Maxime and Vincent have been hard at work over the last couple of months refining the deck and cockpit design, including many of the changes and improvements we discussed.

I’m seriously stoked about these improvements.

The Look

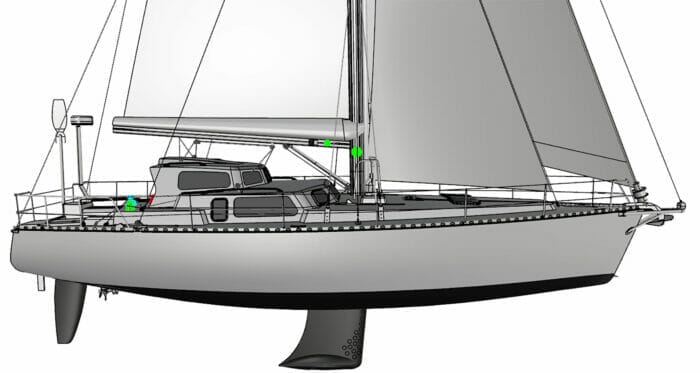

First off, and most striking, we transitioned from what Andy Schell called “the wraparound sunglasses look” to looking the business of offshore sailing.

This is now a boat that will stand out in any anchorage or marina as truly designed to go places…pretty much any places.

In the rendering above she still looks just a tad dumpy but that’s (as before) because the point of view is (although much improved) still a bit too close in and the focal length not long enough.

That said, as a photographer, I’m particularly sensitive to this, but most younger people, who view thousands of images from phones with short focal lengths, won’t even notice.

Anyway, just wait until we have a full rendering from a longer focal length with waterline and cove stripe. I think this boat is now seriously good looking.

Working Renderings

One other thing on looks. The renderings in this article are from the actual working design models, so are grey and utilitarian with no pretty lighting or azure seas. For this phase we want to put Vincent’s time (and our money) into getting the design right, not making pretty pictures.

Take a Look

So let’s start from the bow and look at all these cool improvements one by one.

I will only be covering the changes made since we published these two articles:

So if you have not read them, please do so now.

Also note that many details will be settled while working with the builder (when selected) and so are not shown on these renderings, or are not in their final form.

Hi All,

I have reopened the comments on this article on request of a member but please stay on topic of the A40 and not veer off into subjects that we have covered in depth and discussed to death on other articles and/or online book chapters.

I’d be OK with giving up the traveller, if there’s a good vang and a 5:1 or 7:1 mainsheet.

I don’t see any obvious routings for the port and starboard preventers? Same goes for the headsail furling lines. On many boats, these seem grafted-on and end up as trip hazards. It’d be nice to see them fully considered in the design.

The bow pulpit is really nice. Let’s make sure there’s good access to its bolts inside the forepeak so that it can be taken off for repair in a shop if it ever gets banged up.

Cabin overhead fabric, carpet, panelling, etc. are usually there because the inside of hand-laid fibreglass looks like crap. If the fibreglass part is a nicely vac-bagged structure, then all those thin overhead trim pieces do is to reduce headroom, trap moisture, grow mildew, and give angry stinging insects a dark place to nest over winter. Simply finishing the underside of the deck with a gelcoat spray is a fine idea, saves cost up front, and will make long-term maintenance easier.

Hi Matt,

thank you for the feedback!

The plan for the preventers and furling lines is simply to lead them at the foot of the stanchions, as often done – of course the quality of the fittings matters. Please feel free to tell if I’m overlooking something.

Yes the repairability is part of the bowsprit idea, good to hear you concur! By the way, if this choice is confirmed, we will likely add/remove volumes to the hull shape to make the mounting surfaces forward-looking and avoid shear in an impact.

And good that we agree on (gelcoat-) painted overheads and sides! (something quite common in french boats – and not incompatible with some nice wood trims in the accomodation) To me, simplicity just wins – the first time I did a beginning-of-cruise check-up on such a boat was quite a dream!

Hi Matt,

Good point on the horrors, of deck head coverings, particularly carpet!

And yes, a very good point that the bolts holding the bow platform should be accessible.

On my boat, the cabin overhead, walls and under the side decks are gel-coated fiberglass. They look good and are easy to clean. I can attest to the longevity of interior gelcoat – my Alberg 35 was built in 1964.

Hi Paul,

Good to hear that has worked out so well for so long, thanks.

I’m a fan of the concept and have followed the evolution with great interest. But I have to say your cabin top has really put me off from an aesthetic point of view. From what I can see on the drawings you now have at least 3 different levels, 6 different surfaces and 5 different windows/ports on the cabintop area. Surely a more pleasing design would be possible, easier to execute, and lower in cost. Just my $0.02 after being on board with most of your other design decisions.

Hi Roger,

Sorry to hear that. Each to their own, I guess. I’m now a huge fan of the look, as well as all the benefits the raised areas confer.

That said, what would you suggest to make the look more appealing to you without losing benefits like the hard dodger, light in the salon, great ventilation, very good headroom in the head and galley, better and safer glazing, and tankage under the raised area cabin sole?

I think that changing the top of the dodger to a single surface, without the little raised area, would go a long way to making it look cleaner. Hallberg-Rassy, Amel, and other well-respected marques have previously used a similar aesthetic style to good effect.

As for the differing windows/ports, if you want operable ports that actually stay watertight long-term without costing a small fortune in custom frame castings/extrusions, you’re pretty much stuck with that look. Personally I think it’s fine. The difference in fixed vs. operable window appearance in reality is not nearly as dramatic as it is in a CAD model where every surface edge is a solid black line.

John,

Without going into the CAD drawings and playing designer (which I am, but in another sport), I think reducing the 5 (or is it 6 or 7?) different window shapes would go a long way toward harmonizing the look. Just a first step that would also pay some small dividends in cost. And I agree with Matt’s point that the added raised panel on the top is distracting. It also appears to create what look like two fairly sharp corners on the trailing edge, right where my head might be before learning the boat.

Appreciate your openness to input. As you note, there are a lot of subjective factors at play.

Roger

Hi Roger,

I agree that the raised area in the middle of the dodger should go. In fact I devote several paragraphs in the article above to why. Start reading from “Raised Area on Dodger”.

As to changing the window shapes. Why not attach a rough sketch of what you are thinking? While doing that keep in mind that increasing window area increases stove-in risk and further that opening hatches and ports need to be in standard available sizes otherwise we will be spending a fortune on custom fabrications.

Perhaps the lower center window could be eliminated completely. Based on the renderings here, the visibility forward is not going to be great out of that window anyway. I suppose there might be some loss of light in the cabin but the 2 adjacent windows could be upsized to help compensate.

If you are getting rid of the the superfluous raised area on the dodger could you not place a traveller across there? It might have to be raised slightly to accomodate any curve in the dodger top but this is not an unusual fix. Being at the aft end of the dodger would free up space for solar panels and might improve winching angles and forces (not an engineer).

The ability to either put a good twist in the main or rapidly de-power said sail is so advantageous to basic safety and seamanship I think it is worth fighting for. Losing the traveller this early in the design process is a big loss.

Best

Mark

Hi Mark,

Sure it could be done, but as I say in the article, I’m not sure it’s worth it, particularly since once we have a powerful vang there is no need to have a traveler to “rapidly depower”. In fact with “Vang Sheeting” all you do to de-power is ease the mainsheet. Then if further twist is required, ease the vang. Well set up this is actually faster and easier to do than a traveler.

When I was in the 505 class we all went over to vang sheeting and got rid of the long travellers that had been standard, and it turned out to be a huge advance in function and simplicity. Also reduced the clutter a bunch.

A few boats built a tower where the traveler was to raise the block to reduce sheet tension when the boom was close to centre, which is very like what we have on the a40 in the form of the dodger.

And although our J/109 has a traveler, most sailors at the top of class racing vang sheet.

So the only remaining good reason for a traveler is more twist in light air. Nice to have, but how many A40 owners are really going to use it? So, on balance, I don’t think it’s worth the visibility hit, expense, and complications.

Hi John

I have both vang and traveller on my boat and regard them as complimentary to each other. But I bow to your superior knowledge, skill and extensive research and thinking in this matter. I obviously need to play around with the vang more to realise it’s full potential. One never can stop learning new tricks.

We lost the mainsheet traveller on a delivery of a 55 foot centre cockpit boat last year. I rigged separate blocks and tackles port and starboard to the boom end. It worked reasonably well and maybe if we had played more with the vang it could have worked better. But as you and Drew allude to it was clumsy and you had to be careful to remember to tend the lazy sheet.

Best

Mark

Hi Mark,

On most boats with travellers you are right. For vang sheeting to really work well, the vang must be more powerful and stronger and the boom probably a bit stiffer. When we went over to vang sheeting in the 505 we went through some booms before we got it right. Definitely something the rig designer will need to take into account.

Hi John,

In addition to the bending load on the boom, the extra load from vang sheeting will pull the boom forwards, putting a significant bending load on the mast tube. Not really a problem, but needs attention, of course. I think vang sheeting is a good solution for this boat.

and a very strong gooseneck

Hi PD,

As I remember from working with the engineer at Hall Spars who designed our new mast for the McCurdy and Rhodes the highest loads on the goose necks that need to be designed for are in a crash jibe. Anyway, yes, goosenecks need to be strong, but I’m sure the mast engineer Maxime hires will know that.

Regarding the mainsheet traveller, is it to late to consider a combined system of mid-boom sheeting and end-boom sheeting?

Let the mid-boom sheeting be installed permanently, and make sure it is possible (pad eye or similar) to attach a end-boom sheet for heavy weather use (and to use with a preventer to fix the boom with less bending moments downwind).

The new First 36 might be a good example of how to make an nice and simple interior that is quite attractive.

Hi Svein,

I really don’t like end boom sheeting on a cruising boat particularly in heavy weather. As many sailors have been hurt by the mainsheet, (and several killed) as by the boom. We must remember this is a boat targeted to those who are new to offshore sailing so we want to remove these kinds of risks, where possible.

And it’s hard to see how that could be done without making a lot of changes that would have downsides.

I would also question the utility of the First 36 layout for a live aboard boat, primarily for two people. For a start the head is so pokey that the sink must fold up so one can sit on the head. Not something that would be fun on a live aboard boat. Point being that the First 36 is aimed at a completly different usage profile. (I do agree it has some very cool ideas for the usage the designers are is aiming at.)

Since this boat’s mainsail is big enough that you’ll want a sheet winch for it anyway, I would happily put up with the higher sheet loads of mid-boom sheeting in exchange for getting the damn mainsheet out of the cockpit. Teaching the kids to only cross the traveller on the windward side, and only with the skipper’s permission, has been one of the more difficult aspects of family cruising.

Since adding the Garhauer rigid vang to our C&C 35-2, I’ve rarely found much need to move the traveller off centreline when beating or reaching, and when on a run we just tweak it to give the mainsheet a clean non-chafing lead. It’s easier to set the vang to get the right twist for a given wind speed, then control power and airflow by sheeting in/out from the helm while twist stays constant. We can easily single-hand the boat that way, even short-tacking, while fussing with the traveller always requires either an extra crew member or turning helm control over to the windvane.

For all-out racing performance, yes, you probably want both a long traveller and a vang, but plenty of cruising boats get by just fine with the setup John’s described here.

Hi Matt,

thank you for the confirmation, and I agree on everything!

Matt, thanks for the confirmation. I have a Garhauer vang that I’m currently installing on my Sabre 34 and am glad to know what to look forward to this season!

Yes, the mainsheet can be dangerous, and should be kept clear of the cockpit as much as possible. What I am suggesting is to have end boom sheeting as far aft as possible to clear the cockpit (in a uncontrolled gybe which I guess is the major danger), similar to how some centre-cockpit boats have a mainsheet and traveller aft of the cockpit.

I do not know how safe or dangerous this arrangement is on centre-cockpit boats, and if the the mainsheet clears the cockpit/helmsman when gybing.

The layout of the First 36 is maybe not something that would work for live aboard. However, the interior shows how a few details in wood and nice cushions etc gives the much nicer impression. And those protruding through-deck bolts are not that intrusive (but condensation might be an issue).

The current design shows mid-boom sheeting hardpoints at about 1/3 and 2/3 of the boom length. From a structural mechanics standpoint, that’s going to yield a pretty nice distribution of loads on the boom, at the cost of a relatively high mainsheet tension that must be handled at the winch.

An end boom sheeting point, routed to the dodger top, would be at an awkwardly acute angle and would apply a lot of unnecessary compression on the boom and gooseneck.

An end boom sheeting point, routed to the aft coaming, would be constantly whacking the helmsman’s ear.

Hi Svien,

Sure it could be done, but the issue with all these things is should we? The trade off here is fundamental in that the more requirements we place on a particular part of the boat the less likely those requirement will be met in an elegant way. For example aft Vincent needs to figure the, tiller, table, life-raft storage and launch, vane gear installation and control lines, radar pole, JSD locker and launching, preferably with lines attached to chain plates at all times, checker boards, easy access to a dinghy and to go for a swim, cockpit locker lids, propane locker that must drain overboard…I’m sure there is more. So to add the a mainsheet strong point to that with all the clearance issues is a very big thing to add on top of all that.

And then we would be asking him to do it all again for the present mainsheet position which is going to be preferred by most owners.

The other thing to keep in mind is that in a crash jibe the mainsheet would sweep the whole cockpit from strong point to dodger. This I know from my J/109.

On our centre cockpit McCurdy and Rhodes the mainsheet was only safe because the crew were protected by the boom gallows.

More about mainsheet positioning tradeoffs here: https://www.morganscloud.com/2020/08/28/sailboat-deck-layouts-and-the-outbound-46-part-1/

Thank you for the centre-cockpit and boom gallows information, interesting and useful. There are some high-end centre-cockpit about.

Regarding the mid-boom vs end-boom mainsheet arrangement, my main point is that it is sometimes useful to step back and get a new perspective. The current proposed solution for dodger, coach roof width and rope leads are suboptimal (the rope leads are contrived and the cut-outs for the mainsheet is an ugly kludge).

Maybe a useful viewpoint is to consider the dodger the forward part of a mainsheet/main boom arch. A centrally located winch in the cockpit for the mainsheet, with a rope going straight up and through the dodger/mainsheet arch (thus the rope bit in the cockpit is in a fixed location) and on to the mainsheet boom tackle would be one solution (but still suboptimal, I agree). Leading the mainsheet on the outside of the arch to winches on either side would be an other option (at the cost of an extra winch, a few blocks and more engineering).

I am not saying this is the solution, I just want to provide an alternative perspective that might be useful.

Just an illustration 🙂

Hi Svein,

While that looks interesting, I agree. The problem is how to turn the line elegantly at the dodger edge without creating an assembly that will catch sheets.

That said, if you can show us a design, including the fittings and blocks you will use that solves that without adding more turns and friction I’m all ears.

I do have a design in mind, which I think might fit the bill. Over the weekend I will make a sketch.

One solution could be like this. I have just picked 75 mm sheave blocks. If vang sheeting is implemented, then the load on the mainsheet should usually be quite low (as only the position of the boom is controlled by the mainsheet). Still, it should be dimensioned to full mainsheet loads (both normal and accidental). I am not going into mechanical design of the dodger, I guess it has to be beefed up substantially anyway.

I think it would be possible to reduce the use of footblocks also, by clever design of the shape of the aft edge of the dodger. One mastbase block (instead of two footblocks) could route the rope from the winch up along the dodger side to the top.

I do not have access to fancy 3d design tools, so I can only make crude sketches (sorry).

Hi Svein,

Thanks, an interesting approach. I still prefer the current solution as drawn to adding that potential snag, even with the guard, since the guard itself is a potential snag. (One of the things that is often missed is snag risk with proper preventers in a jibe.) Also, this solution adds harder turns to the sheets so increases friction. This also precludes double sheets, and while I’m not a fan, I still like the idea of providing maximum flexibility in situations that have no down side.

That said, I could be missing something. What do you see as the benefit(s)? And what about the snag risk?

The other thing to remember is that the “German” mainsheet system is well proven on race boats and cruising, so we would need a very good reason to change and in so doing, expose ourselves to unintended consequences.

The guard/handrail can be extended all the way across the dodger. I also think that eventual full mechanical design of the dodger will have to include some reinforcement at the aft edge, maybe some strength could be provided by a beefed up handrail?

The extra friction from hard turns can be negated by using an even bigger mast base type block. But friction is not that big an issue when a winch is at hand.

Double sheets? Just replicate the setup on each side of the dodger.

If I understand it correctly, the current design of the boom/mainsheet/vang setup is for a powerful vang and rigid boom for vang sheeting, and a mainsheet mostly for control of boom position? Quite far from a standard German mainsheet system.

If the German mainsheet system has to be adopted, I have a different proposal for routing the mainsheet to avoid the ugly cutout in the coach roof.

Route the mainsheet on the outside of the coachroof on one side, and the vang control line on the outside of the coachroof on the other side, each to its own dedicated winch.

Call it the uni-German mainsheet system (an example is shown in the attached image).

This system is also used on some Dufours, combined with full end-boom sheeting and a traveller at the aft end of the cockpit. I have no idea why this setup is used, other than it allows trimming the main with a winch on the coach roof.

Hi Svein,

That’s all interesting, but I don’t see any benefits mentioned for the system you are proposing with the turning block on top of the dodger. That’s the key point: why do you want to do any of this? So far I have not heard an answer to that fundamental question.

And further, exact routing of the existing system, including the grooves (or not), will be best done on a mock up, so we really don’t want to waste a lot of time now moving blocks around, just for the sake of it.

The main reason for doing this is basically that it is potentially a simpler system that uses less space and gives less clutter. Instead of a rope going from the cockpit winch island forwards to the mast, up to the boom and back along the boom to a place over dodger, there is a rope going from the cockpit winch island up along the dodger side and to a place on top of the dodger and to the boom.

I can imagine a design for blocks that could be recessed in the dodger structure for a sleek installation, but that would require some custom fabrication (but not overly complicated).

I might be more attracted to well designed and clean systems than your average guy 😉

Hi Svein,

Sorry, I just can’t see that a design with snags sticking up in the worst possible place for preventers and the sheet itself protected with guards that are, at least to me, odd looking, and that are right in the helmsman’s line of sight is a step forward or any more elegant than the tried and proven German system presently shown. And as yet, you have not shared any operational advantages for this system at all, never mind any that outweigh the drawbacks I have listed.

Hi Svein,

I must say I have the same opinion as John on the comparison between the two routings of the mainsheet. “Ours” takes a longer length of rope and may take one more block depending on the exact solution, but clutter is more about the place than the total quantity of stuff, and a clean dodger top really is important. Also note that we don’t lead the mainsheet all the way to the mast, where I agree it would be a nuisance.

Hmm, I think a proper german mainsheet system, where the rope goes along the deck (or similar flat surface) forward, and then to the gooseneck (or to the mast at deck level) and then back along the boom would be a better solution (i.e. give less clutter etc) than the current proposed solution with a turning block on the coachroof.

Imagine what happens when you need to go on top of the coachroof (and dodger) to tend to the sail. Stepping over the ropes crossing the coachroof is an obvious hazard. A clean, flat coachroof would be a very nice feature (for many reasons).

Clutter can the reduced by leading ropes together, instead of having ropes criss-crossing the space above the coachroof.

Obviously, I do not think we are going to agree on a “best” solution, so I do not think I am going to pursue this topic further. But I sincerely (!) hope the cutout/groove in the coachroof is dropped in the final design (I still think it is an ugly and unnecessary kludge, sorry 🙂 ). I have tried to provide a different and fresh perspective on this issue, but it seems I have not managed to break through.

I look forward to see how the final design of the dodger comes along. Is it dodger going to be a separate (removable) structure? How is the reinforcement and fastening going to solved (to resist a crash gybe without damaging the dodger)? Maybe there is going to be an hollow arch-like structure (with space for ropes maybe).

Hi Svein,

Actually I agree with you on a single line going forward on the boom, although I don’t think I would take it all the way to the goosneck. But on the other hand Maxime is very keen on providing people with the option for twin mainsheets to allow twist in the main in light air by weather sheeting and to allow muzzling (I think I just invented a new sailing term) of the boom when the sail is dropped, and he gets the final call on this stuff, also his ideas provide maximum flexibility.

Also recognizes that none of this will be set in stone until there is a deck mock up to test this stuff full size, and there may even be changes after hull #1 goes sailing. Point being anyone who thinks they can get a deck layout perfect on a drawing is smoking something and Maxime and Vincent would, I think, be the first to agree.

As to the engineering on the dodger, rest assured it will be strong enough to withstand a crash jibe. After all, if it can be done with a high arch, it can certainly be done with this dodger. My guess is that will include an arch like reinforcing within the dodger, as you say, but I’m not an engineer so that’s pure speculation. I’m, also guessing the dodger will be part of the deck mould, but again, that’s a guess.

Muzzling is important! So many times one is disconcerted, disoriented, and sometimes dislodged when finding the boom is not as stable as its weight suggests e.g.; tidying the main away in a rolly anchorage. The solid vang will hold it vertically more firmly than the fiendish topping lift alternative. Double sheets will hold it laterally. I think that everything on a boat that is heavier than a crew member should be well secured.

Hi PD,

Sure Muzzling that way is nice, but is it worth the danger involved in not being able to bear off quickly in an emergency because one of the two sheets fouls up? Point being that all these things are tradeoffs and I would not make that one.

Also, be aware that just pulling the two sheets tight against the vang will not make the boom stable because if we lean against it the spring will compress. To to be truly stable you either need a topping lift, or to remove the halyard and use that on the end of the boom, which is a very bad thing to do at sea.

The very best and safest boom muzzling comes from a gallows or crutch, but, again, that would have all kinds of problems with this configuration.

None of this stuff is as simple as we would like it to be! But my thinking is that given the angles of the lines from the blocks and that the boom is well above anyone’s heads, just pulling a single sheet tight against the vang will be perfectly adequate. That solution has been tested and has worked on Boreal’s for over a decade and probable millions of miles.

Good points. It’s a boom brake any good at muzzling?

Hi P D,

in my experience, not better, because the boom has to travel some way before the device is re-oriented from pulling on one side to pulling on the other.

Hi P D,

Not really, for the same reason: the vang.

Would a captain’s policy “always dump the main from the windward sheet first” reduce the twin-sheet downsides much?

ps. I’m pretty much convinced by the single sheet option especially if the owner can add crutches as I show elsewhere. But still wondering about the effectiveness of a twin-sheet policy option.

Hi P D,

yes, sure – and both sheets shouldn’t be in use simultaneously anyway.

That said, the need for such rules is why the one-sheet setup is a better default!

HI PD,

Sure, you an have a standing order, but that does not change a fundamental issue here, two sheets are more complicated and more complicated is pretty much always more likely to hang up. My fundamental rule on running rigging that has served me well for some 150,000 miles is: always look for the simplest solution that will work. And rule number two: do everything you can to remove friction. Twin main sheets violate both those rules.

Something else I have noticed over the years is that the more experienced a sailor is, and the longer they have had their boat, the simpler the systems get.

Or to put it another way, when faced with a problem the inexperienced almost always add complication, and the experienced take it away.

Two part main halyards and halyards lead aft are classic examples: https://www.morganscloud.com/2016/07/12/hoisting-the-mainsail-made-easy-simplicity-in-action/

Bottom line, Phyllis and I sailed a 56 foot boat for 30 years with no automation and without getting in trouble or ever having her get beyond our control, by observing the above rules.

Anyway, this is a solved problem and a dead issue since Maxime has ruled that the boat will come with a default single mainsheet, but will be set up so those who wish to can try double mainsheets. That said, I hope there will be a big red warning in the owners manual about the potential dangers of the latter.

It is funny that you mention a gallows or crutch, I was actually pondering whether it would make sense to build a super low profile crutch that folds down on the hard dodger and can be folded up to really secure the boom. The load is actually quite low so it could be pretty low profile and if it is right next to the sheets, it might not interfere with sight lines or the ability to mount solar panels. I personally really don’t like booms that you can’t properly support but some of that may be related to struggling with some booms that weigh in the multiple ton range.

Eric

Hi John and Eric,

this idea is attractive, but I don’t see how we make a crutch work since we have a simple spring or gas vang, where the upward force can’t be cancelled?

Hi Maxime,

There is no need to cancel the upward force. All that happens with a crutch is we pull the boom down with the vang, against the spring or gas, into the crutch. We did this for years on the M&R 56, works a treat.

More here: https://www.morganscloud.com/2020/11/16/rigid-vangs/

I just re-read that article and see that my recommendation is that boats without a crutch should have a topping lift, which solves the muzzle problem at sea too…but I hate topping lifts…but there’s a hack to sorta-solve that: https://www.morganscloud.com/2020/11/28/topping-lift-tips-and-a-hack/

Hum, again, I think I have talking myself into a topping lift, unless we can come up with a super elegant folding crutch. More thought required.

…The more I think about it the more I think a topping lift is the best answer, particularly since we are marketing the boat to those new to offshore sailing.

Hi John,

One solution I’ve seen to arresting the downward movement of the boom is a short lead from the backstay that can be attached to the end of the boom when needed.

On the A40, this could possibly be a piece of HMPE line led from the Y intersection of the split backstay, with a snap hook or something at the desired height of the boom. (Assuming the whole thing can be kept out of the way of any backstay adjuster hardware.)

When attached, the line functions as a fixed-length topping lift, and the mainsheet can be snugged down against it per usual.

When unneeded, the line could be lashed to the pushpit railing.

Whatever solution is used, I agree that it’s important to be able to fully arrest the movement of the boom when the mainsail is down. IME, body weight is enough to overcome the upward force of a rigid vang on this size boat, so without something to hold it up, what appears to be a steady, static boom readily gives way when leaned on, not good for beginners.

Hi Scott,

I have seem that option too. That said, I prefer a topping lift since to attach the strop it requires standing in a vulnerable position next to the boom end. Fine when in harbour, but not good at sea when the main must be dropped to motor.

Hi John,

That makes perfect sense. Thanks for the additional context!

Hi John,

When topping lifts are mentioned, I assume most are referring to adjustable TLs.

The TL on Alchemy came as adjustable. In my quest to simplify things over the decades (the older I get, the less I like to think: and that goes double to thinking while in action), I dead-ended the TL (for various reasons, I never considered a rigid vang). This proved to have a number of advantages:

1. It freed a sheave at the masthead for a spare halyard to be ready to go.

2. It also freed up line routes and a clutch to make reefing easier.

3. Dead-ended so the TL is just firm when the sail is strapped down close-hauled and then kept well behaved with a bit of shock cord, it keeps the boom at a reasonable height (when the sails are put away) and one does not have to fuss with adjustment.

4. Best of all, for me and my sailing, a dead-ended TL, when adjusted with lazy jacks (3-fall LJ system with a fully battened main), can allow the sail to be dropped right into the LJ’s arms and pretty much forgotten about until covered. Both the LJs and the TL are set up at the beginning of the season and forgotten about; no adjusting.

I am not sure how a TL works with a rigid vang also holding up the boom. With a TL, (and this will sound a bit luddite-ish) on a cruising boat, I would dispense with a boom-to-mast-at-deck-level rigid vang and go with a soft (rope) 4-1 vang to the side-decks adjustable from the cockpit. This seems possibly even more appealing when there is no traveler.

I have sailed with such an arrangement for decades and would not have it any other way.

My best, Dick Stevenson, s/v Alchemy

Hi Dick,

We have already done topping lifts big time here: https://www.morganscloud.com/2020/11/28/topping-lift-tips-and-a-hack/

Point being that we need to stay focused on the A40 here or this thread is never going to end. If we are going to discuss topping lift options lets do it on the above post to avoid duplication.

I would also not dispense with the rigid vang. No offence, but it my experience the only people who question the great benefits of rigid vangs are those who have never had one. I have had rigid vangs on all three of my boats and would not dream of being without one.

One of the larger benefits is when reefing:https://www.morganscloud.com/2010/11/19/reefing-a-sailboat/

We have already discussed the dangers of vangs to the side decks, probably the best way known to break booms and they have killed people too because people start thinking they are preventers: https://www.morganscloud.com/2018/10/02/amidships-preventers-a-bad-idea-that-can-kill/

https://www.morganscloud.com/2014/03/02/rigging-a-proper-preventer-part-1/

Hi Eric,

Yes, I have thought about that too. But I think that is because, like you, I’m used to a large boom with scary weight and loads on the McCurdy and Rhodes. Given that the loads are low on the A40 and the boom is well away from anyone I don’t think it would be worth the complications and expense.

In harbour just put the main halyard on the boom end and snug everything up. The horizontal spread of the blocks on the cabin will do the rest.

I guess the only time we might want a crutch is when motoring at sea with all sail down, but before adding a crutch I would suggest looking at ways the vang can be restricted from further compression, perhaps with a stop. Be worth talking to various rigid vang makers about that.

Hi Svein,

I have deleted that image. I searched on the image name at it seems that you scraped it from the builder’s site. Unless you have specific permission from the photographer that’s a copyright violation that could have very nasty and expensive consequences. If you do have written permission, feel free to put it back up.

See our comment guide lines: https://www.morganscloud.com/2013/11/10/aac-comment-guide-lines/

Sorry, I forgot about copyright issues, will be more careful.

But I guess the idea/concept was easy to grasp.

I should have linked to this image instead 🙂

https://etugri87v3i.exactdn.com/wp-content/uploads/2012/01/JHH5II-14032-460×324.jpg?strip=all&lossy=1&ssl=1

Hi Svein,

Yes, that’s certainly an option, but it has drawbacks too: The biggest problem would be how do you get the mainsheet back to a winch in the cockpit without either a hole in the hard dodger, which will let water into what is now a dry place for people and electronics, or at least three right angle turns with the added friction.

Hi Svein,

Yes, I agree the cut out in the coach roof may require optimizing or even deleting, and so does Maxime. That said, as I have pointed out in earlier comments that said cut out also has some pretty interesting potential benefit’s so I’m not ready to junk it until we get to the deck mock up phase, if at all.

As to vang sheeting not being part of German mainsheet systems, the two are not related. The German mainsheet is a way to route the mainsheet itself to the cockpit. Vang sheeting gets rid of the need for a traveler for de-powering. Two different things.

If you want to avoid the “ugly cutout in the coach roof” or, for those who don’t find it ugly but if it proves difficult to mold, or if it catches feet during some maneuvers, the coach roof could be molded without the cutouts then, instead of having full cutouts, tubes could be glassed into holes at the front and back for the lines to ruin through. The tubes might make useful hand holds below.

The jack lines would have to go somewhere else though.

Hi P D,

I happen to have thought of this solution just a few days ago! It may sound like it creates hidden places, but actually nothing like underdeck halyard conduits. So yes I think it’s an idea we should consider!

Hi PD & Maxime,

I’m glad you brought this idea up, because the same thought had occurred to me too, but I had dismissed it until I saw your comments about its overall practicality and possible added utility of an interior handhold.

To explore the concept further, I modified one of the images in the article to show what a conduit-routed mainsheet might look like. Also, this image shows the mainsheet in “single sheet” configuration, freeing up the port side winch (for use on the vang, possibly, with an identical conduit).

Hi Scott,

That’s certainly an option, but, as I keep saying, not sure I’m ready to give up the groove or slot in the deck.

Also, the way you show it in your drawing you are either adding at least three right angle turns, which is a huge friction hit, or the hand hold/conduit is going to be really low. I can also see no way those turns could be made waterproof unless a very expensive custom fabrication were made with waterproof access ports for service.

That said, I agree, going single sheet helps with the vang lead and simplifies, see my drawing in the article.

One thing though, a vang should never, ever, be lead to a winch. Way too easy to over strain something. Rather the vang needs to have enough purchase that we can get the twist right but not so much that we can break something. Once we can no longer pull the vang in as much as we need to? Time to reef.

Hi Scott,

I’d been thinking a tube would be possible that didn’t introduce any more changes of mainsheet direction. <See attached>

But also see the potential trip hazzard this introduces to the jackline. The Jackline needs some refinement anyway since the original drawing where it passed inboard of mainsheet block. The tethered crew member needs to pass outboard so there was a tangle. A straight tether line is desirable but that seems difficult to achieve outboard of the mainsheet block.

So while we’re refining the mainsheet thinking we should be thinking about the tether line at the same time, which we are. I bet this is one of very few yachts considering the tetherline this early in the design process. Cudos to the team! Further evidence that the A40 is first and foremost an offshore cruiser, and a good one with lots and lots of offshore experience being built in from day-one.

ps. My tube idea is only an option if some problem emerges with the cutouts, which seem fine to me at the moment, assuming a straight line outboard of the mainsheet block can be found for the tetherline.

pps. I’ve also shown a couple of removable struts an owner could add to secure the boom when the sail is down. Struts could be stowed in a winch handle pocket when not in use.

Hi P D,

I don’t see why the jackline needs to run along a straight line: it can very well turn around the mainsheet cabintop block!

Also, regarding the aft end of the jackline, a solution is to keep it at cabintop height, wrap it around the dodger aft edge and have its padeye on the inside of the dodger. This avoids creating clutter between the winches and allows clipping on while still under the dodger.

A tight(ish) straight jackline won’t move much if you stumble and put a load on it. A line that meanders round obstacles will pull itself straight before arresting the stumbling crew member. So, it will allow the crew member to fall further towards danger, and gather momentum before beginning to arrest the fall. The arrest will be later and more violent.

Once the load comes off again the jackline is unlikely to return to its original neat meander around the obstacle(s) e.g.; in this case it might come to rest on top of the mainsheet block waiting to impede the mainsheet path.

I really liked the Jackline when I first saw it because it seemed to be tight from end-to-end. A jackline that is draped loosely around items seems risky to me.

Hi PD,

We are doing POD prevention in the next A40 Article, let’s leave it until then please.

Hi

I enclose a picture of the stainless handhold tube with three control lines/halyards leading from top outer edge of deckhouse near the mast to three jams at the front of the cockpit. A white jackline is attached inboard to the aft end of this handhold/halyard run and goes to the mast. A white tether is inboard of the jams and is easily reached from the cockpit. This allows safe passage to the mast with an inboard jackline.

We have a self tacking jib. On boats without a self tacking jib, the jackline could be run all the way to the bow.

Best wishes,

Charles

s/v Dawnpiper

Picture:

Hi Charles,

As I say on the above article, we are going to look at POB safety and jacklines on the next article, so please save your thoughts on this subject until then.

Hi PD

Exactly! Now you are talkin’! Every block you can get rid of is a win, that’s why moving the part that comes down from the boom to the centre line is a fundamentally bad a idea. You diagram is now the same as mine above, except with the tube.

That then leaves the question. Is the tube better than the slot, and if so why? I’m still thinking on that. I think a lot of that call will come down to jackline use and dynamics.

We’ve hit on a significant conundrum. There will be a solution. I can’t think of it yet but someone will.

Centreline jacklines are best. They maximise the distance between the tether point and the side of the boat. They make it possible to actually restrain the crew person on board rather than allowing them to go over the side and dragged to drown.

The current A40 mainsheet run, dodger design, and outboard mainsheet winch placement are all good for good reasons. They also require the sheet to be routed outboard of the centreline. The mainsheet-route centreline-offset is the minimum distance the jackline must be outboard of the centreline. So it cannot be on the centreline.

Simply put; we can’t have both the mainsheet and the jackline on the same centreline.

A few potential solution-options might be

There’s a solution here somewhere. Long story short, I agree with you “jackline use and dynamics” will be a significant factor.

I’m off to read your “person overboard” book again.

https://www.morganscloud.com/category/safety/book-crew-overboard/

Hi

I enclose pictures of the handhold I had installed on the aft end of a soft dodger contiguous with a hard dodger. It adds a great deal of safety, and adds argument to not have a dodger cutout.

Beat wishes

Charles

Charles L Starke

s/v Dawnpiper

Hi Svien

Based on rigging boats ranging from 505s to a 56′ McCurdy and Rhodes for some 50 years and then sailing said boats a lot, I disagree that this set up is bad.

Sure, it will be further optimized over time, but the basic mainsheet design of taking the sheet forward and then back again at one side has been optimized over decades on race boats and is well proven—often called the German system.

I also don’t agree that the cut-outs are a kluge.

In fact I think the are an interesting and innovative idea for the reasons I detail and should at least be experimented with up to and including the deck mock up.

More here on potential advantages https://www.morganscloud.com/2023/04/11/adventure-40-deck-2-0/#comment-306779

I also think the winch islands as designed are one the best, maybe the best, ways I have every seen these challenges addressed. Adding a central winch would, I think, ruin that.

The new swan 48 has an interesting main sheet arrangement, without a traveller. 2 lines come up vertically from the aft end of the cockpit table to the end of the boom. Not as safe as the dodger top of course but I quite liked it.

Hi Pete,

That’s just the sort of mainsheet setup that recently killed two people just south of Nova Scotia: https://www.morganscloud.com/2022/08/22/lessons-from-a-tragedy-at-sea/

And like in that fatality, the set up on the Swan is doubly dangerous because with the boom out the sheet will be threatening anyone using the winches on the coamings.

Maxime and Vincent have come up with one of the safest mainsheet arrangements I have ever seen. Even in a crash jib no one will be threatened, let’s not ruin that.

Hi Svein,

yes, the recent First 36 is a very good data point on interior look. It was unveiled when we were starting work with Vincent, and I used it as one of the reference points to communicate what the search for simplicity could lead us to do. That said, to me it is too far on the white clinical side (as Alistair writes below), and in our case we should not extend the white surfaces to the cabinetry.

By the way, gelcoat is not the only possibility, and sprayed cork (in some places, not necessarilly everywhere), which brings some texture, is part of the range of options.

Hi Maxime,

When you say not extending the white surface to the cabinetry, I hope we are not thinking about the thin veneer varnished ply so common on French boats? Your should hear several Boreal owners I know on the subject of how badly that stuff wears and the impossibility of restoring it well. I also have the same stuff on my J/109 after 18 years it looks horrible with blackening any place it has got damp and all kinds of chips and dings.

Pictures here, before and after we fixed some of it with…white paint: https://www.morganscloud.com/jhhtips/white-paint-is-our-friend/

I’m still a fan of white paint, and using some solid varnished trim to break it up, just like the First 36. I suspect Beneteau may have gone over to white after receiving the same complaints.

Hi John,

argh, I totally see what you mean – on other boats water stains slowly climb their way from the bottom of the panels, and you end up in an interior refit after some 30 years… No, I was thinking of the look, and think that we shouldn’t go too far with white glossy (what I meant by “clinical”) surfaces.

Hi Maxime,

Good to hear, although from what I’m seeing these veneer interiors at least start to look shabby after 10 years, not 30.

In my experience the solution to things looking too clinical is to go to semi-gloss paint, not gloss. That’s what we had in the McCurdy and Rhodes, and it was very pleasant to live in and not at all clinical, particularly after we put up some art, and added brightly coloured window coverings and cushions. All part of making a boat a home, but the owner’s responsibility, not ours.

That said. perhaps one day we should have a rendering decorated in this way to show what can be done?

Hi Maxime,

I wondered if some sort of other spray would not work too, but did not know enough to suggest anything.

Anyway, as Alastair and Dick point out the key is going to be a high enough insulation value so we don’t get condensation.

Hi John,

yes! (cork spray is often touted as insulating, but it’s just not enough)

Hi Svein,

Sorry, I did not understand you were referring to the look of the First 356, not the layout. I should have read more carefully. Now I have I totally agree.

Hi all,

Thanks a lot for the development!

Two very brief comments, if I may.

Why the Bow Platform is aluminium, not stainless steel?I understand there will be some weight gains, but this way it is much more complicated to repair it. Unlike alloys, SS is easily welded almost everywhere.

2. I hope that by reducing the the overall area of glass the other extremity will not be reached – too small windows area, invalidating the whole idea of the saloon deck 🙂 and yes, the aesthetics remark made above is also a valid argument

Best of luck!

Hi Ignat,

In my experience you can get aluminium welded most anywhere because it’s used so much on fishing boats for gantries etc. Also aluminium is, as I understand it, a much more reliable material than stainless steel—I have seen way more strange failures of the later material than the former. In fact this is why, as I understand it, stainless is almost never seen on fishing vessels. That and the cost.

And finally, aluminium, has a much higher strength to weight ratio than SS, and this is a place where every ounce will hurt.

Same question on stainless vs. aluminum. Also, stainless rails are more able to bend without cracking welds.

I do like the platform design and fairlead.

I set up my F-24 with both mainsheet traveler and twin sheets as a test. Both systems were optimally rigged (7:1 tackle for single mainsheet, 2:1 with dedicated winches and cam cleats for th twin sheet system). I could change systems in about 30 seconds, to compare on all points of sail, tack, jibing, and so forth. At the end of the day, I felt the twin system was a great one to understand, and certainly a great jury rig if the other system is damaged, but it was combersome for all of the reasons you mentioned. I’ve seen it on all sorts of new boats, even Gunboats, but I don’t get it.

As for bringing the boom to windward, it’s something I very seldom do and would not miss, particularly if the sheet is high on the cabin top.

Hi Drew,

Yes, I read your excellent article on your twin boom sheeting experiments when I was writing the above. Very useful, thanks.

Hi Drew,

Main reason for aluminium instead of stainless is weight. As you know this is the worst possible place for it. As I understand it the strength to weight ratio of 316 ss is actually very poor. Testing of strength on Spade anchors with aluminum and ss shanks over at PS seemed to indicate this pretty graphically. That said, if engineers advise us that SS is a better material we will, of course, listen to that.

6000 series aluminum is a bit of a pain to weld, and 7000 series nearly impossible, being frustratingly prone to hot cracking. 5000 series is much more forgiving. I have a strong suspicion that the team is planning to use the common marine grade 5083 alloy for this bowsprit, which is not prone to hot cracking. It can be welded by just about anyone, just about anywhere, using a MIG torch loaded with argon and 5356, 5183, or 5556 filler wire. It also makes nice autogenous welds with a TIG or laser.

Hi Matt,

Thanks for the fill on that. (Matt designs high tech welding gear for a living.)

Hi Matt,

thank you, you just wrote a fraction of the owner’s manual! 🙂

(I once had a broken bicycle frame rewelded in a small town in Cuba, and hadn’t such advice available… anyway I was surprised by how easy it was to find aluminium welders – it took literally half a day between the failure and being back on the road!)

I wonder if some form of raised edge around the winches should be moulded in to prevent water coming down the channels from pouring into the seating area.

If so, the “raised edges” must not prevent disassembly of the winches for servicing. On my boat I need to un-bed (remove) my port jib winch simply to remove the gear assembly for cleaning and lubrication. I curse the designer every time!

Hi Colin,

That’s a good point too that we will need to check for. Thanks.

Hi James,

I agree, we definitely need to me very sure that water will not be, in any way directed toward those seating positions. A slight angle aft, together with your idea of a raised edge, should do it. Thanks for the heads up.

I think the boat looks 100% better in these new renderings.

My current boat has the aluminum toe rails and I’m not sure I could live without them. Great addition.

Deck 2.0 has changed the side of the salon top in the area of the window and hatch to not extend out to the raised deck. What’s the purpose of this?

Just to accommodate the sheets being ‘inboard’?

Hi Rick,

yes indeed. Initially we thought more lines would travel over the cabin top, but after more consideration it seems to work better this way. Please feel free to comment!

Hi John,

I have been enjoying (and learning) watching the A40 progress from afar. Most of my comments were made in the early days of the design.

This round of design refinements I wish to applaud the bow anchor area re-design. I have lived with a similar arrangement for decades (anchor platform out front of the hull, asym tack out front): it just makes all aspects of working the anchor much easier and cleaner.

And I also think dispensing with the headliner is a very good move: simple, while perhaps not attractive in the conventional sense it is in no way offensive, saves weight, and you are right about the hours saved in manufacturing which can be added to the hours spent by owners getting underneath headliners when the need arises.

My best, Dick Stevenson, s/v Alchemy

Furter thoughts:

You might consider, with no headliner, beefing up the R value of the deck core. My headliner had dead air space between it and the deck (cored) which I filled with 2-3 layers of Reflectix decades ago now. In the tropics it made a huge difference with radiant heat (and I already had a headliner with dead air space) and contributed nicely to the insulation when in cold weather.

The white expanse of ceiling will be inspirational to those among us who are aspiring Michelangelo’s.

I concur about the banishment of the headliner. If I have a leak, I don’t want to find out when we heel and water starts sluicing out of the low side of something I have to disassemble.

Hi Marc,

A very good point. With headliners the source of the leak can, and usually is a long way from where it appears below.

Regarding your question about moving one of the two hatches over the forward cabin aft to between the windlass and mast. I think the deck space right in front of the mast is critical when operating the wisker pole. Having a hatch there would be annoying and slippery.

Also, if the dinghy is fixed on the fore deck, we must ensure it will still be possiblle to open the hatches.

It is very exciting to see this design evolve, knowing it is made by people having mainly cruising and safety in mind, rather than the racy looks or charters or boat shows.

Hi Pierre,

I’m not sure that’s true, but the only way to be sure is a deck mock up. The problem with the pole would also depend a lot on where and how the inboard end lift adjustment was set up. For example, with a winch drive on the front face of the mast, I think you would be right, but there are other options.

The answer to slippery hatches is a few strips of non-skid tape, which should be applied to any hatch. Cuts down the light less than you would think. We have always treated all our hatches this way. Way too dangerous otherwise.

Also, in my experience with all of three boats there is no way to stow a dinghy on the foredeck and open the hatches, although they can often be cracked a few inches under the dinghy, which brings a surprising amount of breeze in and has the added advantage that it can stay open when it rains.

Thanks for the non-skid hack ! I’ll certainly use it this very summer.

I find the keel and rudder, not encouraging. I would not want to go a-ground with that keel. How much more expense would there be to angle and strengthen the leading edge? The rudder looks adequate but unprotected (Take a look at an Amel Super Marabu 54). Isn’t there a saying, “There are two kinds of sailboats. One that has gone aground, and one that will go aground”.

Craig

Hi Craig,

We have already thought about grounding resistance and the rudder. Please read this article on the keel: https://www.morganscloud.com/2022/06/08/adventure-40-keel-strength-and-grounding-resistance/

And this on the rudder: https://www.morganscloud.com/2022/03/11/adventure-40-rudder-and-steering-gear/

And then make any further comments you have on the subject on those posts once you are clear on the huge amount of work already done to solve the grounding issue to what I suspect is an even higher level than Amel, or most any boat out there.

We will also have an update on keel grounding resistance and the engineering work done since the first on the subject, in a month or so.

I love the bow pulpit and the more business-like, offshore look. I second John’s point that it should be easy to blow the main in a gust/knockdown scenario (single watch-stander, of course). And a traveller on the cabin top is expensive, clunky, etc.

John, would it be better to run a single mainsheet (5:1 or 7:1 purchase) to a bridle on the dodger top, instead of routing the sheet through the two blocks in the drawings? Might this be more effective at centering the boom? Maybe not. In any case, there might not be enough vertical space to create the proper geometry for a bridle. Just tossing the idea out there.

Hi Colin,

yes the bridle idea works in general, just as the tower John mentions on the 5O5, and it’s seen more and more on some production boats. It’s just that the dodger is already quite high, and the bridle junction wouldn’t reach significantly higher.

Hi Colin,

A bridle is interesting, I agree, but as Maxime says we are already so close to the boom I’m not sure it’s worth it. That said, with this set up there would be nothing to stop an owner experimenting with one.

The other issue with a bridle might be annoying noise with the boom out and the bridle tapping on the deck as the boat goes over every wave.

Hi John,

I also agree that a twin mainsheet system is not nice. I’ve only tried it a few times, but basically hated it for being clumsy and slow. Maybe I could get more used to it, but I strongly doubt that I would ever like it.

A traveller is great, if it’s long enough to cover the most usual sheeting angles. If not, like one on top of the dodger, it seems kinda useless. A beefy vang with a structure to match it will no doubt do that job far better.

I’m a bred in the dye hater of innerliners. Anything else covering or limiting access to the structure of the boat gets a share of that hate. Gelcoat or paint straight on the moulded hull and deck is a great solution. I also think it looks better than any alternative. Yes I’m a fanatic. 🙂

One complication of spraying gelcoat etc is that the moulding might have barely visible pinholes. Spraying anything onto them makes much more visible holes in the finish. It’s a solvable problem, but a nuisance.

We once (1990) mixed in white pigment in the epoxy used for the inner laminate and vacuum bagged it. (A pure racing Formula 28 trimaran, “Mirage”.) That surface actually looked really good, straight out of the bag. Epoxy will gradually get a bit yellow, but we noticed no colour change the 4 years we had the boat. It’s still being raced, somewhere in France. I think it might be worth experimenting with this. It saves weight, cost and work.

The fairlead groove in the cabin top next to the dodger seems to me like it may complicate production, and probably more issues, while giving no benefits. If a rope needs to go there, leading it around any type of corner through blocks is easy. For production cost and reliable quality/strength reasons, I’m allergic to complicated moulds.

Looks like the jacklines run through the groove too. Might be really good for keeping the tether length right.

Hi Stein,

Thank you for these points.

I agree on the groove, one more block sounds like an easier way!

Although the groove eliminates a jackline trip-hazzard aft of the cabin-top.

Hi Maxime and Stein,

I may have missed an alternative, but the last time I looked (helping a friend) it turned out to be very difficult to find a block assembly that would elegantly turn a sheet over the edge of the cabin in that way, so we would need to find a good solution before doing away with the groove. Perhaps a turning block on the side of the dodger, but that gives us two 90 degree turns which is a significant increase in friction.

The other thing we need to check carefully before doing away with the groove is jackline and tether length in conjunction with getting in and out of the cockpit, as PD points out.

Point being that the groove will, I think, reduce drag risk without over shortening the tether, which might make it hard to get around the winces and out of the cockpit.

So my suggestion is keep the groove up until the deck mock up stage so that both of the above can be tested with and without it.

More on drag risk here: https://www.morganscloud.com/2014/10/02/staying-aboardpart-iiiour-gear/

Would standard nuts like these work and save a few $s and builder-minutes compared to custom “pads let into the laminate by removing the core, and then threaded“?

I think this could be a good solution, provided there is backing inserted in lieu of the core during construction.

Hi PD,

Interesting idea. But when I look at the caps on those, and compare to how thick a nut must be, I wonder if they would be strong enough to take the tension on the bolt when proper torque was applied.

Nut strength is generally limited by thread engagement area. In a standard hex nut, that’s proportional to overall thickness, but in the ones in P D Squire’s picture are threaded through the full length of the sleeve. They’ll be fine from that standpoint.

Where those things go wrong is that the entire load is concentrated on the relatively small annulus of the head, so they work fine on metal — but they tend to crush wood & fibreglass, pulling all the way through. They’re also prone to trapping water inside the threaded cavity and therefore subject to crevice corrosion.

Long-term, there’s still nothing better than substituting solid material for core in the areas that will be through-drilled for fittings, and then using conventional hex or acorn nuts with thick washers or backing plates.

Hi Matt,

My concern is how thin the annulus is and that under full torque of the bolt it would rip off, but if that’s not the case, and verified by testing, I thing P D’s idea might be a good one since it would be quite flush even with a washer under the annulus to distribute the load. I’m also still liking the idea of threading into the blocking material that replaces the core itself since that makes the whole area flush, makes it easy to remove the fitting for painting, and makes leeks an impossibility.

By the way, I don’t like acorn nuts because it’s all too easy to bottom the nut on the bolt and therefore get inadequate torque. I know that should not happen if the bolt is the right length etc, but in the real world of a production boat builder…

In the render it looks like the jackline runs inboard of the mainsheet blocks. Once you’re clipped on you’ll want to pass outboard of the blocks. As you say, the running rigging isn’t finalised yet. Just something to note.

Hi P D,

yes totally, that’s a bug, it’s even why the jackline was removed in the subsequent images!

I think plain interior GRP, even gel coated is clinical, cold and unattractive. In my neck of the woods, condensation is significant when it’s colder, even on lined hulls. I may be misunderstanding, but that would be a turn off for me. Ventilated air gaps are a recognised method for reducing condensation. Head, hull liners can be made easily detachable at a low enough cost. I think conduit for cables would be too industrial, the boat has to be a home as well and I am not so sure that conduit and exposed gel coat inside would contribute to that.

Example: my headlining is all exterior grade ply, 3mm I think, with a foam backed vinyl. The panels are attached with teak straps screws to blocks glued to the hull underside. Very simple and easy to remove, maintain. I appreciate the cost escalation but there may be off the shelf panels that can be cut to fit without ply, vinyl construction.

I do like the main sheet proposals and bow platform.

Hi Alastair,

I agree that removable panels is the best solution, in fact I write that in the article above. That said I would never cover them in vinyl, let alone foam backed. That stuff has a history of going very nasty over time, although that might be brand specific, and vinyl attracts mildew like a magnet, or at least it does in my J/109. It’s also difficult to repair, and worse if foam backed

That said, I think you are underestimating the cost of cladding the hull and deck this way. A huge amount of exacting and skilled labour to get all the sheets fitting well and then cut and shape all the trim pieces to make it look good.

Point being if we add too much of this kind of stuff we will either need to cut construction quality or will end up with just another half a million Euro 40′ boat.

The other thing to think about is weight, given that every kg added for this kind of thing is a kg less payload.

That said, these final cost/ benefit decisions will wait until a builder can consult on actual costs of each one. So if it could be done inexpensively enough, without vinyl, and light enough, I would be all for it.

All that said, I agree that if we are going to have a condensation problem, or excessive heat loading, which should be easy to calculate once we know the insulation value of the core selected, we will need to think again,

Hi John,

As you can probably guess, I am very happy to see a proper fairlead ahead of everything else on the bow platform. I think that doing this platform in a marine grade of aluminum makes a lot of sense over stainless due to weight. I have recently been running some numbers on pitch moment of inertia and was surprised by just how important weight is out there. This is not a place where I would eyeball and overbuild, doing proper analysis is worth the effort here. Even making sure that the anchor is no further forward than needed is important.

My initial reaction to the idea of gelcoated overhead rather than a headliner is that I think it would be fine provided you had a system to deal with bolt heads that is clean and doesn’t end up being a headliner. I have recently had some of our headliner down in the area of jib tracks, winches deck hull joint, etc. and the shear number of bolts there is quite a lot. At the same time, I hate how poor the access is on most boats, heck I really want to modernize some clutches on our boat and haven’t done it yet because of how long it will take to get access. Headliners also eat up headroom, add weight and maintenance, none of which are good. From a liveability standpoint, probably the most important thing is getting a nice shade of white that doesn’t look instantly dirty but keeps things bright down below.

I also agree on dodger height, if you can sit up under it and everything else is well designed, getting in and out of the companionway is usually perfectly fine and well worth the improved visibility. On our boat, someone who is 5’5″ can see straight ahead over the dodger including the horizon but they can’t look down whereas someone who is 6′ can see much of the foredeck. Sitting under the dodger, I have a few inches of headroom and can get down below just fine and I am 6’3″. We could probably even push it slightly lower but it came this way from the previous owner and we are happy enough with it.

Eric

Hi Eric,

it sounds like we’ve run the same (simple) pitch moment calculations! So exact same conclusions on the bowsprit/platform and its optimization. Also, you must now be seeing high masts with a different eye!

Thank you for the other feedback too!

I was surprised at how far aft the chain is lead and the location of the winch, which lands the chain in a good place I hope towards the center. I assume there is stainless steel in the chain gutter.

Hi Frederik,

Moving the chain weight aft was one of the first, and best, innovations in the early spec that Maxime wrote.

I would not think SS is the best material for the chain gutter. Expensive and heavy. There are very good low friction plastics that will, I think, do a much better job at a much lower cost.

Hi Frederik,

on stainless steel, I don’t say no in advance, but same point as John on low-friction plastics – another area where taking a look at fishing boats can be useful!

Hi Maxime,

I am glad to hear that you are doing these sorts of calculations. It seems to me that far too many boats have been designed by eye only with maybe a couple of rules of thumb thrown in. In my own line of work, it never ceases to amaze me how big the gains we can get are with a basic first order analysis on things. Usually this shows us a few key areas to focus on then we do much deeper analysis there. I do make sure my team doesn’t fall into the trap of optimizing using CAD only (we have a formal analysis process but that is a function of a bigger team and needing to use common inputs and then roll up our outputs).

Eric

Hi Eric and Maxime,

Good to hear the engineering backs up this old fart’s horror of weight a long way forward.

A horror that originally came from driving race boats offshore and feeling, and seeing on the gauges, the immediate slow down and increased pitch when the bowman went forward for something.

And before that when I was the bowman, being yelled at by the after-guard to hurry it up and get my ass back on the rail if I tarried, even for a moment, on the bow.

That said, I only just learned that this effect is “quadratic” from Maxime. Now I just need to understand better what that word means, although I get that it’s a lot worse than linear.

Hi John,

… and your story is a fine example of why it’s better to learn sailing on not too large boats!

In most matters relating to pitch, roll, and yaw, the moment of inertia is what matters:

Multiply each mass by the square of its distance from the centre of mass. Sum the results.

The quadratic term is that factor of r-squared. Move something twice as far from the centre of mass, and its effect on the moment of inertia increases by 4x.

Weight on the bow is a good example. So is weight aloft in the rig. Adding 1 kg at the top of a 15 metre mast has the same effect on static stability as adding 15 kg located 1 metre up, but its effect on dynamic motions is 15 times worse. Moving 1 kg from deck level (1 m above centre of mass) to masthead (15 m above centre of mass) is a 225-fold increase in that item’s contribution to the moment of inertia.

(Going back a few weeks, this is a big part of why Colin’s new undercanvassed-on-paper SHE 36 is so damn fast when the wind and sea state pick up. It doesn’t have to carry any excess moment of inertia around like a boat with big sails that’s always on 1st or 2nd reef does.)

Hi Matt,

Thanks, that clear explanation will be very useful going forward.

Hi Matt,

thank you, I don’t have more to add to your comment and just want to emphasize once more what you say on Colin’s She 36 behaviour in waves. This is exactly why we kept the A40’s mast height very reasonnable, and started with this premise before defining the rig type (I mean, before choosing it to be a true cutter).

Does a ketch rig lower the moment? (Probably many reasons against a ketch for the A40, just curious)

Hi P D,

Having sailed on one for many ocean miles I’m a total ketch hater, particularly on smaller boats. Adds expense, clutter, generaly makes the moment worse, not better, and all for almost no gain in effective sail area.

Hi PD,

I sailed a yawl for years and loved it, but:

In addition to John’s comments, having 2 complete sets of standing and running rigging to deal with and occasionally replace, almost twice the expense when removing masts etc. does wear thin after a while. As well as no additional benefit in sailing ability and a detriment on some points of sail.

However, the mizzen is a great place for radar, my yawl had that wonderful iconic sailboat look, I loved having the mizzen up weather-cocking me into the wind at anchor and my children almost never forgave me for selling her.

My best, Dick Stevenson

Hi Dick,

Don’t forget that a mizzen is also a great place to hang bananas..but then bananas bring bad luck at sea.

Seriously, good point on complexity and that brings to mind that, in my answer to PD, I missed the huge windage hit of a mizzen and also that mizzens are an even more terrible idea on cutters than they are on sloops because the main mast is further aft.

Thanks Dick & John. So one stick is best even if two is sometimes prettier. We’ll just have to use a riding sail to weather-cock

Yes, sadly, there are times when aethetics must give way to practicality. Dick

So a deck-stepped mast that lowers to keel-steeped by the time the 3rd reef is in might have some merit? Way too complex and risky for the A40, and maybe impossible but perhaps a fun experiment on a small racer.

I share your feelings about headliners: I just finished adding two cam cleats for in haulers on our J-109. Actually mounting the cleats took a bit over an hour including removing the core.

Removing and reinstalling the headlines in the head and aft cabin took three hours and involved disassembling two opening ports because the TPI had installed the headliner before the ports! I was lucky not to have to remove the ports completely., which would have added another day at least.

By the time I got the headliner and trim all back, my neck was going into spasms from the awkward contortions required.

Eric, good perspective on dodger heights. My wife agrees with you. She is 5’5″, and while she can just see the horizon over our dodger top, she can’t see the lobster pots as they approach the bow. The result is unnecessary anxiety, marital discord, and an occasional cold swim.

Hi Colin,

If the dodger height is good for horizon sweeps, you might consider some sort of altitude enhancement for those times when lobster/fish pots are about. Our solution, now for decades, is a foam “helm seat” or helm saddle sold at boat shows (http://www.ccushions.com/). It is rectangular and gives us 6 or 8 inches when we stand on it and can be used behind the wheel or behind the dodger and gives just enough height to see the pots before they find you.

It also doubles as a seat or backrest.

My best, Dick Stevenson, s/v Alchemy

Hi John,

I really wasn’t a fan of the previous “wraparound sunglasses” look, props to the team for fixing it!

Regarding the headliner: on my boat, the headliner is made up of a molded fiberglass liner, and there are some recesses that accept thin plywood pieces where there is deck hardware attached. This neatly takes care of hiding bolts, and there is also wiring run in there. Removing a panel to access a particular bolt isn’t too bad as the panels are of a manageable size. Google “Landfall 38 interior” to see how it looks.

I’m a big fan of keeping it simple, but it might be a good “in-between” option too.

Hi Emile,

at first glance it looks like this solution creates unreachable voids? Which would be a no-go. But anyway, yes, it’s a good example that it’s possible to have a few removable panels where there are many bolts!

Hi Maxime,

Good point, I would be dead set against any liners, except possible one for the head. Two problems with liners, as I see it, are what happens when we need to run wires or add fittings the designer did not think of, and the other a big weight add for very little added strength, particularly on a cored epoxy boat, which is already very stiff.

I like the new look. The render makes it seem a bit more industrial. I liked the previous “sunglasses” look too, even though many did not.

I don’t care about the headliner issue but many admirals will. Perhaps if the final boat doesn’t have one included, it could be an option for a prepared 3rd party option.

Thanks for all the work on this concept. I am having a hard time convincing myself to consider an “old” 40 foot design: Pacific Seacraft 40, Valiant 40, Calibre 40, etc.

John, is storing a 9’ dingy on the forward deck ( when short hopping ) going to cover the windlass; assuming the dinghy will be on deck when anchoring or exiting. Will this layout interfere with storing the dingy on the forward deck?

Also, it appears in this deck layout the dingy tie downs would be the toe rail…causing perhaps a tripping event when going forward under sail & likely a shifting dingy in heavy seas—not good. Is this unsafe? A potential fix could be handrails on the deck for tie downs and for additional hand holds while going forward.

It appears; when going forward while underway, the hand holds are limited in the mid to forward sections. Scary. Hand rails on the mid-deck cabintop could double as tie downs for the dingy and safety rails while crawling forward.