10 Tips To Install An Alternator

181 CommentsReading Time: 7 minutes

More Articles From Online Book: Electrical Systems For Cruising Boats:

- Why Most New-To-Us Boat Electrical Systems Must Be Rebuilt

- One Simple Law That Makes Electrical Systems Easy to Understand

- How Batteries Charge (Multiple Charging Sources Too)

- 5 Safety Tips For Working on Boat DC Electrical Systems

- 7 Checks To Stop Our DC Electrical System From Burning Our Boat

- Cruising Boat Electrical System Design, Part 1—Loads and Conservation

- Cruising Boat Electrical System Design, Part 2—Thinking About Systems

- Cruising Boat Electrical System Design, Part 3—Specifying Optimal Battery Bank Size

- Balancing Battery Bank and Solar Array Size

- The Danger of Voltage Drops From High Current (Amp) Loads

- Should Your Boat’s DC Electrical System Be 12 or 24 Volt?—Part 1

- Should Your Boat’s DC Electrical System Be 12 or 24 Volt?—Part 2

- Battery Bank Separation and Cross-Charging Best Practices

- Choosing & Installing Battery Switches

- Cross-Bank Battery Charging—Splitters and Relays

- Cross-Bank Battery Charging—DC/DC Chargers

- Right Sizing an Alternator

- 10 Tips To Install An Alternator

- Stupid Alternator Regulators Get Smarter…Finally

- WakeSpeed WS500—Best Alternator Regulator for Lead Acid and Lithium Batteries

- AC Chargers For Lead Acid Batteries

- Replacing Diesel-Generated Electricity With Renewables, Part 1—Loads and Options

- Replacing Diesel-Generated Electricity With Renewables, Part 2—Case Studies

- A Simple Way to Decide Between Lithium or Lead-Acid Batteries for a Cruising Boat

- Eight Steps to Get Ready For Lithium Batteries

- Why Lithium Battery Load Dumps Matter

- 8 Tips To Prevent Lithium Battery Black Outs

- Building a Seamanlike Lithium Battery System

- Lithium Batteries Buyer’s Guide—BMS Requirements

- Lithium Batteries Buyer’s Guide—Balancing and Monitoring

- Lithium Batteries Buyer’s Guide—Current (Amps) Requirements and Optimal Voltage

- Lithium Battery Buyer’s Guide—Fusing

- Lithium Buyer’s Guide—Budget: High End System

- Lithium Buyer’s Guide—Budget: Economy Options

- 10 Reasons Why Hybrid Lithium Lead-Acid Systems are a Bad Idea

- 11 Steps To Better Lead Acid Battery Life

- How Hard Can We Charge Our Lead-Acid Batteries?

- How Lead Acid Batteries Get Wrecked and What To Do About It

- Equalizing Batteries, The Reality

- Renewable Power

- Wind Generators

- Solar Power

- Watt & Sea Hydrogenerator Buyer’s Guide—Cost Performance

- Battery Monitors, Part 1—Which Type Is Right For You?

- Battery Monitors, Part 2—Recommended Unit

- Battery Monitors, Part 3—Calibration and Use

- Battery Containment—Part 1

- Electrical Tips

I think Nanni and Yanmar solved most of the very well presented in your article alternator issues. Nanni offers water cooled intercaled generators on their engines: 300 A at 14 V DC, 160 at 28 V DC, and 175 A at 230 AC. These are mechanicaly coupled with the crankshaft between bell housing and reduction gear. It is technology developed with Iskra electronics Slovenia. Yanmar offers similar 4KW AC intercaled generators but only on the 55 hp engine. Although this concept seems to really make sense I think feedback is needed from cruisers actually using it.

I would also like to add on your article that when sizing a suitable alternator for the engine the side loading of the front engine bearing should be taken into account. Sometimes it makes sense to place two alternators on opposite sides of the pulley as to cancel out each other’s side loading on the bearing.

Good point on the coupled generators. I guess my first reaction is that I just don’t like putting something that large and complicated in the drive line between the engine and gear. My fundamental thinking is that the engine is a mission critical system and therefore it should not be messed with in this way. I would want to know what the effect on the engine is if this thing messes up in some way. Having said that, as you say, the key thing is feedback from real world cruising.

On the effect of two alternators opposite each other on the crank shaft bearing. That might be a benefit, although I have to say I’m doubtful. Also, I have just about never seen two alternators opposite each other. Most times they are both above the center line and so at about the 10 and 2 o’clock positions.

I suspect, but am really guessing here, that the issue of effect on the crank shaft bearing is more complex than that and more to do with vibration harmonics that might be worse with two alternators?

An issue with the two alternators configuration is that even when placed on opposite sides of the pulley the second always imposes greater torque on the front bearing due to greater distance from the bearing. ( Torque = Force x distance). Thus twin opposite alternators will never quite equate each other’s side loading on the front bearing. The engine manufacturer can be consulted for max permitted side loading on the front bearing which should be taken into account in single generator configurations as well.

I think that while the distance from the engine bearing to second sheave would be greater than the primary alternator sheave, the sum of the opposite torque vectors, if you want to think of it as such would be sum less then either one, If both alternators are applying the same load on the engine shaft, but in opposite directions and different distances from the fulcrum (the engine bearing) the loads of each neutralize the other, in this simplified example.

Crank shaft bearing:

Most engines have a specified limit for the power that can be drawn from the front shaft, and/or the radial load on that shaft. It’s partly a shaft deflection issue, partly a vibration risk issue, I would hope it’s not a bearing wear issue as that would raise concerns about the longevity of the (much more heavily loaded) crank journal bearings. In any case, if you’re coming anywhere close to that limit, whatever you’re driving belongs on the other end of the engine in a proper rigid mount.

Big generator between engine and gearbox:

Why not? If they’re built well, electrical machines last virtually forever. There is no shortage of motors and generators in industrial use that have hundreds of thousands of continuous full-power hours on them since their last rebuild.

Today’s boat alternators might tend to die after 2000 hours, but there’s no reason why we can’t do much, much better. The bearings in a bell-housing-mounted unit, for example, would see much smaller radial loads than those in a belt-drive alternator, and they could also be four times larger and much better cooled. The thing could be sealed against dust and crud, and since space constraints are now relaxed, the windings could be much thicker (and therefore run cooler) for the same output current.

The couple of times I have looked at max front bearing side load specifications they have been way higher than that imposed by the kind of alternators we are talking about here, so I’m guessing not a problem.

Good point about the potential on generators between the engine and gear. As you say, properly built commercial grade electrical generators last almost forever. Witness commercial grade AC generators, like our 5kw Northern Lights, which has been totally reliable for over 20 years. With just 3000 hours on it I expect it to go another 20 years and in fact the manual does not call for any service of the generating part for 10,000 hours.

Having said that, what worries me is that we are talking here about devices that are, I think, primarily designed and made for the recreational market, are fairly new, and have not yet achieved high volume. Not a recipe that usually goes well.

The other worry is what happens if it fails? If the answer is that the power is still passed through to the gear, then I’m happy. But if things can fly apart in there that will jam up the whole operation and bring the engine down, then not so much.

The point being that an alternator that fails is easily and quickly changed by an all thumbs yachty and can be fixed most places. One of these things would be a very different story. Bottom line, I just don’t trust the recreational marine industry to get something like this right, at least for 20 years.

Just chiming in to agree with Matt on the crankshaft loading. The moment arm tends to be quite small for the front pulley and the loads are relatively low so most of the loads ends up being reacted as a radial force in the nearest bearing. The loads placed on the crankshaft by the rods are quite large. Care should be taken to minimize vibrations, that is just good practice. As to their effect, it really depends on the specific type of bearings in there although most are plain.

Synchronous belts really are superior including from a loading standpoint. Overall, they last longer, have lower loads, less vibration and are much more efficient (you will burn less fuel). I would never intentionally install a V belt these days. For people who are space constrained, there are now some synchronous belts from people like Gates with really high power transmission density.

Regarding in line generators, I don’t see anything wrong with the concept, the actual execution of it is what matters. As Matt mentioned, properly designed motors are some of the most reliable things out there. The things that seem to go bad are the brushes and bearings. The loading on the bearings should be relatively light provided that proper coupling and alignment is done between the different components. If this is not the case, you could go through a lot of bearings quickly. Also, bearing lubrication is key. Most smaller motors use sealed bearings which don’t give the best life. Really, you should either have an oil system (more complexity) or a system to allow you to periodically grease them. For me, I don’t have a big enough battery bank to have one of these make sense so I will stick to my alternator for now.

I don’t think torsional vibrations are an issue for belt driven alternators off of the crank nose, especially since alternator load is relatively constant as opposed to e.g. camshaft or diesel fuel pump loads. It is very hard to transmit strong torsional activity through a belt (as opposed to say, through a geartrain). I think it is primarily a cantilevered issue on the leverage over the front main bearing.

I am more familiar with larger engines, but typically there is one or more bolted joints on the crank nose that attach the torsional damper and front pulley. The diameter of the nose of the crank is generally limited to main bearing diameter and that bolted joint is often a challenge, especially for applications with high loads off the front of the crank, so that may be another limitation.

I know it would be much more challenging, but do people ever drive a large alternator directly off the nose of the crank, through a coupling that allows minor misalignment? I know they sometimes do this for large hydraulic loads off of large off-highway engines and those engines are often spec’d to be capable of driving 50% of their output power off the front of the crank (if you can also do it within side load restrictions).

Thanks in advance.

Hi David,

I have never seen a direct drive alternator on a propulsion engine, although it’s often done on purpose built DC generators, I think. While probably a good idea in theory, the problem with most yachts would be space forward of the engine. Also, each solution would probably be custom for each engine and reasonably complex to do well, particularly since most yacht engines have flexible mounts.

Hi John, I agree with your conclusion. In my sailboat I have much the same experience as you have had. A standard car generator will not last much more than 2000 h. However I have two remarks that will improve charging very much: Proper alignment of generator is very important. Belts and bearings will last much more. Second and the professional solution: Buy a professional generator for maritime use. I use Transmotor generator. The lifetime of a Transmotor kept well is 30 years in a professional ship. A Transmotor cost some more than a car generator, but it is worth it. Maritime gear costs often more than gear from the car industry, but in this case it is easy not to pick the car gear.

When I spec’d my Beta 60 repower, I went for a double PTO so I could run two smaller (90-100 amp) alternators, the output of which would be combined and would be sent to a large house bank (about 1,000-1,100 Ah in the form of six 320 Ah 6-volt flooded L16 format batteries). The start battery would be fed via echo charger, as would the manual/electric windlass battery forward (smaller wire gauges would be required).

In that sense, the spare is already working.

Are you suggesting that a 180 amp (say) is better, and I should carry a second 180 amp alternator? I suppose the second PTO wheel could be used for emergency bilge pumping!

I would add that I have solar, wind and (if necessary) genset options. My ideal is to run the engine less than most, and never, if possible, just to make amps. That said, if I need to motor, I want to make plenty of amps and would use “motoring intervals” to make ice cubes, water and generally light up the joint!

Anyway, your guidance in this would be heeded. The only investment so far is that second PTO wheel. The rest of the gear has yet to be bought and installed while I think these ideas through for suitability to offshore conditions and shoreside electrical independence.

By the way, I have used the serpentine belts and they are indeed a better choice. So far, I like Greenlines.

First off, your design as you detail it should work fine. Having said that, it is not the way I would go. For me, with my fixation on simplicity, two alternators with two regulators and four belts is just more complicated than it needs to be.

Also, when you said “the spare is already working” you highlighted one of my major objections. A spare that is working and having its finite service life used up is not, in my opinion, a spare. In all likelihood both of your in service alternators are going to wear out at about the same time. So to have the backup that we have on MC, you should really have two spares, for a total of four alternators!

Also, I would not add a pump to the PTO since that breaks my rule about adding non-essential gear to a mission critical system.

A tip for microwave users (and other heavy amperage equipment): install a field wire dis-connect switch. This way, when motoring and wish to use the microwave through your inverter you do not hammer the alternator, belts, brackets etc. with amperage demand as the microwave kicks in. If you dis-connect, then, when done, re-connect the switch, the amperage is quickly returned to the battery bank, but done gently through the smoothing of the battery bank’s spontaneous recovery and the regulator’s soft start program.

The above disconnect can also give you full engine power in a fire drill of some sort if you are a bit under-powered. The bigger alternators can demand 6-10 hp or more and one often wants full power at night when the batteries may be down draining hp away from the prop where you might want it.

Also consider the connection to the engine. We de-tuned our alternator not to give it longer life, but because I considered our alternator bracket on our engine to not be robust enough to tolerate high output alternators. As a side consequence, I have considered alternators to just last forever as we have almost 5000 hours on the two I swap every few years.

People tend to think about power in boats as if they have some form of gearing such as a transmission or torque converter that decouples load and shaft rpm which is of course not the case. In boats, the load on the engine is determined by the load on the propeller for a given rpm. Of course, this load depends on many factors like propeller geometry, slip, boat speed, etc. Another way to think about it is that if you give the engine more fuel while you are motoring, its power will increase and you will have an imbalance of forces which results in an acceleration and the shaft speed will increase until the power output and load balance (this is actually a little unfair because the governor for mechanical engines and electronics for the new HPCR engines don’t work strictly on power but it is still generally fair). If you are overpropped, what happens is that you reach a certain rpm where you can’t increase the engines output power above the load from the prop and you get stuck at that rpm.

This can be both good and bad for boaters. The bad news is that a giant alternator can pull enough power that you won’t be able to actually reach full rpm when charging hard. This could potentially be a problem in an emergency situation. On the other hand, if you have the ability to turn the charging off, it lets you have a very large alternator without having to regear or repitch. The reason that this works is that the engine power output curve and propeller load usually diverge a bit at cruising rpm so you have extra power there.

I hope that this makes sense. It just bugs me when people get worried that they are loosing power to something like an alternator when they can still get to full rpm which means that they have plenty of power.

Eric

Thanks, Eric, for the clarification. I can’t speak for Dick’s setup, but my power output curve/propeller load will be variable as I have a four-blade feathering Variprop that is capable of in-water pitch adjustments.

I will have to empirically fine-tune the prop pitch from a baseline pitch to chart my own fuel consumption, my own “best economy cruise speed” and the interplay between RPM and the potential for lugging. Only at that point will I see the effect of a big alternator and whether or not I am “robbing” thrust in quest of amps. The reality is that the alternator load, all else being equal, is a pretty minor concern once I find my sweet spot of pitch and thrust. I selected the Variprop precisely for this ability to be adjusted (carefully) in-water, the reduction in drag of a feathering prop, and the ability to have separate pitching to achieve a “flatter” pitch in forward and loads of torque in reverse, which is desirable if one has a steel full keeler with plenty of windage. That said, I still think an ability to disconnect alternator output might be worth the slight addition of complexity, even as I hew more closely to John’s “KISS” mantra.

Once again, the deep experience of the members here has impressed me favourably.

Hi Marc,

Correct me if I’m wrong, but I believe that the Variprop only has one pitch adjustment in forward and one in reverse? If this is indeed true, the Variprop will not fix the issue that Eric is referring to. In other words, no matter how perfectly you adjust the variprop it will only be putting the full power from the engine into the water (less prop and gear inefficiencies) at one RPM setting. At all other settings you will either be lugging or wasting power that could be used to run a large alternator. I have a post here that explains why this is.

As far as I know, the only way to get all of the power produced by a diesel engine into the water at all of the RPM settings is a controllable pitch propelled. Another option is an Autoprop, which automatically varies its pitch depending on load.

Marc,

If both John and I are correct in believing that the Variprop is a variable pitch propeller and not a controllable pitch one, then John’s statement is correct that even with a correctly pitched propeller, there will be a single rpm where the propeller can put a load on the engine that is equal to the engines maximum output at that rpm and the rpm will also be the maximum rpm that the engine can achieve.

In steady state (no acceleration but constant velocity), the net force on something must be equal to 0. On a boat, this means balancing your propulsive forces (from sails or the propeller) with the drag of your hull. In the drivetrain, it means balancing the force output of the engine with the drag force of the prop. The propeller will have a certain drag force for a given rpm so the engine will be matching this force. Obviously, if the engine can’t output enough power at that rpm, you are not at steady state and the engine will decelerate until it either stalls or reaches a point where its power output is equal to the load. You can also have a situation with a seriously underpitched prop where you can’t use very much of the engine’s power because the propeller load is too low.

The solution to this is to make the load and the rpm independent. A controllable pitch propeller lets you put a wide range of loads on the engine for a given rpm. A transmission would also let you do this as we discussed in one of the hybrid threads. If you think about your car, having only a single gear would be really limiting. You would have to gear it so that you could make it up the steepest hill possible but then your top end speed would be really compromised because it would be like driving in too low of a gear the whole time. Boats have it much better than cars but there is still somewhat of a mismatch.

Choosing the right propeller pitch is really tricky and there is no such thing as perfect. If you wanted to be really conservative, you would wait until your prop was fouled, discharge your batteries and then make sure that you could just reach full rpm while tied in your slip. Unfortunately, this makes for generally slow motoring and high fuel consumption so most people put more pitch than that in.

I hope that I haven’t gone too far off topic here. The takeaway message is that a big alternator could mean that you either need a way to shut it off or take a bit of pitch out of the prop.

Eric

If a diesel engine is driven at say, 70% max rpm with a load torque that is say only 70% of max torque (and power…) at that rpm., its thermal efficiency (diesel liters per kilowat*hours) will not be as good as the same engine at the same rpm. with a load torque that is 100% of max torque at that rpm. (let us say 99%…). But diesel consumption in case 1 will be distinctly lower than in case 2. In fact you can estimate thermal efficiency should improve about 5% in case 2, which means that the extra 30% load torque (and power…) will cost about 25% more diesel, so “marginal efficiency” for those 30% should be about 13% better than case 1 efficiency (30/25 * 100…), and about 8% better than this engine max thermal efficiency.

Those maths suppose that engine has not been sized for max rated engine RPM & torque + full genset load at WOT, otherwise 70% of max rpm. plus max alternator load should not give more than #70% of max possible load torque at that rpm, unless you have à CPP or equivalent. In that case, global thermal efficiency of the whole system can not be better than same without alternator.

Concepts are good but the actual numbers are significantly different. I took the Yanmar 4JH45 (their smallest 4 cyl) rated 45 hp @ 3000 rpm (lowest rated speed I found). I took their fuel consumption (only available on the prop curve) and did a bunch of calculations. At 70% speed (2100 rpm), a standard 0.3 exponent prop curve consumes only 41% of the engine torque available at that speed, not 70%, so you can see how low of load you end up by backing down speed when motoring.

I used your estimate of full load at this speed being 5% improved brake specific fuel consumption (BSFC, in g/kW-hr, inverse of thermal efficiency) from the prop curve’s 262 to a full load value of 249 g/kW-hr. So, if we go from the prop curve to 95% load at this speed, we get an increase of 133% power with a fuel flow increase of 120%, so about 11% of the power increase for electrical generation (133/120) comes for free. Not earth-changing, but not bad. And way better than generating that power at 2000 rpm in neutral with the electrical as the only load.

Other considerations are that this implies a power generation power of 15 kW on this example setup. If we assume (from the video presented) a generator efficiency of 50%, that’s 7.5 kW electrical generation or 576 Amps @ 13 V. So we’re going to need a heck of an alternator, cabling, BMS, battery bank, etc. to accept that.

And per another comment on this article, this would require an alternator cutout if you wanted to reach 3000 rpm with this prop sized for the full 45 hp @ 3000 rpm. So, reality intrudes and demands one of the loads be controllable vs. engine speed, so either a controllable pitch prop, or some kind of programmable voltage regulator. Without that, if both are fixed, you’d need to limit to well below this generation power or else you could never exceed 2100 rpm or put more than 15 hp into the propeller. It’s a tangled web.

Also need SERIOUS cooling to load up an alternator to anywhere near full output at lower speeds, as I also learned form the posted video. So definitely some caveats.

Dangerous talking about parameters that have units of %. There is “delta points”, as in 15 vs. 20% is 5 points of efficiency. And then there’s “delta percent” as in 20% is a 33% increase over 15%. Have to be VERY careful in this area to avoid errors.

Hi John,

You are correct that there is usually power to spare at cruise rpm although the actual power available will vary depending on the specific application. For the size boats that most people go long distance cruising in these days, the draw of the alternator is usually a relatively small fraction of the total power output.

Unfortunately, there is no free lunch and the power to run your alternator comes at the expense of burning more fuel in the engine. The real question then is, what is the most efficient way to charge so that you burn the least fuel. Engines have relatively low efficiencies thanks to a host of losses that all give off heat in the end. Your mechanical losses are typically fairly constant for a given rpm regardless of load. Therefore, if you increase the load, you don’t have much extra mechanical loss so you are dividing a larger overall power output by the same mechanical losses. How the other efficiencies such as combustion track is much more engine specific. Some engines try to be really power dense and end up with inefficient combustion and high valve losses. Other engines are effectively loafing along and a small increase in power will be quite efficient. In the absolute best case where your incremental power output was produced at 100% incremental efficiency, you would still have to make up that amount of energy in fuel. In practice, everything is below 100% efficiency and in engines, it is much lower. For engines like your Perkins, I suspect that the incremental efficiency for charging at cruising rpm is actually quite good. If your engine actually had the extra power to spare without having to increase the throttle, it would accelerate and go to a higher rpm.

I don’t want to make it sound like this is a bad time to charge your batteries, it is usually an excellent time. Running the engine just to charge the batteries is terribly inefficient because your power output is overwhelmed by all of your power losses. In the extreme case, with no load on a running engine, its overall efficiency is 0%.

Along the lines of engine efficiency, it is no coincidence that at WOT, the most efficient operating speed of an engine is very close to its torque peak. Engines are typically designed around a maximum cylinder pressure and the rpm associated with the torque peak is the rpm where there is the best balance of all the factors that make up the overall efficiency.

Eric

I will explain my short comment given above a little: A car alternator will normally last around 5000 hours in a car with a small load. In a boat with 80% load it will last 1000-2000 h. A marine alternator like a Transmotor can last 30 years. Alignment should be done with laser tools. Laser tools is uncommon on boatyards in North America, but the price of this tools are falling fast, so just demand it to be used. When the lifetime of the alternator is 30 years, it is important to keep the engine room clean. Otherwise the alternator will be filled with dirt that can cause damage.

Hi Svein,

The transmotor looks like a great piece of solid commercial gear, much like the Electrodyne that I mentioned in the article. Definitely the way to go if you can fit them. But they are huge and need massive brackets and, as you say, accurate alignment. We tried to figure a way to fit an Electrodyne to our Perkins 87 HP, and there was just no way to get it to fit in the space we have available, and we have more space than most sailboats.

And I certainly agree about laser alignment. I watched a technician aligning the pintals on Bluenoses II’s massive rudder with a laser. Made way more sense, was more accurate, and took way less time than any other method.

Many commercial alternators are too big in a small boat, but Transmotor has small alternators. They can be found on scrap yards in Scandinavia, but a new one is worth its price and will usually fit on a small boat. I have one 40 years old at 100 amp that still works good.

Very good article!

It is Heat that causes premature death to alternators. Make sure that the regulator has an option for a heat sensor connected to the alternator.

Another thing that will improve service life is to improve the cooling of the alternator. An easy way, is to install an engine room fan that blow air on the alternator. If you can take the air outside great, if not just take it low in the engine room.

Then a comment about the 2 alternators instead of one. If done correctly a 2 alternator solution is a good alternative. But I fully agree with John about the mounting issues. Only do it if the engine manufacturer offers a factory mount for the second alternator. Ideally the regulation should be done with one regulator.

I have two alternators on my Yanmar 4JH4-TE. The second alternator is a large frame 130 A, factory option. The standard alternator is replaced by a Balmar 120 A Alternator. (The standard is laying as spare.) Theoretically I have 250 A (Cold value available) but they are regulated to only produce about 70% (165A) of the capacity. The 2 alternators are regulated with ONE regulator and feeding the house bank. The engine start gets charge over a Balmar Duocharger.

I´m soon coming up to 1000 hours and it will be interesting to see if it will be the large frame alternator or the small frame that gives up first!

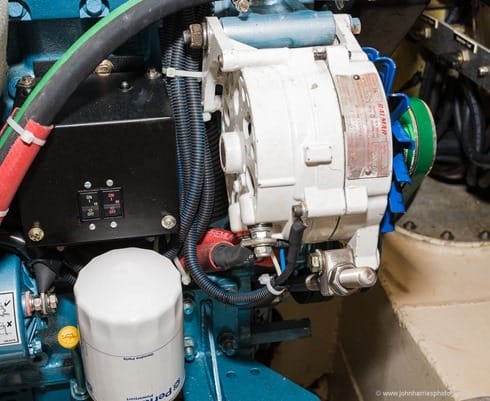

Good point on the desirability of a overheat-sensor on the alternator. You can see one on our alternator in the photograph at the start of this post.

Laurent, I have lived with a DC genset such as you describe for 7+ years now full time live-aboard. It is a small Kubota diesel attached to a 150 amp alternator. I have made it work, but it has been very fussy, especially the first few years. For small cruising sailboats (especially those without aircon), it makes so much better sense, just as John described. Also, just as John described, reliability is an issue, especially for the marinization elements. There are just so few made compared with AC gensets.

Dick Stevenson, s/v Alchemy

Excellent article and good tips. I especially like the discussion of mounting and tensioning which many people don’t think about.

Topic drift which I hope John will excuse (or maybe move to a different article). I’ve never been keen on always running your engine to keep the batteries charged. There is another way – lots of alternative energy sources.

We’re quite happy with the stock 55A alternator on our little Yanmar because we have 375W of solar panels. We very seldom have to run the engine to charge batteries. Usually around mid-winter when daylight hours are short even around 28S / 28N (3 winters). Probably over 5 years we have run the engine about 150 hours to charge batteries now.

We try to keep power consumption reasonable (LED Lights, small well insulated fridge, low power computer)

On passages it probably helps to have a catamaran that steers in a straight line very well and an autopilot that doesn’t use that much power.

Hi Evan,

Good point, if you have plenty of solar, the whole alternator replacement thing can become academic. One of the nice things about catamarans:plenty of space for lots of solar.

Having said that, I would still suggest a properly programmed external three stage regulator because otherwise the few times you do charge with the engine it will be very inefficient and hard on the batteries too.

Hello John

We do supply solenoids aswell. For 3 battery banks, a diode is proposed.

The charging current is not ‘lost’ through the diode. The power which generates the heat is from the alternator so the batteries at (say) 14.0v will receive the same current with or without the diode.

Hi Bryan,

You are, or course, quite right about the current, since current will always be the same in all parts of a circuit. However, a diode has at least some internal resistance and most drop at least .25 volts. Therefore, unless the charging device uses a sensor wire attached directly to the battery, the batteries will receive .25 volts less than they should, which in turn means that the entire circuit receives less current (amps). This may not sound like a lot, but in fact it is enough to substantially affect proper charging when in acceptance phase, which, for most lead-acid batteries is about 14.4 volts at 70F.

Further, since diodes get warm in use, at least some power is being lost, albeit minute.

Don’t get me wrong, I’m not saying that diodes won’t work, only that I prefer solenoids for these reasons.

While it may seem at a tangent to alternator discussion/loads, the type of prop one has logically affects such concerns. The 19 x 15 (nominal pitch) Variprop was purchased rather specifically for its feathering qualities on a “draggy” full keel, which yield under typical conditions a good 0.5 to 0.75 better speed with an identical sail set, boat angle and wind speed/veer over that of the previous 18 x 13 fixed-blade that now becomes the spare.

It was also purchased for the sheer surface area, which, when combined with the ZF25 1.9:1 hydraulic transmission, should yield the sort of desirable torque I wish to have in close quarters with wind on our rather buxom stern quarters. In other words, I accept entirely your comments regarding the superiority of the CPP style in terms of getting the most for the least when the alternator’s in play. That isn’t so much a concern here. I will pitch for a “idealized” RPM that yields greatest fuel economy, with or without alternator use, which, as has been mentioned, isn’t going to be a huge burden or fuel cost. We aim to avoid motoring, but if we must, 4.5 to 5 knots for maximum fuel economy isn’t daunting, and if I need the hull speed of 7, I’m not going to whine that I’ve gone from burning 3 to 8 litres per hour (for example), because if I need our boat to motor at hull speed, the cost of diesel is unlikely to be uppermost in my mind. Even French diesel.

The alternator disconnect idea, given our large solar panel area and a wind genny, is about as good as we are going to expect as a solution to this issue.

It’s clearly, however, a rich topic of discussion and illustrates once again while there’s no free lunch in physics, you get to select from a fairly wide array of buffet items.

I disagree that the single alternator plan is better. Here’s how I did it and why.

The original alternator is tied directly to the starter battery in it’s own circuit. The house bank has a separate circuit and is tied directly to the 150 amp alternator which has 2 belts. The original alternator has an internal regulator, so there is still only one external regulator. The original alternator has only a single belt, which is plenty sufficient, so there is one regulator and 3 belts total.

The normal battery selector switch is used only to tie the banks together in case of a failure. Drops from diodes are eliminated, failed isolators are not possible. Forgetting to change the battery switch when ending charging isn’t a danger. Any time you start the engine the all the batteries in both banks are being charged.

In getting my boat ready to cruise, I tried to figure out how to make any failure into an annoyance instead of a panic. In this case, failure of either alternator – or belt (s) can be dealt with when it’s convenient, not at once. To further that, the big alternator has 2 belts, either of which would be enough on it’s own. With two, you get a little longer life, but again, losing a belt is an annoyance that can be dealt with at a later time. I also made changes to the cooling water system and a water tight bulkhead in front of the rudder, but we’re talking alternators here, so I’ll stick to that.

Here’s the part not mentioned so far and often overlooked: pulley ratios. If you size your pulleys so that at top engine speed your alternator is at it’s maximum speed, it won’t help charging at higher engine speeds, but it will boost your low speed charging. If, for instance, you can change your ratio so that the alternator runs twice as fast at a given speed, you can get as much charge at 1000 rpm engine speed as you used to get at 2000. With my Yanmar 3QM30, which has a top speed of 2800 RPM for short periods of time, 2600 sustained, I could run my alternator at 4 times engine speed and not exceed the 11,000 RPM the alternator was rated at. What this meant was, at an idle I would get around 70 amps instead of a marginal output.

Idling out of the anchorage, I could often have my batteries nearly charged by the time I was underway.

After sailing to an anchorage, I could put a lot of amps back in the batteries by the time I got the anchor set, as opposed to nearly nothing at more conventional ratios. And, when charging at anchor, at around 700 RPM I could put a max charge – around 120+ amps – into my batteries instead of cranking it up to 1200 to 1500 RPM. I also could easily switch off charging if I needed the extra hp for some reason.

On a higher revving engine your ratio can’t be quite as much, but you can still gain if you size your pulleys appropriately.

On another aspect, proper sized wiring, clean connections and short runs add a lot to how your system works. People are concerned with loss from isolators, but too small wiring and poor connections can be far worse. I tried to help one cruiser who was having problems getting his batteries charged and found that he was losing nearly 2 volts from his alternator to his battery bank from long runs (probably 20 feet) of too small wire, many poorly conducting connections, and 2 inline ammeters.

It’s very simple to find out if you have a problem like this. Get a digital ammeter that will read millivolts, then start checking. Check on either side of every connector, at each end of the same wire, even between the battery connector and the post on the battery. You can actually measure the voltage drop in a 2 or 3 foot battery cable. To do this, it must be carrying a good load, so let your batteries run down enough that they’ll take a maximum charge, fire up your system and start probing. If you find more than maybe ¼ volt drop from your post on your alternator to your battery post, track it down. You may find it is one big drop at one connection or many small ones, but cleaning each one and replacing or removing any parts that still show a drop can pay big rewards. Remember, though, that large currents must be flowing to make a drop. The voltage drop will increase as the current increases. (E=I*R). Anything inserted in the line from the alternator output post and the battery post will cause you trouble, ideally there would be nothing but a big old wire. In reality, there will probably be several connections, maybe an inline ammeter (get rid of it and get a shunt) or other gadgets.

Hi Gene,

You have obviously put a lot of good thought into your system. Also, great tip on the whole voltage drop issue. We have huge 00 wiring for just that reason.

I have to say I still prefer the simplicity of one large alternator, but each to his own. On the belt redundancy, that sounds good, but the reality is that in some 40 years of working with diesel engines and belts I have yet to see one break. Slip yes,, wear yes, break, no. So I’m not sure that’s a real benefit. Also if the belt broke on your small alternator you would have to stop because on the Yanmars I’m pretty sure it drives the fresh water pump.

I would also caution against taking the alternator speed up too much. As I say in the piece, alternators wear out pretty quickly under cruising loads and running them faster is only going to make that worse. I would also want to be careful on smaller engines about putting too much load on at low revs.

John, You’re right on top of it! On most engines you’d be correct and you couldn’t do what I have, but my engine was originally made as a raw water cooled engine. The internal water pump, gear driven, is a rubber impeller pump that will draw water from the sea. The manufacturer added an external pump and a heat exchanger, so the alternator and raw water pump are on different belts. If I lose the pump or belt, it’s a simple matter of moving 2 hoses and I go to raw water cooling. Not ideal, but better than being stuck.

Twice this has helped. Once on my boat, the pulley slipped on the pump shaft, losing raw water pumping. Moved 2 hoses, later when it was convenient, I sorted it out and repaired the pump. A second time it was someone else. They were stuck in a remote anchorage in the Bahamas, and a mutual friend knew I had the same motor. Over the radio I was able to direct him changing hoses so he could bypass his internal pump with the external raw water pump. His plan up to then was to have a replacement pump flown in from Yanmar and find someone to bring it to him. With moving a couple hoses he was able to motor out of the anchorage and come to our location and continue until parts caught up with him.

Since it was a sailboat, I question why he didn’t just sail the darned thing instead, but that is a different post, I suppose. When we lost a transmission in the Bahamas, we picked a good route and sailed it back to Texas for repairs.

Gene, thanks for the detailed description of your robust-sounding system. It’s made me rethink (again!) my own plans in this regard.

By the way, I broke an alternator belt while idling the diesel at a pump out dock. I spotted steam instead of cooling water coming out of the exhaust (luckily a side exhaust on the starboard, which was visible from the dock). Coolant temps were past 220F so one could say I caught it in the nick of time. So things like exhaust temp alarms and dual cooling water pumps as described actually seem viable to me, despite the dreaded added complexity.

In tip #6 you mention the “automatic charging relay” to keep the starter battery charged. Are these typically wired to function only under load from the alternator? Should it also close under current from the charger?

Have you ever used a temperature sensor on the alternator? I expect that if you always derate a high output alternator to 80% then over heating should not be a problem, but it could help to protect the alternator.

Hi Chris,

In our latest re-power, I did fit a temp sensor to the alternator. My thinking was that since the regulator’s method of measuring alternator load is very crude (field current) and potentially inaccurate, that it was worth having the additional safety of the temp probe. Having said that, I have never seen the regulator cut the field current in half, which is, if memory serves, what it’s designed to do if it senses an alternator overheat. One other thought, we have a large case alternator, which are less prone to overheating. I think I would strongly recommend a probe for those that are constrained by space to a small case alternator.

Good morning all.

Thanks to the excellent info from AAC, particularly the e-book on batteries, I have just replaced the standard alternator on our new Yanmar with a 160A Aquamaax and Balmar smart regulator. There still remains to be done the tweaking that John describes in order to get the optimum out of this system, but one thing does cause me a slight concern. The Aquamaax is high output, but NOT large case. Although I shall be down-rating the output as suggested, is this likely to be another piece of equipment with a short life?

Yours aye,

Bill

Hi Bill,

I took the liberty of moved your comment to the alternator post.

My thinking would be that since the Aquamaax is not large case it will be doubly important to down rate it and carry a spare alternator. As I say in the post, we have generally get 1500-2000 hours out of a large case alternator before rebuild, so my guess would be that you will want to plan for around half that out of the small case. Of course there are a huge number of variables here, so that is only a guess.

John,

A little off topic, but what is the box with two switches immediately above the fuel filter on your first picture in this article?

Cheers

Don

Hi Don,

It’s the engine control box as provided by Perkins. Contains start, stop, glow plug, etc, relays, as well as the two breakers you see. One for the engine and one for the panel electrical stuff.

Hi John,

Would you kindly share your thoughts re: driving a HO alternater with 2, v-belts vs. a serpentine conversion kit?

Thanks so much!

Hi Keven,

I have not used one of the serpentine belt conversion kits, but I did have a factory standard serpentine belt driving a large alternator on the old Cummins engine and it worked great.

We went with two belts on the Perkins because there was no off the shelf serpentine kit available. On balance, if you have an engine that a serpentine kit is available for, I think I would recommend going that way. Also, it will probably be a less expensive option than having a really good two belt set up made by a machine shop, as we did.

I moved your comment to this post where you will find additional insights in the comments.

Hi John,

I discovered both 24V alternators, one 155amp and the other 55 amp were not charging and because I haven’t taken the boat out many times as yet I have no idea how long it was hidden from me. Usually have the genset running and also the switch between start batteries and house batteries switched on. The last time I took it for a drive I didn’t run the genset and noticed the voltmeter only reading 26V and the amp meters no reading. Held a screw driver behind both alternators, however no magnetic field and both were cold to the touch. Strange that both were not working, and wondered if I did something wrong. It could be that both at one time were working too hard and getting too hot with the previous owner, as sofar I have alwys used the genset. Could it cause problems when genset and generators are all charging all the batteries with the house and start batteries connected? Many thanks.

Hi Rene,

As long as the voltage regulators on all of the charging sources are working correctly, there is no reason that having the generator and both alternators charging should be a problem.

Also I’m going to guess that the small alternator feeds the engine start batteries and the large feeds the house batteries, so there should be no need to gang the two banks. In fact that’s probably not a good idea since the whole idea of having two banks is to that if you inadvertently flatten the house bank you can still start your engine.

Further, if your meter is accurate and the voltage was 26 volts then something is probably charging. If nothing was charging I would expect to see a voltage of no more than 25 volts (assuming some loads), even if the batteries were fully charged when you left the dock. (I’m guessing you keep the boat at a dock plugged in to shore power.)

The fact that the alternators are cold may not be significant since if the batteries were fully charged when you left and the loads are low, they would not be doing much work.

A simple test would be to stop the engine, read the volt meter, and then start it and see if the voltage increases.

Having said all that, it sounds like a complex (motor?) boat, so it would be a good idea to have a technician really check over the charging system to make sure you are not totally reliant on the generator. I would also want to understand exactly what each charging source is connected to.

Also, I would suggest reading a good book on marine electrical systems and then tracing out all the wiring yourself, so that you understand it in case something goes wrong when you are out.

This will also give you some ability to access whether or not a technician you hire actually knows what they are doing—an alarming percentage don’t.

I have not read it, but I hear that this book is good: http://www.amazon.com/12-Volt-Bible-Boats-Miner-Brotherton/dp/0071392335

And this one: http://www.amazon.com/Boatowners-Mechanical-Electrical-Manual-Essential/dp/0071432388/ref=sr_1_1?s=books&ie=UTF8&qid=1428924600&sr=1-1&keywords=nigel+caulder

I’ve read, own and regularly consult both books and can endorse them as good guides to the perplexed. The 12-volt Bible is elderly and looks a bit self-published, but if you are starting from the level of “able to replace the batteries in a flashlight”, it’s a great introductory text. Also, Charlie Wing’s book here is also quite good and is well illustrated: http://www.amazon.ca/Boatowners-Illustrated-Electrical-Handbook-Charlie/dp/0071446443

Thank you John for your speedy reply.

You already guessed right, it is a complex Dutch alu build motorboat, more like a ship. As an old sailor, I know the feelings towards motorboaters, but due to my wife’s handicap, was forced to change sides. However, was one of the first to sail from Holland to Iceland in 1968 in an alu 30 footer with only a radio direction finder onboard. Also, still have the 1982 Whitbread round the world race winner, “Flyer” in the family and when taking diesel courses at Perkins, UK, in 1967? met Francis Chicester there, who also had a 4.108 in his Gypsy Moth. So there is still a lot of “sail” in my blood.

Had all the batteries hooked up together, since sometime earlier, when trying to start both engines, and not hearing how fast they turned over, due to distance, I burned out a starter solenoid. Later was told that Volvo starter solenoids have a problem overheating. It also took quite a few hours to re-charge the house batteries, once hooked up again to shore power, when taking it for a drive a month ago, this time without running the genset.

Hope to be onboard again in Seattle and will spend more time to check out both alternators, and may take them in for testing and hopefully its just some diodes.

Thanks again for all your suggestions and advice, and for the names of the books mentioned.

Hi!

We have a Volvo Penta 2003 from 1993. It is well maintained so will keep if for ARC 2018. The original alternator rates at 50 A. The house bank consists of 300 A (4 x Gel batteries). And a bow battery of 75 Ah. We are not going to live-aboard more than one year.

I appreciate all written in the article and totally agree. But we don’t have time, budget etc to follow the advice. So I suggest replacing the original 50 A alternator with a pirate alternator rating more amps. No reprogramming if I cannot find somebody local who does it cheap. Same dimensions for easy replacement. Vacuum seal the original alternator and stove aboard.

How big should the replacement alternator be then? (Don’t mean size, mean Amps).

I was under the impression that batteries will only charge max 10% (A) of their capacity (Ah) or get damaged, AGM can take more?

When charging all at once I am charging 375 Ah. 10% of that is 37,5 A. So the original alternator will cut it? I don’t need to upgrade to a, say 100 A, alternator?

Less important, but would like to understand it, is – how is charging current limited to the house bank size? Let’s say I mount a 200 A alternator? Would I destroy the house bank or would the batteries’ internal resistance limit the charging current? Are there ways to limit max charging current?

I will also mount <=400 W of solar panels. If they charge near their full capacity while the engine is running, could I damage the house bank (too many amps)? Or will the MPPT and PWM (got both) take care of that?

To make a long story short. The bow battery is currently not connected to the engine, I would have to use starting cables. It is just being charged by the shore power charger that is. So I really don't have a dual bank system. But am considering upgrading to. I want everything to be automatic, no battery switches etc.

Will mount a windlass of max 100 A on bow section. If I reuse the bow battery for the windlass, connect properly dimensioned cables from it to the windlass. When using the windlass, if I start the engine, somebody said there is no way of knowing whether the windlass takes its 100 A from the battery or the alternator or both. So I was recommended to have fat cables from the alternator to that battery as well.

Quite expensive. If I invest in those cables, why not as well use the bow battery as a start battery and create a true dual bank system? So start battery will be used for cranking engine and running windlass. We're just out there a year. I could buy cheaper pure copper cables from alternator to start battery, cheat a bit, they'll last a few years at least? The circuit is at least 10 m so I calculated it to 95 mm2. Maybe it'll work with 50 mm2, but charging will be impaired with a large voltage drop I suppose?

Also, a reason for keeping the Volvo Penta is that it's common and there's spare parts and mechanics world-wide, skilled on it. So I could probably buy a new alternator also in the Carribbean and get help? If so, I could maybe do…nothing?

Thanks for a good forum!

Hi Tobias,

You have a lot of questions here, which I can try to help you with, but the key thing that jumps out at me is that I think you are making a mistake by trying to cut corners and go cheap on your electrical installation. Yes, it’s only a year, but if you have electrical problems for a lot of it, it could be a very long year. You are also planning a passage that will probably take you over 20 days. If this goes wrong you could be doing a lot of that passage with no power at all…and no engine.

With that out of the way, a few answers:

Ok great answers. I think I got the idea to get a 100 A alternator from your site in the first place. Will take that route then.

I am currenty drawing the top down model of the electrical system in MS Visio. I will keep my questions simple, I can figure out the details later if I get the initial planning correct.

I got 4 x Gel batteries (2013) as the one and only house bank. And that bow battery. One house bank makes a simple electrical system. Question is, will the 300 Ah be enough for also running a windlass (with fat cables to it), if I take the bow battery out of the question.

Thing is, I cannot easily add Ah to the house bank. When parallell coupling batteries, one should buy same brand, model and even batch, and connect them at the same time, and leave it like that, I’ve been told. Hard to modify afterwards?

Or could I try to find similar Gel batteries and add a fifth or even sixth in parallell?

Replacing the current battery bank with 6 new batteries for example, is prohibitely expensive. Not entirely ruled out though.

Or should I take the route of creating a dual bank system? Move the bow battery to the aft, near the others/near engine. And add all those relays, switches etc you seem to need (=read up).

Cheers

Hi Tobias,

Hi!

How can I perform a discharge test, please? Will it harm the batteries?

I have done the math. The bank is big enough if I got +400 W of solar panels. I will aim at 500 W. If I don’t run the engine and without the windlass involved.

If I run the engine every few days, no worries.

So I should add a sixth starting battery and create a triple bank? Three battery banks separated:

Bank 1 = 4 x Gel batteries, near engine.

Bank 2 = 1 x starting battery, near engine.

Bank 3 = 1 x bow battery for windlass, near engine.

If Bank 2 fails I want to be able to failover to bank 1. I will figure it out I suppose.

If Bank 3 fails, I want the windlass to run from Bank 1. Some kind of switch between bank 3 and windlass, so I can choose bank 1 instead of Bank 3 for the windlass.

Charging should be fully automatic and charge all three banks from 1. solar panels, 2. alternator, 3. battery charger.

By the way, if I connect Bank 3 to the windlass with short fat cables. Do I still need fat cables from charging sources (alternator etc) or can I choose 25 mm2 for example and have the kind of voltage adjustment gadget that adjusts the charging current, please?

Or will the windlass take most its power from the alternator via that cable? I need to know where it takes its power from. Battery or alternator/other charging sources.

Cheers

Hi Tobias,

I think I need to bow out of this at this point. I can’t design a system for you interactively in the comments. It’s not fair to the other members since the process takes too much of my time away from creating new content for all.

However, what I will do is use your questions (and others) as the foundation of at least one, and probably more, new chapters to this online book. Look for them to start appearing in the next few weeks. In fact I’m going to start on the first one right now.

Thanks. I appreciate what you say. I have some reading up to do before the overhaul of the electrical system.

Cheers

Hi Tobias,

Thanks for your understanding. Yesterday I spent the day writing the first drafts of two new chapters that will help.

Hi Tobias,

We have a 55HP 2002 Volvo Penta diesel which came with a standard 50 Amp alternator.

Following John’s advice in this article, we chose to replace it with a single 120 Amp Mastervolt alternator and smart regulator, on the basis that Volvo sell a specific kit which includes the engine mount bracket, tensioning arm, serpentine belt and instruction set. This kit has been designed and endorsed by Volvo to specifically retrofit the 120 AMP Mastervolt alternator to our specific engine. I like very much that the two components were designed to work together with collaboration from both manufacturers, and that we could order the kit through our Volvo dealer. I have taken as gospel John’s – “don’t-funky-up-your-engine” approach to our main engine, this advice alone worth every cent of our membership IMHO.

Added to this, with our 47 foot yacht and a modest 55HP engine, the new alternator (by my calculation) takes approximately 5HP to run, or 10% of our available power. The Mastervolt smart regulator and Mastervolt electrical management system allows us to manually shut down the alternator (with a single “soft” button press) should we need all the horses for main propulsion at any time.

But what I failed to appreciate from the part description (my rookie error), was the size of the new alternator compared with the old, but even more so, the generous spacing allowed for on the Volvo supplied bracket. This meant I had to cut away the sound and heat insulation from the engine housing sides, and left me only just enough room to glue on some exhaust muffler wrap for protection of the plywood engine bay sides. Not ideal, but the alternator really delivers as promised (we see between 100 and 110 amps charging at the batteries when the alternator is cool, and the smart regulator automatically rates this down as the alternator heats up, or the batteries accept less).

One further minor issue was there was no locking nut on the belt-tension adjustment arm as supplied. This resulted in the alternator vibrating free and rattling against the engine housing sides, held back only by the alternator belt – quick fix though.

So if your engine bay is relatively narrow, you might like to measure more carefully than I did before buying your chosen alternator. Hope this helps.

Rob

Hi Rob!

Thanks for the advice. Our 1993 Volvo Penta 2003 has 29 hp only. I am currently looking at a Balmar that would take 4 hp. To begin with we are at the lower scale of horsepowers needed to go cruising. I would rather have something like 40 hp. Original for this boat was a Volvo Penta MD11 23Hk.

So you did not take the re-programming of regulator path? Interesting. Will talk to Mastervolt! Did you buy their entire package, i.e. alternator AND regulator (and temperature sensor etc?), please?

Cheers

Hi Tobias,

Yes, the alternator and regulator are from Mastervolt, the sensor also. We use Mastervolt for the electrical management computer which makes the interfacing and interrogation more simple.

Rob

Hi!

Considering this one:

https://www.mastervolt.com/products/alternators-12v/alpha-12-90-iii/

From the manual:

“The first step of the three step charge

system is the BULK phase (A), in which the output

current of the charging system is limited by the

maximum output current of the alternator and the

engine RPM. At this stage the major part of the

capacity of the battery is rapidly charged. The

current charges the batteries and the voltage will

rises to the absorption voltage of 14.25V (12V

models) or 28.5V (24V models) @ 25°C / 77°F.

The duration of this phase depends on the ration of

charging capacity versus battery capacity and on the

degree to which the batteries were discharged to

begin with.

The bulk phase is followed by the absorption phase.

(B). The absorption charge starts when the voltage

on the batteries has reached 14.25V (12V models) /

28.5V (24V models) @ 25°C / 77°F, and ends when

the battery is fully charged. Battery voltage remains

constant throughout this stage, and the charge

current depends on the state of charge of the

battery, the battery type, the ambient temperature,

and so on. With a wet cell battery this stage lasts

some four hours, with gel and AGM around three.

…

Once the battery is 100% full, the Alpha Pro

regulator automatically switches over to the float

phase.

An extract, full manual here:

http://images.mastervolt.nl/files/1182264995.zip

About to order now. We are leaving home waters summer year 2018.

Cheers

Hi Tobias,

There is nothing in the above or in the Mastervolt manual that contradicts anything I have written except their claim to be able to accurately detect when the battery is charged, which is marketing hype that most every regulator manufacturer spouts. I have explained why in the regulator chapter, so I’m not repeating myself here.

That said, I took a quick look at the manual, the product in question will probably work well for you, although its regulation algorithm and flexibility is a bit crude when compared to other products like the Balmar MC-612. On the other hand the Mastervolt regulator is a bit easier to program because it only has three controls and they are analog (screw), not digital.

Glad to hear that you have plenty of time.

Missed out one thing. If I am to create a dual bank system. May/should I use the starting battery for the windlass also, or connect the windlass to the housebank (4 x Gel batteries)?

Cheers

Hi John, alternator charging. Do you give priority to the starter battery first and then the house batteries or the other way round? I am thinking of using a BEP VSR between the 2 banks but not sure which should be given priority. Thanks,

Hi Rob,

Wire the alternator to the house bank and then use a voltage sensing relay to gang in the starter battery when the voltage comes up over say 12.8 volts. Here’s one that should work well: http://www.westmarine.com/buy/marinco–digital-voltage-sensing-relay-dvsr-12-24v–14152185?green=C11E6826-749D-5CF4-A6F1-9378C3C08091&cm_sp=Onsite-Recs-_-MB-_-PDP

We have been set up with one like it for 25 years and it’s worked well.

Hi again Rob,

Just googled BEP VSR and that should work fine too.

Hi John, if using a BEP VSR with the sense on the house bank, it would appear that it will be switched on when you are on solar or wind vane charging on the house bank. This can be 80% of the time with it switching on and off frequently. May I know how frequently do you have to replace the VSR? I am thinking of preventive maintenance.

Hi Rob,

Hum, that’s a very good point. This would also mean that the engine start bank would be held at acceptance (~14.4) for very long periods after it was charged and really should be at float (~13.5). The answer is to wire the energizing circuit for the VSR through the engine ignition or an oil pressure (normally off) switch so that the solenoid can only gang the batteries when the engine is running. And, to answer your question, our VSR has lasted 25 years. We do carry a spare.

Hi Rob,

Gave it a bit more thought. At least at first glance, I can’t see any reason why you can’t wire the alternator to the start battery and then set the gang solenoid up so it’s energized when the voltage at the start bank incases to charging levels. Nice and simple and this way the banks will only be ganged when the engine is running.

Yep, that was my initial thought and also that recommended by BEP in using their VSR. But for some reasons, many boat owners used your initial recommendation ie to put priority and sense the house bank. Maybe it is the bank that needs charging most…

Hi Rob,

Yes, I initially defaulted to charging the house bank first, but then when I thought about it I realized that it really didn’t make a lot of sense. Normally an engine start will take a tiny amount of capacity out of the start battery, so in this case the voltage will rise on the start battery to the activation level of the gang solenoid in a very short time and at that point the house bank will start charging. If for some reason, say starting problems, the start battery was heavily discharged, then you want to charge it back up first anyway.

The only possible problem I could see is if the alternator regulator was deeply stupid it could be fooled into switching to float before the house bank came on line but most any decent regulator will be smarter than that.

Hi John, then again you will run into the problem of overcharging the starter battery. Assuming the engine starts on the first crank and the external smart regulator is reprogrammed to bulk charge to the initial 4 hours (which I fully agree that the house bank needs it). But the BEP VSR would just charge both banks. Do you see the problem now?

Hi Rob,

First off, it doesn’t matter which way round you connect the gang solenoid sense wire. Either way the engine battery will be held at acceptance (~14.4) after it’s charged while the engine is running. The point being that the batteries are going to gang very soon after engine start, either way.

But the key point to understand is that this is not a problem and will not damage the start battery. We have been wired this way for some 25 years and our start battery is 14 years old and still going strong. Contrary to what many will tell you, a good quality deep cycle battery will not be damaged by being held at acceptance after full charge for the hours that an engine runs. This is confirmed by our own experience and testing at LifeLine battery. And note that because of our Arctic passages we have motored for many more hours than most yachts. (Some 6000 hours during the life of our start battery.)

The only way to charge the two banks independently is to have two alternators and two regulators and that is a huge amount of unnecessary complication as I explain in the alternator chapter.

My advice is connect it as I detailed in my last comment (sense off the start battery) and stop worrying about it. It’s a solved problem.

Also, you may want to read my latest chapter on batteries to better understand bulk and acceptance charging. During bulk the voltage will be lower than acceptance so in this case it’s acceptance we need to be discussing, not bulk.

Hi John, I have been thinking about what you said. Is this scenerio likely? Alternator connected to start battery reaches 14.4V quickly. BEP VSR gang up to house batteries. Temperature of start battery rises and alternator cuts out. House batteries not fully charged but start battery is. I am about to cut my AWG 2/0 cables for the alternator and wonder should if I should wire it to the house instead of the start as concluded previously. Question is when the start battery is fully charged and still receiving 14.4V from the alternator, what happens?

Hi Rob,

No, it’s not a likely scenario. First, the battery does heat up much with the size of alternators on most boats. Second, the regulator does not stop charging when it senses a warmer battery, it just cuts back the acceptance voltage a tad.

Once a battery is fully charged, very few amps are flowing through it (less than .5) so how many watts are being dissipated by the battery? Answer, not many. Low watts = low heat. Therefore a fully charged battery is not going to heat up.

All of these issues can be answered using the theory in the last two chapters.

charge both banks at bulk charge.

Thanks John! Just what I needed, someone who has tried and tested the system! pardon my apprehension as I have been warned by many not to over charge AGM (first time using AGM) as I will shorten its live dramatically as they will gas lose electrolyte and/or damage them at the same time. I will wire them up as recommended.

Hi Rob,

Glad to help. Useful for me too in that we further simplified an already elegant and simple system by moving the gang solenoid sense wire to the engine battery. I love it when we can simplify.

My “gang solenoid” is a Victron Energy Cyrix-i 400A (https://www.victronenergy.com/upload/documents/Datasheet-Cyrix-i-400A-EN.pdf) and I use two because I have three banks built from identical Victron 12V 100Ah AGMs – 1 engine start, 1 bow (bow thruster and windlass) and 6 house. The first solenoid is between engine and house and the second between house and bow battery.

This solenoid is “smart” in that there is a delay between the time the kick-in voltage is reached and the connect by the solenoid and that time delay depends on if the voltage barely reaches the limit or jumps much higher quickly. I believe this is intended to avoid requent on/off cycling and I don’t think this feature is limited to this particular model or maker. There is also a drop-off delay and there is no sensing wire. The relay uses the voltage on both battery terminals for sensing and will close if the voltage on either terminal goes above the limit and drop off if the voltage of both goes below.

However, I have made a mistake in my setup that I suggest others with a similar setup should avoid. The high output alternator is connected to the engine start because that’s the way it was before I changed the alternator and the batteries and generally rewired everything. I could have changed the connection from the alternator with no additional effort but didn’t because I just thought it natural this way. The AC charger/inverter and the small DC generator go to the house. We don’t yet have solar but I would tend to connect it to house, too.

When I start the engine after a night of anchoring a few minutes before we are ready to haul in the chain, then the voltage of the engine start battery rises immediately to the alternator acceptance voltage of about 14.1 or 14.2V (should be higher, see below). The solenoid between engine start and house does not kick in immediately, though, because of the delay. After about 2 or three minutes it does kick in and I can hear the engine change tone from the additional load of the alternator that is now supplying ~90A to the house battery (at engine idle). Over the next approx 10 minutes, the house voltage rises to 13.something volts which, after another delay, causes the 2nd solenoid to the bow battery to kick in.

However, if we are quick, we are already sailing at this time and the engine is stopped.

The alternator therefore did not help pulling up the chain and AHs drained from the bow battery by the windlass are not replaced. Not a big problem but not ideal.

I can think of two solutions:

(a) Connect the alternator to house. This may not be ideal because engine start should have priority (or does it?).

(b) Find a way to make both solenoids open an close simultaneously. This is what I will try first.

Because of the problems with AH-counting battery monitors explained around here, and in detail by Rod Collins here http://www.pbase.com/mainecruising/programming_a_battery_monitor, I was interested in the Smart Gauge and picked one up but didn’t install yet. I found that it includes a function to drive a “gang solenoid” where the intelligence is supplied by the Smart Gauge and the solenoid is nothing but a solenoid. You can therefore connect two solenoids in parallel and so achieve what I want. This is allowed and recommended in the manual.

An additional benefit is that the buttons on the Smart Gauge allow an emergency parallel of the batteries with no extra wiring. I don’t know when I will get around to install and will try to remember to report the results.

I, too, have not had problems with the AGM engine start battery suffering from overcharging by being held at acceptance voltage for longer than is appropriate for that battery – even though we have motored for days on end, e.g. in the Azores high, and in spite of my alternator regulator being fixed at 14.1V and never dropping to float (however, 14.1V is somewhere between ideal acceptance and ideal float).

I got the alternator with a high-class install by my otherwise competent local engine shop, involving a separate pulley to tighten the existing V-belt for the water pump when the alternator was changed to a serpetine belt.

I should have made sure the alternator has external regulation or can be wired for it. So again I didn’t do as John says and again I will have to pay for it (by swapping out the alternator, probably with a Balmar, and hopefully not have to change the serpentine belt crank pulley again). And again my excuse is that I hadn’t known about this site when I made the decision.

So if you happen to know this site and not have made all those decisions, then you really should stop all thought about “finding your own solution” and just do as it says here. And no “minor variations” or “almost as good”, either. If you stop one bit short of the solution recommended here then chances are you will either have to do it all over again or kick yourself for years and years, living with the result.

Hi Henning,

Great report full of really useful information. I will be very interested in hearing how the SmartGuage works out for you, although I have to say that I think that all of this worry about inaccuracies in amp counters is overblown. After all, so what if one is say 10% out, it really does not matter that much. And most amp counters reset every time the batteries are fully charged…come to think of it, that’s probably why so many people have trouble with them: there systems are set up so they very rarely achieve full charge.

As to connecting the alternator to the house bank, that might be the simplest answer for you. We have been set up that way for years and it has worked well.

Hi John, there is one thing that I never fully understand. Alternator/AC charger has a sense wire that sense the voltage of the batteries they are charging. If the alternator/AC charger are charging at 14.4V at the battery terminals, isnt the sense wire going to sense 14.4V as well?

Hi Rob,

The reason for the sense wire is that the charging cables are carrying a lot of amps so even if they are large and well terminated there will be a voltage drop across them (ohms law). For example there might be a 0.4 volt drop from the alternator or charger output to the batteries.

So if you want the batteries to be charged at say 14.4 volts the voltage regulator is going to need to tell the alternator to put out 14.8 to compensate for the drop. But to do that, the regulator must know exactly what the voltage is at the battery, which is what the sense wire does.

Of course the sense wire does not experience much voltage drop, even though it is a small gauge, because it’s not carrying very much current (amps). Once again ohms law rules.

There is a potential danger with sense wires, that I will cover in the next chapter in a few days.