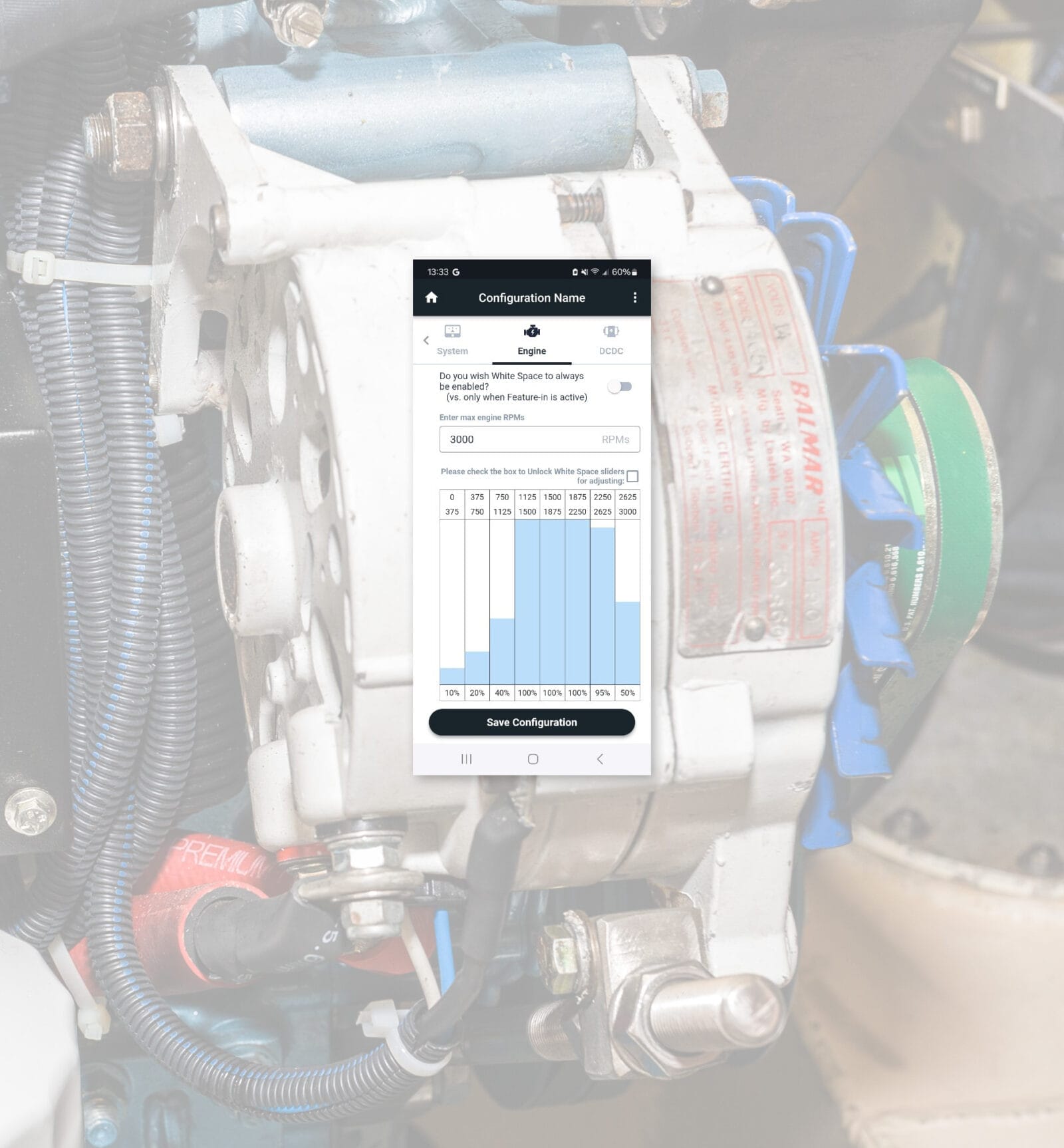

In Part 1 we learned that powerful alternators can have several negative performance, reliability and safety impacts; however, we assumed basic alternator regulation. But by controlling the alternator output with respect to engine rpm we can mitigate a lot of these problems.

This article covers how to pick our values to input into any regulator with this capability and then how to actually do the programming if we use a unit from Wakespeed, John’s preferred regulator.

Calculate Maximum Power

Let’s assume we have a power-hungry boat and therefore want the most powerful alternator that will be relatively safe for our engine, using the following assumptions:

- 40-foot cruising sailboat

- 50hp (37kW) engine at 3000 max rpm

- Cruise rpm 2000

Login to continue reading (scroll down). Paid membership required:

While this article is very helpful if u intend to use both the Alternator and propulsion power at the same time, I respectfully suggest that that may not in fact be the right answer especially if the Alternator is your BACKUP electrical source. Our solar array is my primary means of keeping my batteries charged. My big Balmar is a BACKUP generator. As such I have a switch on the Alternator regulator ignition power line. This allows me to depower the Alternator regulator when I just want the engine to provide propulsion power. I seldom see the need for both propulsion and power generation, but if that occurs, the techniques described will make that more efficient/ effective. If I need electrical power, run the engine out of gear w the Alternator regulator powered. This gives me complete control over these systems.

Yes I use a DC-DC charger to charge my starter battery from the house. That way my starter is always ready to go.

Hi Edward,

Yes, this article is geared towards people who are trying to maximize charging from alternators and therefore fit large alternators to their engines. There are definitely other use profiles out there and it sounds like yours is one of them. But even those other use profiles can often take advantage of whitespace programming as the reasons for using whitespace all still apply. In your case as it sounds like you have a big alternator, you could do whitespace and then either have a field disconnect or use one of the configurable Wakespeed inputs to shut it down when not desired.

You mention running the engine out of gear with the alternator producing. Unfortunately this is a very inefficient way to charge. It makes me wonder whether you would be able to avoid it sometimes if you were charging when already motoring even if you were not totally sure you need the energy? On the other hand, because of weather variability and load variability, if you don’t need an additional charge source sometimes, you likely have a hugely oversized solar array so you may be just fine (see https://www.morganscloud.com/2023/01/24/balancing-battery-bank-and-solar-array-size/).

I have played around a bit with trying to prioritize solar on our boat over the alternator. For our use case, I found that I should just charge from the alternator whenever the engine is running as if we have a big charge deficit, the solar will not be able to make it up and if it is small, then it is very little extra fuel to do the charging. We do have the bulk and absorption voltages set slightly higher on the solar so the alternator cuts back first but I suspect the total fuel savings from doing that are very minimal for us.

Eric

Hello Eric,

I have a configuration with max. two 4kw alternators on a Perkins 4236. The engine has no less than 230nm torque and all seems to run well. Unfortunately I dont have torque values from the alternator manufacturer.

Up to now, I was more fearing that there might be not enough load for the engine when I am charging at anchor without propeller load. After reading your great explanation here, I am now worrying that I am going to destroy my newly overhauled engine by over torqueing it.

I did all the calculations based on kw in an excel-file, which I would like to show you, but cant upload it here.

I dont feel comfortable any more using both of my alternators now and would like to get a competent opinion. Can you help me with this?

Hi Frank,

Eric explains in this article why there is no way to accurately determine whether or not a given alternator is safe on a given engine other than to stick with the largest alternator the engine manufacturer sanctions and then increase a bit from that using whitespace as described in this article.

Also note that it’s not as simple as matching max torque from the engine to max from the alternator because of side loading and other factors Eric explains.

Full details here: https://www.morganscloud.com/2025/07/06/right-sizing-an-alternator/

If it were me, and given it will be hard to find the max alternator spec for that engine, and particularly given you have just spent money on an overhaul, I would remove one of those alternators and downrate the other one with white space to no more than 3 kW at cruise and 2kW at low rpm.

Hi John, thank you for the tips. I have been using the single alternator setup for more than 700hrs. Oil is crystal clear, no consumption between changes.

Having had the crankshaft in my hands during the overhaul and comparing it to some ford big block crankshafts I played with, I think there is a big difference to all modern engines. Calculation of material masses are different worlds. )Lets not talk about efficiency.)

The second alternator was mounted from the beginning (and turning), but not activated as it was more thought as a hot standby. What about the sideload in this case of passive usage?

At the very positions of the two alternators were the original alternator and a compressor for a vigo boat system. that was both v-belts and now its serpentine-belts. The tension is the same i would guess.

I have just recently started to use the second alternator, because the genset is currently waiting for spareparts.

While it was impressing, pumping 6.7kw into the battery bank. (Lfp ca. 35kwh), this was far from the brochure max output (6.9kw). Reducing this to 2kw at anchor would definitely not enough load for the engine.

Both alternators together require approx. the same power as the propeller and that is significantly less than 50% if I didnt calc that wrong.

So summarizing: The criteria to consider – if I understood correctly – are:

sideload on crankshaft

too much torque used by the alt

lost power of the engine

not enough load on the engine (glazing …)

comparatively bad efficiency

is there anything else, i havent seen?

Thank you. Thats a very interesting discussion for me.

Hi Frank,

We are really on the wrong article for this discussion. Eric covers all the issues here: https://www.morganscloud.com/2025/07/06/right-sizing-an-alternator/

That said, I understand that 2kW is not enough load on the engine, but that does not change that you are far exceeding Eric’s recommendations for safe alternator sizing and therefore I shared what I would do given that I regard the main engine as mission critical and therefore would not take this level of risk with it. That’s me, you may decide that you are OK with it. Heck, you might even be OK over the long term, but as Eric explains, in the above linked article, there is no way to know that.

The bottom line here is that charging with the main engine at anchor is always suboptimal, but I would take the risk of glazing, which can be managed, over that of placing loads on the engine that it was not designed to take.

So, again, if it were me, I would either cut my electrical usage (the best solution), or fit a generator. https://www.morganscloud.com/2025/07/24/efficient-generator-based-electrical-systems-for-yachts/

Hi Frank,

As John says, I think the other article on right sizing an alternator contains the information you are looking for. If it is not clear, leave a comment and I will do my best to chime in.

Unfortunately, propulsion engines make poor generators. You are correct that running a big engine with a light load is not good, both for the engine and for fuel efficiency. Taking huge amounts of power off with a belt is usually a bad idea and unfortunately one where we don’t have a ton of information. That leaves generators and non-belt driven setups on the propulsion engine. Some engines have a PTO which can make it feasible to set something up DIY but most are not well suited and risk decreasing propulsion reliability. All this is assuming that you need to charge off the main engine regularly. For a boat where the vast majority of charging comes from either the alternator while motoring, shore power, or renewables and only very occasional out of gear charging is required, it is not a big deal and installing a lot more solar or a generator doesn’t make sense.

Eric

Hi Eric,

thanks for your expert statement.

did a lot of calculation for that too.

O definitely do not want to use

the engine as my primary charging source – way too loud!

Would be great if one could calculate or measure the torque needed ny the alternators. Who could do that if he has the alternator?

And per the sideload, do you think and oil analysis would show wear and tear of the crankshaft half …? sorry.

Frank

Hi Frank,

Calculating torque from the alternator is pretty easy if we have an idea of the efficiency. Take the output power and divide by the efficiency to get the input power. Then take the alternator rpm and calculate torque (see the section “Torque and Power” here https://www.morganscloud.com/2024/05/21/understanding-power-and-torque/). Then if you want to know crank torque, multiply by the pulley diameter ratio.

I am skeptical that oil analysis would tell you about bearing wear in time to act. Plain bearings are intended to have the shaft always riding on a thin film of oil with no contact between the shaft and the bearing. Once you get contact, things go downhill quickly so it would show up in the oil analysis but you could well have already done enough damage that a rebuild should be performed or maybe you will even spin a bearing. Obviously, plain bearings do have some startup contact and this is why you should wait until you have oil pressure to apply any load to the engine. Modern plain bearings are not just basic bronze cylinders and this is to help deal with the startup issue which was a real problem in old engines. If you want to see more on failures, the recent GM L87 engine recall is really fascinating. It appears to be the combination of going to a very thin oil combined with surface roughness issues on parts causing this and their fix is to increase oil viscosity. In fact, one of the best ways to increase the load carrying capacity of a plain bearing in a pressure oil system is to increase viscosity of the oil but that comes at the price of increased parasitics.

Eric

thanks for your comments Eric, I appreciate them a lot.

I will do the math for the crankshaft torque, now waiting for the efficiency ratio from Electromax, Dont expect a critical load by the 2 alternators. See the major problem is the sideload.

Agree with you that the oil analysis result is too late. It may help to find out if the past 700 engine hours have already caused serious damage of the bearings.

Of those 700hrs prob. 680hrs were with one actively charging alternator and the other one passive (0-field) but still connected by the belt . Do you think it makes a difference for the sideload if there is torque or not?

As the existing alternators are at the 10 and 2 o clock position (seen from the craftshaft). What if I add a similar tension at 6 o clock? Could it be equalized?

And another maybe crazy idea: What if one mounts a gearbox at the front end of the engine where the two alternators could be fixed directly? is this like a PTO?

Every manufacturer of smaller marine engines should be aware that charging huge battery banks should be second nature.

Maybe this is out of the box thinking but there are solutions needed for the power hungry crews of today. If we want to motivate our families to join us on the water, we cannot just reduce the consumption until it fits the readily available generating capacity…

Hi Frank,

Torque due to the alternator scales pretty well with power output at higher outputs but starts to diverge at lower outputs. The reason is that there are some parasitics from the alternator that don’t go away as the output is decreased such as the power to drive the fan, bearings losses, etc. Most of the graphs that I have end before this no load conditions but the one that I do have suggests that it is safely <20% of the max torque and that it does vary by rpm.

As to canceling out loads, you can do this to a degree but not fully. There is no magic way to change the torque on the crankshaft, the torque on the crankshaft is the same whether you have 1 alternator or 10 alternators provided the net power supplied by the engine is the same. What you can change is the side load on the end of the shaft. The side load is the vector sum of all the loads. If you have 2 alternators perfectly opposed on 2 belts that are in grooves right next to each other, it is possible to end up with very little side load. However, maintaining this balance is almost impossible as you need the belt tensions to be identical, the alternators to put out the same power at all times, etc. You can certainly do a lot better than a single alternator of twice the size but you can’t actually eliminate it. If considering this, I strongly recommend a free body diagram and then considering what happens if the loads are not perfect such as a broken belt, popped fuse, etc. Note that the components that can fail due to a large alternator can be sensitive to side load and/or torque so you do need to be aware of both.

As to mounting a gearbox to the front of the engine, this isn’t going to change the torque unless you change the charge curve vs rpm. I assume you still want the same alternator power for the same engine rpm which means torque is constant. Maybe what you are getting at is to run a jackshaft up there so that there is no side load on the engine. This is certainly doable if you run a coupling which can appropriately deal with the misalignment as you will never get perfect alignment and then a shaft fully constrained on its own bearings. More popular is to run this sort of arrangement on the tail end of the engine where you know all components are made for high output. The issue with using the tail of the engine is that you need to put a spacer before your transmission or use a power takeoff (PTO). In my mind, the ideal would be a PTO as they pretty much always have clear cut power ratings that take a lot of power and can be set up to be quickly disengaged so have minimal impact on propulsion reliability. Small engines tend not to have a PTO but bigger ones do and some transmissions include one that is coupled to the input shaft so the same as being on the engine.

This trend to huge battery banks and huge alternators is very recent when compared to engine development cycles. I hope the manufacturers start to address this but it will take time and not solve for the engines already in the field or the ones that are not primarily designed for the marine market.

Eric

I’ve been looking forward to this article and I’m not disappointed! Much appreciated.

I had a new Balmar 3kW alternator fitted, together with an ARCO Zeus alternator regulator. Considering how quickly the alternator temperature regulation kicks in, I may be gaining very little over a more moderately-sized alternator, but at least now I have a deeper understanding of the principles behind the white-space programming. Thanks!

Hi Giles,

I am glad to hear it is helpful. It seems that I am hearing a lot of comments about regulators cutting back quite quickly due to alternator temps these days. Have you measured the ambient temperature of your engine room after running for a bit?

Eric

Great article. We are just installing Mastervolt 12kw lithium 12V house bank. We did a parallel Lifeline AGM backup bank after reading your article on redundancy for lithium. It is there for emergency only, and should last a long time with no cycling. The back-up 12v bank, 24V winch bank and 12V starter batteries are charged by DC-DC chargers, or the 6kw Northern Lights driven battery chargers (3). Everything beyond the house lithium bank is always charged. Replacing the engine and 120V fridge compressors and holding plates with a 12V compressor w evaporator plates. Removed the 2nd alternator from the engine, and went with one Arco high output alternator on the standard engine bracket. We will carry a spare. Having just one easily accessible/changeable belt makes life easier. The engine and its crankshaft should be happier without the fridge compressor and 2nd high output alternator hung on the front end. Added 1200 watts of solar to the Bimini, dodger and deck. I have zero interest in davits or davit mounted panels as so many boats do these days. One good Gulf Stream beating would be too much risk. I think we have the right amount of solar, genset, batteries and redundancy with risks minimized. All of your battery, alternator, regulator and solar articles have led to so many questions and leap-frogged solutions. So thank you. My technical network believes the Arco regulators are more reliable than Wakespeed. Time will tell.

Hi Peter,

Sounds like a great and robust system. If memory serves this is for a J/160?

Interesting that your contacts think the Arco is more reliable than the Wakespeed. I have heard the opposite, but, as we both know, that does not make it true, so please advise how you get on with the Arco over time.

One thought, did you consider taking the lithium bank up to 24 volt and running the 12 volt loads of the lead acid kept charged by DC/DC chargers. I’m in two minds about the recent trend to increase the voltage of the main bank and so am interested in your thinking.