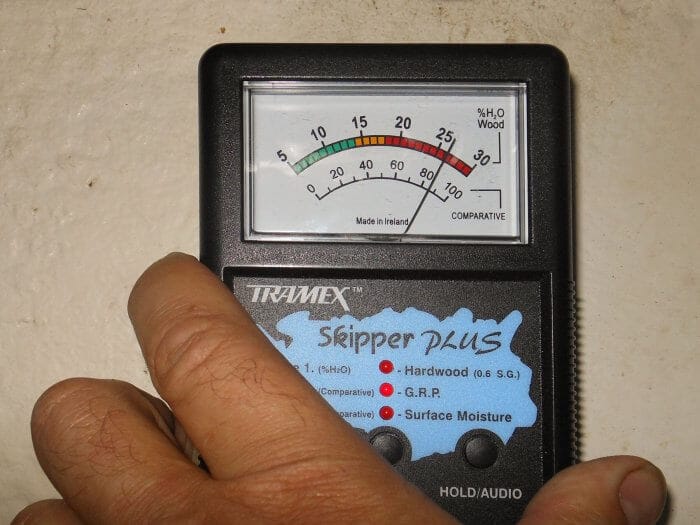

In the last chapter we looked at choosing and managing a surveyor. In this one, I’m going to share what I learned from Steve D’ Antonio about one of the most important tools in a fibreglass boat surveyor’s arsenal: the moisture meter.

First off, let me make clear that this article will not make us experts in moisture meter usage. Neither do I (or Steve) recommend that we even aspire to that goal. While a moisture meter newbie might gain some useful information—more on that in a minute—using one to accurately assess the state of a hull requires deep experience.

So better to hire an experienced professional surveyor, or perhaps a boat yard technician (see last article), to do the work for us. As we say in Bermuda, “don’t buy a dog and then bark your own self”.

That said, what we can do is make sure we know enough about moisture meters to recognize whether or not one is being used properly by the person we hire. And, further, we should always discuss moisture meters with a surveyor before hiring them, since we can use the knowledge we have gained from Steve to disqualify poor surveyors.

For example, if a prospective surveyor says, “I don’t use a moisture meter because they don’t work”, that’s Latin for, “I don’t know how to use a moisture meter” or “I can’t be bothered”.

Either way, that surveyor has just eliminated themselves from our list. (Judging from the comments here at AAC, that response is surprisingly common.)

Planning For Success

Next, we need to make sure the boat to be surveyed is set up so that the surveyor can use a moisture meter effectively:

Hi John, what is “dishing”? I’m not familiar with that term.

Hi Chuck,

Sorry, I should have better defined it. Dishing is were the bolts holding a fitting to the deck compress the core, that should have been removed, so that the deck around the fitting has a dish like depression.

Ok got it now, thank you!

re “dishing”

Once in a blue moon you will encounter a boat with a deck laid up from a properly built mold. It will have a raised 1/4-3/8″ platform under every stanchion base and on-deck fitting. Instead of sitting in water until the bedding eventually breaks down they will remain relatively dry and last years more before developing problems.

Which brings us to the first inspection step before you consider using a moisture meter or even going below on your dream boat. Walk the deck and put your shoulder to every safety rail stanchion while looking for movement between the deck and base. Whoops- you bent the stanchion? Makes you wonder how sturdy the rest of the boat is!. I recall a Valiant 40 that I was enamored with back in the day. I didn’t have to get out the moisture meter to know that I was looking at a deck re-core after watching a mini-firehose shoot out from ever stanchion base!

Another word of caution. Be aware that if the boat originated from China or Taiwan it is common practice to keep the apprentice carpenters busy by cutting up all the left over plywood scraps into little pieces that can be used as deck core. We did a $250,000 insurance claim repair on a 55′ trawler that was only 6 months old when the worms started crawling out of the woodwork. Doesn’t even have to come from Asia, as several Westsail 43’s s owners discovered when their deck core had been totally eaten by termites. The factory procedure on those boats involved pressing a sheet of cheap fir plywood into polyester resin while it was still in the mold.

When it comes to boats and Boeing airliners—- buyer beware!

Richard:

“Be aware that if the boat originated from China or Taiwan it is common practice to keep the apprentice carpenters busy by cutting up all the left over plywood scraps into little pieces that can be used as deck core.”

While you amended this comment later on in your post, let me reiterate, as someone who has spent countless hours working on and crawling through Asian-built boats, and as someone who has spent a great deal of time in Asian boat yards, these defects are by no means limited to boats built in Taiwan, China and elsewhere in Asia , I have encountered them on US, Canadian, European, and Australian-built boats (including insect infestations). China/Taiwan are no different than almost every nation other that builds boats, the quality runs from outstanding to abominable.

“The reason Steve recommends lab analysis is that even a reading of 100 (full scale) on the moisture meter he uses, only indicates 1.5% moisture content in the laminate. ”

To clarify, that’s 1.5% moisture content…by weight.

Hi Steve.

I have no doubt that you are correct, and your sample size is far larger than mine. My comment was triggered by my experience with the trawler I mentioned. I had 30 year boatbuilding veterans on my crew, and as each new layer was excavated we were grew more incredulous at the way it was put together.

Richard:

Understood, and I’ve had my share of those cases as well, from all four corners. I suspect part of the bad wrap Asian boats get is partially a result of the law of averages, they make a ton of boats, at affordable prices, so we see more of them and thus more issues. But it irks me when people paint with a broad brush, trashing Taiwan or Chinese builders, they are some of the sharpest and most capable builders with whom I’ve ever worked.

I feel that way about Sub Zero refrigerators, a lot of luxury motor yachts have them and i see a lot of failures, is it because they are inferior or because they are popular, I still haven’t decided.

Hi John,

This article was a good reminder for me. I’m no broker or surveyor, but frequently get asked for an opinion. Maybe I should actually get a moisture meter…. Rod Collins at http://www.marinehowto.com is a good source of detail knowledge on several topics. He has an interesting article called “Understanding the moisture meter”:

https://marinehowto.com/understanding-the-moisture-meter/

Hi Stein,

Great link, I will add it to the further reading in the article, thanks.