Alternator Installation

With almost no exceptions1, the alternator that our engine came with was specified and installed to just keep the starter battery charged and so will be totally inadequate to supply even a part of the electrical needs of a modern cruising boat.

But a well-specified and properly installed upgraded alternator can supply a substantial part of a cruising boat’s electrical needs by charging the batteries when the engine is being run anyway for propulsion, as well as providing backup for a separate generator and stepping in for the solar panels when the sun don’t shine—what’s not to like?

For example, on our McCurdy and Rhodes 56, typically better than half of our normal usage would be provided by the alternator while motoring in and out of anchorages and/or harbours.

Of course, in these days of ever-better and less-expensive solar panels, many cruisers will wonder if upgrading the engine alternator is even worth it?

The answer is a resounding yes on most-all cruising boats:

- Large solar arrays:

- Add weight and drag and therefore negatively affect both boat performance and stability to a much higher level than many believe.

- Often make sail handling difficult, and even dangerous.

- Make the boat more susceptible to storm damage.

- Wind generators are often even worse, and are noisy, too.

To be clear, I’m not suggesting solar arrays are a bad idea—though I do think wind is over for most of us—but I am saying that the most functional cruising boat electrical systems use a combination of sensibly sized solar, a good alternator, and, for boats with large electrical needs, a stand-alone generator.

So let’s look at what a real cruiser’s alternator is, and how to install it properly.

Login to continue reading (scroll down). Paid membership required:

Hi John,

Lots of good tips here.

Regarding #14 on Airflow, I don’t like the idea of using the engine intake to suck hot air from around the alternator. If done well, it may cool the alternator just fine. The problem is that you are putting hot air into your engine which is less dense. From a combustion standpoint, you talk about massflow of air not volume flow of air as massflow determines how much fuel can be burned. Hot air will significantly reduce engine output at high rpm. There is a reason why engine builders talk about cold air intakes a ton. This not a purely academic thing, when I designed air compressors, one of our biggest issues was fighting intake pre-heating as it essentially lowered the output and could do it by 30% if we were not careful.

The engine is a big air pump so much of the cooling in a lot of engine rooms is actually due to the engine pulling hot air out. This isn’t great but if you add the extra heat of a big alternator, it gets to the point where you absolutely do not want to send all that heat through the engine.

Another thought on #7 on only having 1 alternator is that in most applications, the second alternator outputs extremely little. The actual energy to start an engine is not very much. Assuming you are still using a lead acid start battery, it should still be at an SOC in the high 90%’s after a start which means its ability to accept charge is very limited. So you might hang the parasitics of a 50A alternator on the engine all the time to only pull a few Ah off of it each start, you might as well send that over a DC to DC battery charger.

Eric

Hi Eric,

Thanks for confirming my discomfort on the air intake, and good point on the second alternator not doing much useful.

Some engines include factory provisions for second alternator mounts or even factory-installed second alternator options with integrated wiring harnesses, control panel annunciators, etc. How much of your negative opinion of second alternators remains in those cases?

Hi Mark,

I still really can’t see the point, particularly these days when we have DC/DC chargers that are low cost and reliable. Also see Eric Klem’s comment. Which engines are you referring to? Other than Beta Marine who will add a second alternator on request, I don’t know of any. And I would bet that the cost of a second alternator on the beta would be more than a DC/DC charger.

I was thinking about many Beta engine models that include a factory option for a second alternator. I was also not thinking only of the alternators charging separate batteries, since some regulators include provisions to coordinate the charging of the same battery bank by more than one alternator. With such coordination, using more than one alternator can be a way of getting more charging amps, which a DC/DC charger cannot, of course. I also wonder whether something like using two 4kW alternators is a net benefit or loss compared to using one monster 8kW alternator — or a less extreme example: a pair of 2kW instead of one 4kW.

Hi Mark,

That’s complicated, but Eric covers how to evaluate the loads of two alternators in his article about alternator sizing: https://www.morganscloud.com/2025/07/06/right-sizing-an-alternator/

My thinking is the more separate bits we add and complexities like two alternators controlled by one regulator the more there is to go wrong. Also I would never try and drag 8kW out of alternators. Even if the engine front end can support it without damage it’s horribly inefficient and would put a huge amount of heat into the engine space. If we really need 8kW, at Eric points out, the right answer is a stand alone generator, which is way more efficient, and gives us backup, rather than putting all our eggs in one basket and cluttering up a mission critical system. More here: https://www.morganscloud.com/2025/07/24/efficient-generator-based-electrical-systems-for-yachts/

Beta Marine will also upsize the primary alternator, do a serpentine belt setup with two alternators, or, as is in our case work out in-line PM generator heads that are much more efficient. Their engineers are absolutely brilliant and very, very patient.

having just one large alternator on the 12 V ship up to certain size is probably the most pragmatic approach. Once the size goes up that would require upgrading the engine set up to 24 V which adds about $2500 to the bill which makes separating engine and house circuits much more attractive.

Engine-driven refrigeration is definitely a thing of the past. But I don’t see why the watermaker pump and an emergency bilge pump can’t be mounted on the engine assuming there’s enough space.

Hi George,

Each to their own, but I stick by my dislike of adding complications to mission critical systems like engines. If nothing else, so doing makes it harder to service the engine. Also over the years bitter experience has caused me to come up with John’s third law of boat maintenance: Problems with a machine go up by the cube of the number of tasks said machine is asked to perform. This law really kicks in when we add stuff the manufacturer of the machine never envisioned when they designed it.

Hi John,

they certainly go up, but I doubt, it is a cube.

with proper engineering and reasonable space I’d expect linear.

so much said, there are plenty of installs that are hard to work on without extra contraptions, in which case I’d opt for your approach.

Hi George,

You may me right, I used to say square, but then… To me it’s just way cleaner to install a single large alternator and then use electricity to drive all the other stuff like watermakers pumps etc. Also more flexible in that we can use electricity from different sources (shorepower, solar, generator…) to drive those other machines.

Hi Mark and John,

With two alternators, one is usually the smart and powerful one, charging the house bank. The secondary alternator is usually an original small dumb one that just keeps the starter battery charged. This is usually a lead acid battery, so that works fine, but…

A smart CD to DC charger could make the start battery last perhaps twice as long. Smart charger means it’s aware of the situation in the battery and adapts to it. A dumb alternator does no such thing, ever, and typically can both undercharge and overcharge, on the same setting. Both will kill the battery, slowly.

I think a second alternator is inefficient, reduces system reliability much and ends up costing significantly more than just using a smart DC to DC charger.

Hi Stein,

I agree. The DC/DC charger alternative is less expensive, has no moving parts, is maintenance free, is simpler to wire, and kinder to the battery, what’s not to like?

The other thing to note on the settings is getting all of the different charge profiles to work together. This is more on the set-up side but my Mastervolt default settings wants to absorb and float at a different time as the Victron MPPTs and the WS500 as they feed my Lifeline AGMs. It’s not necessarially hard but I will sometimes see the WS500 drop when the sun comes out as the MPPTs do their thing. Yes, I need to get the MPPTs on the shunt but until then keeping the alternator at optimal output can be a challenge.

Hi Douglas,

Sounds to me like the acceptance exit criteria current WS500 is set too low. 1% of battery bank capacity is right for Lifeline AGM and acceptance voyage should be 14.4V assuming a 12 volt system. The default settings on the WS500 tend to be too conservative, You can verify the above in the Lifeline manual. Point being there is no reason the solar should fool the WS500 if its set up right:https://www.morganscloud.com/2016/06/04/how-batteries-charge-multiple-charging-sources-too/

All great points here John. I’ve seen (and personally burned up) waaay too many belts and alternators over the years. It was a steady source of income while living on the hook in the Caribbean for awhile – with a copy of the 12v doctors alternator book and a clamp meter, I became the local ‘alternator guy’. Will work for Rum. No arguments with the points made.

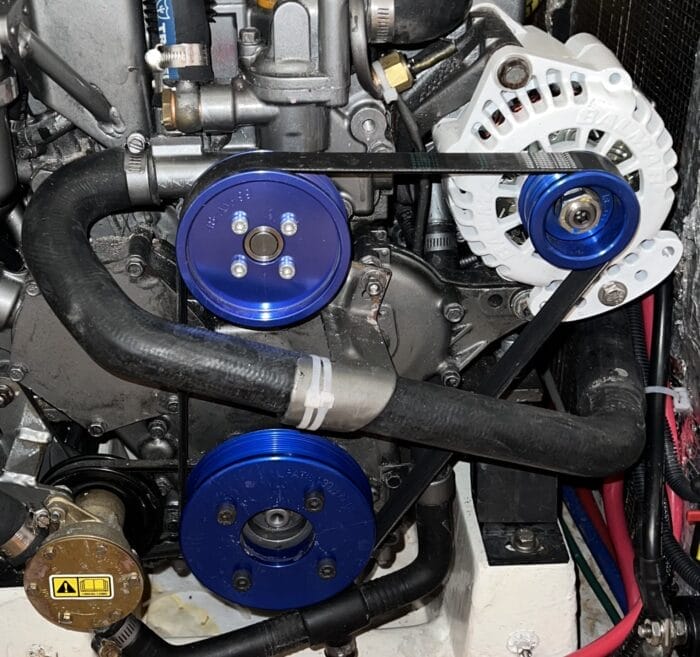

Check out the attached pic – that’s 4 x 100A @48VDC alternators – on one belt!! yup – nearly 20kW…

Seen at the SeaAirSpace Defense trade show in DC last April. Not sure who or what needs that kind of power, but folks are trying it!

Hi Ben,

Yikes that pic is disturbing! Why on earth would anyone do that rather than just have a far more efficient stand alone generator. I also wonder if they checked with the engine manufacture about putting that much load on the front bearing.

indeed. truly wacky…

I do like the 180 degree belt wrap they are getting on every alternator due to the strategic placement of the idlers…

Perhaps they’re competing for the Rube Goldberg of award.

Hi George,

I think you got it! A shoe in for the gold medal.

Hi John,

Well, I just finished a full rebuild and did follow all your tips but one : I kept my original starter alternator, and also kept the beefy service bank alternator that was already properly installed on the engine.

The starter alternator is a basic foolproof system connected to a basic lowtech AGM battery

My other beefier alternator is regulated by a WS500 managed via DVCC by a CerboGX connected to a BMS NG to dump the amps in my lithium Victron NG Bank, and from then I have two DC chargers charging my AGM house bank.

As you can see, this is quite a complicated path with many possibility for failure. I do have some level of redundancy (I carry a space Cerbo GX, I have two redundant DC chargers), but still. For example I know of at least one account of a failure at sea of a brand new WS500 (as reported by Matt Rutherford in his excellent podacst )

I like the idea of having a lowtech option, and in case I need some amps in the house bank I can just start the engine and use my battery parallel switch (which connects the starter AGM bank to the house AGM bank), and boom maybe I wont use my microwave or my boiler, but at least I can cover the vital stuff while I take my time to fix the house alternator circuit.

Hi Brann,

As you say complicated. Given you gave lithium maybe get rid of the AGM house bank and just use one of the batteries as a serial critical load backup: https://www.morganscloud.com/2022/07/03/building-a-seamanlike-lithium-battery-system/

So doing would also save you a lot of weight and space.

Also, the existing starter alternator is not really a viable backup because it is probably internally regulated so will tail off way to quickly and would also get burned out quickly if you had to rely on it. Therefore, as I say in the article I prefer a spare large alternator.

As to failure of the WS500, I have always carried a spare alternator regulator and on the M&R 56 had it wired in so that just changing over a couple of wires would bring it online. On the J/109 I have the same set up using the internal regulator that comes on on Balmar 6000 series alternators as backup.

A note on Beta. When we ordered our Beta 50 last year their largest offered alternator was just 120A. We bought the Balmar XT170 and had it delivered to them for installation prior delivery.

It is our only alternator, we did not want it to be the second. We use a Victron DC/DC to charge the starter, thruster and windlass batteries.

Hi Pepijn,

Sounds great, and I love that Beta will install our alternator of choice, does them credit.

I did an alternator upgrade when I bought my boat a couple years ago. I installed an Electromaax 215 amp alternator with their E-maax pro regulator with the alternator deregulated to 80%. It’s been working great other than, it seems the tach is powered by the field output of the alternator, and when the batteries are full the field drops below 5% and the tach stops working.

Is that normal? Or do I have something installed wrong?

Another question: I installed a blue seas switch with alternator field disconnect in the positive output of the alternator. I want to confirm it is indeed safe to turn that off when the engines running in order to maximize power to the prop. It won’t damage the alternator to cut the field output while it’s running?

Thanks

Hi Adam,

No losing the tack when the batteries are full is not normal. The tack is driven by a pulse output from the alternator that in some cases passes through the regulator, not the field wire, so something is wrong. Best to contact Electromax.

Also, I would not turn off the alternator that way. Whether of not you would get a spike is a function of how much the alternator field contacts disconnect before the output contacts. Not something I would trust. If you really want to do this the right answer is a separate switch in the field wire. That said, a better answer, by far, is a Wakespeed WS500 alternator controller and its whitespace feature so you are not relying on remembering. I’m also guess that a change to the wakespeed will solve your tack drop out issue too.

All that said, you may be able to solve all this with the E-maax pro regulator (I don’t know it’s features and capabilities).

Regarding #6

Link is pointing to Balmar Large Frame Alternators (94-Series, 94LY-Series and 95-Series) which have been discontinued as of 2024.

Recommendations for alternatives?

Hi Olli,

Thanks for the heads up, I will change it. I can’t recommend another brand with any certainty since I have only used those from Balmar but Bruce over at Ocean Planet seems to like American Power Systems, and he is usually a reliable source for this kind of information since the last thing he wants is a lot of warranty issues.

Bosch USA offers humongous school bus alternators that might be just fine if run at 70 percent.

Do you have a link? On bosch.us, the search for “alternator” doesn’t come up with results, same with the token “schoolbus”.

Content free website, but a start

https://www.boschautoparts.com/p/long-haul-high-output-alternator

https://www.amazon.co.uk/Bosch-AL9964SB-BOSCH-New-Alternator/dp/B0BXZLSMC2

https://dwdiesel.com/c/EngineComponents-StartingCharging-Alternators/p/1146749

12V 275 watt 660usd 14 kg

https://www.fleet.boschautoparts.com/documents/647135/1488079/Long%20Haul%20High%20Output%20Alternator%20Brochure.pdf

they do not state the voltage, which is very odd.

Neither does this one

https://bermantec.com/shop/products/delstar-alternators/300-series/300-series-24-volt-400-a/delstar-alternator-100-31210/

this monster, not from Bosch Has 400 amps at 24V at a paltry 35 kg

https://bermantec.com/shop/products/delstar-alternators/300-series/300-series-24-volt-400-a/delstar-alternator-100-31210/

Hi George,

Did you find efficiency numbers, or better yet, graphs for these? If they are around 50%, as most legacy alternators are, the torque requirement are going to be prodigious, ditto ventilation. Probably transport trucks don’t care much, but we yachties will.

Bosch used to be more forthcoming with real information, but if memory serves, they were at the high end for legacy alternators.

Also, if memory serves, beta could have managed to install it using a serpentine belt. But in the end, we opted for the Zanardi PM in line installation, with which they were really comfortable, and it gives us about 3 kW at 230 V out typical propulsion RPM but loading the generator heads out less than 50% of rated power.

In normal, single alternator install, I would stick to your recommendations regarding amps.

Hi Ernest,

Looks interesting but I note that once again they are touting high output at low rpm, so we have to be super careful about damage to the engine from excess torque, since torque goes up for a given power as rpm goes down, and diesel engines are more vulnerable to damage at low rpm—double indemnity: https://www.morganscloud.com/2025/07/06/right-sizing-an-alternator/

Something I think we need to keep in mind is that a lot of these things were designed with the long haul truck industry in mind where the engine is what? Maybe 400 hp? Fitting one of these on a 50 hp yacht engine might not be a good plan.

indeed.

even puny school buses in the US have comparably huge engines – Cummins Diesel – 240 to 300 hp around 6 l.

so yes and again, though we went a completely different route, a) on a traditional one alternator set up I’d stick with your recommendations and b) in our case we had hundred percent support by beta engineering. this allowed us to come to resolution with which all sites were happy.

Hi John,

thank you for another great article. I would like to add some words.

Regarding #7. Two alternators (properly mounted) have some advantages:

Better heat distribution. It’s easier to run them cooler.The side force applied to crank shaft is the resultant of the forces from the two alternators. If the alternators are on the opposite side of the crankshaft the forces cancel.Because we have 2 alternators with 2 serpentine belts, the belts doesn’t need to be very tense – good for fresh water pump bearings.Of course if we have two alternators of 2kW each they will generate 4 kW of heat. From my experience it’s still manageable but we need to improve the ventilation in the engine room. If we still need more power we should go to 24 or 48V.

Efficiency – the efficiency of the alternators is terrible but that is only true for 12 volts. If we have 2kW (150 amps) alternator @12v we can assume that it will generate 2kW of heat and we have 4kW of load on the crankshaft. But if we have 8kW @ 48V (also 150 amps) it will generate similar amount of heat as 2kW 12v alternator. So the load on the crankshaft is 10kW. And we have the efficiency around 80% – similar to the generator.

So the efficiency of the 48v alternator is similar to the AC generator but for much smaller price and huge space savings. We can have Mahle MG976 48v 150A alternator for just 1000$. Then we add 1000$ for WS regulator and 1000$ for beefy mounting. For 3000$ we have equivalent of Integrel 😉

For the rest of the money that we would spend for AC generator or Integrel we can spend for high tech lithium bank with all accessories. Of course we need small 12v bank that is powered from 48v bank via DC2DC charger.

So if we need really powerful alternator we should go higher with the voltage. It’s efficient and not so expensive. My experience shows that two alternators (2×2,5kW @12v) do no harm to the engine. On my next system the voltage will be 24v.

I hope these speculations weren’t too off-topic.

Michal

Hi Michal,

That’s interesting, but how sure are you of your numbers? Do belt tensions really cancel out? I’m not sure, but Eric suggests that we actually need to do a free body diagram: https://www.morganscloud.com/2025/07/06/right-sizing-an-alternator/ And is belt tension all that can damage your engine. What about torque? Eric covers that too.

And as far as an 8kW 48volt alternator putting out the same heat as a 2 kW 12V volt alternator that would imply that the 48 volt alternator was four times more efficient than the 12 volt. Heck that would make a 48 volt alternator more efficient than a generator or integral, both about 80% efficient, which I’m near certain is not the case.

I do agree that 48 volt alternators are a bit more efficient than 12 volts but I find it very hard to credit that it’s 400% more, more like 10% I would guess. Can you point me at a 48 volt alternator with 80-90% efficiency? I checked, and like most alternator manufactures Mahle does not claim any efficiency numbers and I could not even find a power output curve for them.

Keep in mind that power is measured in kW and kW stay the same regardless of voltage: W=I*V and efficiency = output kilowatts/drive kilowatts. Just changing voltage has no effect on that equation.

Eric also state that efficiency of 48V alternators is not a lot more than 12 Volt. (Integrel is an exception, but that’s because it’s not an alternator but more like a stand alone generator.)

If you believe ARCO’s published numbers for their Zeus A8000-48V alternator, “sustained cruising output (Hot, 6,000 RPM)” of 7.383 kW from a PTO load of 10.5 kW yields 70% efficiency. Not quite 80%, but still substantially better than 50%.

And to push the point a little further, 3 kW going into heat from that alternator would be equivalent to a 12V alternator producing 3 kW of electricity and 3 kW of heat. So, the 48V alternator is producing more than twice the useful electric power from the same heat budget.

But really, it fundamentally looks like all of ARCO’s published numbers for their high output alternators are in basic disagreement with the 50% efficiency assumption, with their 12V offerings coming in at about 66%, and the 24V and 48V alternators at 70%.

I’ve got nothing to independently verify their published numbers, so I’ll just note that they are different from the 50% assumption, but not different from Eric’s position that the higher voltage alternators offer only a small efficiency advantage over 12V alternators.

Hi Mark,

That sounds more like it although more efficiency increase that I feared (10%), which is good news. Still at even 70% efficiency that’s quite a bit less efficiency that a stand alone generator or Integrel at ~85%. Anyway, certainly better than 12 volts but still concerning particularly taking 10.5 kW off the front of the engine, over 14 HP.

I would also like to see an efficiency curve from ARCO, since it’s all too easy to pick one place on the curve and use that to sell the alternator. Do you have a link?

Anyway, good to hear that the efficiency on 48 Volt alternators is better than I thought, but I would still stick with Eric’s recommendations that trying to take that kind or torque off the front end of the average cruising boat engine and injecting all that waste heat makes no sense, and the problem would be better solved with a stand alone generator (which gives us backup and quieter), or if no room for that, conservation—the often forgotten, but often best option.

Hi Mark,

Just checked and American Power Systems are claiming 73% for 48 volt, so that’s good news! That said, I would still like to see an efficiency curve by RPM since it’s all too easy for marketing types to cherry pick.

Hi John,

my assumption was that the amount of heat generated by the alternator is proportional to the current. This is a slight simplification on my part. I’m pretty sure that this is 100% true for the amount of heat that is generating by the rectifier. But rectifier is not the only source of the heat. I’m not sure if this is 100% true for the heat generated by the stator.

But real world data shows that my assumption was very close. I have no data for mentioned Mahle but couple of others examples below.

As Mark mentioned below Arco 24v and 48v alternators has 70% efficiency. Volta 56v alternators – some of the alternators have 70% and others 80% of the efficiency.

If we assume that all the lost power is converted to the heat 8kW alternator 80% efficient will generate same amount of heat as 2kW 50% efficient.

If we mount exactly same alternators on opposite sides of the crankshaft then the side force is zero. But such configuration is not very common in real world. 2 times 2kw alternators at a 90-degree angle to each other will exert less lateral force than one 4kW alternator. So 2 smaller alternators are better for crankshaft bearings than one BIG alternator. That was my point.

Torque – I agree with you. Too much torque can damage the engine. But what does it mean “too much” ?? It’s almost impossible to find real numbers. But we can use Nigel Calder’s Integrel as a guide what torque will not damage the engine. Integrel is a 8kW 48V alternator with smart regulator, smart programming and smart mounting. But it’s just an 48v alternator that is driven by the engine crankshaft. The efficiency is around 80% so the PTO is 10kW. We can see the pulley sizes of Integrel in your review here – https://www.morganscloud.com/2019/02/13/nigel-calders-generator-replacement-machine-part-1-what-you-need-to-know/

So the torque will be same as with regular 8kw 48V 80% efficient alternator.

I know that they installed that system on catamarans with engines smaller than 50hp. And they are still in business so I think that 10kW PTO will not hurt our engines.

Of course this is lot of power and if the installation is not done right we can damage something. But with proper mounting, smart programming (WS or Arco regulators) and some tweaking we can have truly powerful installation for cheap comparing to AC generator or Integrel.

And I understand that you John and Eric need to be more conservative with your advice, because this is for general audience.

Michal

I made some calculations based on Eric’s data from previous article about sizing the alternator.

I think that it’s very interesting.

When the alternator has 50% efficiency the generator is 28% more efficient than the alternator.

But as the alternator efficiency increases, the situation is reversed.

At 70% alternator efficiency it’s 9% more efficient than generator.

At 80% alternator efficiency, it’s 25% more efficient than generator.

25% efficiency gain over the generator is the exact number what Integrel claims to be.

Above numbers are correct if we are motoring anyway and the fuel efficiency is 192g/kWh.

If we are generating the power from alternator(s) without propulsion then the efficiency is much lower. According to my engine manual if the load on the crankshaft is 8kW then the fuel efficiency is 290g/kWh. So comparing to the generator the efficiency is terrible.

To generate 4kW of power we’ll burn twice as much fuel than the generator if we have alternator that is 50% efficient.

Even if we have 80% efficient alternator, still we burn 45% more fuel than the generator.

So if we generate power with the alternator is better to do it when underway, what (with good system) can be more efficient than the generator.

But if we don’t have the generator the savings (money and space=money) are so huge that the efficiency is not so important.

Michal

Hi Michal,

That’s very interesting and encouraging for alternators, but one thought. Where did we get an 80% efficient alternator in this, other than Integrel, which is not an alternator?

The highest claimed I was able to find was 73%. As I have said, to believe that I would want to see an efficiency curve preferably one developed from independently verified numbers. In the absence of that I would guess the average would be lower.

How much lower, I don’t know, but marketing types have a long history of cherry picking one good number, in this case an efficiency peak that may or may not be attainable in real world use, and running with it.

So, yes, I agree, if we are motoring anyway, and if we are willing to go to 48 volts (or 24) this makes alternators even more compelling.

So that’s great, but it’s also usage specific and only focusing on boats that can make all the electricity they need while motoring anyway.

It also ignores the issues of changing to 48Volts (or 24) including complexity and a large drop in fault tolerance (see my Integrel review).

Also generators, like the Northern Lights, have a mean time between failures (based on my own experience) that is 5 to 10 times better than alternators, provide a back up electrical source, are much quieter, don’t clutter our engines, or risk damaging them with too much torque on the front end. And are way better when we need power at anchor.

I have long been an alternator fan and recommended them over huge solar arrays for years, but, as always, horses for courses.

The Integrel “On Engine Generator” component of the E-power product definitely is an alternator. It has some differences and technical improvements from older, primarily automotive alternators, but so do newer alternators from other manufacturers. Integral’s own answer to the FAQ “How is Integrel E-Power different from a high-power alternator?” calls the OEG “The E-power alternator”, so it hardly seems necessary to insist that the OEG is not an alternator when even Integrel’s own marketing doesn’t try to carry that water.

The difference in the Integrel E-power system is largely about the control of the OEG, not that the OEG is somehow fundamentally different from an alternator. It is a fair question to ask how much of the advantage an Integrel E-power system has over old-fashioned marine alternator systems remains when the point of comparison is instead to newer and higher voltage high-output alternators when they are coupled with smart regulators that have been appropriately programmed.

Hi Mark,

Sure I could be wrong about that, but Nigel himself assured me it was not a standard alternator, and, if memory serves, that it was more like the back end of a generator. But anyway, let’s not get distracted arguing about who is right about details like that. What’s material is actual efficiency at peak load. I just scanned the very useful paper that William Murdock linked to. I need to dig deeper, but it seems to indicate that often peak efficiency is at lower than peak power. If that’s true it’s really important and means we should not just use one claimed efficiency number when determining maxsafe alternator size or the heat we will need to contend with.

I would also suggest that you might want to think about the level of certainty you are expressing in this discussion about things you are maybe not certain about, for example the relationship between current and heat, rather than power.

You will note that even Eric, the only one in this who is really qualified to opine with any certainty, is very careful to be clear about what he does not know for sure, and I’m trying hard to learn from that.

John, I said nothing with a claim of certainty about current, heat and power, and I don’t appreciate the unwarranted remonstration. In fact, the last relevant comment i left was that ARCO’s numbers seem to support Eric’s position that higher voltage alternators can be only a few percent more efficient than 12V alternators.

On those ARCO alternators: The 70% efficiency they claim is at 6000 RPM, which is substantially higher than for the typical efficiency peak of an automotive alternator. If anything, peak efficiency of those ARCO alternators may be somewhat more than 70%. I also have real questions about whether Integrel’s 80% efficiency claim is anything more than peak efficiency, and whether 80% is just the efficiency of their alternator without including the total PTO power in an analysis of system efficiency that would include things like belt losses. In short, I remain very interested in seeing more real comparison between Integrel’s E-power system and some of the available 48V alternators and smart regulators than can be gleaned from product marketing.

Hi Mark,

Sorry you found the remonstration difficult, but I don’t think it was unwarranted, particularly since we caution against over-certainty in our comment guide lines: https://www.morganscloud.com/2013/11/10/aac-comment-guide-lines/ (#1.4). I suggest you go back through your comments and look at the tone. I know that often when I do this with my own comments I’m disturbed by how certain I sounded about something I was wrong about.

As to efficiency, I just learned from that paper William so kindly found that to accurately evaluate efficiency we must look at both rpm and output power. For example an alternator might be 70% efficient at 6000 rpm at 50% output but only say 60% efficient at 6000 rpm at 100% output (I made those numbers up for illustration) so we really need graphs showing efficiency plots much like fuel island plots, to draw any real conclusion. And then, of course, temperature comes into this. Note: I need to read that paper again since I just scanned it, but I think that’s what I learned.

To that end I have written to American Power Systems to ask them if they can help us out with that information.

Anyway, assuming I did not get the paper wrong, a single efficiency number quoted by a company trying to sell alternators is pretty much useless for our purposes and dangerous to draw conclusions from.

By the way, it’s this kind of complexity that leads me to be uncomfortable with pronouncements of fact.

Enough is enough already, John.

Your original remonstration was unquestionably unwarranted. Again, I made no post claiming to be certain about the relationship between current and heat vs. power and heat. I have reviewed my comments before you falsely claimed that I had done so. There were only six, two of which are focused on asking questions and do not make any claim about the relationships among current, voltage and heat. The next three were compromised of my first responding to your request of Michal for information about a 48 volt alternator with 80-90% efficiency with the volunteered information that ARCO’s published figure for their 48V alternator amounts to a 70% efficiency; secondly, me following up to myself by simply running some of the math comparing the efficiency claim for that ARCO alternator against a presumed 50% efficient 12V alternator; and thridly, me following up to my own follow up by clarifying that ARCO claims a substantially higher than 50% efficiency for all of their alternators, not just the 48V one, and that their published figures with the small difference in efficiency between their 12V and their higher-voltage alternators actually support Eric’s position that higher voltage alternators can be only a few percent more efficient than 12V alternators. In the first and third posts in that chain I did quite the opposite of asserting certainty, instead making it quite clear that I was only citing ARCO marketing claims and had no independent verification of those claims.

Finally, in the post immediately preceding your unwarranted remonstration, I pointed out that, contrary to your over-certain assertion that Integrel is not an alternator, the Integrel E-power “On Engine Generator” is, in fact, an alternator — explicitly called so in Integrel’s own FAQs about the difference between E-Power and a high-output alternator. Suddenly the error in your own over-certainty became a detail not worthy of further discussion even though you still had to try defend your correctness by claiming that Nigel Calder himself assured you that the OEG is not a standard alternator and that it is more like the back end of a generator. That is in turns both irrelevant (since I had already noted that several newer alternators are also not “standard”, old-school automotive alternators) and of no help to your “not an alternator” claim (since the back end of a typical generator is principally comprised of an alternator and a voltage regulator.) The biggest conceptual differences between a fixed-rpm AC generator and a DC alternator are the fixed vs. variable rpm and the lack of rectification to DC in the AC generator. Of course, there are differences in durability and robustness between an automotive alternator and an alternator that weighs several times as much in an AC generator, but a typical AC generator remains, conceptually, an unrectified alternator. Beyond that, much of the difference is in how the alternators are controlled. That is precisely what I was getting at in the second paragraph of my post immediately preceding your initial remonstration — and I rather suspect that it was what Nigel was trying to convey to you about the Integrel system: that the Integrel controller has some elements that are more similar to those in an AC generator’s voltage controller than they are to an old-school automotive regulator. But that neither makes an OEG not an alternator nor does it close the question of home much real difference there is between Integrel E-power and newer, more efficient alternators coupled with newer, smarter, programmable regulators.

Regardless of those technical issues, you have now seen fit to again remonstrate me, only now with a link to an admonition not to express opinion as fact, even though I did no such thing. Rather, what appears to have again set you off is that 1) I dared to challenge your claim that Integrel does not use an alternator; and 2) I pushed back that your initial remonstration was, in fact, unwarranted. 1) The Integrel OEG is, in fact, an alternator. They explicitly call it an alternator in their FAQ. What Nigel Calder said to you does not change that. 2) Your initial remonstration was baseless and unwarranted. I had made no confident assertions expressing my opinion as fact. What is fact is that you are not just over-confidently asserting your contrary opinion as fact, but are actually asserting a falsehood against me. Two things that I am equally certain of, however, are that your repeated, unwarranted remonstrations of me give every impression of hectoring or badgering a person who disagrees with you in an effort to have the last word, and also that I deserve your apology, not your continued remonstrations.

I take no joy in making this post, put your persistence demanded an answer.

Hi Mark,

Perhaps you are right, In thinking about and can certainly see some off your points. These things are difficult and despite 20 years of doing this I’m far from perfect. On the other hand, perhaps I had a point, which is worth you thinking about.

Let’s move on.

Hi Mark,

I reviewed again and found that on at least one point I had confused you with another commenter. My apologies.

Accepted

Mecc-Alte Zanardi PM units claim well above 90 percent. But they will likely need custom mounts.

Hi George,

Sounds great, but those are, (I think) generators not alternators, and I think there are drawbacks, although I can’t remember what they are. Perhaps voltage regulation, or size? Anyway, I know very little, but suspect there are good reasons they are not being used on yacht engines. Matt, Erik?

They are generator heads used in high-end alternators. Beta was happy with them because they are a major customer of Mecc Alte in the UK – which made this an engineer to engineer challenge.

the nice thing is that they produce from about 1700 rpm to 2400 rpm – we had the engines derated accordingly.

they are quite big and they come with an inverter that produces 230 V 1 phase output from the internally created varying voltage multiphase power.

Hi All,

To my knowledge, Zanardi does not make a unit intended for engine alternator type applications, they are intended to be the generator head (sometimes called the alternator head on an AC genset) of a genset.

Permanent magnet motors/generators are a different beast than variable field. With variable field, it is very easy to regulate the output by simply varying the field current. When you have a fixed field as you have in PM units, you have to do something else which starts to look like a giant DC to DC converter when you try to handle the varying speed of the engine for propulsion and the varying voltage of the battery bank. Without being a EE who doesn’t mind home-brewing a lot of high power electronics, you can’t really make it work yourself. Another interesting thing to note on PM motors is that their losses when you are not generating power are much higher. If your alternator always needs to output, this doesn’t matter but if you motor a lot in a battery absorption, float state or even alternator disabled, you will find that your efficiency will go way down. If you want to understand this more, you can read up on why some of the electric cars that use front and rear motors actually use PM one one axle and induction on the other despite PM generally being more efficient and power dense than induction when powered.

Eric

Hi E ric,

Thanks for the fill on that. Although I got that regulation would be an issue, I should have twigged that the permanent magnet is the core issue making these units unsuitable.

This is sliding into terminology confusion again. To physicists and electrical engineers, something that turns rotation into alternating current is an alternator — it’s where the name comes from: alternators produce AC, not DC. From the perspective of physics and engineering fundamentals, what gets sold into the automotive and marine markets as an “alternator” is actually an alternator connected to a rectifier that converts the alternating current into direct current.

Correspondingly, almost all AC generators combine an alternator with means to control the frequency of the alternating current and shape the waveform some. Usually that’s a matter of running the prime mover engine of the generator at a single, fixed frequency that is synchronized with the output AC frequency, but some newer AC generators use electronics to decouple the alternator’s frequency from the output frequency. In any case, statements like “it’s a generator, not an alternator” don’t make sense at the level of physics and fundamental engineering: AC generators and automotive-style “alternators” both incorporate alternators.

The terminology confusion gets even worse when permanent magnets are used to generate the magnetic field in an alternator instead of the more common field wiring and electromagnets. Some manufacturers of these devices with permanent magnetic fields insist on marketing them as permanent magnet generators (PMGs), while others insist on calling them permanent magnet alternators (PMAs), and yet others insist that there is a distinction between PMGs and PMAs — but the distinction is not consistently agreed to, so one manufacturer’s PMA is another’s PMG and vice versa. And then things get even more confusing when a clever guy like Nigel Calder starts marketing alternators that use both electromagnets and permanent magnets while also putting a rectifier and other control electronics in a external case separate from the alternator proper. There’s no fix or resolution of all of this terminological confusion over just what an alternator is or isn’t other than to be aware of it and to try to be careful.

Back on permanent magnet devices. Because they don’t need to spend energy producing the magnetic field in the alternator, PMAs/PMGs can be more efficient than alternators with conventional field wiring. There is, however, no way to control the strength of the magnetic field produced by the permanent magnets, so the amount of electrical power produced by these permanent magnet devices is just a function of the speed at which they are rotated. It’s similar to more conventional alternator if there were no way to vary the electromagnetic field strength by changing the voltage on the field wiring. If the PMA/PMG doesn’t produce enough electricity at low RPM, too bad. If it produces too much electricity at higher RPM, well then you need to find some way to use the excess or dissipate it as heat. So, yes, more efficient, but significant drawbacks or challenges. But in any event, use of permanent magnets does not determine whether a device is an alternator or a generator or a generator head or whatever marketing has come up with this week. From the physics and fundamental engineering perspective, it’s a alternator whose alternating current output can be sent to other equipment packaged in different ways to produce useful DC or AC electricity.

Good summary, thanks.

Hi Mark,

Thanks for the clarification.

Hi Michal,

I’m about as certain as I ever get that heat generated is proportional to power, not current. The physics here is that power is what gets work done (including heating). We don’t say a 10 amp heater (at 120 volts), rather we say a 1.2 kW heater.

And yes, I agree, using Nigel’s numbers can be useful and in fact Eric says that.

Eric also says in his piece that if you have a more efficient alternator and know that, it’s pretty safe to adjust his calculations upward to account for that. So we are all on the same page there.

So sure, if you want to hang a really big alternator, say 8kW on a 50 HP, you can do that, but I personally would not go against Eric’s warnings (adjusted for efficiency).

He is a professional engineer and has a history of designing compressors, which are just diesel engines running backwards, so I trust him over anything you and I can come up with, or, for that matter, claims made by someone trying to sell us a big alternator.

there are some thoughts of Delco Remy on alternator efficiency here. https://www.tomorrowstechnician.com/wp-content/uploads/SmartProducts/RemysNewTechnic_00000011830.pdf

Hi William,

Thanks so much, I gave it a quick scan and it looks really interesting. I will definitely dig deeper. Clearly a lot to learn from someone who clearly knows their subject.

As to the amount of torque that we can safely consume to drive an alternator, I believe that the Integral drives its electrical generation device from the rear of the crank. Is that correct? If so, engines are designed to be able to output 100% of their rated power from the rear of the crank, but are typically NOT capable of putting that level of power out of the front of the crank safely. Cummins used to spec a general rule of thumb that 50% of the rated power (or torque) could be taken from the front of the crankshaft, and I believe that was a bragging point, so not sure I’d assume all engines can match that.

The other thing I have not seen discussed is the torsional vibration impact of hanging high inertia items (e.g. large alternators) on the front of the engine. I am not a torsional vibration expert, and this applies much more to hard coupled devices (e.g. hydraulic pumps driven directly by a driveshaft coming out of the front crank pulley) and may not be an issue for belt driven alternators, with their smoother torque characteristics and the “softness” of belt driven components, but would be interested if some of the experts have comments.

Hi David,

There are two versions of Integrel, the original that runs off belts, and a parallel hybrid version that runs off the back end between the engine and gear.

As to discussing the potential damage from torque, Eric provides a deep dive here: https://www.morganscloud.com/2025/07/06/right-sizing-an-alternator/

Hi All,

Good news on alternator efficiency. I wrote to American Power Systems to see if they had graphs rather than just a single number, and they passed me on to Bruce at Ocean Planet who is always a great resource. I now have two graphs that show that at least APS 24 and 48 volt alternators have efficiencies at the output percentages and rpm we are interested that are in the 70% range. Bruce is also checking on 12 volts.

The key point here is that APS are willing to share graphs across rpm and output which is far more useful than a single efficiency number that can easily be gamed by marketing departments.

I will share more once I have taken time to put all the implications together.

Thanks to Mark and Michał for pushing this important issue.

I will be changing this article to reflect my new understanding including publishing the graphs.

Hi John,

Thank you very much for writing to the APS. It will be very interesting to see those numbers because they are on marine market.

I left some links to 80% efficient Volta alternators in my previous comment but you are right. Without the graph that can be only true for only one specific rpm.

And I hope that the tone of my posts was not too offensive. If it was, then I’m sorry. That was not my intension. I’m also not English native speaker so sometimes my sentences don’t reflect exact context.

You are doing a great job on this site.

Michal

Hi Michael,

No worries, all good and thanks for the kind words.

As you say the key is knowing the efficiency over the entire range of rpm and output, so I would strike any vendor off my list who was not willing to share that. Having looked at the APS graphs I am suspicious that other vendors claiming 80% are cherry picking and should not be trusted.

John , I use a Balmar belt tensioner on my new Beta 35. I don’t like it much, at least in my installation. I have searched for a picture of the tensioner you built on Morgans Cloud and can’t find it. Is the photo still on the site somewhere?

Hi Terence,

It’s still in the article above, including a description. See under the pic of the Balmar belt tensioner.