do and why you do it a certain way. An example of my confusion; in Calder’s tome, he shows lots of grounding symbols at the end of circuits but doesn’t explain what that feature is in the real world, similarly on your circuit the engine is grounded – why the keel, why the engine? What is the battery negative’s role in grounding compared to a common negative bus – is that also grounded at the same place as the engine block? I am hoping that your next series of articles will explain that. No need to explain here, just hoping that I can join all the dots and maybe have that epiphany moment when it all comes clear. Thanks, Alastair

Hi Alastair,

As to Nigel’s book, I’m guessing the ground symbols you are seeing are chassis grounds on devices like shore power chargers, inverters, water heaters, etc. Those grounds are part of the AC system and so not relevant to the DC system we are discussing here. I have written about AC grounding here: https://www.morganscloud.com/2021/08/10/check-your-boat-shore-power-system/

On a DC battery supplied system there is only one ground point and that’s usually the engine chassis where a single connection is made to reference the negative to ground. (The exception is a floating system on a metal boat where the DC system is not referenced at all. More on that here: https://www.morganscloud.com/category/aluminum-boats/care-tips/)

The connection from that point to a keel bolt is actually part of the bonding system which ties all the underwater metals together and then to underwater anodes (zincs).

The whole topic of bonding is a complex one and not really relevant to the design I’m going to discuss, but it is an interesting one, so if there is enough interest I could do something on that, but it will be several months since I have a huge backlog of other subjects I have promised to write about.

Another yes-vote for the lithium option.

Regarding the battery installation in the picture (and schematics) , the main overall requirements in the Norwegian regulations for leisure craft (which closely follow the European regulations), includes the following points:

-proper ventilation to avoid accumulation of explosive gases from the batteries

-proper fixing system

-protected against water intrusion

There are more detailed technical requirements in the regulations for maritime electrical installations.

Ventilation from underneath a settee in the saloon might be difficult to asses.

I can also add that for the start battery connection to the starter motor there is no requirement for a fuse or overload protection.

Hi Svein,

That’s pretty much the same as ABYC. On the starter motor, ABYC has the same exemption. the reason is that once we get to big motorboat engines fusing the starter becomes a problem since said starter can take huge currents. However, for our usage on smaller engines, I always recommend fusing the starter circuits and have had no problems doing that, up to and including a 120 hp six cylinder Cummins.

I think that the requirement for proper ventilation is not fulfilled in many installations. In may local harbor I have heard a few stories of overcharged and gassing batteries (when hooked up to shore power). It is a low probability event that might have large consequences, and it is difficult to properly evaluate the risks. The potential for and extent of gassing increases when the charging current increases.

The “perfect” solution, a dedicated sealed battery compartment with separate ventilation to free air might be easy to implement in a new construction, but might be difficult to add to an existing boat.

In my current boat the batteries are beneath the bed in the aft cabin, with “ventilation” through a narrow cable slit into the engine compartment.

Hi Svein,

I have never worried about that requirement, much. First off, the explosive gas given off by a gassing battery is hydrogen which being the lightest element is very difficult to contain and will escape, I’m pretty sure, through the joints of pretty much any battery locker.

We are then left with possible corrosive and harmful compounds in battery gas, which we definitely don’t want to breath. The best answer to that problem is good quality really smart chargers (most are not) backed up with a battery monitor that has a high voltage alarm. And even with smart chargers, we need to manage them some: https://www.morganscloud.com/2010/09/04/agm-battery-chargers/

And then if I fitted liquid filled batteries, I would also fit recombining caps.

And finally, I don’t think it’s a good idea to to leave shore power charges switched on and charging when the boat is unattended.

So, sure, a hermetically sealed compartment with outside venting is a perfect world solution, but it’s also not very practical, and, I think, not even necessary.

I agree that a for a lead-acid battery ventilation is probably not a big worry.

However, for the lithium option the situation might be different.

I my research on how to properly install lithium batteries I have read “Best Practice/Guide to use of lithium batteries on leisure boats” (an early version of what should become the regulatory requirement for use of lithium batteries on leisure boats). The link is on this page: https://norboat.no/294/batbransjen/installasjonsveiledning-litium-batterier , but it is all in Norweagian, I am afraid 🙂

There is a firm requirement for venting gases from lithium batteries, due to thermal run-away, to free air.

The gases from a lithium battery in thermal run-away is both flammable and poisonous, so such precautions might be appropriate. I guess it would also be easier for insurance companies to accept lithium batteries if they are installed in accordance with regulatory requirements.

Hi Svein

I agree, lithium containment and ventilation is an evolving area and I’m guessing that many people who are installing systems today will end up with boats that are uninsurable because they don’t comply with lithium compliance standards that are still not finalized and will in all likelihood become more stringent as they are—ABYC is working on exactly this.

Another vote for a discussion on Li-batteries, John. Reason being that I guess is that almost everybody that has to change batteries, considers Li as an option.

Currently I have 4 AGM’s rated at a total 240Ah/24v on the 7th seasons. Soon they will most likely be exchanged for a lead/carbon mix – real “drop-in’s”.

Have looked into the building of a bank of individual Li cells with separate BMS and concluded that to much of a costly charging system will to be adjusted/changed to accommodate Li.

The lead/carbon bank will last another 7-10 years, and then the battery world may offer something worth changing to.

Maybe the upcoming article on Li will prove my conclusions wrong. Look forward to seeing your views when the time and opportunity arises.

Hi Petter,

I think you are making a very good call by passing on lithium for this replacement cycle. More on why in future articles.

Hi Petter,

One more thought. Do make sure your carbon foam battery bank is fault tolerant since I’m hearing that Firefly (guessing you are using them) still have some occasional QC issues. See this post for more on that: https://www.morganscloud.com/2017/01/28/three-tips-to-make-your-cruising-boat-more-reliable/

Also, here’s another article on the realities of carbon foam: https://www.morganscloud.com/2020/12/04/firefly-carbon-foam-batteries-are-great-but-read-the-fine-print/

All that said, I still think carbon foam is the best option for most of us these days.

There are alternatives to firefly.

Victron makes a battery

https://www.victronenergy.com/batteries/lead-carbon-battery

Apparantly allows for drawing down lower than normal AGM without damage cycle life and capacity. In addition they accept a larger charge current than AGM’s.

Any views or comments on the above is more than welcome.

Hi Petter,

Yes, we are now seeing alternatives to the Firefly which is a good development. That said, both of those options only accept charging at 0.3C which is actually much less that both FireFly and LifeLine AGM, not more. LifeLines can tolerate inrush currents as high as five times their 20 hour discharge rate and FireFly 1C for short periods and half that continuously. More on this in an upcoming article.

The thing about lithium that so many people don’t get is it’s a system with the charging system. All of it needs to work together. I think you have pointed that out in your articles but either people don’t get it or there are just new people to educate.

Hi Edward,

So true. The biggest culprit in this collective delusion is the people pushing “drop in” lithium.

Hi John and all,

Having just had my battery charger turned off and inadvertently not turned back, on I am curious about whether a low voltage alarm might make sense. I caught it but I could have drained the batteries.

Programable settings might be nice.

I am wondering what others think and whether there is any recommendation. I would think the alarm could be rather simple, but, then again, it would have to deal with voltage drops related to short but potent loads.

My best, Dick Stevenson, s/v Alchemy

Hi Dick,

Rather than just fit a low voltage alarm, I would add a battery monitor, assuming you don’t have one already, since most of them have an alarm function and they also do a lot of other useful stuff, and they are not that expensive. More here: https://www.morganscloud.com/2018/08/13/battery-monitors-part-1-which-type-is-right-for-you/

I’m also in the throws of installing the new Balmar monitor and will write more about that later in the summer, once I have had a chance to use it.

Hi John,

I have an old but accurate battery monitor which has served well, but has no alarms. I check it a number of times a day, but tend not to do so when plugged into shore power and the battery charger is keeping the batteries topped up (I look forward to your thoughts on battery chargers and battery care at some point).

A quick story and warning possibly to some readers. I believe it is common to have integrated battery charger/inverter units transfer seamlessly from shore power to inverter if shore power is lost. This might be helpful in some scenarios to not have AC disrupted.

In cold areas, I warm the boat with a space heater when on shore power. If power is disrupted from shore my old, but still working well, Trace inverter charger would take over and keep the space heaters going. If not noticed, one can quickly deplete one’s battery bank to the point of damage.

Some research a few years back indicated that new inverter chargers operated the same and were not program-able to undo this seamless transfer, so when it came time, I bought 2 separate units even though the real estate for two was hard to find.

My recent incident was merely operator error: I turned off the battery charger when needing to do some work on a running engine and I do not like 2 charging systems active at the same time. Then I forgot to turn the charger back on. Caught the error a day later when battery level was 12.2v but only because I noticed the circuit breaker switch for the charger was off.

So, I thought of a low voltage alarm. I look forward to your report on the Balmar unit.

Thanks, Dick Stevenson, s/v Alchemy

Hi Dick,

I agree on integrated inverter chargers, for both your reason and mine: https://www.morganscloud.com/2010/08/28/inverter-charger/

Hi Dick,

When I went through this thought exercise, I came out with largely the same conclusion as John that alarming relative to the SOC was best with lead acid. Ideally, you would have an alert that you were getting towards the need to charge point and then a proper alarm when you had reached it. Of course this assumes you are keeping your meter properly calibrated and that you get to full charge occasionally.

For our boat, we concluded that our other risk is when we are ashore for a day or so and the fridge is running. We have it on a low voltage cutoff that shuts it off at 12.1V at the fridge. Yes, we do run the risk of spoiling some food but at least we don’t also have to replace the batteries. I have definitely heard of a lot of weekend sailors who leave the fridge on with shore power and come back to damaged batteries due to a shore power failure. Ours battery switch is off if we are at work so this doesn’t apply to us although it does mean the fridge has to pull down whenever we get onboard. One thing to watch out for with low voltage cutoffs is what voltage they auto-reset at. If it is a big load relative to the battery capacity and this includes batteries that no longer have a big capacity, there will be a lot of voltage sag and just shutting off the load may bring the voltage up enough to cause it to reset, restarting the load and pulling the voltage back down to where it shuts off again, etc. I have witnessed this short cycling on a few boats. Of course, if you put the reset voltage too high, it means that if you do something like run the windlass with the engine off, it will turn off your stuff and leave it off without resetting, also not good. If you are running a cutoff, I think you have to put all your big loads on it and really think it through. I am not totally convinced they are a great idea but alarms are useless if you are not there to hear them so no perfect solution. One good rule of thumb is that if you can’t clearly write out a set of rules for an alarm or control to follow, it isn’t going to work and I don’t know of a simple set of truly fail-safe rules here.

Eric

Hi Eric and Dick,

That all makes sense. The best solution I have found, although far from inexpensive, is remote monitoring via cell phone. I had a Sirens system on the McCurdy and Rhodes which worked great and I have just installed a BRYNKL system on the J/109. Not only do we get warnings about under and over voltage while not on the boat, but also bilge monitoring and security. I will report on the new system and how it compares to the Sirens after I have used it for a bit. The other advantage with these systems is that some insurance companies will give you a break for installing one, which helps a bit with the eye-popping cost.

Hi John. Are the followup articles with the proposed design done? Am I looking in the wrong place? Thanks.

Hi Thomas,

Not yet, I got distracted by all the interest in lithium and my concern that many of our members were getting conned by companies selling “drop in” batteries with BMSs that could not communicate. I have two more articles on that, including a seamanlike lithium installation, one of which is all written, to get though, and then it will be on to the design.

Thanks John. Do you by any chance have the schematic done? I’m stuck on the hard for a few more weeks waiting for a rudder repair and thought I’d take the opportunity to work on my electrical system.

Hi Thomas,

In first draft for, but not ready for distribution. I also need to make the changes of things I learned more about while installing our system. I also need to update the BOM since I figured some ways to save. Given that I’m planning a week or so off to get our boat launched and spend time with my daughter and family, I’m guessing well into July before I get anything out that would actually be useful. Sorry it does not fit better with your schedule.

A very interesting article. I am sure many people are interested in this topic.

I have been mulling (cogitating?) over this exact issue. I have recently bought a new to me 80’s Alu cruising boat. Forgetting that I had this subscription (I joined up when I thought I had closed on a cruising boat – only to have the sale fall through) I was asking about this exact issue on forums. Most poo-poo’d the idea saying it was an unnecessary expense.

Yet here it is on your site – for exactly the reasons as I was thinking, you have outlined the same rationale. My boat, built in the 80’s is bound to have had PO’s add circuits over the years. The electrical panel has pieces of tape with names of the circuit scrawled on the tape and stuck over the original circuit breaker names. The most recent owner who I purchased the boat from has self installed a N2K network – and not that well done. My fear about the electrical system is it going wrong in some remote part of the world and not be able to figure out the wiring (since it was most likely done DIY style).

I want to make extensive changes to the galley (pull it out and reconfigure it to suit my needs). I want to take out the nav station since I dont need it in my use case, and so give more room to the galley. This gives me a chance to take the electrical panel out and rewire the boat. I want to do this with new tinned wire, as it seems that Garcia did not use tinned wire in the 80,s (dont know about now).

Ok so that is all well and good and its refreshing to get a take on this from a seasoned sailor.

But how do we redesign the electrical system? Who do we go to figure out all the items needed? Your article on battery selector switch is good to know and well worth doing. Having an alternator isolator is another good tip well worth knowing. Not getting this work done by the boatyard is a great tip – I thoroughly concur with getting outside specialists to come in and help on this. But how to incorporate all these ideas into a wiring schematic if one is not an electrical engineer ?

Is there ANYWHERE we can go to get a consultation to figure all this out?

Your thoughts are highly appreciated.

Hi Mark,

If you read, and take your time with, our online book on the subject, and maybe read Nigel Calders excellent book on boat systems, there’s no reason you can’t, as Ernest suggests, come up with, and install, your own system.

And you can always ask questions here on the relevant chapter in the online book.

The other tip I would give you is while you do this stay away from forums (comments here are fine) and YouTube since the majority of people in those places have no idea what they are doing, but many are emphatic.

A few years ago I wrote a two part article on how to decide who to listen to: https://www.morganscloud.com/2018/11/20/which-old-salts-should-we-listen-to-10-ways-to-decide-part-1/

I’m starting a systematic read of your online book John and look forward to it in preparation for an electrical system refit on our 1989 Ericson 38. In the meantime I’d like to plug Nigel Calder’s online electrical systems courses at Boathowto.com. I just finished the 101 course and found it much easier to digest than his book. I don’t have any experience in marine electrical systems and was overwhelmed by the book, but this course broke things down into easy to understand chunks that built on each other very intuitively. I found it well worth the expense.

Hi Jim,

Good to hear, and good on you for covering the basics before diving in. There would be a lot less poor outcomes if more people did the same.

Regarding the Lithium route, I keep reading and learning all that I can while still likely to remain with the Lead Acid / AGM for now. Any new equipment I buy is with the option of lithium, just in case. Meanwhile, maybe something new will break through like Lithium Sulfur or the Solid State Batteries. 🙂