I have noticed lately that looking for and discussing the “best” seems to be more and more the way the cruising world is going. I blame two trends:

- Forums, where much of the discussion seems to be an argument about what boat or piece of gear is “best”, which leads to ego polishing around who has the “best” and ego bruising for those who lose the best-battle.

- YouTubers who leverage the quest for best in their relentless battle to break out of the pack of thousands labouring for nothing (except making Google richer) while trying to become one of a handful of YouTube stars cruising the world funded by advertising.

But the bottom line is that there is no best. We all have different aspirations, needs, boats, cruising grounds, finances, and levels of experience, so to suggest that there could be a best of anything for all of us is just plain silly.

OK, enough generalities, let’s look at the specific thing that set off the rant above: YouTube video #100 from Steve over at SV Panope in which he sets out to identify the best anchor with numerical analysis.

Now, before I go any further, I need to make clear that nothing in this article is a criticism of Steve and his excellent work, or to suggest that he is in any way biased.

Rather, I think that the work Steve has done over the last few years is some of the most important anchor testing done by anyone, anywhere, ever.

And if we listen carefully to Steve, he constantly warns us of the weaknesses in the quest-for-best, but the problem is that those in the grip of best-lust tend not to hear such warnings.

So let’s figure out how each of us can use Steve’s excellent data, mixed with my real-world experience, and that of others who comment here, to arrive at a best anchor for each of us.

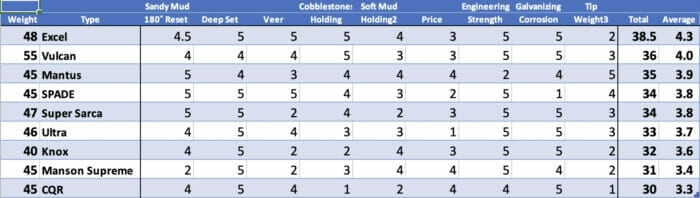

And to make that task manageable, let’s just focus on Steve’s top 11 anchors. See the table I built from his video at the top of the article.

Now, given that we are trying to individualize the conclusion here, what follows is how I would select an anchor, not how you should—veering off into the latter would kind of miss the whole point of my rant above, wouldn’t it?

Anyway, although this will be all about me—I know, what else is new—I will discuss my reasons for the selection criteria I chose, which will help you develop your own.

And, by the way, this is not just an academic exercise given that Phyllis and I are now in serious boat shopping mode and almost all the candidates we have looked at are equipped with anchors that we want no part of—amazing how many obsolete anchors are still out there.

Weaknesses

So, first off, when I study the above list two methodology weaknesses jump out at me:

Hi John,

For me, the main missing factor is weight, ie if we were to increase the anchor weight up to the next size, how would the table look then.Having moved up from a 45lb CQR to a 60lb my anchoring concerns were totally gone.I do accept some issues with the CQR but the improvement was remarkable.

The table would not be a linear improvement I would expect.

Hi William,

I agree, weight is always a big factor, and we talk a lot about that here: https://www.morganscloud.com/2019/04/24/specifying-primary-anchor/

That said, I’m not sure how adding weight to this analysis would do anything but muddy the waters, particularly since, if memory serves, the CQR we had that let us down so many times was 85 lbs and our 65 lb backup SPADE regularly outperformed it—faster setting and better holding. In fact it was setting the two together, because we did not trust the CQR, and regularly diving on both that convinced us to go over to a SPADE and get rid of the CQR.

Hi John,

on one side, I agree that considering weight as a variable would complicate the analysis. On the other hand, I figure that for any given boat, going up sufficiently on weight could take the strength out of consideration. (Confirmation bias disclosure: I have bought a super-sized Mantus)

Hi William,

I had a 60+ CQR on my 40-foot sailboat for years and always made it work, albeit with some (sometimes lots) of effort in certain anchorages in the Bahams/Carib. But it was in the Med that the CQR really gave us a hard time and we were lucky as the new generation anchors were just getting some press. I switched to a similarly weighted Spade and it was like night and day. Getting my anchor a good stick went from being a hit or miss over 30 minutes or so to a first time set most every time.

My best, Dick Stevenson, s/v Alchemy

Hi Dick,

We had exactly the same experience with the CQR when we got to the west coast of Norway where it went from the marginally functional we had experienced in the thick mud of the UK and Nova Scotia to completely unusable often refusing to set after over an hour of trying and at least 5 attempts. On at least two occasions we gave up after trying several set attempts in several different places and went alongside. At that point we knew the CQR had to go.

Luckily we already had a SPADE as a secondary anchor. Swapped them over and problem solved, even though the SPADE was lighter than the CQR.

Hi John,

Interesting. We spent 2 seasons wandering (joyfully) the coast of Norway and experienced no anchoring issues. Of course, we had our Spade by then. Dick

Hi Dick and John, I am now building a larger yacht and have a 135kg Manson supreme.

On the advice given here I will switch to a Spade and paint it with white Jotun glass flake.

Hi William,

I think that’s a good call. It would be heartbreaking to build a boat from scratch and then have her end up on the beach for want of an anchor replacement that is of truly infinitesimal cost in comparison to the boat.

When I brought my boat it had a massive old CQR buried in the forepeak. With considerable effort I wrestled it out of there and dumped it on the finger with a ‘free’ note on it. It was gone the next day and I’ve never regretted it.

As a spare anchor it was far too heavy to deploy; getting it out and onto the foredeck would have been a dangerous mission however I went about it.

(My primary is a decent homemade stainless steel copy of the original Bruguel that both PO’s have told me worked very well for them. Eventually I might upgrade it to a Spade or Excel, but there are more urgent things to be done first. And for a storm anchor I might go to a large two part Mantus that I can store in the bilge near the centre of the boat.)

Hi Philip,

We gave away our CQR too, it’s a lawn ornament in Norway.

One thought for you. I would not put too much weight on the recommendations of the past owners of your boat. Confirmation bias is a scary thing. Test it carefully yourself, particularly reset after a wind shift (use Steve’s protocol) before trusting it.

I’m also not a believer in the idea of storm anchors, particularly stowed in pieces in the bilge. In my opinion our best bower should also be our storm anchor. More on why here: https://www.morganscloud.com/2019/04/24/specifying-primary-anchor/

Speaking of YouTube, I have always lusted for a version of Mystery Science Theater 3000 where your head shadow watches various YouTubers and makes snide remarks. That’s would be glorious I think.

Mr. Lambert, yes, I would pay money to see that, I think.

Me too!

Rocna, Bruce ?

Bill

Hi Bill,

I would not touch either or even put them on my list.

Both have dangerous dragging modalities: https://www.morganscloud.com/2019/05/24/anchors-resetting-failures-with-rocna-and-some-thoughts-on-vulcan2/

I have had better luck with the Bruce (& clones) than with most other cheap anchors. They do beat the CQR. But I don’t trust them unattended.

It’s probably worth noting that, at least around here, training courses and the supply chain are 15-20 years behind. You can’t just walk into a store and buy a Spade etc. and the guy behind the counter almost certainly won’t know how or where to find one. We at AAC may think this stuff is obvious and proven, but a large chunk of the recreational side of the industry is still telling people that welding a hinge on an 1850s farm plow is the right way to hold a boat in place.

Amen Matt – well said!

Any dock walk on the Great Lakes will reveal CQRs and Bruces galore, although I do find it significant that when I changed up to a 30 kilo SPADE, our old 45 lb. CQR did not find a buyer on Kijiji. We ended up giving it to the Sea Scouts who sail out of our old club in Toronto.

I simply ordered the SPADE online and shipped directly to our club. I can’t say it’s had much of a test in terms of squalls or wind shifts on the way to Nova Scotia, but we expect to anchor out extensively cruising the “Atlantic Bubble” this summer.

Good call. That’s what I did with my Excel. But for all your friends who don’t want to pay shipping, Crafts Cove Marine in Halifax (no conflict of interest; I almost bought an anchor from them) carries the Spade. Here’s hoping the lockdown breaks soon, but meanwhile I’m sailing out of Chester, and yes, I’m the only one so far 🙂

We are waiting on East River Ship Yard to complete the jobs we are there for. A lot of their customers are from the HRM and are not supposed to be preparing their boats. See you out there.

Hi Ben,

That’s good to know given that I will be looking for one soon, thanks.

John

Cost should not be a factor? Let’s evaluate that notion… Try these two words: “Discount Parachutes.”

Hi Karl,

Love it!

That reminds me of an old friend who was a parachute rigger in the US Navy. He had a sign behind the counter where the flight crews picked up their chutes. “100% guaranteed, if it does not work, bring it back and we will give you a new one”.

Considering that an anchor is, conceptually speaking, a sort of brake, parking or otherwise, it’s interesting that very few people buy a car based on its braking power. It’s just assumed that the brakes will be adequate to the forces involved, are known due to extensive testing and have to meet certain minimum standards and have to be pretty far gone to fail those standards.

But sailors have you…and Steve.

For those in the UK and previously unable to source the Sarca Excel Jimmy Green Marine has a pallet load of them en route from Oz as I write.

I have made a cardboard template of the Spade and I think it will fit my boat without modifications so I will probably go for the Spade but its nice to have an alternative.

An FYI: The March 2021 has an admiring article, examination and case study of the Excel anchor also looking at their aluminum version for kedges, stern anchors and those concerned with weight.

My best, Dick Stevenson, s/v Alchemy

Ummm.. “The March 2021”???

The March 2021 what?

Guessing you’re referring to a magazine. Question is, which one?

I suspect Dick was referring to the Mar-2021 issue of Practical Sailor [page 7]

Thanks!

John, I sold my Rocna Vulcan, partially due to your recommendation and Steve’s about the reset issues of Rocna, and have been using the Excel for over a year now and love it. As a full time cruiser who lives on the hook, my anchor setup is crucial to me.

Question– have you tried the Excel at all? Could your preference for the Spade be biased because you’re used to it and have used it a long time? (OK, that’s two questions, including a leading one).

I’ve never used the Spade, but based upon your recommendation it would be my first choice behind the Excel, but because I haven’t tried it in real life conditions I can’t say which is better, I just “assume” the Spade rocks because trusted sources like you and Steve say so!

Hi David,

No, I have not tried the Excel, but Colin has: https://www.morganscloud.com/2019/04/09/spade-sarca-excel-or-some-other-anchor/

And even if I did try an Excel for a few weeks, that would tell us nothing, (unless it turned out to be a terrible anchor), which I don’t believe it is: https://www.morganscloud.com/2019/04/09/spade-sarca-excel-or-some-other-anchor/

David, did you sell an original Rocna or the newer Vulcan which doesn’t have a roll bar? I have just sold my roll bar Rocna and replaced with a Vulcan. I hear the mantra that price shouldn’t matter, but Amazon are now selling Vulcans to order, at half the price of a Spade. That is a big difference. I need to get some hours on the Vulcan but am hoping I don’t have to change again. Anyway be interested in which Rocna you sold.

The new one, still looking very shiney:

https://www.cruisersforum.com/forums/members/27361-albums1537-picture33613.jpg

Well, I can’t say that after reading this site for a few months, that I’m at all surprised who the adjusted winner was, but you do at least admit you might be biased. Regardless, I agree with most of your weighting’s, and I thought the exact same thing when I first saw his chart. And since I’m planning to buy an excel for our new boat, I will try to find out if they’ve corrected the hole deficiency you’ve noted, because I absolutely agree with you on that. Though I wouldn’t be against carefully enlarging the hole if necessary and I was sure it wouldn’t weaken the overall system. On that note, I’m a little skeptical of your assessment that old, really rusty chain that doesn’t “appear” to have lost any measurable diameter is in fact still full strength. You seem like a man who appreciates science – next time your replace some chain (or just cut off a couple feet if that’s no time soon), send it to a lab and have them do a pull test and see how it holds up. It’d certainly be an interesting data point (send a piece of new chain along as a control). Thanks for the article.

Hi Peter,

I didn’t “admit” anything, given that admit implies bad behaviour. What I did was share my experience, which obviously colours my opinions, so others can evaluate what I say to make the best choice for each of them.

And I would never enlarge a hole in an anchor. Anchors are no place for amateur modifications at least unless you have the engineering training to do a full of stress analysis before messing with it. Also, enlarging the hole will remove the galvanizing and make it rust, which seems to be important to you.

And finally, I did not say that the chain was full strength, what I said was:

This was based on careful measurement with a dial micrometer against an unworn part of the chain.

Rust can cause pitting, which causes stress concentrations, which are starting points for fatigue cracking.

If it is uniform, superficial rust, and you clean it off before making your inspection, the effect may well be minimal.

But I would not assume no or minimal loss of strength simply from the diameter, if pitting is present.

This is one of the reasons why we specify chain’s working load as a small fraction of its actual breaking strength.

Hi Matt,

Yes, I’m aware of the dangers of pitting, so we also polished several links up and looked very carefully at them with a magnifying glass, and those at least looked good. (We were on our way to Greenland so were being super-careful.)

Also, let’s all keep in mind that the commercial chain use world, including offshore fishing and binder chain on trucks, where the consequence of failure it pretty terrible, don’t even use galvanized chain.

The point I was trying to make is that yachties tend to get overly worked up about a bit of rust on chain and anchors and then try to justify that by saying that strength will be materially affected, where in fact it mostly won’t, particularly because, as you point out, a large safety factor is used.

Bottom line, if someone doesn’t like rust spots that’s just fine with me, but don’t try and justify it by making a bunch of claims about strength reduction.

Anyway, we are getting a long way off subject here, so I probably should not have used the chain metaphor as it seems to be turning into a red herring.

Interesting about the Excels John.

I bought one four years ago after reading your articles about Spades. The local anchor specialist actually reccommended the Excel over the Spade as said a few Spades had come up with only the shank.

Anyway one day we were anchored at my fathers least favourite anchorage that he’d spent 30 years avoiding, ‘shit holding in there, drag every time’ he’d said countless times. (CQR)

We stopped in at that anchorage one afternoon as the wind was 35 and climbing. Down went the Excel and the wind really started howling about an hour later, gusts of 55 out in the Colville channel but more where we were because of the steep hills.

The boat was doing over a knot hunting at anchor, the chain taught as a bar and I was very happy it was daylight in case we started dragging, but it didn’t budge at all.

Next morning when we left (there wasn’t a breath of wind!) we pulled the anchor up (we don’t have a chain capstan so it’s the old school manual method) it wouldn’t budge, it was the only time I’ve had to tie the chain off and drive over the anchor to lift it off the bottom, it had dug itself into the end of the flukes as shown by the hard clay stuck to it.

Been sold on the brand since then so found it interesting to see your results.

Hi Murry,

Glad you like you Excel.

That said I’m pretty sure the often repeated assertion that SPADEs come up with just the shank is just one of those memes that gets going, but has little basis in fact. (If you know of specific documented incidence(s) please advise.)

There was one incident some 20 years ago where a boat was lost in New Zealand when a SPADE came apart, but I’m pretty sure the anchor was assembled backwards since at the time WEST marine were sending them out that way (first hand experience).

Anyway, since then SPADE have modified both anchor and bolt to make separation pretty much impossible, particularly since the bolt is not load bearing in use.

Maybe that was the incident they were referring to John, the shop has been in business many years (Chains, Ropes and Anchors in Auckland) and they seem to know their subject a lot better than most.

(they sell both brands so thought it was interesting at the time they recommended excel).

They didn’t mention the modification though so who knows, perhaps the markup is better on the excel.

Hi Murry,

Their markup is almost certainly better on the Excel, given that the SPADE must be shipped from North Africa and the Excel from Australia.

Hi John,

First of all, good to read you are back on those controversial subject with your … er … flare.

Interesting analysis but you do understand that you are setting yourself up to have the Spade come in a distance 2nd if, and it is a big if, the Excel has seen the error in their ways and beefed up the shank to chain connection. If it is given a 5 instead of your 1, the Total would be 292 and average 26.5.

I knew mathematician who was a near genius warned me of a condition called numeritus. It is a condition that make people prove something on numbers alone which may or may not prove anything.

Hi Timothy,

First off, I don’t see 292 to 280 as a “distant second” any more than I see the present 280 to 272 that way.

Second I really don’t mind which anchor comes first. Like you I have huge suspicion of this type of analysis, and that was the whole point of the my article: be careful with stuff, make your own decisions, think carefully about your own weightings, and don’t let anyone else tell you what’s “best”.

That said, I think the exercise has benefit. Certainly got me thinking about a whole bunch things, including one big criteria that both Steve and I missed…

Hi John,

I bet it was a relief that Steve hasn’t managed to find a real performance weakness with the Spade yet. Just kidding, on a more serious note, I think that if we look a little deeper at the data, it doesn’t change your conclusion. Your weightings seem very reasonable to me so lets keep that for the discussion. When you have multiple categories for a single metric like performance, I generally try to weight the total category then break out weights below it but since you ended up with 68% of the weight going to performance, I am not worried about it. When reviewing a Pugh, the first thing I generally do is look at consistency, often having a 1 and a 5 ranking is far worse than two rankings of 3. What you see is that actually all the top few anchors in the performance categories are consistent with each other (they are unfortunately not consistent overall but I figure that is a reflection of the bottoms) so there is no standout which might average the same as all the others but have no specific weaknesses. Another good test is to try to throw out each column temporarily and see if the rankings change. For performance, they are basically unchanged among the top anchors but what does happen is that when you look at all columns, the Excel really gets penalized for chain attachment which I think is reasonable but should be understood.

To me, where it gets tricky is when you try to combine data sets. Steve knows that he is testing in limited bottoms and has actually stated that he hopes to test in some other bottoms and has specifically mentioned both hard sand and grass which I look forward to seeing. With this limited data set, you end up having to pull in more data unless you cruise Puget Sound and the San Juans only. Prior to him doing these video tests, there were a bunch of pictures taken of anchors in action, primarily by one couple in the Med, that werehelpful. I believe those were mostly hard bottoms and some were multi-layered. Since the photos were not of anchors of the same weight with similar treatment, you have to be a little careful looking but they did show some trends which don’t always give the same ranking as the Panope testing presumably due to the bottom. Then someone like you (John) who has enough experience with their chosen anchor in their chosen areas to draw on their own experience as well. For example, you have a lot of experience with a Spade in Kelp, something which most of us only encounter occasionally and even then it is usually not a true kelp forest. My own experience with the Spade has been much more limited (50 sets?) and with smaller anchors that I did not personally own. It was leagues better than anything I had previously used but as we got south along the US east coast, I started to notice that it was struggling to set in heavy grass and in hard sand sometimes had trouble burying deep which you can see in the photos of it in the Med. When it came time to buy myself, I got a Rocna believing that I could get similar performance in most bottoms and improved in hard sand and weed but what I missed was the reset issues in cohesive seabeds so in the end made a poor choice. At that point it was a question of buying a Spade or the newcomer Mantus M1. Had I been sticking to Maine and north, I would have bought the Spade but some of the places I had seen it struggle are places we go to with some regularity so we decided to go with the Mantus and accept that it was not as robustly constructed and there is always a spare aboard. My hope was that someone would design an improvement that combined the best attributes of the best anchors and I still hope that, especially with the roll bar bending Panope has found.

At one point I was tempted to put a bunch of anchors into CAD (this can be a little tricky but between manufacturer information and pictures at good angles is doable for a few with not too much time) and try to understand what metrics corresponded to good anchor performance. With CAD of a few good performers, you could easily do things like measure tip weight, measure tip weight when on different angled slopes, measure tip weight with a blob of mud stuck to the fluke, measure the incidence angle of tip to the soil (my hypothesis on the problems with the Mantus M2 is that the shank is effectively too short making this too great of an angle and there is not enough resistance in the wings in a soft bottom), look at the effects of tolerances for things like shank parallelism to the fluke, etc. Of course, this would have been a bunch of work and only really applicable to someone interested in designing a new anchor. Inevitably it would have ended up with many hours in my shop building my own anchor and I just didn’t want to go there so never did any of it. I would assume that anchor designers should be doing some of this work and I certainly hope that they are not only designing to the nominal case as that is what often gets you in trouble. There seem to be a few companies looking to push performance now so hopefully one of them will improve on what we have today and if they do, I will happily buy one. One thing that I am convinced of is that it is possible to improve over all of the current anchors but the improvements may not be as large as going from the Bruce generation to the Spade generation. And while I hope that anchor manufacturers keep iterating, I also hope that Steve of S/V Panope keeps doing his thing as it adds lots of value but is a lot of work too.

Eric

Hi Eric,

Good analysis, as usual. To me the big take away from your comment is that further improvements could be made, and I certainly agree with that. That said, I fear that development seems to be a bit stalled with most of the effort going into marketing, rather than development.

I think the other problem is that very few anchor buyers (maybe less than 5%) have any idea at all about what really matters in anchor selection, so even if a good engineer developed a better anchor they might not get any market traction, particularly since I also agree with you that any further improvement is unlikely to be anywhere near as dramatic as that made by SPADE over the Bruce and CQR.

History supports this rather negative view in that it was over a decade before the SPADE and Rocna really stated to displace the old anchors and even today people cling tenaciously to their Rocnas despite its known and dangerous weakness.

Hi John,

I hope your pessimism is wrong but I fear that it is right. On a product like this, it is always hard to know where the next improvement will come from. The number of anchor manufacturers that have come and gone continues to be high (remember the XYZ, the Hydrobubble, the Oceane etc). This being a small business, most people capable of doing anchor development won’t be capable of marketing so that makes it especially tricky.

One of the really interesting things to me about Panope’s testing is that a lot of the failures occur at loads that you would encounter in a severe thunderstorm or real storm but are above the loads that many people power set at which is not a great place to be. This really speaks to the issue of many people thinking an anchor is working perfectly when it isn’t at all.

Eric

Hi Eric,

Very good point about the number of cruisers that don’t set their anchors properly and are therefore often nowhere near as secure as they think they are. I would guess that this is a lot of the reason there are so many Bruce anchors still out there since size for size the Bruce has very poor ultimate holding.

Off topic a bit, but have you ever given any thought to the question of concave or convex fluke shapes in relation to ultimate holding? I used to think that a convex shape like the SPADE or Mantus was always better, and still think that might be true. But on the other hand, perhaps a shape like the Excel buries deeper. Any thoughts? I need to take a deep dive into Steve’s videos and see if there are any clues to the answers.

Hi John,

I have given some thought to the concave vs convex debate but to really get to the bottom of it, I think you have to also have a background in soil mechanics which I do not. I do think that blanket statements lumping all convex or all concave anchors together in terms of performance are dangerous and miss the point that it is much more nuanced than that. I believe that the highest holding power is generated by the anchors that set best, keep seabed flowing across them, bury deepest, have the biggest flukes, have a good fluke shape and have the largest fluke angle. These are all obviously somewhat intertwined and improving one can make another worse.

In terms of setting, I do think that there are some small benefits to concave in some designs. Looking at ballasted anchors like the Spade and Excel, the ballast will contribute more to tip weight on the concave anchor if everything else is equal. If you think of the anchor as having 3 points of contact that define a triangle, most of the ballast is outside the triangle for a concave anchor so it actually creates a small moment which disproportionately adds to tip weight. Convex anchors have the ballast mostly or all inside the triangle which means that its weight is shared across the 3 points of contact. Also, the angle of incidence is going to be different. The convex anchor typically has a toe that is turning down while a concave one is turning up so you will get some angle change and this would favor the concave all other factors being equal.

As we now all know, keeping seabled moving and not getting stuck to the fluke is important not just from a setting and resetting standpoint but also from the standpoint of holding power. By keeping it flowing, the anchor can set deeper and it gets under undisturbed soil. Concave anchors are pretty safe here, the seabed is constantly being forced off of them whereas convex runs the risk of compacting it into the fluke and not keeping it moving. Given that there are some anchors like the Spade that perform very well but also do have some amount of soil compacting on the fluke, I suspect this is not a hard and fast line as to having any buildup on the fluke. Bragging about the anchor lifting up huge amounts of seabed is definitely not a good thing.

Deep setting is definitely important to high ultimate holding as it means there is more soil that needs to move to drag although it does have its limitations both in terms of ultimate holding in places where there is a barrier to digging deeper but also in terms of ease of retrieval. I suspect that fluke geometry plays a roll, the ballasted anchors have more resistance to burying the fluke than the unbalasted ones as you have to force the seabed apart rather than just cut through but then they also don’t have to try to bury a roll bar once you are set to that level. When it comes to the concave vs convex question, the deepest burying anchor may well be flat like a Bugel or Fortress followed by concave. The Excel appears to have a few key differences than a Delta in that it has a flat surface around the perimeter and this may well be enough to give some of the benefits of a flat or concave anchor in burying. When combined with good setting, I think the ideal anchor would leave the soil almost undisturbed just with a thin slice through it leading down to the fluke.

If you meet all of the other needs, there should be some benefit to a small amount of concavity of the fluke to help concentrate force but it would take a real soil mechanics person to answer the question properly. Also, they would have to answer it for many seabeds and I think that the ideal amount changes.

To me, the key in all of this is balancing the factors and some anchors balance it better than others. For example, the Rocna has a comparable fluke size to the Mantus M1 and a significantly higher fluke angle but somehow whenever the 2 get tested side by side, the Mantus almost always has higher holding power. Thanks to Panope’s videos and a couple of other sources, I believe that the difference is that the Rocna does not keep seabed flowing across it leading to it not burying as deeply and having an effectively smaller amount of soil above it engaged whereas the Mantus is one of the few anchors that come close to leaving the soil almost undisturbed with just a slit. The king of holding, the fotress, has huge flukes at a high angle and buries deep with its flat shape. When you look at the anchors out there, I think that there are some incentives to go concave but if pushed too far, it can quickly result in much worse holding. If you showed me a very concave anchor and a flat anchor and I had to choose without any testing, I would take the flat any day for holding.

Eric

Hi Eric,

Thanks very much for tackling that. I learned a lot, but the particular stand out point for me was the idea that an anchor should slip cleanly into the mud leaving as little disruption as possible. Totally stands to reason, but I had not really thought of it in quite that way before.

Eric, I am just a mere sailor without your engineering credentials, but I did a little work for Brian Sheehan, formerly of Fortress Anchors, and part of our discussion revolved around the ad hoc term of mode of action,, in other words, the means by which the anchor works. With tip-heavy anchors such as the SPADE, this is arguably accomplished via entering the seabed at a favourable angle for burying and makes use of inertia of the anchor itself. The Fortress goes in more like a garden hoe in that it relies on area to do its holding after the initial sharp entry at its fluke tips. Different modes of action, or so it seemed to me. Different seabeds/substrates would seem to call for it, which is why our inventory is a 30 kilo SPADE best bower, and a 21 pound Fortress and a 15 pound Fortress for the rare time we want a stern/kedge anchor.

My wife and I were discussing this after breakfast. We worry ourselves sometimes.

Hi Marc,

What I wrote is certainly not definitive, there are people who have studied this problem much more than I and there are also people with other relevant training such as people trained in soil mechanics. I would certainly love to hear from any of these people if they are members of AAC.

I would argue that inertia might not be the right word for how an anchor like a Spade digs in (that would imply it doesn’t want to change position and that everything is happening much more quickly) but yes, they use tip pressure to get the fluke in and then a combination of that tip pressure and the force of the soil on the partially buried fluke to keep it going in. I do agree that Fortress and Danforth set differently from other anchors partially due to very little tip weight and partially due to the pivoting flukes. Since they have such low tip weight, I believe that they rely on a few factors to get them burying. One is simply very sharp tips which helps tip pressure to compensate a little for the low tip force. Probably more importantly is that they start their initial set at a very small angle to the seabed and can usually get under enough material before there is enough resistance to cause the fluke angle to go to the maximum and they have to really dig. At this point, they can dig as the tips have caught enough to resist them pulling through so the only direction to go is down. In very hard sand, I have seen them stand up quite early and then the tips pull through and they stand no chance of setting unless you release tension and let it sit back down. The lower the final fluke angle, the easier they are to set but also the ultimate holding power goes down so 32 degrees seemed to be the industry agreed upon compromise point. My experience and I believe a lot of others would agree is that these anchors can really struggle to set in some bottoms where an anchor like a Spade has no issues. Danforth and then Fortress just pushed the compromises to a different performance point, they have amazing holding power to weight but they get it by setting with very low tip force which doesn’t always work well. I see uses for them but they are much more specialty than the anchors being discussed here in my opinion.

Eric

We consider them “lunch hooks with benefits”, so I would concur. I do think as you’ve pointed out that, not to make a pun, anchors with these very different modalities cover the most ground for the typical cruiser. We’ll know more after this summer as we intend to anchor out a fair bit, and indeed, if the COVID numbers stay high here in Nova Scotia, that might be necessary.

Nice. Let me add a conversation starter.

Veering Performance. I’ve done some veer testing, but Panope has taken it much farther. Three things seem to contribute to the ability to turn without upsetting: deep setting, a shape that can slice sideways, and drag aft (like a riding sail of drogue).

The advantages of deep setting are obvious.

The need for drag aft is more subtle, but I observed this when testing in-line tandems; the exact possitioning of this back-drag is what keeps the anchor straight when turning. My current theroy is that side kick-outs (Excel kick-outs, Mantus wings, and the Fortress stock) are the best way and kick-ups are the worst way (Delta, Rocna). The drag must be aft and low.

Finally, the fluke must be able to slice sideways. Flat or slightly convex seem to have the edge.

So where does this lead? I don’t know.

Interesting and a little provocative. We’ve been mulling over the pros and cons of a riding sail, particularly as our two backstays make it a litte more complex. It’s possible, one might think, that even our high aft deck or pilothouse might provide that drag aft. I will check out Panope’s veering tests, as Steve’s is a metal sailboat, I believe, as is ours.

Hi Marc,

I believe that, in those locales that attract wide ranging cruisers, you will find few riding sails. You will find whether veering loads feel that problematic. That said, I would think that twin backstays might lend themselves to an easy to put up and design riding sail as the “wedge” design appears to be the most effective.

My best, Dick Stevenson, s/v (another) Alchemy

That “wedge” solution is our current idea, as well. We have yet to encounter a veer so severe that I was concerned about breaking out, probably because of the paranoia I bring to forecasting and the opportunity to drop the hook in protected places. I’m sure either the weather or the anchoring ground will test us this coming summer.

Hi Drew,

Me neither, all I know is that our SPADE had never dragged once set in a couple of thousand sets in places from Greenland to the Eastern Caribbean and most places in between over 25 years and that during that time we were often subjected to huge veers, sometimes scores each hour resulting from katabatic gusting. Also, for the last 15 years or so (since selective availability ended) we have always set a GPS WP on the drop point, and then set a tight drag alarm as well as checking if the anchor had moved off the drop point on retrieval. We also would check with radar ranges. In all that time the SPADE has only moved a measurable amount once and that was in very soft mud in a small cove in your part of the world.

My point being that all this theory is great, but it needs to always be sanity checked against real world experience. I know you know this, but I do worry that those new to this are getting overly influenced by YouTube videos that, no matter how well done, are just a few sets in a limited variety of conditions.

Hi Drew,

Great prompt, characteristics that relate to veering performance is one that is definitely less obvious to me so it is good to hear your thoughts on it. I would not have come up with the drag aft concept but now that you say it, it makes sense. A few things I would love to hear your thoughts on:

Is there a common failure mode for most of the anchors? For example, do they roll down towards the angle of pull until the fluke pulls free or at least is up enough that the angle causes it to corkscrew out? I would think that the combination of a decent amount of roll with a lot of yaw moment in the absence of axial force would be a bad combination, almost like breaking out an anchor at 1:1 scope except that there would be more resistance on one side of the fluke.

It strikes me that shank geometry would likely have an effect. A long shank with a “low” attachment point would seem to provide more moment about the yaw(vertical) axis and less moment about the roll (shank) axis than a short and tall one. Of course, changing this geometry has many other effects on the anchor performance.

I would also think that fluke geometry plays in here. For example, if one fluke is a flat triangle while another is cone shaped, I would expect the cone shaped one to be less roll stable. I would also think that anchors that have lower yaw resistance would have an advantage, resistance to verring seems like it can’t be good.

Do you have any thoughts on how mud fouling effects veering? In general I consider it a major negative as we know it causes resetting issues and it isn’t consistent so would be hard to design to work with. But with an anchor remaining embedded and actually veering, I would think it would be a negative too. It seems like it will promote uneven blade pressure and give the anchor not the desired shape.

Finally, I am curious if you have thoughts on the Fortress performance in veering (not resetting). It doesn’t have the best reputation for this but is that confusion, lack of burying deep enough, fouling on the flukes, etc?

Eric

This. I bought a Manson Supreme to replace and undersize Delta during the Rocna shank controversy. Although it was a big improvement over the Delta, both in size and shape, the clogging and reset problems in sticky mud eventually became clear to me. At first, I thought I was the only one, since no one talked about it. Since then, I’ve come to see a roll bar as a “patch” solution to righting, used when better solutions aren’t working. SPADE is one the best in this way.

That said, I’m not a big fan of scoops either. Soil anchors for construction and snow anchors for climbers are slightly convex, because in most conditions this causes more compression and better holding. The Excel is obviously on to something, using what amounts to twin convex planes. It’s a subtle aproach and there is probably room for evolution.

But you nailed it,observing how slowly the market turns. For the last decade it’s been in love with roll bars. The combination of the bar for righting and a big fat scoop is visually obvious and comforting. Make it bigger and they’ll like it even better. The Excel looks like a Delta, so it couldn’t work. The fluke on the SPADE looks too small. And all of them work well enough, that unless you stay out in bad weather, sample poor holding ground, and really pay attention, they all (newer designs) seem about the same–they work. How many times have you read “This new anchor is great–it held all night in 25 knots!”

Hi Drew,

So true that most anchor reports are based on one or two experiences in comparatively mild conditions and are therefore useless.

Also people seem to be taking Steve’s testing as definitive without refining it with real word experience and common sense. The way people defended the Rocna for years after it proved to be a dangerous anchor is a classic example of how this lack of open mind and due diligence can end badly.

The other thing is that some of these new anchors that are scoring high are from new companies with little track record and even so a good score on one of Steve’s videos and they become “the new best”. Scary stuff.

Another anchor thread. Where ever you turned to, all anchor threads turned the same way. I love it ! So much passion and intensity.

Great stuff! My instant reaction when I saw the first table, and having not read the article was no weighting, irrelevant categories (if holding security is the factor of interest) and a real risk of skewing the average by the irrelevant categories.

I like your analysis, in the context of adventure cruising, but slightly disagree with some of them as I think only holding categories should be used, but that is just my opinion. I agree that cost should not be a consideration in anchor holding tests and I would also include galvanising in this as zinc rich paints can be used to manage galvanising repairs. I would also consider attachment as not necessary and simply eliminate an anchor that does not allow a strong shackle to be used.

I think in the type of cruising you support with your research and advice, the conclusion is great as it ultimately represents a reliable anchor.

I chose a Knox for 2 reasons: I wanted to change my CQR to a better New Generation Anchor (NGA) and Knox was made local to me and therefore supported a local business. I did my research and concluded that it was a fine anchor for my needs. I am planning on northern cruises and would likely buy a Spade for the extra security it offers.

Your comment on price is quite correct, it is not the first thing on your mind when you really need that anchor to hold.

Hi Alastair,

I could certainly see the wisdom in dropping all criteria except holding and setting, but I would always add strength too.

Hi John,

interesting article. I’ve never really considered the shackle issue to be a big deal as we were always able to solve it by using two properly rated Crosby 209 shackles to adapt however I appreciate that it caused some concern to others. Even before Collin’s article came out we had been discussing the issue with the manufacturer and he responded by modifying the shackle holes to accommodate appropriate shackles. This change in manufacturing was made over a year ago.

thanks again for all the great content on your site!

Nick Shaw

Ground Tackle Marine

North American Distributor for Anchor Right Australia and Excel Anchors.

Good to hear, thanks Nick! Now if you could just get them to add the recommended chain size for each anchor.

Hi Nick,

I really don’t like the two shackle option since the shackle in the anchor stock will not be able to properly align to the loads and therefore will be subjected to pry loads that no shackle (or swivel) is designed to take, so in fact I would call two shackles poor practice even though I used to do that before I learned better.

So, very glad to hear this is fixed. Could you please provide us with a table showing the new hole sizes in each size of anchor. You can upload it as a jpeg. I will then add that to our review of the excel.

John,

Many shackles, and certainly many Crosby shackles do allow side loading, although to a derated factor of WLL. The shackles even have marks at 30, 45 and 60 degrees cast into the body in some cases, for both Bow and Dee types. At 90 degree loading typically there is a 50% reduction in WLL, if the load is taken at the end of the Bow or Dee. I do agree with your point, hence mine is moot, as any anchor shackle should be able to fully articulate through the slot to give an in line pull. Just for information: –

https://www.thecrosbygroup.com/catalog/shackles/application-information/?language=en-US¤t_catalog_page=94

Hi Alastair,

Yes, I’m aware of that specification, but as you say, it’s not relevant to this case because here we are adding the prying load against the pin cheeks. I spoke to a Crosby engineer some years ago and his answer to how much it would reduce the SWL of the shackle was “don’t do that”.

I think the reason that people get away with it (including me before I knew better) is that the safety margins are so high and most of the time anchor rode loads are pretty low, but then again it only takes once. Bottom line, it’s poor practice.

Ok, I’m a bit bummed because I just bought an Ultra Anchor and swivel! At least I was smart enough to avoid the roll bar, and I was happy that the Ultra was at least on the list. However, I’m trying to avoid buyers remorse and would appreciate a little color regarding your view of the Ultra anchor. I purchased a 100lb Ultra for a 41,000 lb displacement HR48.

Thanks!

John

Hi John,

My thoughts on the Ultra are here: https://www.morganscloud.com/2019/11/11/some-thoughts-on-the-ultra-anchor-roll-bars-and-swivels/

By the way, don’t forget the search function in our menu which can get you quickly to just about anything we have written about.

Hi John, I’m about to replace my anchor so great timing, thank you. Just a quick question, the Vulcan on your test list, is that the new(ish) Rocna Vulcan or another product?

Hi Alex,

Yes, Vulcan made by Rocna. Some thoughts here: https://www.morganscloud.com/2019/05/24/anchors-resetting-failures-with-rocna-and-some-thoughts-on-vulcan2/

Also, I suggest scanning through the comments since I think there are some reports on the anchor from members.

In the marina here, all the serious cruisers ( Bass Strait, Tasmanian waters) have either an Excel or Super Sarka. Everyone swears by them. Also helps that they are locally made just up the road in Melbourne.

Hi Tony,

Indeed a good data point. That said, one thing I learned a long time ago is that common usage is more indicative of ease of sourcing, good marketing and reasonable price, than function. For example the Rocna became a dominate player even though it has a very scary dragging modality and even after the company got caught using substandard steel for the stock.

The point I’m making here is that good seamanship is a lot about keeping open minds about our gear and not becoming unthinking fan-boys following the herd.

Great discussions here. I think the key probably isn’t in splitting hairs among the top performers which will probably do great everywhere. It’s probably more valuable to find the anchors that should be rejected. For example, my experience with the Rocna on the East Coast in Chesapeake was not great (lack of setting, a few drags on wind shifts) and when I switched to a Mantus I saw a huge difference and have never failed to set or stay set. But since my main cruising areas involve softer substrates like mud and sand the Mantus seemed the best choice given it’s relatively large fluke area relative to weight. It’s performance in mud was correlated in Steve’s tests and also in practical sailor testing sometime ago, and perhaps slightly better than the spade. But, I can see that if you anchor in a lot of rocky areas the rollbar vulnerability could give you pause….

I think the point is any of the anchors on your short list are likely to perform the same side-by-side in 99% of conditions…

Hi Michael,

I agree that all will probably be good performers. That said, one thing I do worry about is which of these anchors will, over time and hundreds of sets, turn out to have hidden weaknesses that could become a serious problem in a cruising area that finds said weakness. For example, the Mantus might last less than a month of cruising in Labrador, or even maybe Newfoundland before getting irrevocably bent in the rocky bottoms prevalent there.

I also wonder how some of newer anchors will make out in challenging substrates. For example many people are just assuming the Vulcan is as good as a SPADE, and it might be in easy anchoring areas, but given that it has far less of its weight on the tip I wonder what will happen in hard bottoms and or kelp.

So, if it were me, and I was again bound for challenging places I would always carry at least one SPADE because we know from experience that it works well everywhere, and has no really bad habits. Or to put it another way, consistent reliability and flexibility are things that none of the above, or anything that Steve is doing, measure well.

Side Loading of Shackles. Someday I’ll research this, but I have not dug deep into it yet. It is interesting.

https://www.youtube.com/watch?v=nDIq9y3Xpeg

According to Crosby, a shackle loses 50% of it’s strength when loaded at 90 degrees. But…

Fortress puts the pin in the shank. CQR does it that way, but the shackles are burley. All stockless anchors for ships are pin-in-shank, and they yaw.

I’ve seen good engineers argue that side loading is easier to engineer with certainty than a situation where the bow can jam at an even worse angle, which I have seen. I think CQR saw it that way. I asked several people at Fortress and never got an answer; with their shanks, I think it is a non-issue since they bend first. So would Danforth.

I don’t think we know enough about anchor shank strength and shackle jamming to be definitive on this issue. I know I don’t know enough and I can find well proven contrary examples. Bow in shank seems obvious, but I don’t think the best choice actually is obvious.

Just one of many design elements.

Hi Drew,

Now there’s something I had not thought of: that the shank would bend first. And as it bends the the shackle loading will become ever better. I can only say…Duh! Definitely time for a rethink.

That said, I did note in the video that the shackle was through a hole that is a close slip fit and that the tester had also shimmed the lug it’s through. So now I’m wondering about what happens when the shackle is oriented with the the pin through the anchor shank but it’s a sloppy fit and the shank is way thinner than the shackle jaw width. Both are the case with most anchors.

Any thoughts on that?

I’m staying with “I don’t know” and I’ll be collecting info and my thoughts.

Ah, the rarest answer on the internet!

Hi to All,

These data are not the latest from Steve.

I invite all of you to see Steve videos regurarly because thare are many update as he test various anchors.

Everyone has opinion but here are data that are not updated at this day.

As I can see in Panope video #109, after Epsilon test (the last test of group 45 lbs anchors), the best anchor was Viking 20 (4.9 vs Excel 4.4 [Spade 4.2]).

The mistake was that you have never mentioned Viking … giving us partial infos. Your opinion … is opinion but the datas are datas.

I clarify that I’m not a Viking sponsor … only rigth info.

Thanks,

Adriano Mari

Hi Adriano,

Perhaps I was not clear enough. My intention with this article is not to provide a definitive analysis of the best anchor, but rather to suggest improvements to Steve’s rating methodology that each of us can use to select the anchor that is best for us. The other thing I bring to the table though these articles is wide and deep real world experience that provides a useful sanity check on Steve’s videos. So you can use the above methodology to evaluate the Viking yourself, a far better way than just me (or Steve) telling you what to buy.

Perhaps if you have a read through our anchoring online book you will find this approach useful as you make your own decisions: https://www.morganscloud.com/category/anchoring-mooring/online-book-anchoring/

Very happy with my Spade Anchor. Re. Corrosion… my boat came with a Spade and I noticed there was fairly significant corrosion. I sent a picture to their customer service and they replaced the anchor for free. Evidently their early models did not have sufficient insulation between the led weight in the tip and the rest of the anchor. Been anchored for 4-5 months per year for the last 5 years and don’t notice any corrosion- although the yellow paint is completely gone.

Hi Michael,

Thanks for the report, that’s pretty much our experience too.

Can we talk about chain for a moment?

The problem we have is that the current galvanized, rusty in parts, is difficult to get down into the locker when lifting the anchor so we have to stand there and make sure it beds down. It is a notorious problem on some oyster 72s.

One proposed solution is to replace the galvanized with stainless which is more ‘slippery’. And the thought is that it is also possible to reduce the chain size as the stainless is stronger.

What I don’t understand is that given the chain weight is a huge part of what makes an anchoring system work at all, why would I want to reduce the weight of the chain? People seem very nonchalant about this but first principles suggests there must be a cost to it.

Hi Peter,

I would (and have) argue differently. I think it best to choose chain by strength and put the weight differential into the anchor. Weight in the anchor is far more potent in ground tackle effectiveness than weight in chain.

The argument for heavy chain is primarily that it provides a nice catenary which keeps the angle of attack, anchor to seabed, optimal. I believe this to be the case in light and moderate winds, when it really is not necessary, but the catenary largely disappears when you really need it: gale force winds and above.

I make this argument more fully in an article: “Choosing Chain: Challenging a Maritime Myth” which I believe can be found on Steve D’Antonio’s web site.

Come back if not found and/or with questions/comments etc.

Dick Stevenson, s/v Alchemy

Hi Peter, The URL for the article is: https://stevedmarineconsulting.com/choosing-chain-challenging-a-maritime-myth/

My best, Dick

Hi Peter,

I would figure out why your chain does not go into the locker smoothly and easily and remedy that issue. I would do this, even if the remedy entails some boat surgery, way before going for stainless chain of which I have misgivings.

My best, Dick Stevenson, s/v Alchemy

Hi Dick,

Totally with you on the stainless chain, what do you think of duplex stainless

Hi Dick,

I agree. I had to rebuild our anchor locker and after I did that it stowed 380′ of galvanized chain absolutely reliably. Most boats have very poorly designed lockers.

Hi Peter,

First off, I’m not a fan of stainless chain, and second the benefits of chain weight are much misunderstood and generally small to no-exsistant. You will find in depth analysis of both issues and much more in our Anchoring online book: https://www.morganscloud.com/category/anchoring-mooring/online-book-anchoring/

Thanks everyone.

I find the idea of chain weight not being the critical factor in extreme conditions persuasive.

Fixing the chain locker turns out to be non-trivial. I have a friend with the same boat and he is no mean hand with tools and whilst he has improved matters he has not solved it.

Hi Peter,

Yes, fixing a bad chain locker is a real pain in the neck job, as I can attest. That said, as I often tell myself when I don’t feel like solving a problem properly:

People with more experience than I have noted:

Some anchors set well only at high scope, after which you can safely reduce it (I guess sometimes short-scope breakout force is higher than long-scope setting force?).

In some soft conditions an anchor will hold better after it’s been allowed to “soak” (allow time for soil compaction), so a good deep set should amplify this effect.

Those of us with small or no engines will never set the anchor at anything like the load we hope it will hold, so I have the impression that at least for us, setting is just about making sure the anchor catches and begins to bury, as opposed to e.g. fouling its tip on a shell or a rubber boot or the bottom is impossible. This makes me think that one benefit to chain is that at setting loads the catenary gives you high effective scope, better set, etc, and that may ultimately be helpful after all?

Hi Ben,

We have an in depth article on all of that that covers all the points you bring up in detail: https://www.morganscloud.com/2014/01/06/20-tips-to-get-anchored-and-stay-anchoredpart-2-technique/

We also tackle catenary while setting here: https://www.morganscloud.com/2018/12/10/anchor-chain-catenary-when-it-matters-and-when-it-doesnt/

By the way, as far as I know, the only anchor that benefits from short scope while setting is the Fortress.

Thank you for calling out the “industry” of vloggers. The amount of low quality content from very inexperienced people is very frustrating.

Hi Keven,

Glad to hear that someone else is aware of this. Probably the most scary trend I see in cruising today.

This is a great thread.

I’ve just bought the Mantus with the Mantus swivel for my new-to-me boat, a Belliure 41 that weights in just under 22,00 pounds. The boat originally came with 2 CQRs (both undersized in my opinion) and a modern Fortress.

I spent quite a bit of time on the phone with Mantus going through the metallurgy of the anchor I bought and coupled with using the largest size recommended for severe storm use, I’m not concerned with the shank strength. It will yet to be determined if the shank strength will ever crop up. I’ll check back in 5 to 10 years.

One point no one has mentioned, and I’m not sure yet if I’ll actually do this but at this point I feel I will is stowage. I’m planning to take that large anchor off and stow it when doing crossings where it will be of no use. The Mantus is the only anchor on that list (as far as I know) that can be taken apart for stowage. I considered that to be a nudge towards choosing this anchor.

I very much agree that there is no such thing as “the best”, everything is a compromise. From my perspective, pretty much any of the “good performing” anchors on that list will be a major improvement over the older style anchors, with perhaps the single exception of the Fisherman’s anchor in kelp. I feel having different types of anchors on board is better – then the question becomes: which combinations should I cruise with?

Question: If the roll bar gets in the way of setting in kelp beds, why can’t you just take it off? Again this question would only apply to the Mantus where disassembly is possible. Thoughts?

dj

Hi David,

We have in depth chapters in our Anchoring online book that take a deep dive into most of the issues you mention. For example, we explain why we don’t like swivels, why stock strength is important and why we don’t recommend stowing the largest anchor below: https://www.morganscloud.com/category/anchoring-mooring/online-book-anchoring/

As to taking off the Mantus roll bar, the problem is that the anchor requires the roll bar to right itself into the setting position since it has very little weight in the tip itself. Also the geometry of the anchor is all wrong for it to work without a roll bar. Based on that, I’m pretty sure that without the roll bar, particularly in kelp, it would not work at all. Bottom line, the Mantus designer put the roll bar on the anchor for a reason.

I’ve been using a Sarca Excel for a few years now. Good results except that I have had it foul on its own chain a couple of times while lying in a reversing current situation for multiple days. The sharp angle on the end of the flukes seems to be the cause. I can’t be sure if this happens while retrieving, if it happens when re-setting on current reversal, or if the flukes were not sufficiently buried. The fouling did not result in dragging.

Hi Matthew,

Now that’s an interesting observation, and yet another selection criteria that I (and Steve) did not think to add to the above analysis. Looking at the photos of the Excel I can certainly see how the slot between the two ears on the fluke would act as a chain catcher.

Others can see what I mean on this photo: https://www.morganscloud.com/2019/04/09/spade-sarca-excel-or-some-other-anchor/

Definitely something to think about, thanks.

What an excellent example of a failure mode that a few tests won’t reveal. I’ve found that it takes 50-100 deployments on a variety of bottoms before I feel like I really know an anchor.

I have noticed that the Excel is more difficult to fully set in a very firm bottom. I do NOT mean that it has less holding capacity or that it won’t go deep (it holds a ton and will go deep), only that it takes more force to set the fluke below the surface than anchors with thin flukes, such as Mantus or Rocna. It was pointed out above that a thin blade disturbs the soil less. The anchor resets wonderfully and rotates well, but unless the load is high, it will tend to stay shallow in a firm bottom, and so it makes sense that this sort of fouling is possible.

But no doubt this requires very specific circumstances, and so most of us would never experience it, perhaps not in 1000 nights. Or perhaps much sooner on very firm bottoms.

I hate anchor testing. A lot of work, uncontrolable data scatter, and the impossiblity of recreating the conditions that ACTUALLY make anchors drag. My current belief is that modern anchors very, very rarely drag in a straight pull on a good bottom. They hold very well. It is some weird combination or a bad spot in the bottom, and how in the heck do you create tests to measure failure modes we barely understand, since we weren’t on the bottom to see what actually happened? How would you recreate a “bad” bottom (other than very soft mud, which the Chesapeake Bay provides me with in abundance).

I refuse to say anything definitive! I’ve tested lots in the Chesapeake, and I don’t even have a personal choice for an area I know so well! (I agree Spade is probably the best over-all anchor. It ticks all the boxes. But super soft mud is not it’s strength. Those that can do better in super soft mud have clogging or reset failings, or don’t like weeds.)

Hi Drew and Eric,

It has always been a delight to read your comments, but just recently, your comments on anchors and anchoring appear to me to stand above the rest. There are others also among the responders who should be acknowledged for sure, but the degree (and weaving together) of knowledge, balanced thinking, observation and clear writing in the recent comments seemed worth acknowledging..

Thanks, Dick Stevenson, s/v Alchemy

Hi Matthew,

We have had a 35Kg Sarca Excel since 2017 around NZ East Coast and the SW Pacific in a variety of seabeds. I try to snorkel down to observe the anchor set whenever the water is clear enough to find it and observe the set. By doing this and then logging my conclusions, over the last four years we have been able to usefully refine our technique with this anchor.

Key leaning (from our experimentation) has been:

Now, overall, we are happy with the Excel and getting set. But we think other anchors could be more foolproof in the setting.

Br. Rob

Great to hear you emphasise that Steve’s numbers are nothing more than the world’s best starting point 🙂

Shackle sizes:

Steve provides a few for the anchors he has on his desk, which may be a good starting point if ~20-lb or ~45-lb anchors are your game. The video is #92.

I have 1/4″ G7 chain (WLL 3150 lbs (yes, 3 significant figures is amusing)) and a 3/8″ Crosby 209A shackle (WLL 2t = 4000 lbs). It fits the Mantus M1 45 lb I got for the boat I was hoping to have by now, but currently lives on my Excel #2, for which it is overkill 😉

I have not seen the Crosby 209A in Canada, but only the 209 (which claim a WLL only half as good). Not sure why we only get the half-strength ones up here… do you think the rated shackles are worth it? It provides a bit more versatility in matching G7 chain strength without adding an oversized link.

Incidentally, if you swing that way, more amusing is the problem of splicing nylon rode to G7 chain. Nylon has poor fatigue life: you should replace it after it’s seen around 10,000 cycles (e.g. a good storm or two) at 10% of its breaking strength. If you want nylon to last for more than a season, perhaps better to work it below 5% or so of its breaking strength. For my 1/4″ G7, that means I’d want about 1.125″ nylon rode. On a 33′ trimaran. You still need the oversized link, but at the other end. Has anyone tried dacron (or UHMWPE etc) rode with a suitable set of elastomer snubbers? More of a hassle to handle, but might have redeeming qualities…

Re. Nylon working load. My suggestion is that you get a load cell and measure the the actual rode tension with rope rode (I have done this on monos, a 34′ cat and and F-24). You will find that with rope it is about 3-5 times lower than the ABYC table gives as the standard for ground tackle. The table is based on a worst case senario (shallow water, long fetch, steep chop, all-chain, and no snubber) with sharp snatching of the load. I talked to the people and did the testing.

It is hard to match any rope to G7 chain. Unless you are going all-chain, you might as well go with G4. Your just making life complicated for small weight savings. If the purpose of the chain is to provide some weight for catenary, you are not actually saving anything at all. G7 is really for all-chain rigs.

On a tri the shock absorption comes from the long bridle. Use climbing rope and the ride will be smooth! Or just use 7/16-inch nylon. Not elastomeric snubbers; less reliable and less capacity than a good length of rope. (you still secure the rode to the cleat as a back-up, but with some slack in it).

Polyester isn’t crazy, so long as you have a good lick of chain (at least 75′ in front of it to give catenary and/or nylon snubbers. It must NOT be yacht braid, but rather a high-stretch brait made for this purpose… which you probably can’t find in the US but can get from the UK, where it is more popular. The rope is secured to the bridle with a prusik hitch.

UHMPE is crazy. No stretch, too hard to grip to be practical. That said, I use a nylon rode and UHMPE bridle on my F-24. In this case, the rope provides the shock absorption. If I used polyester rode, I’d need nylon snubbers, and the UHMPE bridle is more compact (I leave it rigged).

Hi Drew and Ben,

I agree with Drew. G4 is the sweet spot, G7 for special situations only. Complete analysis of all of this and shackles in our Online Book: https://www.morganscloud.com/category/anchoring-mooring/online-book-anchoring/

Hi Ben,

Yes, getting the 209A is definitely worth it. Try Defender in the US. They do a great job of shipping to Canada.

Does anyone replace their Crosby shackle on a schedule? Feels like it could be the weak link when using HT chain and wondering if/when age or fatigue can degrade them?

Hi Michael,

If the shackle is a 209a and properly sized, it’s stronger than the chain, not weaker. Also, given that almost all anchoring loads are, I’m near certain, below the fatigue limit of the steel used for both the shackles and chain, fatigue is not an issue. You can read about fatigue limits here: https://www.morganscloud.com/2013/05/03/cycle-loading8-tips-for-boat-and-gear-buying/

Bottom line, properly sized chain and shackles get replaced because they are rusting, not because of fatigue.

Hi John,

Thanks for another great article. Newbie question – are you assuming the stainless steel version of the SPADE in your comparison or would that not matter?

I believe I have found the answer in your “specifying primary anchor” article – galvanized steel would be the material of choice.

Hi Nick,

You got it. Stainless SPADEs are not a good idea since they did not change the build scantlings but SS is a lot less strong than the steel used in the galvanized version.

The only way to make a stainless anchor properly is to start from scratch on the design and up all the scantlings. I believe Ultra may do that, but that anchor has other issues: https://www.morganscloud.com/2019/11/11/some-thoughts-on-the-ultra-anchor-roll-bars-and-swivels/

I purchased my first sailboat just over a year ago so I’m a total novice here.

My research last year led me to purchase an oversized (77 lbs for a 45′ 38k lbs boat) Ultra anchor with the recommend flip swivel. I’m surprised that it rated so poorly since the Ultra looks so much like a Spade anchor and since the flip swivel seems like it makes fouling on itself much less likely.

I made my choice based on what research I was able to find at the time (I was not aware of AAC) largely based on it’s being so close in design to a spade. How can it rate so differently? I’d love it if someone could shed some light on this for me.

The other question I have is with choosing a second anchor to compliment the primary anchor. What two anchors cover the various anchoring situation?

Hi Tom,

Your second question has already been answered here: https://www.morganscloud.com/2015/05/01/kedge-secondary-anchor-recommended-type-and-size/

Thanks Alex. I’m still learning how to navigate all of the fantastic information here. I also found the article already written about the Ultra anchor and swivel. I hope that my upgrading the weight as much as I did will help offset it’s appearance shortcomings.

Hi Tom,

Sorry I missed this. My thoughts on the Ultra are here: https://www.morganscloud.com/2019/11/11/some-thoughts-on-the-ultra-anchor-roll-bars-and-swivels/

Hi John and others,

I hope this is the right place to post this but wanted to add a few thoughts on ranking holding power. These thoughts try to look at it from the user perspective as opposed to the data perspective so even though the data may tell you 2 results are very different, sometimes the user doesn’t care as both are acceptable or not. At the upper end of the scale, I think that there is a practical limit beyond which holding power doesn’t do anything useful. If we take an average 40′ cruising boat, I don’t think it is unreasonable at all to have a 60lb main anchor. Then you have to pick your design conditions and I would suggest that 60 knots steady is appropriate, it should cover pretty much anything short of cyclones/hurricanes. If you are in an area with a decent chance of a hurricane eyewall hit and plan to ride it out at anchor, then I think it is not unreasonable to consider carrying a true storm anchor in the bilge that is something like 2-3 times bigger than your main anchor but hopefully you are just not in those areas. If we take 60 knots, that gives us a design load of something like 1200 lbs (trying to synthesize predictions from a few people including Drew). This would mean that you anchor would be seeing a load 20X its weight in these conditions. So maybe 30X would be a good point where we say additional holding power is not beneficial or not enough to be differentiated on a scoring scale. To me that would mean that an anchor achieving a >30X holding power to weight ratio would get a 5. If you don’t cap the scale like this, you can end up with a scale that makes some anchors look significantly better than others but practically, they all have sufficient holding power and the user will never notice a difference. Combining data from Steve and other tests in this normalized way can help broaden the understanding of behavior across a broader range of bottoms although the anchor sizes should be pretty close and it needs to be acknowledged that differing test protocols will give different results.

The bigger concern is probably the low end of the scale. Some of the early tests when anchors like the Rocna came out focused on hard sand bottoms where the holding power is really high and much of the conversation seemed to ignore that in many bottoms the holding power was an order of magnitude less and this was where we should be focusing our attention. Ideally, we would find an anchor that actually achieves the 30X mentioned above in every bottom so Steve’s table would just be all 5’s. You could view this as a binary where you get either a 5 or a 1. Unfortunately, I think that you are unlikely to find an anchor that truly meets the 30X in all bottoms so it is useful to have a scale that maybe goes from 15-30X as below 15X should probably not be considered so it would get a 1. Related to our discussion on Fortress anchors, this raises the question of how do you know if the bottom is good? Looking at these numbers, if I were faced with a real storm bearing down on me, I would try to pull as hard as possible on the anchor to test the bottom before I needed the holding power. What I have previously done was to move the anchor rode to the stern to use the improved forwards thrust that most boats have to set the anchor and I believe this would be my practice in the future as well. It would be theoretically possible to get more by using winches and other anchors but that would be a time consuming mess that would make it hard to retrieve all your gear. Using forward thrust on most boats should get you pretty close to the design point and doesn’t leave many bottoms where you will fail below the design point.

Of course, this is only about scoring. In the real world, I would not get too fixated on an anchor having an exact holding power to weight ratio, if it is a bit low, then it is not a big deal to simply get a slightly bigger anchor. If an anchor has only 1/2 of the design holding power, then that probably is a problem as doubling size might be a bit much. Looking at just Steve’s ~20lb data and ignoring the cobblestones making the incorrect assumption that it is representative of all bottom types, the anchors that would get perfect holding power scores by my scoring method are the 21lb Viking and 17lb Mantus M1. There are also several anchors that are close enough that with a little oversizing, they would be workable including the 17lb Mantus M2, 21lb Vulcan, 21lb Spade, 21lb Excel, 26lb CQR, 22lb Rocna. I took a look through Steve’s latest ranking chart and scoring this way would certainly change things, for example in clean sanding holding, there are anchors scoring as low as a 2 but achieving >30X holding power/weight. What really is the right way to score is certainly open for debate and I am sure someone could convince me to change some of what I just wrote. Thankfully, Steve is providing the data and doing a good job of a summary table so it is easy to look at these sorts of questions. Of course holding power isn’t the only selection criteria and several of the anchors I see as doing well here would be non-starters for other reasons for me.

Eric

Hi Eric,

Thanks for a great comment that has clarified something that has been worrying me for a long time: cruisers fixation on ultimate holding power as an anchor selection criteria.

I need to think about it some more, but I think your 15x-30x,1 or 5 scale (maybe we should just say pass or fail) is the best way I have heard yet to rank anchors.

Then, once we have anchors sorted that way, we can crank in some of the other criteria like stability, fast setting, self fouling, strength, etc; criteria that are often far more important than ultimate holding when accessing overall reliability.

Then I think we also have to use a pass/ fail criteria based on where we wish to cruise. For example if bound for say Labrador, or even Newfoundland, I would give the Mantus M1 an immediate fail because of the huge and vulnerable roll bar. In fact all roll bar anchors get a fail from me because I don’t trust hem in rocky bottoms or thick kelp.