There was an age, not all that long ago in the grand scheme of things, when technological progress was a slow, measured affair. Revolutionary new developments in materials science, in hull design, in manufacturing processes and in many other engineering fields were few and far between. The “state of the art” progressed at a pace that allowed everyone to catch up before the next new development hit.

That age ended a century ago, and the pace of science and technology has accelerated rapidly in the intervening years. With new technology comes new decisions: Do we keep the old ways of building things, or can we do better now? It’s a question that needs to be asked periodically; even NASA and Rocketdyne are now taking another look at the F-1 engine from the Saturn V moon rocket. Their theory is that by re-evaluating a successful but imperfect design in the light of new knowledge, we’ll be better equipped to improve on it.

The marine sector may not have NASA’s resources, but we would nonetheless be wise to periodically revisit our old ideas. Quite often, “we’ve always done it this way” is code for “we don’t want to re-evaluate in the light of new knowledge”. The halyard reel winch, a.k.a. the Wrist-Breaker, is a prime example: it persisted for years after vastly superior drum winches were available, simply because that’s how things were done the last time the decision was considered.

A more modern example is the growing use of carbon fibre composites to replace metal parts. Carbon was, for many years, an expensive luxury item—the sort of thing you’d splurge on for a one-off racing boat where every piece was custom made, and kilograms were more critical than dollars. Such a wonderful exotic material was, of course, deemed far too expensive to consider using in more plebeian applications, such as on cruising sailboats.

Carbon—Not Just For Millionaires

Times have changed, and five minutes on Google and Alibaba will quickly reveal dozens (if not hundreds) of suppliers on each industrialized continent who are ready and willing to provide raw carbon and a huge variety of prefabricated carbon parts.

Consider a 62 mm (2.5 inch) rudder shaft, 2 m (6 feet) long. In regular 316L stainless, it’ll cost about $550; in the more corrosion-resistant Nitronic 50 grade, it’s roughly $1100. Depending on the exact specs needed, $800 to $1500 and a bit of time for tool-up and delivery should get you a similar shaft in pultruded or spiral-wrapped carbon. Pestering these suppliers for more details will net you a bewildering array of carbon fibre choices, some off-the-shelf and some semi-custom.

It seems that carbon’s problem isn’t that it’s rare or excessively costly, but rather that the multitude of possible ways to use it makes the designer’s job more complex. Specifying a stainless rudder shaft involves a few quick calculations and checking some standard reference tables; specifying a carbon one requires more careful analysis of how the part will be loaded and how the fibres should be oriented to handle the loads.

A Long Term Problem

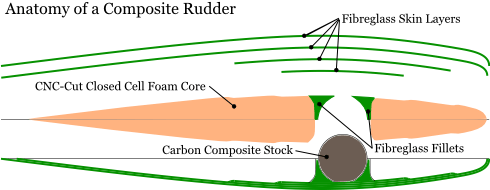

Why, though, would we want to re-evaluate something as simple and well-proven as a rudder? The standard design—a foam/fibreglass blade moulded around a stainless steel armature welded to a stainless steel post—has, after all, been tested to death for decades on thousands of boats.

We re-evaluate it now because “tested to death” is an apt description. Stainless steel does not fare well in damp, anaerobic conditions like those found inside a water-saturated rudder blade. The difficulty of bonding fibreglass to metal, and the huge difference in thermal expansion coefficients, all but guarantees that water will eventually seep through the joint where the metal stock enters the composite blade. It works for a while, but the uneasy mix of metal and fibreglass eventually gets wet, and the salt water goes to town on the hidden stainless steel. The points where the armature is welded to the shaft are particularly vulnerable, and there’s no way to inspect them without destroying the entire assembly. These rudders can and do fail, sometimes catastrophically, and usually with repair costs that cause credit-card issuers to shiver with delight.

Until a few years ago, the stainless shaft and armature—despite its well documented flaws—was still the best solution we had. Fibreglass shafts aren’t stiff enough—they’ve been tried, but they flex like crazy. Bronze works, but its price is high and volatile, and it has the same thermal expansion issues as stainless when it’s combined with a composite blade. Titanium is even more costly, and the skills needed to machine and weld it are rare. All-aluminum construction can work, but is labour intensive—not to mention its vulnerability to corrosion, which calls for constant vigilance over the life of the boat.

A Better Sailboat Rudder

Now, though, we have a new material on the scene. Carbon composites are incredibly stiff, making them ideal for deflection limited applications such as rudder shafts, and they don’t corrode. Carbon’s price tag is falling rapidly, there’s a network of commodity suppliers, and a growing base of workers who can handle it properly.

Many still think of carbon as being so costly that it’s only appropriate for high-end, one-off parts; in fact, carbon parts are costly because they tend to be high-end one-offs. Now that carbon fibre is a commodity and can be deployed in mass production, it’s time to re-think some of our old ways of doing things. Either we’ll solve some long-standing problems, or we’ll gain a better understanding of why existing solutions work the way they do.

Comments

[Do you have questions on the properties of the materials mentioned in this article? Now’s your chance to get the answer. Or do you have a first person account of a failed rudder, or of the use of carbon fiber in rudder shafts? Please leave a comment.]

If the boat is designed from the beginning to accomodate a composite rudder, then I believe you can obtain all the advantages that such a design provides while avoiding the cost of exotic materials such as carbon. It might be something you consider for your Adventure 40. For example, while they are generally maligned by “real” sailors, Hunter sailboats incorporate a host of innovative features that are intended to not just lower production cost, but also sometimes reduce or eliminate common maintenance problems. My 1995 Hunter 336 has an all composite rudder, with a fiberglass rudderstock and fiberglass over foam blade. The rudder stock is a full five inches in diamater, rather than the two and a half inches that you mention. At that size, flexibility of the shaft is not an issue, but the boat had to be designed to accomodate a rudderstock that size – it would most likely require major surgery to retrofit one to a boat built to take a much smaller stainless steel rudder shaft. But even though the boat is 18 years old now, I know I have nothing to worry about regarding hidden corrosion inside the rudder leading to unexpected failure. The only downside to the design that I’ve been able to discern is that the composite shaft might not give you any warning if you damage it. By that, I mean that if run up on a reef with a boat possessing a conventional rudder with a stainless steel post, the fact that the rudder is now sticking out at a weird angle (i.e. bent shaft) tells you that you broke something. But a composite shaft that’s been overstressed won’t bend, it will just develop a multitude of cracks that might not even be observable, but which could ultimately result in a sudden failure. I personally take comfort in the fact that when the manufacturer of my rudder attempted to determine the ultimate failure strength of the 5″ composite shaft, their test rig easily destroyed a conventional rudder with a stainless steel shaft, but the test rig tore itself apart before it was able to break the composite shaft.

Interesting anecdote about the Hunter rudder, Robert.

Regarding damage, I think the best way to handle that is to make the shaft far stronger than the middle of the blade, which is in turn far stronger than the tip and trailing edge of the blade. If you hit something, you’ll shred part of the blade, but the shaft and the rest of the blade may be left more-or-less intact. It’ll be obvious that it needs to be pulled for repair, but you can limp home on the surviving fraction of the rudder.

Now all we need is a rudder manufacturer that is able and willing to create composite rudders for existing boat designs in the way that Foss does today. Just knowing that a technology is available does not make it practical, and you cannot expect the average yacht yard to be able to build such rudders. Maybe Foss will pick up the gauntlet.

(Oops, hit return too soon).

I for one would vastly prefer a composite replacement rudder for my boat, and as Matt points out, its only a matter of time.

I am aware of at least one facility near me- CCI in Ottawa, ON- that can build custom composite foils for a wide variety of existing boats. There are several others scattered around the globe with similar capabilities.

The full benefits of composites, though, are only available when you’re looking at a large enough production run to justify the cost of good tooling. Making one rudder is a costly, labour-intensive task; making 70 identical ones is much easier and cheaper on a per-unit basis.

Matt,

I am very excited that you are now contributing here, that is great.

Reading your post got me thinking about whether it would be beneficial to decouple the bending and shear loads on the rudderpost with the torque. While this is rarely done, I have seen some traditional boats with tackles rigged to the top of the rudder to actually turn it so that the shaft sees no net torque. I have never sat down and tried to figure out the relative magnitude of these stresses. Is this something that you have done and if so can you share the relative magnitudes? It seems like rudders that are not well balanced can exert quite a torque on the shaft. Obviously the magnitudes of the stress components will depend on the design but it would be interested to get a feel for whether it matters.

Whether it is practical to do this is a totally different problem. I suspect that people might consider it a step backwards to have tackles directly attached to the rudder.

Eric

The steering torque is not negligible, but for a spade or partial-skeg rudder it usually works out to be pretty small compared to the bending loads on the shaft in normal operation.

Both of those conditions are dwarfed by the bending load you see in the “anchor dragged so it backed into a reef at three knots” condition. Anything that can survive that is way overbuilt for normal use, and I’d have a hard time calling something a “cruiser” if it were likely to lose its entire rudder in such an incident.

Torque has to be considered a bit differently in a composite design than in a metal one. With a metal shaft, you can design it for the worst-case bending load and quickly check that it’s OK in torque- which it almost always will be. With composites, you need to consider both the unidirectional (for bending) and spiral-wound (for torque) fibres in the shaft. So it’s more effort at the design stage.

Matt,

Thanks for the comment on that, it makes sense. I realized after I posted that the everyday forces probably are not the ones to worry about except for fatigue reasons and that something like a hard grounding would present much higher loads.

Your point on direction of loads in a composite design is a good one.

Eric

Hi Matt,

When the earliest examples of carbon shaft rudders were built there were a number of failures- I suspect because the engineers were using static stiffness numbers for carbon composites to determine their scantlings without taking into account the cyclical loading and point loading that the rudders were subjected to. Once they learned what the real world loads are they have become extremely reliable.

Rudder shafts are certainly one application where the extra initial materials expense is both cost effective and necessary for proper design, and as you point out carbon rudder shafts should eventually become the new standard. However that doesn’t mean that there aren’t better or simpler design choices for specific boats, like eliminating the rudder shaft entirely by using a transom hung rudder.

For some high load applications like chain plates it may not be immediately apparent that carbon is not the best material of choice.

Richard, Excellent point. I am very pleased to have a tramsom hung rudder on Raja Laut. It is so simple to inspect and maintain. Emergency control of the rudder, should that become necessary, also becomes simpler affair.

Today of course it would be designed as a lifting surface rather than a barn door sort but that could even be easily accomplished today if there was a serious desire.

Richard & Victor- thanks for bringing up transom-hung rudders. I, too, prefer these if they’re compatible with the rest of the design: they’re simpler, easier to build, easier to maintain and you don’t have to worry about hard-to-reach seals and bearings.

The potential for ventilation and the extra clutter on the transom can be problematic on some types of boats. If neither of those is a blocking factor, transom-hung is often an appealing option.

I wouldn’t say carbon doesn’t corrode “Carbon composites are incredibly stiff, making them ideal for deflection limited applications such as rudder shafts, and they don’t corrode.” At some point there may be contact with stainless, and galvanic corrosion does occur with the carbon taking a big hit.

Excellent point, the common example being the stainless steel race for the shaft bearings. That is why the carbon shaft should have an outer layer of fiberglass to electrically isolate it at that point.

PKP & Richard, you are of course correct that carbon- being right at the top of the galvanic series, above stainless and way above aluminum, iron or zinc- should not be electrically connected to metals.

Matt

Surely it is not the carbon “taking a big hit”, as PKP alleges?

An other example for carbon and the time it takes to get it’s use right are tha masts for windsurfing sails. Now most of the mast are a last 30% carbon, where in the beginning even does where rather expensive. And not too realiable, too! The first summer when carbon masts became widespread, I observerd 4 mast failures and had one failing in the familiy. While in the 10 hears before that, you almoste never even heard of a broken mast, exept in very special circumstances, normally infonlving waves and stones.

While now they became reliable too, there are some things you still have to doo differently. One example is that they just don’t like beeing bent for days at a time. or getting heated up in the sun, even if the are protected from direct sunlight.

It will bi most interessting to see how it maks it’s way into more and more uses as the standart material.

Matt,

At least one use of carbon has found its way onto our cruising boat. That is a carbon fiber whisker pole (we fly an asym so the pole was sized as a whisker pole, smaller than a spin pole would be). This change has transformed our downwind sailing (8 years now). Formerly we wrestled with a heavy aluminum pole that, until tamed with guys etc., quite scared me on a moving foredeck. Now we wield with a 14 pound cf pole that has much fewer personal dangers when deploying at sea and is far easier to handle in all respects. As a consequence, we use the pole far more frequently. When it comes to those purchases that seem like splurges at the time, the cf pole has paid great dividends. And casual observation seems to indicate the prices are now are much less.

Dick Stevenson, s/v Alchemy

Hi Dick,

A really good point. We used to feel that wrestling our aluminium spinnaker pole was the most dangerous job on the boat since it took both of us, using both hands, to move it around. Our change to carbon has been absolutely wonderful, we would never go back.

I used to own a Tillotson Pearson (TPI) built Freedom cat ketch. The composite rudderstock was very well done. I think they inflated a bladder inside it to push resin through. To my knowledge, none of the TPI built Freedoms ever suffered a rudder failure. Although my boat was a skeg rudder, many other models were spade rudders. I was impressed with how well these TPI boats fared compared to other manufacturers.

Nice.

Thank you for sharing.

One technical question about rudder shafts and/or chainplates of composite boats: Why is aluminium not, or so rarely, used instead of stainless or carbon/composite ?

I understand that most existing composite boats have stainless rudder shafts and chainplates, which migth be a problem because of limited resistance of stainless to fatigue rupture after 10 years or so. Also 10 year old stainless parts are very difficult/impossible to test accurately for metal fatigue.

Next usual choice for composite boats is carbon rudder stocks and composite (E-glass or carbon…) chainplates. This option seems quite accepted today for competition boat, but less so for cruising or blue-water-cruising boats. Looks like the main issues here are habits and some doubts about the durability/maintenability of those elements.

Most aluminium boats have stainless rudder shafts and aluminium welded chainplates (sometimes with small stainless inserts…). Looks like aluminium is quite OK in that case for chainplates (no significant concern for metal fatigue even after 20 years or so….), and I understand that aluminium migth be a good choice for rudder stock as well, because of its better fatigue resistance than stainless or perhaps because of its better testability for fatigue wear after 10 years.

Looks like the true reasons why aluminium sems not used at all today for chainplates and/or rudder stocks of composite cruising boat are that composite/carbon is a better option for racing boats, and that stainless is quite good or excellent fot today throw-away-type limited lifetime cruising boats….

Hi Laurent,

Just to clarify, I don’t think I have ever seen an aluminium boat with a stainless steal rudder shaft and I really can’t see how that would work.

The big benefit of aluminium shafts on aluminium boats is that the whole rudder assembly is made of the same material and is watertight with no tendency to corrosion.

While you are right that aluminium has benefits over stainless steel, there would be little benefit to using an aluminium rudder shaft for a fiberglass rudder on a fiberglass boat since you would still have the problem of water getting into the rudder at the impossible to seal joint between the the aluminium shaft and fiberglass blade. The same problem applies to chain plates.

Only fiberglass or carbon for chain plates and rudder shafts allow us to solve this problem properly in a way that will last, by building complete assemblies out of materials that have about the same coefficients of expansion and that can be reliably joined together.

You could, of course, build an entire rudder including the shaft, out of aluminium for a fiberglass boat, but then you would need to take all the precautions against galvanic action, like an isolation transforms and a floating ground system, that an aluminium boat has.

By the way, this is one of the reasons that sail drives are, in most cases, a really bad idea: They might be fine on a boat that was wired and maintained to have immersed aluminium, with the above precautions, and an owner that understood the regular checks required, but none of that happens on the average fiberglass saildrive equipped boat. The result is that two weeks plugged in at a marina with a ground problem and we have swiss-cheese-saildrive.

I know some OVNIs and also french composite boats (“Bénéteau” or like…). The OVNIs I know have skeg rudders, so shaft is of limited size and all aluminium. I never had the opportunity to dissect sophisticated aluminium boats, the Derector style or so, and I thought that, when they had spade-rudders, corresponding shafts where generally stainless. I guess electrolysis could be prevented in that case with a composite rudder sail and a good electrical insulation between rudder bearings and boat.

For modern cruising-boats, I guess that today with reasonably priced CNC routers, it should not be very difficult to manufacture metal-and-composite spade-rudders that could disassembled for maintenance without to much problems. Metal skeleton could be welded with 3 or more horizontal parts extending front and rear of the shaft, and then CNC-grinded to fit precisely into sail. Composite sail could be molded around a shape like a sword scabbard with a bolt-on plug. This way skeleton could be removed from sail at any time for inspection and repair. I guess this solution does not adress the issue of poor testability of stainless fatigue and so, it might not be that much interresting for stainless shafts. Using aluminium rudder-skeletons, I guess it might be a good option for today’s cruising boats, composite or aluminium, allowing skeletons to be completely tested at regular intervals, and perhaps even to be protected by some appropriate paint system. I understand that carbon rudder-shafts have performance advantages over this solution, but they seem more expensive (depending on the number made…) and also more difficult to test and maintain.

Concerning electrolysis on a composite boat, I guess this kind of skeleton won’t have much problems if it is isolated from the other metallic parts of the boat. If the boat is glass-polyester or glass-epoxy, this should only requires isolating the rudder commands (steering-wheel cables, autopilot jack…)

For chainplates, I agree that on composite boats, composite chainplates have advantages vs. metallic ones for the leak/seals-maintenance issue. I guess that metallic chainplates still have some arguments for them, for instance a better resistance to tear (at least to cosmetic tear, if not necessary mechanical tear…) and I guess that trying to convince prospects to buy today a boat made “the way thy made them in the 60′ ou 80′” is hard enough, so that having to sell them also the fact that this boat’s chainplates are plastic and not metal, looks like a marketing nonsense. I don’t mean that this nonsense might not be technically justified, I just say that I would go to “some” length to find an acceptable metallic solution, and aluminium chainplates on a composite boat might be a good answer to the stainless chainplate fatigue, and fatigue testability, problems that have been mentioned.

Hi Laurent,

I guess I’m not sure why one would want to go to all the trouble of designing and building a rudder that could be disassembled for inspection when proven technology exists to build a rudder that will last the life of the boat with a carbon shaft and S glass skins bonded with epoxy. The composite rudder will, I’m pretty sure, be cheaper to build too.

As to a “marketing nonsense”, I can’t agree. Carbon has proved in many industries to have a lot of attraction to the market. But even if you are right and me wrong on that point, such issues will not enter into the Adventure 40 design process. My whole concept for the boat is that she will be designed and built to go to sea based on the experience of people who have done just that combined with sound engineering and design. If the market can’t get its head abound that concept, well, so be it.

I’m also confused by your separation of gear for cruising boats and gear for racing boats and implied assumption that gear that was developed for racing boats is intrinsically unsuitable for cruising boats. By that test cruising boats should not be fitted with modern multi-speed winches, or self-tailers on those winches, to name just two of the hundreds of items that are now used with great success on cruising boats but that were developed on racing boats.

Personally, I have developped some interest about the use of advanced CNC manufacturing equipment in industries that don’t use them very much today, on the assumption that the costs of those equipments is decreasing and will continue to decrease over the next 20 years or so.

Today, for reasonably-priced end products, like affordable sailing yachts, those equiments are still expensive and the general idea is that using them significantly today in a busines-projects demands some savings in manufactured products in order to be able to pay for those costs. The most obvious field for those savings is probably the materials used: iron instead of lead, aluminium instead of carbon etc…. Customers should accept that because of better, or much better, design and fabrication qualities.

In that logic, the overall costs for a fully disassemblable aluminium and composite rudder should be quite reasonable. Most probably significantly lower than for a carbon-shaft and glass-epoxy rudder if manufactured in significant series using CNC equipments. I agree that it is not true if we speak of more limited hand-made series.

As I see it, the technical issues concerning the A40 or similar boats are relatively clears and matures and don’t seem to ask serious technical feasability questions. The big issue concerning this kind of boat today is the size of their market, and the possibility to sell enough of them to be able to build them at reasonable “industrial type” costs. Looks to be more of a business question than a purely technical one.

So, I think that usual maketing/salesmanship textbooks should not be completely disregarded in this kind of projects, even if the most common pitfall for past failed boatbuilders has been to pay too much attention to marketing and not enough to boat, and boat-building, techniques.

Point is that one very present advice in todays marketing textbook is “keep the sale’s message simple” (kind of a marketing version of engineers KISS-type advices…). So, if you are selling modernity, you should not try to make subtle distinction between what you consider modern and what you don’t consider so contrarily to “common accepted wisdom”. This way most customers will typically buy boats with iPads plus carbon-fiber plus stereo-systems plus dance-floors etc….

If your basic discourse is to sell iPad-incompatibles ways of sailing, then you are building a marketing position of refusal of current mainstream discourse, which is quite OK, but, according to marketing textbooks, it is supposed to be very counter-productive in that case to enter immediately into subleties about what you consider “bad modernity” and what you consider “good modernity”. Much easier to say that mainstream builders are evil and that you refuse each and every of their main selling points (iPads, carbon-fiber, stereo-systems, dance-floors etc..). Of course we are speaking of marketing, not of technique, so the question is whether you can/must speak of carbon-fiber in your main sale discourse, not whether you can/must use carbon fiber in boats. But point is that composite chainplates look like a real headache in that kind of logics. I don’t mean it’s a definite argument to refuse them but I think that this argument is strong enough to consider very seriously technicaly acceptable other solutions which might be easier to sell in those circumstances.

Concerning racing-boats vs. cruising boats, I think that if you compare yacht industry with car industry, in both cases competition products have been developped using better design techniques, better manufacturing techniques (CNC…) and better materials. Point is that for the last 30 years or so, it seems that R&D investments for production boat development have been excessively low or nonexistents. When you look at Bénéteau latest products the Océanis 55, it looks like all the architecture & design has been subcontracted to Berret Racoupeau Yacht Design, a team of 9 architects/engineers in la Rochelle France, interior design has been subcontracted to Nauta Design in Milano Italy and prototype develoment and production tooling have been subcontracted to Seaway in Begunje Slovenia. So, it looks like Bénéteau has run a business projects, but not really a technical project. I wonder who is in really charge of what, and who is in charge of R&D concerning modern boat design and boat manufacturing techniques applied to cruising boat. I guess the answer is nobody because there was no budget for that. So “progress” is supposed to flow naturally from subcontractors because Berret Racoupeau, Nauta or Seaway will give that for free to Bénéteau as an addition to the work they have been paid for. I guess that Bénéteau got what he paid for, and R&D stuff he might get this way will limited and probably not very relevant.

Looking at expensive new materials, like cabon fiber, to adopt them Bénéteau only needs to ask if there is a supplier for corresponding masts, rudder-shafts etc. at what price, and if price is reasonable, ask Berret Racoupeau, Nauta or Seaway to make basic enginneering caculus to integrate corresponding equipments. This way they can adapt more advanced materials very easily but I sincerely doubt they do manage a serious technical approach to correctly integrate the advantages their customers might get from racing-boat progresses. I guess that it is possible to get a better value for customers by applying a more reasonable technical approach and investing more in R&D applied to real customer needs, and less in simple-to-plug often-quite-expensive materials. Compared with car industry, it look likes Ferrari or Porsche were doing their jobs, and Ford or General Motors were still building cars like they did in the 20′ or 50′, but with a few very advanced components they bought directly from Ferrari or Porsche suppliers.

Laurent, as it seems I can’t answer your post, I’ll do it this way.

I wanted to ask if I understand you correctly that you’re saying that, from the marketing point of view, the A40 should be sold as a simple, sturdy, survive most things yacht that is build to sail around the world.

That it is made as it is to be a comfortable boat to go around the world, and that this is what it is build for.

And only after that, if a costumer asks, you should explain to him what type of material is used for what and why a gatched is missing only if he asks for it.

Is that more or less what you were saying?

Please correct me if I’m wrong.

I think the A40 is John’s stuff and he has given clear definitions of its purposes and clear descriptions of some technical points concerning this projet.

Reading all this and contributing a few comments, I understand that:

– mission seems very clear

– technical feasability seems OK with a few technical options to decide

– commercial/industrial feasability of the project is far from aquired and seems to be the big problem today because the whole idea is to build enough of those boat to reach low production costs in order to sell them at an affordable price, and there is a big doubt about the capability of the market to accept the minimum required number of boats to succeed commercially and industrially.

So, I think that salesmanship and marketing look strategic in that project, and that it seems much better, according to marketing textbooks, to broadcast simple marketing messages, a bit rude toward established mainstream boat-builders, than to enter too early into marketing subleties about “good progress” vs. “bad-progress”. Practically it might means positionning this boat as a clear reaction against all the well-known progress-type sales arguments of the established mainstream boat-builders.

I don’t think it must have a very big impact on the technical definition of the boat (perhaps on its color scheme ?….), but I guess that it should prevent its salesman from speaking too clearly, and too early, about carbon fiber, it might also not encourage the use of carbon fibers if other more classic options seem OK and it might also not encourage the use of composite chainplates if other more classic options seem OK…

“I’m also confused by your separation of gear for cruising boats and gear for racing boats and implied assumption that gear that was developed for racing boats is intrinsically unsuitable for cruising boats.”

Retired surveyor here. I learned surveying at the Chapman School of Seamanship, and one of the first things I learned was about the factor of safety for the INTENDED USE of boats. Racing boats and their gear generally have a factor of safety just over 1, cruising boats 5 to 7. Circumnavigators (and paranoid cruisers such as yours truly 🙂 prefer a factor of safety closer to 10. Are there exceptions? Of course, consider the Vendee Globe boats … But we are not cruising on those boats, and neither are they.

Other exceptions? Sure, Mr. Moneybags who can afford lightweight gear oversized for its intended use, I actually know one of these people, he is one of the top 10 heart surgeons in the USA, and if he had any interest in this web site he would hire staff to read it for him.

Racing gear is not “suitable” for cruising boats for the sad simple reason that the gear which meets our required factor of safety is generally well outside the budget of the vast majority of cruisers.

Hi Laurent,

To be brief, the reason aluminum is rarely used for rudder shafts is because it isn’t stiff enough by volume. In order to achieve the necessary stiffness you have to make the shaft large, which makes the rudder fat and makes engineers like Matt unhappy. (LOL)

I understand aluminium stiffness is about 1/3 that of stainless steel, so, in stiffness-specified applications it is generaly not a good choice, but I was wondering whether rudder shafts of cruising boat demand that much stiffness. I understand that “classic” spade-rudder designs with stainless shafts and composite sail have been developed for racing boats in the 70′ or 80′, and that for those boats rudder stiffness was a concern and metal fatigue was clearly less so (I guess those boat where not suposed to last very long….). Plus, rudder bearing capable of supporting “some” bending of rudder shafts where just beginning to appear.

Nowaday, carbon rudder shafts are the prefered option for racing boats, and cruising boats are left with either racing techniques from #30 years ago, that is stainless shafts, or today’s racing techniques. Point is that aluminium shafts might be a very good option today for cruising boats only, provided these shafts are built more flexible but as strong or stronger, than stainless or carbon ones. I guess this should not be a problem with appropriate bearings which have been developped since the 70′, and it might give a much better fatigue resistance and testability than stainless at a lower cost.

Might be some kind of interesting technical option that has not really been tested because current cruising boats manufacturers are either staying with old habits or adapting latest racing boats technologies, but not spending much resources on new technical options that can not be sold to racing-boats manufacturers….

As Richard mentioned above, aluminum is not terribly stiff- you need a large diameter shaft, which means a thick blade, which means hydrodynamic performance can suffer.

Aluminum is also very low on the galvanic series, making it vulnerable to corrosion. In all-aluminum boats, we work around this problem by using extreme caution with electrical stuff, where metals meet, and with the placement of sacrificial anodes. Metal boat owners know this and pay very close attention to it over the life of the vessel. Put a little bit of aluminum in an otherwise electrically “easy” boat, though, and it’ll eventually be neglected- turning it into a hot spot for corrosion.

It’s also worth noting that aluminum is terrible for fatigue. Unlike steels, it has no fatigue limit and keeps getting weaker and weaker with repeated load cycles. This poses some difficulties in aluminum design, but is a real pain in fabrication- it takes a lot of skill to weld aluminum in a way that doesn’t render the joints much more vulnerable to fatigue than the surrounding structure is.

Composites don’t have a fatigue limit either, but unlike aluminum, they don’t require a master journeyman’s skills to fabricate. You can take a first-year student, show her how to lay the fabrics and core in the mould and where to hook up the vacuum and resin hoses, and her second part will be production quality. (I have done this on solar cars, and the parts were still near 100% condition at the end of the vehicle’s service life.) The complex, labour-intensive part is making the tooling in the first place, and successive parts are relatively easy and cheap- this is, after all, why the hull itself is so often made of composites.

I guess that rudder-shafts do not really need that much stiffness provided bearings accept some more bending than usual. In that case aluminium shafts less stiff but slightly stronger than existing stainless shafts are of limited diameter and should be quite OK.

I understand that aluminium shafts are better, or much better, than stainless for fatigue wear (better resistance and much better testability…) and that galvanic corrosion should not be a big issue because shafts can be easily isolated in most cases (composite boats…)

I understand that steel fatigue resistance is good but stainless fatigue resistance is awfull and aluminium fatigue resistance is somewhere in between with much better testability than stainless. So the question might be: what is the appropriate fatigue test for aluminium rudder-shafts at what period. ?

We are speaking of industrial-type series production with CNC machinery, so fabrication complexity and/or costs for aluminium shafts or skeletons should not be an issue. CNC fabrication of composite is more expensive and I guess not realistic today for affordable yachts manufacturing.

I guess that the basic point about the A40 and about most of the technicalties in this blog starts from the idea that current boatbuiding practices are, or might be, far from optimal and/or from real markets needs, so the argument about the supposed advantages of composites because of cheap labour as currently used for most yachts hulls in North-America seems a bit contrary to this basic point.

Hi Laurent,

Matt, Colin and I all believe that a composite rudder with the carbon shaft is almost certainly the best option for fiberglass boats—on a cost to longevity and reliability basis—and particularly the Adventure 40. You don’t agree, and that’s fine.

I would suggest that most everything has been said on both sides of the argument and that it is time to move on to other things.

Let’s agree to disagree and leave it there please.

Hi Matt

As someone who has lost a spade rudder (see elsewhere on this site) due to stainless steel metal fatigue initiated by internal corrosion in the blade. I think that the time is long overdue for a move to carbon for this type of rudder.

Many rudders from production yachts from the 70’s and 80’s are also afflicted – an accident waiting to happen, I think, soon to be followed by the later move to aluminium stocks, many of which have not been electrically bonded as the manufacturers suggest. I think within a few years aftermarket rudders in more suitable materials will provide nice work for some enterprising laminating shop.

Kind regards

Colin

Hi,

Carbon seems to be an excellent choice for fiberglass boats. I do however have some bad experiences with this type of rudder. Nothing that can be prevented by proper engineering though.

Most rudder designers do not account for backing up into something hard, may it be a beach, a rock, a submerged trunk, a sheet of ice etc. Carbon is not great when it comes to shock loads or point loads, but these kind of loads will happen to any cruising boat at some point during their life, and should be considered when designing the rudder.

Another option might be a hollow steel or stainless steel shaft, low cost, stiff, durable, not fatigue sensitive and if designed properly, weightless under water.

I have designed the ice-reinforced steel rudder for our own 50′ boat according to this principle. Material cost were around $300 for the entire rudder, 35 hours of labor, and even tough the scantlings are way over done, it still floats in water. We now have a rudder with which we can back up onto a rock at full speed without any damage, and that can be lifted or carried by one person alone. This would be my personal preference for any boat that is to be used for some serious cruising stuff.