As recently as five years ago, selecting an alternator was simple. Most of us had 12-volt boats, with a few 24-volt. And 12-volt alternators were about 50% efficient, and a little better than that for 24 volts, but not enough to justify a change, at least not as the only reason.

But now we have a whole new generation of alternators with claimed efficiencies as high as 80%, and further, with the availability of higher-powered DC/DC chargers it’s easier than it was to install a charging system and battery bank at a higher voltage than the loads on the boat, so it’s time to take a deep look at choosing the best alternator for our particular usage profile1.

Login to continue reading (scroll down). Paid membership required:

Hi John . I went a completely different way . I got an Echo Tech alternator and direct coupled it to the the end of the crank shaft on my Yanmar 3jh engine that came from a blown up electrical end of a generator . It runs at 1800 rpm and gives me 220 amps at 12v at that RPM . No belts , no side loading of the crank shaft .

Hi John,

Sounds good. A stand alone DC generator. I will be comparing stand alone against on engine alternators in part 2.

Look forward to that . I also put a Wanner Hydra Cell on the same engine . 220 amps and 40 gallon an hour water maker .

Hi All,

Last year I destroyed our 50 year old Westerbeke 40 by hanging an alternator onto it that the motor was not designed to accomodate. Amongst all the people/vendors I used to supply the bits to put the 250amp alternator on the engine, nobody told me not to do it. After the keyway in the crankshaft (supporting the pulley) literally distorted, destroying the pulley and irretrievably damaging the crankshaft, over a four year period of time. I took lots of pictures. Nobody (mechanics) had seen this happen before. The Westerbeke was repairable but the cost and effort made this prospect “uneconomical” ….So…we re-powered. We have a Yamaha 4JH57 in place. It was a really big job. And expensive. To be honest, the Westerbeke owed us nothing. I knew this engine well. I changed the ‘diaper’ for it for over 30 years. It was a leaking, maintenance intensive project. If I had not ‘killed’ it, it would have gone on underperforming and leaking for many years….. The NEW Yanmar is a dream. Sometimes I go into the engine room just to ‘stare’ at it! It is a much bigger motor but actually uses less fuel….. OK… MY QUESTION TO THE KNOWLEDGABLE AND EXPERIENCED GROUP!… The Yanmar comes equiped with a Valeo 125 alternator. During Sea trials we were lucky to get 35-40 amps. It is ridiculous. I asked the vendor to install a larger alternator, externally regulated. They said doing so would void the warranty with Yanmar. They claim, ‘side loading’ will damage the engine. I don’t really believe them. I know from looking into this that there are heaps of Yanmar owners using more reliable, higher output alternators on the motors. Balmar claims they have a 170 amp alternator XT-CR-170-K6 that is manufactured as a ‘drop in’ replacement for the Yanmar’s Valeo alternator. Does anyone in the group have ideas on installing a larger, 170 amp Balmar alternator? Thanks all…

Hi Devon,

Eric has done two parts on how to safely size an alternator and also how to program the regulator to make a larger alternator safer:

I strongly recommend following Eric’s guide lines rather than relying on anecdotal information from the comments here, or anywhere else, for the reasons in the pink box in the article.

https://www.morganscloud.com/2025/07/06/right-sizing-an-alternator/

https://www.morganscloud.com/2025/08/26/making-large-alternators-safer-with-whitespace-programming/

I also wrote an article on installing an after market alternator: https://www.morganscloud.com/2025/08/06/10-tips-to-buy-and-install-a-liveaboards-alternator/

Will do John, Thanks for the support.

Hi Devon,

Sorry to hear about your issues.

The extremely low output on your new setup would be very frustrating. I assume you have made sure that the reason for your low output is due to thermal and not something else like improper voltage programming. If it were my setup, I would be tempted to measure engine room temp and alternator case temp in a way that I could have the engine compartment sealed up and see actual temps during operation before doing anything else. It seems like your engine room temps might be really high or there might be another issue and it might be that putting a new alternator on won’t get you the output you want until you fix another issue.

Eric

Hin Eric,

I’m guessing the very low output that Devon is experiencing is because the stock Yanmar alternators use internal regulators that are very simplistically programmed to just keep a starter battery charged. I experienced the same thing years ago when I re-powered with a Yanmar and I know the Volvos have the same problem (from Boreal).

Of course he could have the alternator modified to use an external regulator, and I bet it would then put out full power, but I don’t recommend that because this generally results in these stock alternators burning out very quickly, which I found out the hard way when I did just that to my Yanmar mentioned above.

Thanks Eric for writing. Engine room temps are not the factor as during the sea-trial I wrote about before we had the space open so we monitor the new install. Only 35-40 amps output. On the day, the OEM Valeo alternator (rated to 125amps) temp as measured with an infrared thermometer, was about 69C…. The Valeo alternator its internally regulated. When I asked about getting the Balmar kit for it to externally regulate it, the Yanmar people told me this would void the warranty.

Do you have any info on direct mounting an alternator to the flywheel pulley on the front of the motor: no belt, just the alternator on a mount that couples to the front of the pulley? When we run the motor, underway, it is at about 2000-2500rpm.

Hi Deven,

This warranty thing has been a long term PITA with both Yanmar and Volvo, and I don’t think a direct drive will help.

Being a law abiding Canadian I would not dream of suggesting that you just keep the stock alternator around to slap back on if the Yanmar techs are visiting…although I did hear of some random Bermudian…

The other option is one of the magic boxes I describe here: https://www.morganscloud.com/2022/09/23/cross-bank-battery-charging-dc-dc-chargers/

This is what Boreal do to get around the warranty problem.

Thanks for the message John. All good.

Between the warranty stuff and the electronic controlled motor it is a new world for sure from the old marinized tractor motor. If the Yanmar manages as well as the motors in the Japanese cars I have owned in the past, I will be pleased enough. Just trying to not do anything stupid to it.

Hi Devon,

Good plan. I think that as long as you follow Eric’s guide lines on alternator sizing (see links I provided earlier) you will not do any damage.

Hi Devon and John,

Sorry, I somehow had a thermal limitation stuck in my head which it sounds like this is not. If it is just the stock internal regulator, then that is really frustrating especially given Yanmar’s position on warranty.

Eric

Hi Devon,

I also have a 4JH57 with the standard 125 A Valeo. I easily (meaning relatively low engine rpm, well below 1500) get 60-70 A out of it. In fact, I could get even more if I didn’t limit the charge current feeding my 12 V Lithium bank with two 50 A DC Buck Boosts, each set at 40 A. And this may be the difference, as the Buck Boosts also increase voltage up to 14.2 V from an entry at about 13.7 V from the alternator…

John and Eric may have a view on this, and whether it points to the Valeo regulator’s inability to deliver high current into relatively high resistance systems at the alternator’s nominal 14.55 V regulation voltage.

Hi Jean-Louis,

What’s happening here is that the buck boost DC/Dc chargers are showing low resistance to the alternator and so fooling it into thinking that it’s connected to a highly discharged battery. This is similar to the solution I suggested to Devon and discuss here: https://www.morganscloud.com/2022/09/23/cross-bank-battery-charging-dc-dc-chargers/#magic

These series of articles are so timely. I have been ping ponging back and forth about high output alternators and a standalone generator recently. Really looking at 48 volt alternators from APS and wondering about how the engine would handle the side load. Devon’s post was educational to say the least.

Feel like I am six years old and it is ALMOST December 25th. 🙂

Hi Daniel,

Yes, I agree, Devon’s post is very valuable, although I’m sorry to hear it cost him an engine. At least it was on it’s last legs anyway. Only a few days to wait for the final part that should give you the information to make the final call on this.

Hi John,

I agree on the importance of efficiency and applaud companies that will actually publish this stuff. And thank you for digging into this more, you were able to find information that I was unable to. The publicly available data on this is quite poor and as you point out, full of marketing nonsense. A friend of mine got all excited about getting a 48V alternator from one of the big brand names a few years ago but also is a big enough nerd to have instrumented it and was really disappointed to find that the actual number was around 60% for his operating point and peaked in the high 60’s.

With regards to pulley ratio, one thing I don’t often see mentioned is ability to charge at idle. You could argue that it isn’t truly required but I think it is nice, especially for using the windlass. Many of the alternators in your image won’t be charging until well above idle with a normal pulley ratio. You can fix this by going to a taller ratio but then you need to watch the maximum speed of the alternator which I have found is often hard to find. If you overspeed by too much, there are a few spectacular failure modes. I know Bruce mentioned step up ratios as high as 4:1 which could mean an alternator spinning ~15000rpm on some engines, that is not a speed you do without first checking the spec. I also don’t know how available the pulleys to do that are? You can only downsize the alternator pulley so much, at some point you need to start upsizing the crank pulley and if you do that, you need to change your waterpump and other pulleys if you want them to run the right speed.

Eric

Hi Eric,

Good point on the benefits of high outputs at idle, but I just want to check that I had it right when I pointed out that a taller ratio ups the danger of damaging the engine since torque will go up, assuming the same power output from the alternator, because the engine will be at a lower rpm?

Yes, switching from a 1:2 engine:alternator ratio to a 1:3 ratio would yield more torque on the engine at a lower RPM. Some engines will be ok with that; others may not.

Overspeeding the alternator is a real risk. An alternator with a 10 cm diameter rotor and a 1:2 pulley ratio is subjecting its rotor to 3,578 g of centrifugal acceleration when the tach reads 4,000 rpm; in other words, the centrifugal force trying to tear the rotor apart is 3600 times the rotor’s own weight. Switch to 1:3 pulleys and it has to withstand 8,051 g. At 1:4 it’s being ripped apart at 14,314 g.

That’s not quite jet engine rotor burst energy (“For engineering purposes, the turbine disk fragments are assumed to have infinite energy at the moment of release; they will cut through any practical material and cannot be stopped”) but it’s certainly something to be careful of.

Hi Matt,

Thanks for confirming that. I finally got my aging brain wrapped around torque thanks to Eric’s excellent two part article, but even so…

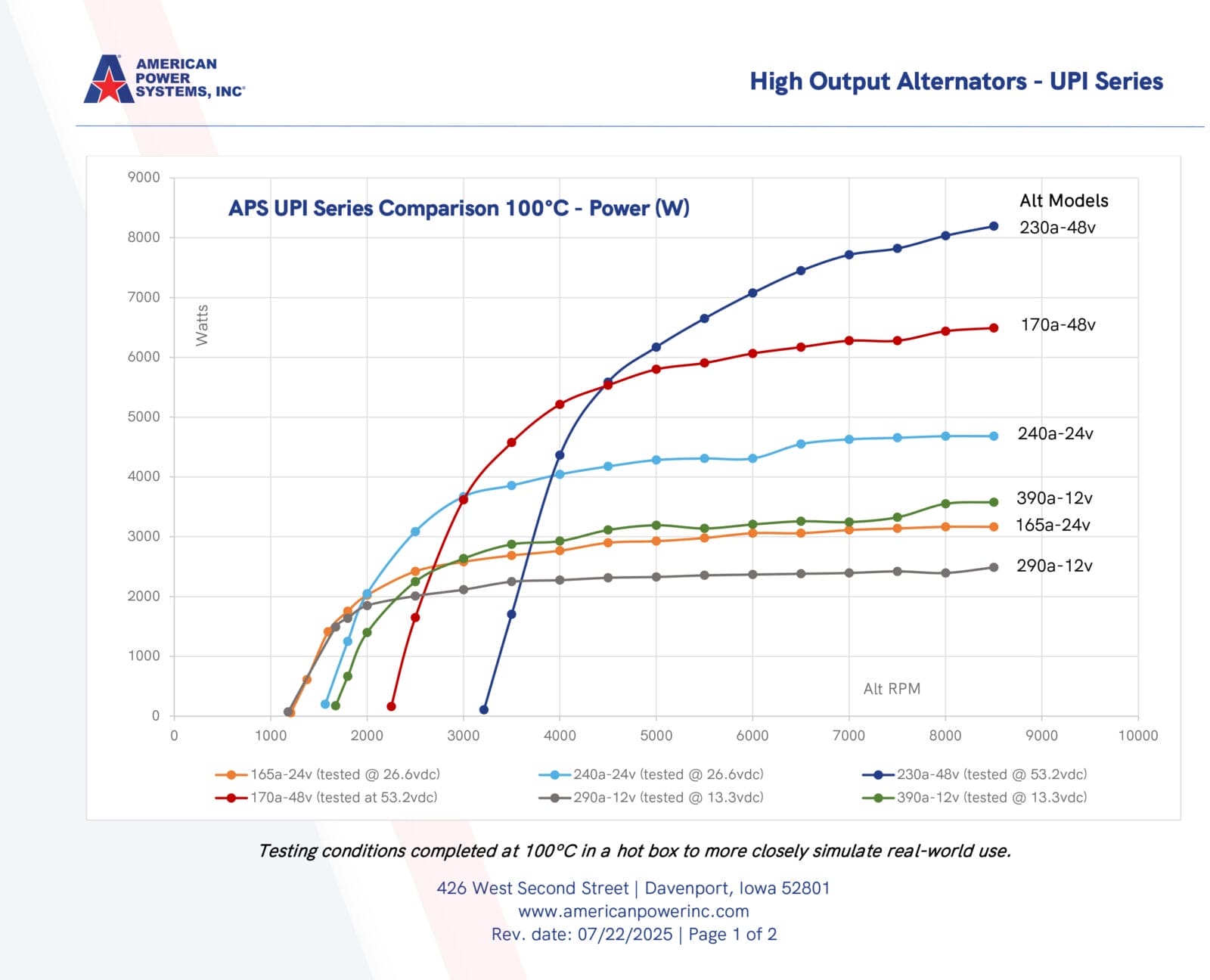

I received an email today and the curves for the new APS UPI alternators have been published.

https://www.americanpowerinc.com/pdf/UPI_comparison_sheet_OPE_new_v2.pdf

Interesting to compare the power curves with the UPI vs HPI alternators.

Hi Daniel,

Thanks but those are the power to rpm curves and are the same as the ones I published at the top of this article. The curves that are still embargoed, and are much more important, are the ones that include efficiency and torque.