Yea, I know, you don’t have time for a lot of theory BS. I get that, we are all busy. But I can absolutely guarantee that you will have better results and happier cruising if you break a half hour or so free for this, and the next two chapters.

Can’t I just pay someone else to get my cruising boat electrical system up to cruising standard, you ask? I wish, but, sadly, it never ceases to amaze me how ignorant many, perhaps most, technicians around boatyards are about how electricity works. Yes, even those who have worked on boat electrical systems for years.

And the ignorance of said technicians pales into insignificance when compared to the pure unadulterated rubbish spouted by many people who sell marine electrical equipment.

And don’t even get me started on the level of BS that flies on the forums when things like batteries and charging are discussed—you could drown in the stuff.

The point being that we can waste a boatload of money and still end up with an inefficient, unreliable electrical system if we don’t have this basic knowledge.

The good news is that if we understand just a little bit of electrical theory we will immediately be able to detect the rich aroma of marine electrical BS before any harm is done. And the even better news is that this stuff is not that hard to grasp.

Let’s do it.

“More than a little shocked” is covered in a future chapter: “Careful Where You Put Down Your Spanner”.

This is all timely as I’m getting six L-16s next week that will comprise our house bank. Your labelled lugs look excellent.

Looking forward to the rest of the chapters as I am not that comfortable with electricity and the concepts around it.

Marc – A really good way to label is to use a standard Dynatape label, the printed ones, not the stamped letters, slip under some clear adhesive shrink wrap, then shrink the shrink wrap. A water tight joint and solid label.

Thanks, yes…I am trying to source clear heat shrink…maybe I can find it in the States online as locally it’s proving a bit of a unicorn.

Genuinedealz.com, waytexwire.com, and McMaster.com all have clear heat shrink and other products.

Just a small correction: If I remember my highschool physics right the symbol for votage is U. V is the symbol for the unit (Volts) that voltage is measured in. So Ohms law is I=U/R while the basic units are Volts (V) Ampaere (A) and Ohms(Omega). Another Law that one should really know is P=U * I. P being wattage. The unit is Watt(W). So Ampaere is a measurement of Power only if the Voltage is known. Likewise Ah (Amphours) is a measurement of energy only if the Voltage is known. For example if an appliance uses 10A on a 12V system this is 120W while it is 240W on a 24V system. Not only tecnicians but also Journalists also get this wrong all the time.

That’s correct!

Hi Enno,

You are, of course right, but these days V has become common usage, even at Wikapedia: https://en.wikipedia.org/wiki/Ohm%27s_law

And I will be talking about watts in the next post as well as defining potential difference.

OK. I see this seems to be language dependent. The german and french wikipedia uses U while the englisch uses V. (The norwegian wikipedia got it mixed up 😉 I wronly assumed that this would be the same across languages.

When I was in school voltage was E. E=IR.

Any lithium tidbits would also be appreciated.

Jim

Hi Jim, We have a full chapter on Lithium: https://www.morganscloud.com/2014/01/26/lithium-ion-batteries/

Hi John,

A very nice start and I look forward to the next installment.

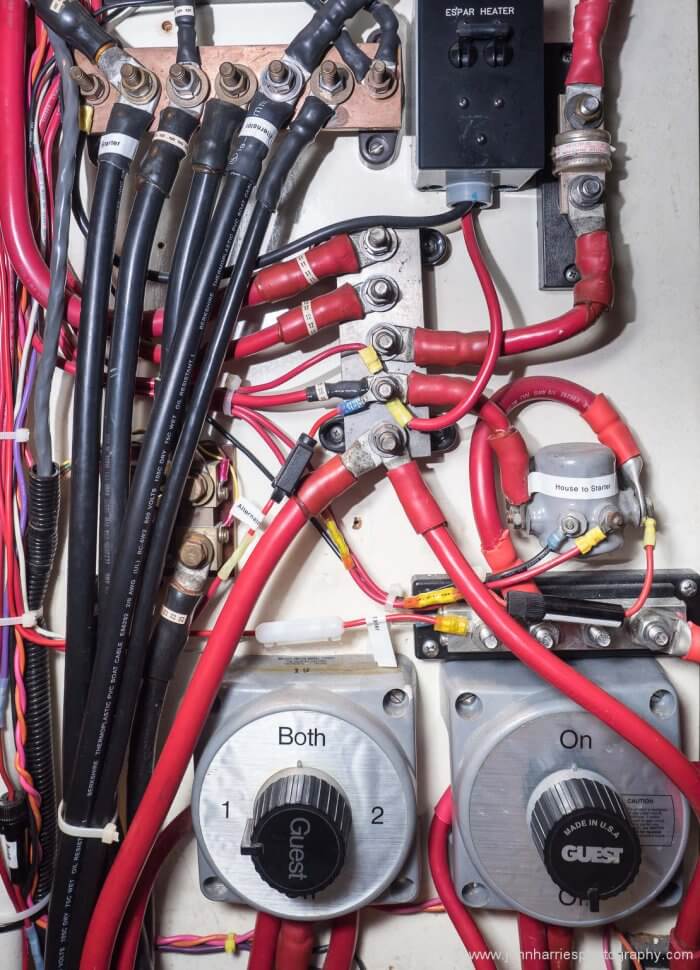

I love pictures of wiring and yours is most elegant and a distribution area to aspire to. A couple of comments: I believe that most rules/regs (ABYC for ex.) limit the number terminals to a post to 4, with the one carrying the most amps on the bottom. Your post carrying 5 terminals could have one or more distributed to the other posts easily. It is hard to tell from the picture, but the large amperage wire looks to be on top of a smaller terminal: again easily remedied.

In the lower left of your photo is a particularly nasty bit of cut off wire tie waiting to scratch an arm as it passes through. A wonderful addition to one’s tool chest is a small flush cut diagonal cutter made by Xcelite which will leave the ends of wire ties smooth as the proverbial baby’s bottom.

Finally, and only because I am on a roll here, I would suggest securing the grey colored cable carrying multiple wires so that it does not rest/chafe on the threads of the adjacent post it passes next to.

My best, Dick Stevenson, s/v Alchemy

Hi Dick,

Thanks…but then again: https://www.morganscloud.com/2014/10/17/perfect-or-good-enough/

Hi John and all,

With respect to your “good enough” response to my comments about electrical practices, number of terminals on a post etc. I should have made my thoughts clearer. It is my take, that rules and regs (guidelines) vary widely in their practicality (and even in their wisdom) so “good enough” for sure has its place in many/most projects.

I pay most attention to rules & regs when I am at my most ignorant, when I do not have the experience to judge good enough. Generally, I like to follow the accrued wisdom, the guidelines if you will, until they start to make little or no sense when compared with experience. Most of us are, and will remain, amateurs in the electrical work we do on board. And many of us do a lot of electrical work for a variety of reasons. It is good to know what is recommended practice.

I believe the event that scares my most on a boat is fire and way too many fires start electrically. The down side of electrical problems can be a catastrophe, so “good enough” has to be very good. The ABYC guidelines for electricity on board are the accumulated knowledge of experienced marine electrical people, and, in my read of them: they make a lot of sense. One of their primary purposes is to promote practices that make it unlikely for heat to build up: for fires to start.

Many distribution posts are tall enough to fit far more than 4 terminals and there can be a strong temptation pile them on when it can save work and time. Similarly, it can be easy to put a high amperage terminal on top of a lower amp carrying terminal. The results can be more heat. Knowing the guidelines can allow you to make wise “good enough” calls

As said in my first email, your distribution area is to be admired and emulated. It is certainly better executed and safer from fire than the vast majority of boats out there and even brand new just-out-of-the-factory boats could benefit from an electrical survey.

My best, Dick Stevenson, s/v Alchemy

Hi Dick (and Steve),

By linking to the article I certainly was not saying that you were wrong. (That’s why I said thanks.) And, in fact, I have made a note to make the changes you suggest.

The reason I linked to the article was because I wanted to make clear that perfection is simply not attainable, at least if we ever want to leave the dock. Or to put in another way, I would venture to guess that someone would be able to find a problem that needed fixing on any photograph of any part of Morgan’s Cloud (or Alchemy) that I posted here.

Some of those problems would warrant fixing, but any boat owner that set out to fix all of them would be doomed to the marina for life. I wanted to make sure that our many readers that are trying to get ready to go voyaging understood that.

To paraphrase Churchill: the danger of forums and crowd sourcing is that they both contain the sum of all the participant’s fears.

As I say in the linked post, the secret to getting out there is prioritizing, not aspiring to perfection.

Hi Dick,

I am severely electrically challenged, but know just enough to agree completely with your thoughts on electrical fires on boats. Hence we have always engaged competent electrical guys to work on our boat, homes and businesses. I do not trust myself with any high load DIY electrics, even 12V DC, but that’s me!

2 years ago we had the standard bi-annual electrical survey done in our workplace, and we’re offered ( at no extra charge) an extra survey using a heat sensing camera. The camera picked up a faulty connection in one of our server racks that was over 70 degrees centigrade, in normal mode. The inspector suggested that this was a possible/likely pre-cursor to further deterioration and a fire hazard, so we quickly replaced the offending junction.

I wonder if such an addition to boat electrical surveys should be part of the guidelines for boats, given the horrendous record of marine electrical fires on boats and the highly corrosive atmosphere our electrical systems endure?

Rob

Rob:

Indeed more and more folks in the marine electrical world are relying on IR cameras to identify hot spots. These have dropped dramatically in price since they were first introduced, and are now within reason for any yard or independent marine electrician. While there are stand alone products from Fluke and others, in the interest of keeping my traveling kit bag as light and compact as possible (my checked travel bag typically weighs in between 50-65 pounds as it is) I use a tiny product called SeeK; a camera that plugs into the USB port of my smart phone, it cost about $200. I routinely use it to inspect the backs of electrical panels and battery banks. It’s well worth the price.

Hi Rob,

I very much agree with your comments and feel that your use of competent marine electricians is likely wise. You also mention electrical surveys. Both, however, depend on finding people who can do the work well and that, to me, is a problem. There is only one person I know who I would trust to do a competent survey on the electrical system of Alchemy and it is Steve D’Antonio who has added the recent contributions here to AAC.

I have had one superb marine electrician in my time and I played surgical assistant (handing tools, making coffee) to him for some major jobs on Alchemy and learned a great deal in the process. Since then I have done the majority of DC work on my boat and, casual observation of the work of electricians on friend’s boats have not made me change my mind. Let me also say that that is not solely the competence of the electricians. Good electrical work takes time, both to design and think through, and then to execute properly. One must also have an impressive array of parts etc. Many boat owners go for those who do jobs for the least amount of money and do not want, expect or know what a good electrical installation entails.

With respect to pyrometers, IR temp sensors, I have used one for years that I got for diagnosing some refrigeration issues. Since then it has proved quite handy for a variety of diagnostic chores on Alchemy: base line temps on various parts of the diesels, heat leaks in insulation, testing thermostat opening temps and checking out terminal connections. When/if you buy one, make sure it has the range to do reefer work as well as the heat level diesels can generate.

John has talked wisely in the past about taking regular deck walks on offshore passages. I would suggest regular visitations to the darker hidden regions where our electrical connections often reside for a thorough inspection including a fingers-on-push to those connections to see/feel whether they have loosened and visually whether everything looks to be in order. The best thing any owner can do for his/her electrical system is to do a complete schematic. Doing so will immensely speed trouble shooting when its necessity rears its head, but also stimulate thoughts about designs that might not make sense or practices that should be changed.

My best, Dick Stevenson, s/v Alchemy

Hi Dick,

I would agree that one is often better off with a well informed and diligent amateur 12 volt electrician than many of the professionals.

I’m also a strong believer in regular inspections of the “hidden regions” as well as an hourly careful check of the engine spaces whenever under power.

As to schematics, that’s a very good idea, but can be fantastically time consuming to do well. A simpler and quicker option that is very nearly as good is to number every wire attached to a terminal and then build an spreadsheet list of where each wire goes. You can buy pads of stick on numbers at any electrical supply shop.

As a sort of adjunct to the best practice Dick mentions of checking the securing of various studs and terminals, when commissioning in spring I go stern to bow giving every hose clamp a quarter-turn (the average) and every terminal screw or securing nut a check. I also look for loosened or worn cable ties, as one of the worse things to happen is a loom of wires coming loose near a moving or hot engine part.

This can take an hour or two, but it gets one to rarely seen parts of the vessel, hopefully to preventative effect.

Thanks Guys for your comments,

Steve – what a great gadget for the smartphone – how accurate is the heat calibration in your experience? Have you used it also on your own boat, say approaching an anchorage on dark cloudy nights? How does it perform? Have you used it for low temperature applications also as Dick marvellously suggests?

With regard to our own install, we have a full schematic of the electrical systems, and I have traced every circuit. But I rely (and trust) fully our excellent provider here in NZ (Enertec Marine) to do any major work or upgrades.

best regards,

Rob

Ps. Specifics on the above mentioned tool: Xcelite 170M General Purpose Shearcutter, Diagonal, Flush Jaw, 5″ Length, 3/4″ Jaw length, Red Grip

Dick

Hi John,

I like the idea of numbering at the terminal. This immediately identifies the wire in a way that schematics may not do.

And I agree that good schematics are quite labor intensive, but they do make for a good winter project and a superb way to become better acquainted with your electrical system if the boat is new to you and a way of thinking about (and troubleshooting) the whole system. Schematics also lend themselves to an initial piecemeal approach: high amp carrying wires, wiring for lighting etc.

My best, Dick Stevenson, s/v Alchemy

“Why do we use “I” for amps?”

Intensity (of current or electron flow)….from the French “intensité du courant”. This is what André-Marie Ampère used in his papers and it became standard in the 19th century.

Just a fun fact…back to boats.

Robert

Hi Robert,

That’s fun to know…I didn’t.

John, a very nicely explained intro to electricity, and I second your comments regarding the lack of understanding and ineptitude by many industry sales folks and even pro’s. It’s disheartening.

Further to Dick’s comments regarding ABYC guidelines, and with respect John, often when I complete an inspection the longest section of my report involves electrical system defects and faults and violations of ABYC standards. And almost as often, boat builders or sellers retort with, “you are nitpicking” and “what are the odds of that happening?”. Having been in this business for 28 years, and having turned wrenches and stripped a lot of wire, and as an ABYC Master Technician, I can say with assurance boats owned by nitpickers are more reliable, and if it can happen, preferably underway, at night in poor weather, it will.

The ‘four ring terminal rule’, with the largest terminals going on first, is as valid a point as they get, I’ve seen the fall out where it’s violated, read on. It has nothing to do with perfection, it’s as relevant as Ohm’s law where electricity is concerned, in fact it has everything to do with the R part of Ohm’s law.

Just a few months ago a client complained of that all too familiar acrid burning electrical smell around his engine. I asked a few questions and determined that it only occurred shortly after starting the engine. I looked over the starter cable connections and sure enough the starter positive cable was touching the block (another ABYC violation), as many do, on its way tot he starter. I figured for sure that was the source, but alas it was not, the insulation was intact. Interestingly, however, the real culprit was the dramatically undersized block bonding wire, you know that little skinny green wire you see connected to so many engine blocks. Most of the insulation had melted off of it, and each time the engine was cranked it glowed red and emitted a puff of smoke. Rest assured, every ground, DC negative and bonding wire connected to the engine block must be capable of carrying full fault, i.e. in the event of a short circuit, current (another ABYC requirement). In this case, the DC negative connection ring terminal to the block was loose, and it was comprised of 6 ring terminals (the seminal ABYC violation), a bonding junction point of sorts, and it was made over a painted surface, so it’s resistance was high to say the least, which transferred the bulk of the cranking load to the lilliputian bonding wire, overwhelming it with amps. Yes, this means the bonding wire needs to be the same size as the DC positive cable.

I’m no knee-jerk follower of ABYC guidelines and perfection is often unnecessary where systems are concerned, however, where electricity is concerned, ABYC compliance has a direct affect on reliability and safety, of that I have no doubt.

Sorry for the rant John, it’s your site and you have the last word.

Hi Steve,

I agree, and, as I said to Dick, I intend to fix the things he noticed, that’s why I said “thanks”. But on the other hand nothing he pointed out has much in common (ouch, bad pun) with the example you sight. One is a major violation with dangerous risks, the other a small oversight in an easily and regularly inspected place. (You will note that none of the cables or terminations in the photograph show any signs of heating and all of that wiring is over 20 years old with tens of thousands of miles of safe reliable operation to its credit.)

In addition, see my reply to Dick.

Some ‘rants’ are more illustrative than others. Thanks.

Hi Steve.

A very useful comment. I am completely rewiring my boat (almost finished), following ABYC guidelines. Your post made me go back and check all Connector Blocks, buses etc, and I found two cases of large cables on top of small. Thanks!

Regards

Bill

OK, I am new to boating. I have three switches near where my 2 batteries are stored. One is a negative, and two are positive. The negative and at least one of the positives have to be in the “on” position for the batteries to work.

1. If I leave one of the positive switches in the “off” position I am assuming that I am only drawing from one battery and the other is in reserve. Is this correct?

2. Do they both get charged if only one is in the “on” position?

3. What is the negative switch for?

Hi Greg,

Hum, I can’t give you definitive answers without getting on the boat and tracing the wiring, but here are some guesses.

On an overall basis, it sounds to me like an amateur with little understanding wired your boat, so I would suggest you find a competent electrician to take a look and make sure that all is good. Sorry, I know that’s a daunting and probably expensive suggestion, but I still think it’s a good idea.

Switching the negative side (as well as positive) is often used as an attempt to mitigate corrosion, it’s common on European (especially French) vessels. Never turn off just the negative sw.

Simple ON OFF switches for house and start also aren’t uncommon, however, there’s usually another ON OFF between them for paralleling. There are some advantages(provided the switches are wired accordingly, with parallel cables connected to the load side of the start battery ON OFF sw) to this arrangement in that a defective, i.e. shorted start battery could be completely isolated from the system, while still paralleling the house for starting purposes. I actually prefer this approach. Without the third parallel, however, sw it seems you don’t have that capability.

Hi Steve,

Good point about the possible reason for the negative side switch. Having said that, my thinking would be that if the boat is wired in such a way that stray current corrosion is a problem, that should be fixed. Adding a switch in the neg side is, at least to me, a kluge that masks the real problem since the stray currents will be around whenever the boat is in operation.

To clarify, when I said I preferred this approach, I was referring to the three ON OFF battery switches for house, engine and parallel, NOT the negative battery switch. As I said, it’s typically a European thing, I’ve never found merit, corrosion or otherwise, in disabling the DC negative connection.

Hi Steve,

Absolutely, I knew that you knew that a switch in the negative was not a good solution to stray current problems, just wanted to make sure that others were aware.

Hi John. Please keep on going with these great articals. Iv just bought a 800ah 24v battery bank to go into our new boat. They are lithium batteries. They should arrive next month then we can fit them. Along with lithium chargers. We hope that you are going to cover lithium batteries in future pieces.

Hi Alan,

We already have an article on Lithium batteries: https://www.morganscloud.com/2014/01/26/lithium-ion-batteries/

Hi John.

Yes Iv read this artical. Nice basic stuff for jan 2014. We are two & half years down the track from there. Iv made the decision to go lithium for most of those reasons in that artical. A couple of reasons that are not mentioned are; the power flow voltage from lithium batteries in General is a flat line of voltage Not a curve voltage that comes from lead acid. Constant stable power to instruments and appliances. Our big benefit from lithium will be comfort. Most boats go out for the weekend / week and people on board semi camp for the weekend / week.

For a live on board scenario sustainable / plenty of power is everything. Basics like shower, lights (led’s), instruments, refrigeration, water, washing, drying ect. If we are to enjoy a life on board, using our boat as a home then make it like home ? ( if you wish to keep your partner ). Now your saying this guy is a softy but how many couples do you hear of that the whole boating venture falls apart after a couple of months because the partner is OVER CAMPING!

It’s easy to produce power cheaply now. Don’t think of one 100w solar panel as power. Think of 1000w of folding panels as power. Don’t think of one 300w wind generator think of two 500w generators. Both items are in the realistic price range now not like four years ago! For the sake of $4000 you can do this. Plus the cost of a decent battery bank to store this power say another $5000 for a 600ah @ 12v. Remembering that this is the equivalent of approx a 1000ah lead acid battery bank. Weighting about one third the weight for the same usable power. Now compaired to bits and pieces on your boat that is nothing! Now how more enjoyable would that trip be with a happier partner. Also remember that these batteries should last you for a lot of years if you don’t discharge / charge at a very high rate. So I will just answer one flaw in this that some people will be thinking where do I put 1kw of solar panels on your boat. Think about it if your on an exceptionally long sea cruise you could only use maybe one third of these solar panels. But when you arrive at your destination put all your panels on deck, where ever to collect that free power. Also think that solar panels above the deck will act as an insulation barrier to keep your boat cooler in the warmer climates. Your wind generators will have looked after you in passage anyhow.

Life doesn’t have to be that hard, so enjoy it. For a very small cost of your boat this is attainable. What is the use of the latest techno gadgets if your uncomfortable, rationing water, dirty cloths or have that noisy generator blasting away for hours on end.

PS. My comment’s here are for those that spend a lot of time on their boat and want to enjoy their adventure.

Respectfully Alan

I just bought a new Lagoon 450S. Was hoping to try and understand all this battery and solar business. But I am even more confused. Lol! I must be really slow.. why after all the years of charging systems is it not straight forward and proven?

Hi Mike,

I hear you. I wish I had an answer to that…other than welcome to boats! I’m just working on a new battery bank and associated charging for our boat and am finding all the choices intimidating too, and I have been doing this for over 30 years, so I feel your pain.

Anyway, have a read through this online book and that will give you a good grounding (ouch, bad pun). I will be adding some more chapters in the next couple of months.

I have an electrical problem that I hope I can get some suggestions to solve.

I have a 2003 Sabre 362 and last fall developed some type of short in my electrical system so that there is always a 0.4 amp (seen on my battery monitor) draw even with the batteries in the off position (dual rotating switch on/off switch). I have disconnected the bilge pump, radio, alternator, shore power charger and battery monitor one at a time, after I have fully charged the batteries, to see if one of them is causing the amp draw because they by-pass the on/off switch. After disconnecting, I let the system sit for a few days and then check the voltage to see if there is a drop. The batteries (AGM, 4 years old) are all good and hold a charge. I am looking for advice on what else to test and if there is any testing equipment and/or procedures that I should try.

Hi Stan,

First off, you may not have a problem, or at least not the obvious one. Sometime these battery monitor systems drift over time and lose their zero set point so that they read a draw, even when there is no draw. (I know this because my old Link 2000R exhibited this behaviour.)

To test for this:

If you read zero, it’s the battery monitor, or possibly a poor connection in the wires from the shunt to the battery monitor.

If you get the same .4 amps, or close, you know you have a real issue.

In this case, the next thing to do is to draw an as-built circuit diagram showing how everything is connected together. Once you have that done, so you can clearly understand the way everything is put together, start disconnecting loads until you find the bad one.

One other thought. Don’t forget that the battery monitor itself uses some current (amps) so if the supply lead is connected to the load side of the shunt it can, at least with some units, read it’s own draw.

And finally, you may wish to give the chapter above a read, since an understanding of Ohms law will really help with this kind of trouble shooting.

Thank you for the response John.

* The batteries are good – I have fully charged them and disconnected the positive terminal wire and left them for 6 weeks this winter with no loss in charge.

* My testing has included monitoring the battery charge voltage directly at the battery in order to see the loss of charge due to the short some place.

* I have included disconnecting the battery monitor from the system in order to see if that is causing the 0.4 amp draw. When I went and tested the charge after 2 days the batteries had dropped from 12.3 volts to 12.0 volts. So it appears to be something else.

* The starter battery has no issue so it has been isolated properly from the house batteries.

I will make my map and read the chapter as per your suggestion as the next step.

Hi Stan,

Sounds good, but I would still do the test I recommend because it’s definitive. All of the tests you have done above could be influenced by a secondary cause.

If you don’t already have a good quality multi-meter, buying one is worth it just to have on the boat anyway.

Basic Marine Electrical – Part 1 of 6

https://www.youtube.com/watch?v=fHZtYFH-0Pc

Problem solved. Traced to AM/FM/CD player which has a wire that by-passes the main battery switch whereby the radio memory is maintained.

Thanks for the input and the Basic Marine Electrical video.

John, if i have an engine alternator, solar and wind gen all turn on at the same time and if I set them all to charge at 14.4V, they will charge the batteries equally ie say 15 amps each with a total of 45amps going into the battery (assuming the batteries will accept 45 amps). Correct?

Hi Ee Kiat,

Assuming that each of those sources can actually produce 15 amps, then the answer is yes that would be correct. That said, it’s unlikely the regulators would be that perfectly balanced so in the real world there probably will be some difference. But practically that does not matter since the only time we care is when the battery will accept more than a single source can supply. In that case each source provides all the amps it can until the battery voltage reaches 14.4. That is assuming that the regulators are all properly programmed.

Hi John, Assuming the solar panel is providing a charging voltage at 14.4, how can the alternator regulator tell if this voltage of 14.4 is that reached by the battery or by the solar panel charging voltage?

Hi Ee Kiat,

It can’t, but that doesn’t matter. Read the next chapter for why.

John: Hi. I have a 1990 Pacific Seacraft 31’ (Crealock) and am doing a major refit of her this summer. The electrical system (charging, cranking, etc.) has “evolved” over the years and is now a bit of a hodgepodge. While I’m very mechanically handy and OK with electrical, I’d like to get a paid consult with someone to help design the battery bank, charging systems, monitoring, etc. using latest technology. Who would you recommend? I just checked out Marine How To and the website says that as of 7/15/20 they are totally booked on paid consults. Thank you very much. Dan Coate, Pompano Beach, Florida.

Hi Dan,

I’m sorry, I don’t know anyone other than Collins at Marine How To.

My suggestion would be to read through our online book on the subject and join ABYC for a year.

https://www.morganscloud.com/category/anchoring-mooring/online-book-anchoring/

You might also want to get a couple of books. I have heard good things about Boatowners Illustrated Electrical Handbook and the 12 Volt Bible. And finally read all the relevant articles over at Marine How To

These sources between them should give you the knowledge to then sit down and design your own system on paper.

The benefit of this approach is that you will really understand your system once it’s done. ABYC will cost you a membership, but is well worth the money if you are doing a refit since making sure everything is to code will enhance the value of your boat. I’m a member and I check stuff there all the time.

A final tip: don’t get dragged into the coolest electrical system in the marina trap. Keep it simple and don’t be tempted by very new technology. Also, if you are going to add solar and/or wind, be careful not to go too far and screw the boat up with too much clutter and windage on deck: https://www.morganscloud.com/2011/02/25/clear-the-decks-for-action/

If you have specific questions along the way I would be happy to answer them if you leave a comment on the relevant chapter in the online book.

John: That’s very helpful and I will ping you from time-to-time with questions. I think I understand most of the concepts, just would appreciate an “adult in the room” from time to time. Take care…fair winds and following seas!