Adventure 40 Reveal—On Deck

130 CommentsReading Time: 11 minutes

More Articles From Adventure 40:

- Overview

- Reliability And Quality

- Twenty Two Adventure 40 Core Principles

- Adventure 40 FAQ—The Boat

- How We Will Build The A40 At A Great Price AND Deliver Great Quality

- Adventure 40 Dimensions and Hull

- Adventure 40 Rudder and Steering Gear

- Adventure 40 Keel—Draft and Shape

- Adventure 40 Keel—Strength and Grounding Resistance

- Adventure 40 Rig

- Adventure 40 Reveal—Hull, Cockpit, and Rig

- Adventure 40 Cockpit 2.0

- Adventure 40 Reveal—On Deck

- Adventure 40 Deck-2.0

- Adventure 40 Reveal—Galley, Head, and Aft Storage

- Adventure 40 Reveal—Salon and Forward Cabin

- Adventure 40 Design Funding Round

- Adventure 40—Engine and Drive Train

- Adventure 40 Electrical System—Part 1, Voltage and Batteries

- Unbundling The Adventure 40

- A Model T Offshore Voyaging Boat

My biggest concern here was whether the trade-offs made in deck and rig design would bias the boat so heavily towards ocean passages that she’d be frustrating to sail in light airs and close quarters. There are places around here where the Sail Canada exam standard of “tack six times in 10 min, then gybe six times in 10 min, then reef the mainsail while making way” isn’t just a test exercise, it’s how you *have* to sail.

I’m glad to see that the boat, as presented now, looks like it’ll be just as workable (and fun) under those conditions as in the open ocean.

In a way, it brings to mind the Ford Bronco, which is designed to be fully capable in seriously tough off-road situations, but is also totally competent at performing routine day-to-day tasks. The serious off-road market with no consideration for normal daily use was good for maybe 10,000 of those a year; the “yeah, it’s capable of that if I ever *want* to, but realistically I’m going to be using it light-duty most of the time” market has already snapped up over 95,000.

By making a boat that is fully capable of serious offshore cruising but is also totally competent at the much more common day-sail and inshore tasks, the total addressable market becomes *much* larger. The commercial picture for the builder is thus more favourable, so the boat’s more likely to be built and can come in at a better overall price.

I generally agree that curved glass is a pain to replace if it’s ever smashed, but do note that a curved pane is much stiffer than a flat pane of the same weight, or else is lighter than a flat pane of the same stiffness. Curved glass is cheap when mass produced (a replacement car windshield can be had for $250), it’s the customization that’s expensive, so simply keeping the design unchanged for many years and many thousands of boats might be enough to enable an efficient OEM supply chain for spare parts.

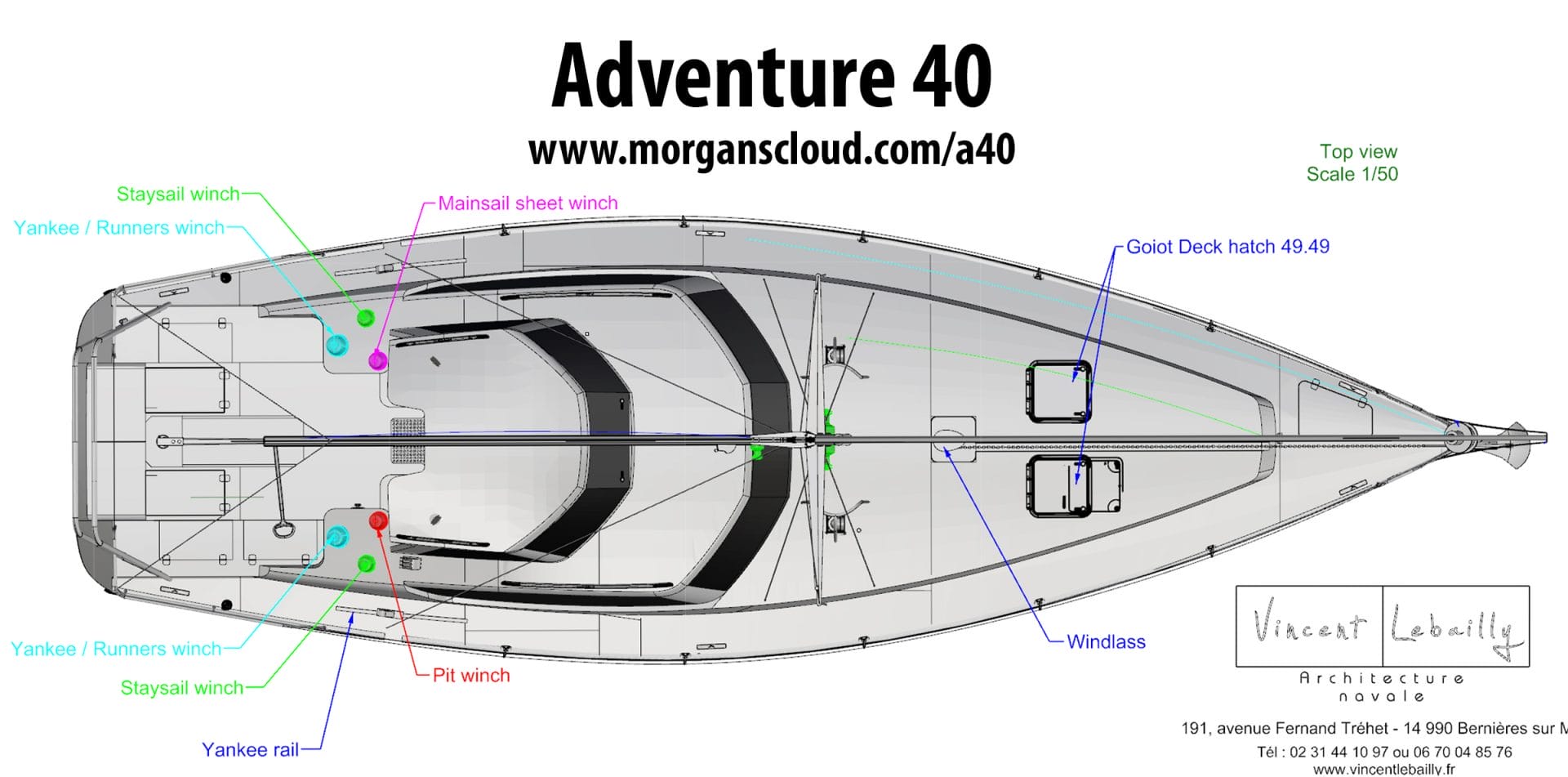

The anchor windlass and locker at the mast is nice. I’d love to see that setup used more often.

I’d be strongly inclined to use laminated monocrystalline silicon solar panels on the dodger and coach roof, rather than heavy glass-framed panels on an arch. 15 years ago, Gochermann encapsulation was so good that you could bend the panel, break the silicon cells inside, and the encapsulation would still hold them so tightly together that electrical continuity and output would be maintained across the crack. Surely something similar or better should exist today.

Hi Matt,

I hear you on the added strength of curved glass. In fact I had that in an earlier draft. But even if the factory can supply replacements that still leaves us with the issue of difficulty of replacement and shipping to a remote place.

Bottom line: I have never yet seen a boat that is more than ten years old and with serious ocean miles on it that does not need one or more windows re-beaded, so we must make that easy.

The other good thing about flat is in a remote place with a broken window we can just substitute any old piece of polycarbonate.

And finally, sure I hope thousands of boats will be built and the factory will be able to supply parts for years to come, but what if that does not happen?

Easy owner service is in a core A4t0 requirement.

Matt wrote:

“My biggest concern here was whether the trade-offs made in deck and rig design would bias the boat so heavily towards ocean passages that she’d be frustrating to sail in light airs and close quarters. There are places around here where the Sail Canada exam standard of “tack six times in 10 min, then gybe six times in 10 min, then reef the mainsail while making way” isn’t just a test exercise, it’s how you *have* to sail.

I’m glad to see that the boat, as presented now, looks like it’ll be just as workable (and fun) under those conditions as in the open ocean.”

My question: Matt, on what basis do you think so? I’m not drawing the same conclusion so I’d love to hear you expand on your thought.

Also, at what point does the draft of the A40 make it almost exclusively one thing not another. 6.5 feet…..

On the arch question: Isn’t one of the principles of the A40 that the ultimate user decide their own priorities, but have the infrastructure in place to do so cost effectively?

If an individual owner wants to overload an arch based on their individual needs, what of it? An arch allows the owner to configure equipment based on the current mission, which might change from year to year. The arch present and in place provides ultimate flexibility compared to no arch at all, in my opinion. It also makes the sailboat more marketable, not less.

Same with the dinghy question. Dinghy lashed on deck. Dinghy stored below decks. Dinghy on davits. It’s not up to the manufacturer to decide these questions. The manufacturer ideally provides hard deck attachment points, and / or interior storage space, and / or lifting mechanisms, and / or davit attachment points (back to the arch) for whatever mission the owner of the boat is currently pursuing, with missions again that may change from time time. Six months of Caribbean sailing is one mission. Transatlantic from North America to Europe followed by cruising in the med for a year, or a month, offer entirely different requirements. Same boat; different configurations, even within one ownership of the boat.

Such flexibility also gives the second owner of the boat all the options they may perceive necessary as well. Again, makes the boat more marketable, not less.

I think the mission of the design build is flexibility into the future, allowing matching boat to current owner and current mission. The more options, the better.

Said another way, the owner of a newly built home doesn’t build a 100 amp electric service if a 200 amps service might be necessary or foreseeable at some future point. It’s entirely cost effective to provide the robust flexible infrastructure at the original build stage. And it becomes a critical marketing, selling point later.

Build it robustly. Build it with vast flexibility. Let the owner configure it to their need and mission.

Mark Gadue

Jack Aubrey Tartan 34

Hi Mark,

The arch, no arch decision is still TBA, so thanks for your thoughts. And I have come around to hard points for davits.

That said I disagree on the idea of vast flexibility at a design goal. To me that idea translates to trying to build an all things to all people boat, which is totally against the A40 core values, and would result in just another boat that’s not really good at anything. The A40 is primarily an offshore voyaging performance sailboat, so if we can improve her for that mission by deleting the arch, that’s what we will do. On the other hand if the arch contributes more to that mission than it takes away in weight and windage, there will be an arch.

Can I just say that I think davits may not be a core part of the A40 mission ?

Works for me. I would hate to do that to an A40. Still, easy to give those who want to install them the hard points to do so.

I have an OVNI with its fairly substantial arch in the back. I don’t know how much it affects performance, but I suspect quite a bit. Especially since I also have a wind generator there! The arch however I suspect result in the boat being very steady on anchor (even with the mast so far forward as it is on these centerboarders). Personally I like the arch for all the convenience reasons, and they make a lot of sense on anchor and when cruising. Plus I personally think they add a lot to the looks of the boat (if that even matters, as everyone have different preferences). As a side note, I have a Hydrovane with the “Stubby” vane, and I do not notice any issues from the arch on any point of sail.

Further, I had 100 W of solar, and upgraded to 240 W in the middle of this last summer. From my experience, 100 W is not enough for anything more than keeping the batteries topped up when the boat is not being used. It is not even close to enough for topping the batteries with just the fridge on for example.

However, 240 W was more than enough to keep me totally self sufficient on anchor in the summer in Northern Norway (even though we have midnight sun, the angle of the sun even at noon is so low that we never get full output). That was while running the Eberspächer heater from time to time, the fridge, some electronics etc. While sailing, if heeled the right way, they would produce enough for a several days as long as I was using the wind vane instead of the electric autopilot. I don’t use a lot of electric equipment, but at the same time, I have a modern boat and don’t live minimalistic. The 240 watts, produce 450-500 W/h a day even on fairly bad days over the entire summer. Good days is over 1 KW/h. These numbers are for solar panels mounted on the stern arch, with no tilting, in the summer months north of the arctic circle. I don’t maintain it any other way than wiping the dust off if it’s too much. If you tilt them and actively try to harvest more energy, you can.

I guess most people on here have a fairly good understanding of their daily energy usage, so maybe this was not very useful. But I would say that having about 200 watts would be very helpful. Much less, and I don’t think it is very helpful anymore.

OPE have a lifeline solution for solar that I think can work, but require that they are removed in rough conditions and before going to sea.

I would definitely drop the wind generator! I would MUCH rather spend the money on a REAL alternator on the main engine, and just run it from time to time. It is way more predictable, less annoying than the constant noise, and gives you hot water. Also, if you sail in the areas where you can’t use solar (the arctic in winter), the weather conditions are such that you will use the engine from time to time anyway (I have no evidence for this comment other than my personal experience from living in Northern Norway most of my life).

Arne 🙂

Arch out is good for wind resistance reduction and in my opinion aesthetics as well. A diesel engine and efficient charging from an alternator and some solar on the ridged cockpit Cover would, I think work better than maximising solar space on deck.

Agree with the RIB points and inflatable dinghy. Also like the windlass and chain storage aft, a great idea for sensible weight distribution.

I think flat glass is the way to go for both ease of installation and strength of joint. However, would a Perspex type of polymer have the strength and rigidity? Likely mouldable at a lower cost than glass. Surprised that modern adhesive sealants are a risk area for sealing curved glass, but nothing to base that on.

Mast work area is good too and I feel the side deck width on a 40 footer is good to support going forward with confidence. And of course the ridged top and handholds just improves that reliability and security. I liked your articles on jackstays so would be interested to see how they work here.

As for looks, these renderings are good and the style is good, although initially I was not so sure, but not now. I love the cockpit but I am less sure of life raft storage under the table, but that is probably a concept I would need to rationalise. On passages in reduced visibility, I have removed life rafts from under seat locations, or deck lockers, for rapid access.

Regards, Alastair

Hi Alastair,

Thanks for the support on flat glass and the dinghy.

I’m not a plastics expert, but I have never seen any sort of plastic glazing go for more than about five years in the tropics without hazing and also they all seem to be prone to scratching.

Still maybe there is a material I don’t know about, but we can’t use anything experimental since that would be against an A40 core value.

Hi Alastair,

many thanks for your comment!

On windows, I reacted with a separate message below.

And making the liferaft ready when sailing in fog really speaks of one’s approach to safety!

I agree with your thoughts on appearance – you can’t have new without it being different. I don’t hate the current appearance. Like you, I’d also like to see it with white structure instead of black. I wonder if the black makes people think of modern catamarans, a style that isn’t terribly popular around here.

Matt makes an interesting point about stiffness of curved glass that I hadn’t known. Thank you for your input, Matt!

Arne makes another great point that I’m likely to be running the engine pretty often to make hot shower water, so lets make electricity at the same time and do away with some of the renewable infrastructure.

Some days when I dream of buying an A40 I imagine it paired with this 3.3 meter hard dinghy. I get the desire for a clear foredeck too. Everything is a tradeoff. I think you’ve convinced me about abandoning the arch, though, despite how excited I was for it originally.

Still can’t wait to see this available for sale!

Hi Nathan,

I agree on how cool those dinghies are. In fact my buddy Hans gave me a tour of his just a month ago. However, having seen it, there is no way to have one and stow it properly on a boat under 50 feet.

Hi John,

Overall I think this looks quite sensible. I do have a few questions and concerns but can’t see any big issues.

On the dinghy, I have to say that I am not a fan of dinghies on the foredeck in coastal waters for most boats in this size range although it is boat design specific (aft of the mast is way worse still). My reasoning is mostly based around visibility. By the time you get a dinghy up on the foredeck when you are sailing, on many boats it becomes super hard to see other boats off the leeward bow. Around here, it also makes seeing lobster pots really problematic and unlike other boats, you need to be looking almost constantly which means constant contortions to look. This shouldn’t be too hard to examine in CAD with some typical heel angles and sail trim to see if it actually makes any difference. When I look at boats sailing around, a very large percentage are sailing around in what I would consider an unsafe arrangement where visibility forward is too restricted with the most common culprit being low genoas and the next most being stuff mounted on deck like dinghies and liferafts. It looks like the A40 would be large enough to potentially use my favorite coastal solution which is the Weaver Snap Davits (https://www.weaverindustries.com/index.cfm/category/6/davits-for-inflatable-dinghies.htm) or one of the other similar systems. The reason I like these is that they put the dinghy in a protected enough spot for coastal sailing while keeping it unobtrusive and low windage and it is so fast, there is no resistance to using it. We have almost never been underway in our own boat with a dinghy in the water and it is hauled every single night although we use a more traditional system as our boat is a little too narrow for this. There are of course trade-offs and in this case it probably means having a windvane that is removable for inshore use, making sure that your MOB plan doesn’t rely on stern entry and being willing to accept a bit more pitching. At least some of the Saga 409’s were built with a special pole in the aft end of the cockpit to flip the dinghy up against. If this is not an option, for our area I would still prefer traditional davits to the foredeck for coastal work on boats where the visibility was impacted and then still stowing below for offshore. If you include an arch, there is an in-between option which is to include a rotating inverted U pole to make them do davit duty without the huge overhang of davits (not sure the name but you can see it in the stern shot from this post: https://www.morganscloud.com/2016/01/21/eala-bhan-sails-home-the-maiden-voyage-of-the-boreal-55/).

With regards to power generation, I generally agree on wind generators although for winter time trade winds on power hungry boats, they can make a lot of sense otherwise solar is the answer to me. I too am curious on whether the walk-on panels are mature enough for use or not. If they are, this would make a huge difference in how we view solar. We have a rigid panel that tilts fore and aft by about 30 degrees which really helps production. However, around here I suspect we would do even better if it tipped side to side as we spend an awful lot of the time heeling away from the sun. Side tilt is trickier to implement and it would be an interesting windage tradeoff. I wonder if anyone has ever done a comparison on typical long distance routes given the prevailing breezes, weather, etc to see which angle of tipping is better?

Other thoughts:

Eric

Hi Eric,

If you mean that a lot of water gets let through overhead hatches by means of fast sluicing water slicing through the gasket to frame connection (which happens to Lewmar hatches – and probably others- when green water is going fore to aft at speed) then I suggest this hack: Most hatches have space around the perimeter between the hatch and the deck/frame. Take an appropriately sized rope and circle the hatch filling the space and tie it off in a circle that is unlikely to migrate from its “filling the gap” position in the closed hatch. This rope breaks up the sluicing, drains its power and allows the gasket to do its job. I put these on before offshore passages and it has stopped the spritzing of salt water that occasionally sprays through, but when it does, spreads salt where you do not want it.

My best, Dick Stevenson, s/v Alchemy

Hi Dick,

That sounds like a great hack, I am sure I will be trying that. One of the mistakes I made a few years ago was taking a ridiculous number of hours to rebuild the original Goiot forward hatch on our boat rather than replace it as it has a design flaw that means it is very sensitive to how it is closed. After too many wet bunk incidents, I stuck a hastily made G10 breakwater to the deck with 3M VHB as a test and it has solved all issues but is not a permanent solution just due to how I built it. I am thinking of doing the breakwater permanently on the forward hatch and then trying your trick on our midships one as I rarely worry about it but it has caused issues on occasion.

Your idea also sounds at least as easy to use as the canvas hatch covers I grew up installing before any real sailing and it doesn’t require the hassle of making those.

Thanks.

Eric

Hi Eric,

Glad you like the idea and think it will work for you.

On Alchemy, I used fuzzy inexpensive 3/8” braid which fit snugly and cut it just a few inches less than the perimeter of the gap and seized in some similarly sized bungie cord. This allowed easy on/off and the “gap” in the back has never been a problem. I did this for all the hatches on the boat that I opened. The hatch over the nav station and electrical/instruments is only opened yearly for cleaning and “exercise” of the moving parts. This I secured on a more permanent basis the encircling rope with some small stuff.

With these inserts I have yet to get the offshore “spritz” that occasionally found its way into the boat before.

My best, Dick

Hi Eric,

I think the visibility over the dinghy on the foredeck will be fine given that the cockpit and seats are about 18″ higher than you and I are used to on a boat this size.

I base this on our McCurdy and Rhodes which had a higher centre cockpit so we could see over the dinghy fine, even though the forward cabin top is higher on that boat than on the A40.

That said, your point about davits for inshore use is well taken and there is no reason that those who want then can’t add them. We could even have a couple of hard points in the deck to mount them.

As to the forward locker, I think it may drain overboard like on my J/109. We have been discussing this and it’s still TBD.

Good idea on hatch breakwaters. They could also incorporate a bolt rope slot for pram hoods.

Hi John,

Do you know of a way to make the bow locker gravity draining without adding a surge tube? I have tried various deflectors and found that they either let a jet of water in soaking everything or they don’t allow full draining. A surge tube shouldn’t be too hard from the factory but is one of those modifications that stinks as an owner and having a constantly damp area is not good.

I hope you are right on the dinghy and visibility. Being high in the cockpit is good for looking over the dinghy but is bad for looking under the jib.

Eric

Hi Eric,

Yes, good point on the difficulty of keeping a self draining locker truly dry. I’m not sure there is a truly dry solution. So, maybe better to to just focus on sourcing a really good water tight hatch and then have a drain that goes aft to a sump in the middle of the boat with a automatic pump in it. Said sump could be shared with the chain locker.

We were set up this way in the M

Hi Eric,

On visibility. One of the advantages of the cutter rig that we really enjoyed on the M&R is that visibility is better because the jib top is high cut and the staysail is sheeted further inboard so easier to look around. Also, because the staysail is smaller and set further aft the blind spot is way smaller than on a sloop. So, on balance, even with the raised cockpit, which we had on the M&R, I think the visibility to leeward will be better than most boats.

In fact visibility was a lot of the reason that Maxime dropped the original blade jib idea, and after sailing our J/109 I think he is right—total and very large blind spot to leeward that means we must get up and lean out to leeward every few minutes.

Hi Eric,

thank you for the feedback and questions!

Yes, these dinghy storage solutions on the transom make a lot of sense for inshore!

On the slope of winch islands, we’ll have to double-check it on the mock-up, along with winch and other stuff spacing. And we have various margins to decrease the slope if it ever turns out to be necessary.

Regarding the hatches, I was thinking of raising them slightly, but of course breakwaters are another solution, with a better visual impact.

On self-launch of the anchor, we’re lucky to be equiped the AAC way, with 8mm-only G70 chain and an oversize anchor, which places us at a better starting point than most others. On top of that, the additionnal horizontal lenght of chain is 4kgs, to be multiplied by the friction coefficient in the gutter (less than 1, obviously), and compared to the 25kgs of anchor, themselves to be multiplied by a smaller than 1 geometrical coefficient to account for the slope at initiation of launching… so of course the additionnal friction will eat up a fraction of the self-launch force, but likely not enough to, together with the other frictions, prevent the launch – provided, of course, that we have a well-designed roller, with a geometry such that the anchor really wants to go down.

On securing the chain in heavy weather, we don’t know of the details yet, starting with where on the chain path will the chain stopper be. Also, there may well be a mooring cleat close to the inner stay chainplate, that could have a role in avoiding movement of the untensioned chain.

Hi Maxime,

With regards to the anchor, if you haven’t seen Steve Goodwin of S/V Panope’s videos, he does one on launching and retrieval that may be of interest. The Spade is featured at around 17:15. Unfortunately it doesn’t appear that he gives data on self-launching for it but quickly watching the video suggests that it should be very good and it likely isn’t a concern. https://www.youtube.com/watch?v=8z05gayWeRs

Eric

Hi Eric,

thank you for the link, I didn’t know of this very video!

Yes, it looks like the Spade works well even with this most basic roller geometry! Since we’ll have a more elaborate fitting with two successive rollers to facilitate self-launch and limit vertical movement of the anchor’s aft tip (and chain), it will be even better. I now recall there’s a design of such a roller by Ed Joy in this article: https://www.morganscloud.com/2016/09/14/the-quest-for-a-perfect-anchor-roller-part-1/ (in our case with the bowspit, we may be more downward-oriented) And even, in the same article, a shot of the perfect mooring fairlead! 🙂

What about putting the chain inside a tube like the Borèal? That would keep it off the deck, prevent slapping as it’s raised.

Hi Timothy,

Sure, that’s an option. Maxime and Vincent will be working on this over the next few months as these details are finalized.

Hi Timothy,

let’s add that we don’t see much reason for the chain to go in very large vertical movements when raising anchor, as long as the roller is well-designed. Also, the bottom of the gutter will push the chain slightly up when it’s tight between the roller and the windlass, preventing the chain from becoming a (bass) guitar string.

A tunnel (probably built by slightly modifying the deck and gutter shape and adding a thin composite lid) would hide what’s happenning inside, we would have to make sure that the lid can be removed in the long term, there would be increased risk that the chain catches something and leads it into the tunnel… none of this is a huge issue, but they are things to consider.

Hi Eric,

I think you are right. We never had any problems with self launch of our Spade on the M&R and the distance to the winch was not a lot different. Of course the anchor was heavier, but then so was the chain.

I wouid definitely want an arch! it is a cruising boat not a racing boat. I think you are overstating the drawback of the weight on the stern. I weighed my very substantial arch (built to hoist a dinghy) and it was 35Kg – equivalent to a child standing at the back of the boat. Is that really going to noticeably affect the pitching of the boat? Certainly I don’t feel the slightest difference since adding my arch and the advantages are just uncountable.

One small detail that stands out like a sore thumb to me – why is the engine control low down on the starboard side, directly where it will inevitably get fouled and caught by lines, and where it will be awkward to reach down to in many circumstances – eg coming alongside to a quay on the port side? The obvious place to mount it would be at the front edge of the cockpit table, where it is high up, easily reached when coming alongside, and if mounted below the front lip of the table completely protected from entanglement.

Hi Richard,

Final position of the shift is still TBA. We discussed why it’s there and alternatives in on Part 1, so if you have suggestions, please add them there.

Richard- after we just spent the last year of liveaboard cruising, including crossing the Atlantic twice- I understand what they’re saying about the problems with an Arch, AND I’m with you on how useful they can be. We had poor davits and and a poor dinghy, that experience definitely convinced me that having a good dinghy, with a simple and convenient way of launching and retrieving it daily (while an outboard is mounted)- will be a key consideration for our next cruise. We found ourselves anchoring way too close to shore/other boats sometimes because of the difficulty of launching the dinghy and setting up the outboard on those stops where we were only spending one night before moving on (so that we could just row to shore without mounting the outboard). I haven’t even begun to touch on how much I wished we had “just a few more watts” of solar generation if only I had somewhere to put it…

Sure, ultimately all my decisions/preferences went with seaworthiness of the mother vessel first, but I cannot overstate how important the dinghy was to daily life during the trip, and that aspect will absolutely factor into my future considerations of how to have our next boat set up.

All THAT to say,… I will completely understand if the A40 ends up being built without an Arch,… but I sure hope they’ll build it in a way that considers making it straightforward for an owner to add one (ie. hard-points strong enough to support an arch that can lift a dinghy with outboard) if they wish to.

Hi James,

I guess it depends on how you see convenience and how much you value it over an uncluttered boat. Phyllis and I have cruised for 30 years without davits and storing the dinghy on the foredeck when coastal cruising and deflating it and striking it below when going offshore without finding it unduly onerous or ever wanting to clutter our boat up with davits. To make that work it is important to have a decent hoist to get the motor on and off the dinghy, but other than that we just used a halyard to bring the dinghy aboard, or, in places where dinghy stealing was a problem, to bring it out of the water but outboard resting against the toe rail.

To us all of this is just part of cruising and in fact we even enjoyed figuring out how to do these tasks in the quickest and most efficient way possible. Kind of the zen of dinghy management thing.

The point being that this modern idea that all cruising boats must have a huge great heavy RIB with a big outboard is just a trend, not a requirement for happy cruising.

That said, the A40 has fixed rails around the cockpit and I have mentioned to Maxime that we should make them strong enough to support an arch and davits, but do realize that adding both to a boat this size will make here very cluttered, trim the boat stern down, negatively effect her sparkling sailing performance, and, with the dinghy in place on the davits, make the vane gear unusable—stowing the dinghy high enough to clear the vane gear would be horribly unseamanlike.

Alubat Ovni models have arch, and most of them had used windvane steering without issues.

Hi John and all,

a few words on the look: I gladly admit it wasn’t at the top of our priority list of things to get absolutely right the first time, and it coming out so strongly in the comments was a surprise! But of course we’ll have to get it right anyway.

Going forward, we’ll very likely explore (for comparison purposes, not as a final choice) a different look on the basis of not-much-changed roof and dodger volumes, probably trying a more “flat-panels-and-angles” look. In the meantime, here is an image of the same design, the only change being more white and less black. And since in the end this is a matter of taste, it would seem fair that the first owners have a say on which solution we choose – if their opinions don’t go in too many different directions!

By the way, I totally confirm that it will be practical to remain tethered all the way from cockpit to mast. That’s even the main thing governing the roof shape: we have to walk inside of the shrouds, if we are to be tethered in a safe and practical way.

Hi Maxime, I think the white/flat glass option looks much better. I wonder, and this may be impossible in this interation, if changing the ‘flow’ of the lines on the coachroof glass and dodger would help the look? I don’t know where I read this, but I recall an old yacht design book talking about how all the lines on cabintops and such should intersect at the bow if you extend them forward. I think the most obvious example of this is the old 25′ Vertue class boats, one of which went around Cape Horn.

To me the fundamental issue is a pretty high structure in a relatively short boat. The Vertue has the same problem on a much shorter boat, but the way they’ve angled that doghouse makes all the difference to my eye. Combining an old design philosophy with a new idea?

Hi Andy,

Glad the look is starting to work better for you, and I agree that the Vertue is a good looking boat despite the high cabin and dog house on a small boat—it can be done.

Before we go any further with this looks issue, I’m pushing Maxime to have Vincent produce renderings with a longer focal length. As a photographer I’m very sensitive to focal length and “camera” position. I would estimate these renderings are from about the 35 mm (full frame) equivalent to 25 mm. No pro photographer who ever wanted to work again would shoot people or a boat with that wide a lens. The correct lens for people and boats is about 70 mm, (or longer) which is that fashion photographer’s favourite focal length. The reason is that that lens renders objects about the same way the human eye and brain do. Point being 70 mm is reality, not 25. Even a beautiful person (or boat) is rendered ugly by a wide lens: fat, huge nose, and on it goes.

I think you will be pleasantly surprised when we publish these new renderings. At that point it would be great to get your thoughts, since they will then be based on what people will actually see when we have a real boat.

By the way, the only reason we see so many images shot at wide angles today is the cell phone which, due to tech limitations, usually has a ~25mm lens as “standard”. This is also why young people are numbed to how bad wide angle shots of people are. The good news is that modern phones are getting better in this regard.

I think this looks good. Hopefully they can be made to be flat panels.

I am familiar with insurance companies requiring backup solid panels to be secured over all large lites and portals if a boat is going offshore, and I see no discussion about this or requests here, so I wonder why? Shouldn’t there be a way of securing temporary plywood panels or something?

Also, regarding the channel from the bow to the windlass for the chain, what is that going to be lined with to prevent damage etc.? Will there be some “capture” or tie points so that the chain does not slam up and down (possibly) during pitching in heavy seas due to the length? …Perhaps enough chain tension will prevent this… something to consider.

I see a light bimini frame in one of the renderings, so I believe the design team has been considering how that would work should the owner chose to add it.

Hi Frederick,

thank you for raising the point on back-up panels for the windows. In my opinion, and how uncareful it may sound, here we can very likely rely solely on making the glass very thick. In other cases, this would be totally unwise – as we explained about the keel and grounding. But here the problem is different: the main case to consider is “simply” the high but relatively evenly-applied pressure of a big slam into water, and, while the pressure to take into account is difficult to determine, then it’s only beam and panel mechanics, and making the glass thicker, or the window smaller, until we’re good.

(see also this comment by Eric Klem: https://www.morganscloud.com/2014/12/27/qa-safety-of-large-pilothouse-windows/#comment-245676 )

We’ll double-check how this is engineered on professionals vessels such as pilot boats – any information welcome. And because we’ve just changed from acrylic to glass, there may be subtleties, for instance around the glass-to-structure connection, that we’ll need to learn.

On the channel for the chain, the materials are still to be determined, and of course that’s something to get right. And there were a few words on chain movement in comments slightly above.

Hi Frederick, Maxime and all,

It is my take that a quite unlikely break in the hard dodger window would be really lousy, but not be catastrophic as in compromising the integrity of the boat as the cockpit companionway is designed to be closed off. Many of us with soft sides sail the same way.

So, storm shutters would not be necessary as they might be for those vessel with big windows on the side of their cabin.

My best, Dick Stevenson, s/v Alchemy

I like the deck plan.

Power: If solar panels are deck mounted, consideration for ease of replacement should be paramount. Moderate sized solar wattage, with a good sized alternator for efficiency recharging domestic hw, eutectic plate on fridge, freshwater, etc.

Provide good battery setup in the protected area of the cabin with decent space for owner ease to change to LFP. Also I think the design should anticipate the owner adding removable lifeline solar of 200-250 watts.

Curved Glass: Looking at the plans and renderings the curves of the actual glass panels appear to be gentle, with the larger changes at the structural points. The curves have been made to provide a uniform intersection condition between the deck and the cabin, and the cabin top and hard dodger. It is going to be a difficult task to flatten the glass and have the sills look uniform for example. I think John’s point about having the glass flat and easily replaced is good, perhaps a flat glass study should be done to see how it might look. It could save some significant money and might look less “styled” but very purposeful, and save owners a bundle for maintenance and replacements.

I would vote for saving money and not building an arch, a radar post is an reasonable alternative. I thought of an alternative location on the hard dodger like power boats, however that would become a problem when dousing sails, so that’s a bad idea.

Hi Frederick,

Totally agree on ease of replacement of solar. Maybe we could mold in some sliders or something to facilitate attachment of at least a couple of the panels on the dodger to facilitate replacement and maybe allow an air space too. That said, we will need to be careful about adding too much height or screwing up standing on the dodger.

If the boat is moving at 6 knots or more a hydro-generator works well. If it is travelling slower something like the the solar Flin kite (rated for up to 15 knots, possibly more) could be hoist. https://www.youtube.com/watch?v=7vE39OgqcLc

Hi PD,

As I wrote in the last article, the A40 will be able to sail in all but the lightest air at 6 knots of better, so not a problem.

That said, the boat will come with a basic and functional electrical system designed to be easily expanded, as well as a hard point for a hydro generator, so you can select whatever generation solution you like best for your usage.

The arch. I like the arches on Ovni sailboats where you can use it for dinghy stowage while sailing inshore. Then stow the dinghy below deck while offshore. However, I am interested to hear about the dinghy storage ideas (foredeck while inshore?). Also, as you mentioned the radar, solar, etc. can be mounted there.

I would have thought polycarbonate (or similar) would be better than glass. Curvable, available, replaceable, durable, lighter, easily sealed. Also better insulation and less condensation. And it doesn’t smash.

I have flexible PVCs. Surprisingly efficient. Really good in overcast conditions and partial shading. I avoid stepping on them, just to be on the safe side. Surely solid PVCs would be swept away in a knock-down? You might actually squeeze 600 watts on the rarely-stood-on surfaces on the Adventure 40 and for me a real priority spend. (EUR2600 April’ 22.

Has anyone had success with those tilt-up davits? No windage, light, strong, won’t interfere with the windvane (as long as the dinghy is stowed). And on that, could the trim be designed to take a bit of extra weight in the stern? Perhaps affording a little more tankage (black water?) for those not wanting a dinghy stored here, or stored in a locker here when folded up. And besides, I think storing on the foredeck is really dodgy. Incidentally, a dinghy set-up can pay for itself in a year in saved marina fees. I hear what you are saying about a minimalist dinghy set-up John, I’m happy knowing my little 10 hp can tow us out of trouble if need be. (But what a bugger it isn’t a 15hp 2-stroke, (weight, stowability, maintenance.)) But, interestingly, I was really attracted to its go-fast capabilities, but in fact we mostly pootle at just a few knots. Actually, we spend just as much time just rowing it, like in our youth. So make sure you get one that is easily rowed and sufficiently durable around the rollocks. (You did ask for our thoughts on dinghies here, John.)

I have my radar and bits just on a pole. Can’t see the benefit of a whole gantry. And they must be bloody dear. Also, a pole can be set up to be easily unplugged and stowed if (ah! when) anticipating adverse conditions.

Mark.

Hi Mark,

Good suggestions on the dinghy, particularly rowing ability. We always bought Avons for just that reason.

I would like toe rails of fenestrated aluminum rather than solid teak or synthetic wood.

Hi Michael,

yes, sure, that’s the plan! Not clear in the model as we didn’t represent the holes, but the profile is of such a rail.

Hi Michael,

I like those too, and I can confirm there will be no wood on deck since that was in my original spec and I will breath fire if anyone tries to change it. Wooden toe rails were invented to torture cruisers. Ours fell to an air chisel.

Yes! Essential for positioning snatch blocks and ferrules on dyneema loops!

Hi All,

We now have a rendering with white around the windows. I have added it to the article above. Tell us what you think.

Hi all,

… and after a few days of your answers, it sounds like this change may remove most of the negative reaction to the initial look. But please keep on commenting! Keeping in mind that correcting the design towards flat (and probably slightly smaller) glass windows, as we’ll do, will likely take us slightly further away from the initial look.

Have you considered reverse slope windows? Less greenhouse effect, less glare, less chance of rainwater entering any open port holes. Something similar to the Garcia Exploration. Just a thought.

Thanks for the work you’re doing!

Hi Timothy,

reverse windows certainly have their advantages, but here we wanted to keep things simple! That said, it’s not impossible that when we re-design the coachroof to fit flat glass panels, the windows will end up slightly more vertical than they currently are.

I actually liked the black window frames better!

They gave the boat more personality.

Well, small detail altogether – main thing is that it is functional and sails well.

Hi John, Maxime and all,

I like what I see. I love the good planning concerning deck work, and how using a harness will be zero hassle and actually do its job. I love seeing the anchor windlass near the mast. A Spade anchor has more launching power than most anchors, so it should have no problem pulling some more chain, especially since this boat will not have an undersized anchor. Rockna Vulcan and several others have the same ability.

If I were to specify a boat for myself, it would not have an arch and no davits, but it would certainly have a solid relatively long and wide bimini, to get shade and more solar. That would also make it easier to arrange a simple dinghy lift method for inshore use. I’d probably use an arced U shape lifted from the aft end of the bimini. Since arches are so popular, I guess it might be good to have attachment points ready for that, but I hate having an oil drilling platform stacked on a boat. Ugly, harmful for the sailing properties and a real problem in extreme weather.

Radar scanner and Starlink can be stacked on the same pole, Starlink just enough above so it can adjust orientation. Most low antennas can also share that pole, below the scanner. I also see no need for a wind generator except for in very unusual cases. Solar is just better, even in not sunny weather. Those who need much solar can easily get at least 1kW nominal, maybe 2 kW, if they opt for a bimini and no arch. That’s a luxurious amount, especially if the boat also goes for lithium, which gives the effect of an about twice as large solar panel area.

The looks of the superstructure seems more attractive with the white frames, but I’m far from certain that this is a valid opinion.

Hi Stein,

Good point on the Starlink and radar being on the same pole. I should have thought of that. I will change it.

As to Bimini with solar, I’m sure many will do that, but I hate the things since they obstruct the view of the sails and make it difficult to access the boom for the cover etc. Also, once people put solar on them, Biminis start to become difficult to strike down in heavy weather.

In looking around it seems that Biminis start off seamanlike, but then tend to evolve into a cockpit obstructing monster. Bit like arches that way, I think.

That said, I can’t see anything to stop those that want one having a solar studded Bimini.

I also think that once we are aiming at 2 kw of solar on a 40 foot mono hull what we are building is a solar farm, not an offshore sailboat. Still, once again, I’m sure plenty of people will do that.

Hi John,

As I’ve noticed many times, we seem to have many similar opinions, like now. On the perhaps possible 2kW solar, I totally agree that it’s far more than most can realistically use, but it’s interesting that it might be possible. In the not far future, electric propulsion will be the normal auxiliary power for serious sailboats. Then the need to generate power reaches a whole another level. The A40 is probably better prepared for that than most similarly sized boats. More future proof. If this boat was for me, I’d say 0,6kW (nominal) solar is comfortable and 1kW is excessive.

I agree on biminis too. It looks bad, is windage and weight and in the way of a lot, but I have found it necessary to just swallow that camel. It’s just necessary in hot areas. My thinking is that a fully or partially hard permanent bimini could be advantageous. Perhaps it could anchored to the aft end of the dodger, but not as a continuous cover. It should definitely not cover the aft part of the cockpit.

I think I’d consider a “Targa arch”. Perhaps worth the pain. That would then perhaps be like an arch that is not on the stern but rather over the cockpit. It could be the main structure for a fold out bimini, perhaps also stacked slide out solar panels. Perhaps the main sheet should be on this arch, not the dodger?

I’m throwing out thoughts here, not opinions. The core is that there is an issue with sun protection. The boat needs a strategy for how owners might install some variation of a bimini. I still don’t think a bimini should be standard on the boat, and definitely not a stern arch, but perhaps a further forward arch could offer some useful solutions?

Hi Stein,

I think we are over thinking this whole Bimini issue, at least as it relates to sun protection. Owners can easily add whatever bimini top they want, with the fixed rails being a great and easy place to put the mounts.

Desired Bimini tops will vary by owner and I can’t see any benefit in the boat being provided with either as standard. Doing so will just put the price up and will always be a compromise that will not make any owners happy because we would be trying to satisfy every owner. Totally against the A40 core values.

Then when it comes to solar, we need to make sure there are proper places to mount enough (owner supplied) solar in a seamanlike way to power a basic but functional usage profile, probably assuming vane year use at sea, (Watt and Sea for those who want autopilots). If that means an arch, we will have an arch, but if we can do it without, so much the better.

At that point some owners will festoon the boat with solar using fixed Bimini frames and really dangerous stuff like huge panels clamped to the rails, and in so doing ruin, or at least reduce, the boat’s sailing capabilities.

That’s their choice and in keeping with the A40 core value of providing a good base boat that’s easy to customize, but not trying to be the arbitrator of that customization, which would be a fool’s errand.

There’s a lot of emphasis on reducing weight at the ends for this design. Is there a thumb rule for evaluating the impact of the weight reduction/relocation for those who are considering modifying their own boat?

Hi Ben,

the important quantity here is the moment of inertia around the pitching axis, meaning that the detrimental effect of each weight is given by its mass times the square of its distance to the center of mass of the boat, when seen on a profile view (that is, neglecting the port-starboard dimension) (caveat: if considering a long object such as a mast, the formula is more tricky). It’s less complicated than it sounds, and allows you to assess two different reduction/relocation actions and compare them against each other.

(sorry for not putting this in a simpler form, doing so depends on what modification we’re discussing!)

I find this weight centralisation confusing. It seems to me that weight in the ends dampens both the frequency and amplitude of pitching compared to centralised weight. Why is fast pitching preferred? It seems to me that slow pitching is less uncomfortable, and less disturbing of airflow over the sails. In the case of ground tackle, doesn’t this weight in the forepeak help the hull to steadily slice through waves rather than trying to climb up and down each one? If the bow is restrained from vertical motion by the fwd weight won’t that reduce slamming and pounding, especially upwind?

Hi P D,

I guess an actual engineer will also chime in here, but my ten cents worth:

You mention frequency and amplitude, which are indeed relevant, but not quite the way you say. More mass further away from the rotational centre will indeed reduce the frequency of the motion. Reduce the motion speed change and number of motions in a time frame. This sounds good, but isn’t.

At the same time the amplitude (distance) of the motion will increase accordingly. “Concervation of energy” and that science stuff… 🙂 The bow will dig deeper into the wave and jump further out of it. More weight has to be accelerated and decellerated. More water will be pushed away. More energy must be used, so it slows the boat down. It’s also clearly more uncomfortable. Short faster motion is generally easier to handle than slower longer motion. The degree of change in feel from a relatively small mass at the bow or in the mast can seem surprising. I’ve tested some.

This issue is also relevant to seaworthiness. A boat that reacts quickly to the waves is safer than one that has a delay in its reaction. Avoiding extra weight and getting it close to the rotational centre is definitely essential for the sailing abilities, seaworthiness and comfort of any sailing vessel.

Hi Stein,

Good explanation, thanks.

Hi PD,

Added to Stein’s good explanation below, I can confirm from real experience that keeping the weight out of the ends adds to comfort rather than decreasing it:

Replacing the old cracked aluminium mast on our McCurdy and Rhodes 56 with carbon, had the same effect as taking weight out of the ends on pitching moment and the boat got even more comfortable going up wind, with even less pounding.

Interestingly, the only time she was less comfortable after the change than before was motoring with no sail up because of the faster, but lower amplitude roll.

Past my pay grade to explain the reasons for these two conflicting results, but none the both were noticeable.

I have also noticed that when a boat is going faster upwind, all other things being equal, and assuming she is well designed to reduce pounding, she gets more comfortable, not less. And there is no question that keeping weight out of the ends is faster.

Hi John,

I think the difference you observed in comfort may well be pitch versus yaw. In pitch, you want as little rotational inertia as you can get as you want the fore and aft buoyancy to stay as constant as possible. I don’t know of any boat that has too little although it is certainly theoretically possible but at quite extreme numbers that are probably unachievable at any performance point. Pitch inertia basically serves to put you out of phase with the waves which is not good.

I know that in some conditions in roll, higher inertia is more comfortable as the accelerations are lower. In the roll direction, the side to side immersion is barely changed as you roll unlike pitch. In the days of the fishing schooners, they actually learned that the crew preferred the motion of a little more ballast but placed higher in the bilge. I guess with hauling varying amounts of fish all the time they had the perfect experimentation platform. Taking a look at capsize resistance, the inertia coming from the mast is quite important because it can dampen the roll axis acceleration for long enough for you to get through the wave trying to capsize you. Anyone who has motored a sailboat without the rig knows the motion is quite snappy. I have been on boats that are a little snappy in roll, particularly under power as you say but far worse are ones that are not snappy enough. The funny thing is that several of those boats owners boast of the advantages of the smooth roll motion and how they were smart and put the ballast higher up.

Our boat has quite a tall rig for its size (same as the current A40 actually and we are only 36′) and it is fairly standard aluminum section. As a result, our boat does great in light air for her type and is generally a good all around coastal cruiser but give us short steep waves on the nose and it is really annoying. I also don’t care for the amount of roll we get motoring in little wind or sitting in an open anchorage, I would prefer a snappier motion with less amplitude. Our hull is pretty round in all sections and some squaring up under the stern would also serve to add damping for those rolly anchorages.

Eric

Hi Eric,

That makes sense and certainly works with what I have observed over the years. As you say, on our M&R we were more than happy to trade a bit snappier roll for less pitch and more speed.

As to pitch on the A40, one of the reasons Maxime and Vincent went with a cutter rig and large foretriangle is that it let them shorten the rig and still have a great SA/D, In fact they have already worked with Z-Spars on this whole issue. So I think that the A40 should have much less of a pitch problem than your boat (and most others) given the longer waterline and same rig hight. A good trade off for a boat that primarily designed to excel offshore.

Hi Eric,

thank you for the historical piece of data on roll! Yes roll is tricky, there is just no way to push the roll frequency out of the range of wave frequencies experienced at sea.

And thank you for the real-world confirmation with your rig!

Interesting discussion about weight (and its repartition). I hear less weight is better, and centered weight is better. But at the same time, the Brewer comfort ratio favors heavier boats (of equal length and width). I guess it all depends on what we mean by “comfort” ? What do you think of this ratio?

Hi Pierre,

For sure less weight is better for speed, but generally not very favorable to comfort – although one’s definition of comfort may include sailing ability. On the Brewer ratio, see what John wrote in the previous reveal article, and remember that our approach on weight centering will add a lot on top of that!

Hi Pierre,

Another thing to think about on comfort is how long we are out there beating our heads against the wall.

One of the big drawbacks of slow heavy boats is that not only are they slow through the water up wind, they also don’t generally point well in swell because of the pitching. The result is that that they get caught out in more heavy weather more often and for longer. I sketch out a scenario in this post that demonstrates how it’s way more comfortable to be safely at anchor in sheltered waters than still taking it on the chin because we have a slow boat that pitches a lot: https://www.morganscloud.com/2022/02/13/adventure-40-dimensions-and-hull/

Thanks John and Maxime for your answer. It’s just that I’ve come to beleive the croud on the web saying a bluewater boat must have a confort ratio of at least 30. And I think the Adventure 40 has a ratio of 26 (I might be wrong on this number). So putting the Adventure 40 in the bluewater category looks to me as a little revolution. Which kind of makes me happy, because my 42 foot sailboat has a comfort ratio of 25 and is not too large aft, making me think my boat might be more “bluewater” than I thought.

Hi Pierre,

We humans like things that we can predict, so we develop rules about how everything will be. The rules are useful, but often not quite as universal as we might think. A comfort ratio must be seen in the context it was originally conceived. The Brewer thing is perhaps a bit dated? The calc becomes meaningless when applied to a catamaran. Also modern designs can sometimes go outside of the framework of old observations.

My main opinion however, as part of “the crowd on the web”, 🙂 is that we’re all trying to seem more knowledgeable than we actually are. We serve our ideas as if they’re wisdom, hiding that they’re just preferences and temporary opinions on our road towards understanding more. This very post isa good demonstration of that. Also, saying it this way makes me feel I gain credibility. Double win! 😀

I think we can rest assured that the crowd on this site is a better guide to what actually seems to work on the sea than the general online boating crowd. That latter crowd seems to be very slow in its knowledge development. Here, knowledge is balanced between our common actual experience, challenged by the most advanced knowledge and most modern tech we can find. That’s a pretty great formula! I think the people here are more trustworthy than an old ratio rule and old opinions about it. Since I come from racing, I probably accept harder motion of a light boat than some others and consider it more comfortable than the slower but bigger movements of a heavy boat, because to me slow = painful. So I can’t be trusted…

Hi Maxime,

I had forgotten, or maybe never knew, that the effect of distance of added weight from CM is exponential not linear. That explains a lot of what I have observed over the years. Thanks

There is a lot of good thought about the ease of replacing the windows.

But at the same time trying to fit solar panels on the deck. It may be possible to make these easy the change but will the same size and type of panel still be available in 10 years (these are specialist panels that can be stood on). And will they be available in whichever part of the world you are when you break one.

If sailing in the tropics is planned then some form of cockpit sun protection is almost mandatory and not just at anchor. This is to both prevent sunburn and stop overheating.

So from my point of view there will be a shade (that may fold away). But will be up most of the time. So why not make a portion of this shade solar.

In addition: how do you deal with an Hank on staysail with a dingy on deck right in front of it?

I 100% agree with Dan about cockpit sun protection. The sun in places like NZ or Aus is brutal and shade and protection from it is essential.

Hi Martin,

You can have any Bimini top you wish and the rails each side or the cockpit will make a great way plave to mount it.

As a Kiwi I totally agree we can’t spend long in the sun. I’m reserving judgement until we see the interior arrangements. If done well, it might be possible to stay inside on sunny days while still enjoying good views of the boat’s surroundings. “Doing it well” will involve attention to 360deg sight lines throughout the heel range from a variety of interior positions, ventilation and cooling, and the provision of comfortable sitting, standing, and possibly lying places that afford good outboard sightlines.

Hi Dan,

On solar availability, I think we need to stick with stuff we can realistically control. Equipment becoming obsolete and no longer made is just a challenge of cruising.

Also keep in mind that solar panels will not come standard, but be owner supplied.

The biggest reason for not adding a bunch of solar to a bimini is it makes it hard to strike down for heavy weather.

That said, owners can do whatever they wish in this area.

As to the staysail, there should be enough space between that and the dinghy for owners who don’t go nutso on the size of the tender. Anyway, good point, we should model that out for a recommended dinghy.

Very exciting stuff!

Maxime, I like the white roof pillars. They seem to have a “slimming” effect, thought perhaps that’s just the perspective in your graphic.

John, if we envision the bow locker as stowage for a downwind sail, among other things, wouldn’t it be preferable to use a watertight hatch (and a small bilge pump)? This is the setup on our Allures, and we really appreciate it being a dry locker.

I love the concept of the anchor windlass amidships, a la Boreal. I look forward to learning how the the muddy anchor chain can be isolated from the cabin/bilge.

RE: electrical power and dinghy stowage, A40 owners will customize their boats to fit their mission and locale. My preferences: 1) radar pole; 2) flexible solar panels permanently mounted on the cabin/dodger roofs; 3) Inshore/Anchored: davits and a canvas bimini with flexible solar panels (velcro tabs); 4) Offshore: stow the dinghy, bimini, and bimini solar panels below decks.

Hi Colin,

thank you for the feedback!

On the bow locker, of course it’s always better to make the hatch as watertight as possible, but then the solution with the locker bottom raised above waterline and drainage to the sea strikes me as a good simplification, for not that much of an inconvenience.

On the chain locker – well, the solution will be similar!!

And on equipment, it looks like the two of us have similar preferences!

F-rib would be the ticket https://www.youtube.com/watch?v=CXtBNiaQIGM&t=35s&ab_channel=boats.com

Hi Douglas,

I agree, the F-ribs look very interesting. The key issue would be whether or not one could fit down a hatch so it could be stowed below offshore.

Hi all,

Alastair’s comment above made me realize that while implictly, for Vincent and I, the windows were just thick acrylic (Perspex, plexi, etc.), maybe this is not that obvious. Sure they will age with time, but then making them flat to facilitate replacement makes a lot of sense. Please feel free to discuss this and tell us what we may have overlooked!

Hi Maxime,

I would really like to see us investigate glass. Otherwise I fear we will be condemning our owners to complete window replacement every five to 10 years if they want good visibility.

Just look at how quickly hatch lenses fog and scratch, particularly in the tropics.

We used best quality plastic, after much research, on the custom hatches on our McCurdy and Rodes and could barely see through them after 10 years, and we were not even in the tropics that much.

Maybe there is new tech that fixes this but before I believe that I will be taking a screw driver blade and raking it across a sample. Glass passes that test easily, but I have never seen plastic that does.

Hi Maxime & John

We have curved glass in the hard dodger on our 2002 Trintella 47 built in Holland. It’s super, clear, and does not leak. It’s possible to use glass! and we love our glass!

(And I like the white trim.)

Best wishes,

Charles

Charles Starke MD

s/v Dawnpiper

I agree that flat glass is the best way to go. There isn’t a plastic in existence that can come anywhere close to tempered or laminated glass for longevity in a UV-heavy, scratch-prone environment. The ease of repair/replacement of flat panes will likely outweigh any cosmetic or stiffness advantages of curved ones for this application.

Even the “45 times more scratch resistant than uncoated cast acrylic” plastic that costs $100 a square foot in half-inch thickness is rated at only Rockwell M100 hardness (glass is closer to B90-B100). The difference between that and glass is so great that you can’t even measure them on the same scale. The hardness test used for glass will utterly destroy the plastic, and the test used for plastic won’t register at all on the glass.

(OK, so anyone with a drill and jigsaw can make a new acrylic pane, while you need a specialized shop to make a new glass pane – but I don’t think that outweighs the need to replace plastics regularly from UV & scratching, whereas glass lasts literally forever unless you shatter it.)

I much prefer the look of the black window trim with a white infill surround.

Also, I would vote for flat glass, not acrylic windows. Our last boat needed the acrylic windows replaced every 4-5 years, adding to the maintenance load/cost. The worst part was that after just two years, there was visible hazing which spoiled all the benefit of the view from their deck level position. We got fed up and replaced them the last time with glass (8mm exterior pane laminated (1mm) to a toughened 5mm interior pane).

Hi Ann,

Thanks for the confirmation on problems with plastic and information on the glass you used. Very useful

Hi Maxime,

We have a hard dodger with an acrylic wrap around windscreen weathering in NZ’s extreme UV conditions. Some observations from having used acrylic for our dodger may be helpful:

Acrylic allows folding of the windscreen which adds great strength, without needing intermediate uprights or joints. Folding allows for flat surfaces which are easier to construct, without resulting in a “boxy” look, and the folding can be achieved by any competent handy person.

You may get micro bubbles from the heat application along the bend, that you can only see if you look really closely. This may not be good enough for a new yacht, though it doesn’t bother us.

The all round visibility through a wrap around windscreen has to be experienced to be appreciated. See photo.

Acrylic is light, incredibly strong and easy to work. It can be easily shipped ready formed for replacement, or sourced and shaped locally.

Before we had our hard dodger made, we visited a boat with a ten year old acrylic windscreen that our boatbuilder friend built and installed and it was still clear and perfectly acceptable in NZ UV conditions – some of the harshest anywhere. If we have to replace our screen after 10 years, we will be well satisfied.

I do wonder if most damage to the softer acrylic surface is from abrasion of ropes and people standing on hatches and windows. With the A40 deck design and mainsheet traveller placement, this should not be an issue. But time will of course tell.

Acrylic reduces solar gain and tinted acrylic reduces it dramatically. Clear acrylic would be a solar trap in full sunlight and clear glass would be horrible in NZ conditions. We have gone for a light grey tint and are pleased that we don’t bake, even in NZ summer sun.

But be aware that even slightly tinted acrylic (or glass) would not be certified for commercial use in NZ in the dodger, which must be clear, as it obscures faint lights at night. So we need to be diligent on passage and look to the side of the dodger periodically at night.

As an aside, I crewed from NZ to the Pacific Islands on two recognised “offshore yachts”, one a HR 48 and the other a Laurie Davidson Cavalier 45, both centre cockpit designs. I was surprised how much spray comes through a forward facing openings on passage, with the wind forward of the beam. So most of the time we had the windows / openings closed, even in around 15 ->18 knots. This made under the dodgers damp, hot and stuffy, and the crew prone to sea sickness (not me thankfully, though I was off my food for over a day, which is VERY unusual for me).

So we went with top opening hatches in our dodger that we find much drier, unless the conditions are really gnarly. This also allows checking of sail trim from under the dodger as a bonus. I notice there is not much positive sheer on the A40 bows or any great flare, so she is unlikely to be a “dry boat” with the wind forward of the beam offshore – just an observation.

We already own our forever yacht Maxime, so have “no skin in the game”. But admire what you are taking on and following the design posts with much interest. Bon chance.

Hi Rob,

Thanks the report. I think the inconsistency between your report and Ann’s (and our own) on acrylic fogging may me a function of the thickness required for structural use, rather than the thinner you are using. I too have had good results from thin acrylic, although that does require regular maintenance since the acid rain we get in Nova Scotia just murders the stuff unless we polish it off regularly.

Anyway, we can debate this all day, but one thing we know for sure is that glass does not fog ever, does not scratch, and requires no polishing, so I will continue to push hard for it, particularly since reducing ongoing maintenance costs is a core A40 value, even if it means we need to spend more up front. Glass will also increase resale value, which is another core A40 value, since nothing looks worse than fogged acrylic.

Hi John,

I can see glass making sense for a production boat, rather than a custom dodger. But just in case glass turns out to be impractical to build with, or for cost, or weight reasons:

I don’t think thickness of the acrylic would be relevant if it already has good clarity when new, but perhaps your thinner acrylic was manufactured using the optically superior cell process, rather than a thicker acrylic that perhaps used the cheaper and optically inferior extrusion process?

We have Plexiglass which uses the cell process for manufacture, which offers superior optical quality when new and more importantly as I understand it, stays optically purer over time. This is just what I have read.

Regarding the fogging and clouding issue John, this affect all acrylics including Plexiglass, as they are exactly the same material.

But how acrylic has been cleaned and what it has been cleaned with, will make a big difference.

Dirty cloths, boat sponges with sand in them, brushes and rigid rubber or plastic squeegees will scratch all acrylics, from new.

Cleaners with solvents like alcohol or with an ammonia base, will cloud all acrylics in a short time, from new.

If you use any polish or film protection product, it needs to be specially formulated for plastic glass – for instance Rain-X Plastic. Normal Rain-X for glass will cloud your acrylic.

We do use Rain-X Plastic, and then when needed we use warm water from a squeezable drink bottle, and a soft silicone squeegee to wipe and dry the screen.

Every six months or so, we use a little dishwashing liquid with the warm water and a clean microfibre cloth, squeegee dry, and then reapply Rain-X Plastic.

Hi Charles, Ann, Rob, Matt and John,

many thanks for the reports and advice, got it!

In particular, the point on resale value had escaped me (it shouldn’t have!), and is very important indeed.

She’s looking really good.

Stern Arch/Pole/Solar

This complex decision is tied up with energy loads and battery sizing and charging. Everyone will have different opinions driven by their use cases. My use case would be higher latitude cruising with a need for extended duration independence.

Feels like there are two paths. One, a minimal energy arrangement with a windvane, panels on the coachroof, a pole aft and maybe just an ice box as I doubt refrigeration would be supported. Small battery bank and related charging. Or two, a higher energy arrangement with an arch for panels, refrigeration, and autopilot.

While obviously cheaper, I doubt many minimalist arrangements would be sold. You could just build and sell the boat this way, knowing owners would modify to suit their perceived needs. In this case, have provisions for an arch, a larger battery bank, lithium charging, a nice hydraulic ram, mountings for refrigeration, etc.

Or you could build it with the arch, larger batteries & refrigeration up front. Work out the wind interference on the vane. Experienced industry folks could give guidance here. An arch could also provide the aft edge of a bimini and davits/engine hoist for those that want them. Personally, I don’t like arches due mainly to the visual clutter aft, but I’d trade that in return for refrigeration, an autopilot, and reliable power generation.

There is another line of thought that says to just get rid of the idea of the windvane. It’s day has come and gone. Properly installed, hydraulic drives are very reliable and serviceable, and steer better in every condition. Marconi v gaff rigs. Fin v full keel. Barn door skeg v spade rudder. The world is moving on. Now where did I leave my sextant? 🙂

On the dinghy storage problem, I would likely just use inflatable kayaks on a boat this size and stow them away deflated somewhere. But I am odd. Most will want a place for a RIB and 15HP outboard and all that implies. Ugh.

By the way, please have non-cored areas for through hulls specifically for watermaker installations. I’ve seen hulls destroyed by previous owners installing watermakers. And while I’m dreaming, kevlar layer in the laminate around the waterline forward, and epoxy resin instead of polyester/vinylester for longevity.

Didn’t see a track for the staysail?

Ventilation. If no panels on the coachroof, you could put another hatch. Also, a small hatch hatch in the glass panel behind the mast is very effective for additional ventilation.

That’s all for now.

Hi Whitall,

The boat will be sold without all that gear and dead simple. This is a core Adventure 40 value and explained in earlier posts.

Then owners can customize to their hearts content, but if we get into all that and options we will soon have just another very expensive boat.

And I agree that the arch decision is driven by the electrical system. In fact I say that in the body of the article.

As to the windvane we already dealt with that at length in another article.

Hi All,

We are getting a lot of comments on things we have already covered in other articles as well as comments suggesting stuff that’s outside of the A40 core values that were long ago agreed, and that we must stick with if this project is going to work.

So before commenting, please at least look through the A40 table of contents: https://www.morganscloud.com/2022/11/09/adventure-40-reveal-on-deck/

And it might be a good time for all of us to have a re-read of the core values article:https://www.morganscloud.com/2014/08/31/twenty-adventure-40-core-principles/

I vote for the arch to allow owner installation of solar panels, antenna’s, etc.

Core value or not, I’ll also vote for refrigeration included. I just think the number of ocean crossing boats without it is about the same as the number without engines. Sure, it can be done, but 98% of future owner’s will install it. When the time comes, I’ll vote for an included main and jib too.

HI Jonathan,

Everything will be in place to make refrigeration easy to install: good box, breakers, hard points in the hull for sea cocks, etc. That way each owner can install exactly the fridge they want—way better than the builder imposing their choice on everyone. I’m also betting that there will be commissioning companies that will provide different packages of kit for the A40 for those who don’t want to do their own.

This is indeed a core value and as such is inviolate if we want to get this done at the price envisioned: I explain why here: https://www.morganscloud.com/2013/10/10/adventure-40-an-overview/

As I say in the article, the arch decision will depend on whether or not we can get make propper space for the items you mention without it. If we can, why add the weight and windage of an arch?

On deck mounted solar panels some care needs to be taken. I have one on the main hatch garage and also had the same on my previous boat. When dry the non slip qualities are excellent. When wet the non slip ridges moulded into the panels seem to hold the water or dew captive and become very slippy. Both panels are from well known makers.

On the glazing two things. The jacklines seem to be crossing the front windows. Will dragging a metal safety clip across the glass/perspex be an issue ? Secondly I personally find the smoked glass a bit creepy looking. And while the will cut out some sun glare they may reduce visibility at night.

Are we allowed to comment on the rope boom vang in the illustration yet or are you saving that discussion for a later day ?

Mark

Hi Mark,

Good point on what is, and is not, really non skid. I too am highly sceptical about solar panels claims of being truly non skid and safe to stand on repeatedly. Still, maybe there is something around we don’t know about.

As to the clip, it would be an issue on and sort of plastic, but glass would not have a problem. We will also be putting a lot more work into the jackline system before it’s final.

And I agree on smoked glass.

Don’t worry about the vang yet, since we are a long way from final on that. We do have a spec of where success will lie though: https://www.morganscloud.com/2020/11/16/rigid-vangs/