In Part 1 we got the mast upright so it was not leaning over to one side or the other.

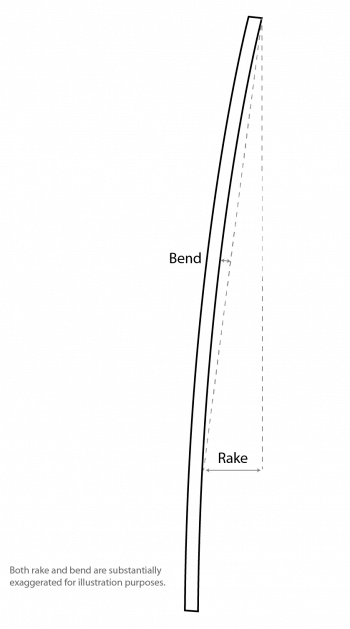

Now let’s set the fore and aft rake and bend.

But before we set off on that long and winding road, we need to make sure we really understand the theory of tuning. That’s what this chapter is about.

Yeah, I know, we would all much rather I just jumped into a step-by-step guide.

I get that but there are just too many variables to come at tuning that way.

Rather, each of us must clearly understand how all the different factors interact before we start twiddling turnbuckles.

The good news is that Part 3 is a step by step guide to setting rake, prebend and getting the mast straight…but first you need to read this.

Why? Because by understanding the theory each of us will be able to deal with pretty much any tuning situation—way better than monkey read, monkey tune.

Let’s do it:

Login to continue reading (scroll down). Paid membership required:

Hi John,

Good explanation of rake and bend. One note on rake is that boat trim really matters. An awful lot of boats are down by the stern and only get worse with people in the cockpit. On our own boat, we had to relocate batteries and a few other items to get the fore and aft trim right and then we run very little rake, just enough that it looks right.

Even weirder looking to me than a boat with no or negative rake is a schooner or ketch with equal or decreasing rake as you go aft. Many of the older schooners used rake for a totally different purpose (mitigating bad slatting) but that is an aside.

I am seeing an increasing number of boats around us that have masthead geometries that are setup so that as you increase backstay tension, you also increase bend but that may be out of the scope of what you want to cover.

Eric

Hi Eric,

Good point on trim. Thanks for the reminder, I will put that in part 3.

As to increasing bend with backstay tension, I wrote about that a bit under Backstay adjusters in the above and will expand on it in the chapter on the final tune under sail.

In one of the sillier projects of my long and disastrous career, I was hired by an American/Hong Kong consortium to convert an aluminum 12 meter into the only 24 passenger USCG certified America’s Cup boat on the planet. We bought the boat, two masts, and a container full of sails for about the cost of an new Catalina and then had it shipped from Long Island NY to Seattle in the middle of the winter. I got a call from the truck driver from somewhere in North Dakota where he had gotten jammed up trying to maneuver the 90 foot masts into a place to purchase trip permits. Once out of that town he hit upon the perfect solution. He just drove non-stop to Seattle with no permits but a lot of Mother’s little helpers. (a la Grace Slick/ Jefferson Airplane)

As I was unpacking the container I came across a giant hydraulic cylinder about 3″ in diameter & 6′ long.. Turns out that it was used to change the mast rake by moving the butt while underway. Standard sailing procedure involved throwing the mast head forward about 6′ on every downwind leg.

Among the other oddities of the rig was the mast weight rule. Since they had to weigh 1,000 pounds, the masts were chemically etched to reduce weight and then ballasted with lead in the base. Peculiar to the NYYC team, they had reduced the weight of the masthead lock to the point where it regularly jammed, requiring that a crew member be sent aloft to beat on it with a hammer before sail changes. Their other solution was to spray the sail track with silicone, thus ensuring that the Australian sand in the air was captured for posterity.

Fun with boats.

Hi Richard,

I love these stories of yours, although they must be more fun in the telling than the living.

Funny the things people have done with old Americas Cup boats. Ted Turner converted the old wooden 12 meter “American Eagle” to use for ocean racing. I use the term converted loosely, in that he did not change much and the rig was pretty much the same as designed for racing in Block Island Sound. Ted sold her to fellow Bermudian Warren Brown who continued to ocean race her. A friend of mine crewed on her and his stories of dealing with that rig offshore and at night will make your blood run cold. Eventually they dropped the rig over the side on a trans-Atlantic race. Just imagine motoring back to land on a 12 with no rig!

Hi John,

In that same era that you describe, the 6 meter Worlds were held in Seattle. We were out spectating when the wind returned to it’s normal summer force of zero. We towed Turner back to the dock but didn’t even get a thank-you to say nothing of a beer.

On my conversion of NYYC 42 I built a custom full batten mainsail system using Harken traveler track because ball bearing systems that large hadn’t been developed yet. Cut out the mid deck and welded in two 12 passenger longitudinal seats. Adapted hydraulic motors to all winches. Powered it with a 70hp Suzzie similar to the Beta you have in MC.

In principle you could singlehand the boat once it was done, the only problem being that by that stage in 12 meter development they had reduced the size of the rudder to the point where you had to tack the boat using the main to assist the rudder. Perhaps throwing the mast back and forth was part of race maneuvering as well! LOL

We may laugh at the silly products of Rules, but on the other hand back then no one would have thought of racing in the Southern Ocean on flush deck open cockpit boats that are continually swept by waves like the current Volvo boats.

John, some queries: how do these parameters change for deck-stepped masts; how do two backstays affect the issue (save for counting identical turns), and how do running backs, which are eased or tensioned according to point of sail and/or conditions, affect pre-bend and rake in the sense that they aren’t always in use?

Hi Marc,

Good questions. I will be covering most all of them in the next three chapters.

For double backstays counting turns won’t tell you anything since that would require them to be identical in length and that the two chain plates where exactly the same distance from the top of the mast. The chances of that are slim to none. However, I will share how to get them close enough to the same tension in the next chapter.

Did I miss something? You said to set the rake, but I seem to have missed the part about how to do that.

Hi Cynthia,

See part 3 for specific steps. I will make that more clear, thanks.

Part 2 (above) is about the theory of rake and prebend. A drag to go through all that first, I know, but if we don’t understand how all the variables interact first, actually setting rake won’t go well.

Hi John, I have a question. If I have a furling main aft of the mast on a 10mm “standing rigging”, should I introduce mast rake and bend? I suppose both would slacken the aft mast standing rig and do the reverse of what it is intended here. I now have to retune my rig as my port cap shroud has come off the groove outwards of my lower spreader (I only have 2) by some 15mm and using your method to see if it will “resit” the cap shroud back to the lower spreader. Any advice that you can give would be most appreciated. Thank you.

Hi Ee Kiat,

I have never worked with a furling main like that, but given you want the luff as tight as possible I would have rake, but limit bend as much as I could, using the aft lowers, assuming you have them.

Hi John, yes, I have 5 standing rigging on each side, the forward intermediate and lower shroud, the aft intermediate and lower shroud and the cap shroud. I have a staysail shroud but no running back stay. Should I use the aft lower shroud as well as the aft intermediate shroud?

Hi Ee Kiat.

Sure, I think the idea here will be to keep the mast very close to dead straight, or maybe just an inch or so of pre-bend.

Hi John, have you come across examples of older boats (made in the 1980s) where the cap shroud does not fit into the groove of the lowest spreader tip and require siezing wires to keep them in place? Assuming the mast is aligned to be vertical.

Hi Ee Kiat,

Yes, it was quite common to require secure wiring of the shroud to the spreader end. The other problem can be that dissimilar metal corrosion between the aluminium spreader end and the shroud can cause the groove to enlarge over time, so it’s not a good fit. In this case the spreaders should probably be replaced, although it can be a challenge to find a mast maker to make new ones.

Thank you John. Finding a mast maker is another problem!

Hi William,

The former. The classic one is to force prebend, say with a baby stay, with the mast blocking in and so not be able to see that the mast heal is too far forward for that prebend and rake setting. The result is an S bend with a terrible hard spot at the partners.