In 2015 I bought a Jordan-type series drogue for Iron Bark, my 35-ft Wylo-class steel gaff cutter, designed by the inimitable Nick Skeates. She displaces 11 tonnes so the drogue is 97-metres long with 124 cones, as recommended. The drogue was supplied by OceanBrake.

The cones are made of a heavy cloth with a rubberised backing, seamed all round with heavy tapes well sewn on. The bridle and first section of the drogue are 18-mm double-braid nylon with a tail of 14-mm nylon double braid. The splices, seizings and attachments of the cones are all strong, neat and seamanlike.

I thought the whole thing to be exceptionally well made and fairly priced.

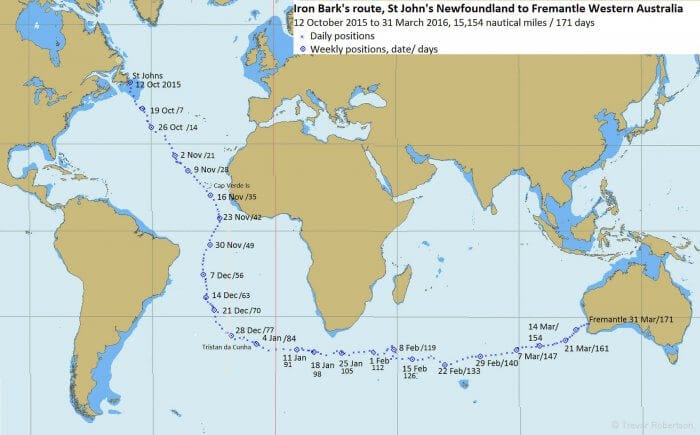

Since fitting the drogue I have sailed from Scotland to Newfoundland and Labrador, then south down the Atlantic and around the Cape of Good Hope to Australia, and on to New Zealand, with a diversion to Australia’s tropical north coast along the way. During that time I used the drogue on six occasions. Here is what I learned:

What an excellent and informative analysis, one drawn from a real life at sea in truly testing conditions. My takeaway, barring further reporting, is that drogues under the most trying conditions must be considered expendable safety gear, but offer so many advantages otherwise that this is an acceptable element of their use. As for the vane damage, there are some vanes where the paddle can be lifted up and out. Was this an option for you or was the vane still actively steering with the tiller otherwise lashed? I’m wondering if an autopilot could work under these conditions, particularly when otherwise driven under bare poles or perhaps just a reefed staysail?

Hi Marc

Regarding the drogue as expendable is perhaps a bit harsh, but it certainly is a high-maintenance item. A complete set of spare cones is probably a good idea for a long Southern Ocean passage, but unnecessary for the North Atlantic where the distances are less and the conditions not so severe.

The vane damage issue is going to be different in every installation. In my case I believed there was a greater chance of fouling the paddle stub if I removed the paddle so left the paddle attached. The difficulty of removing the paddle while hanging head down over the stern in rough weather also played a part in that decision. The real problem was the Aries weak link failed to protect the paddle leg.

There is little reason to have an autopilot or self steering connected while running with a Jordan-type drogue. The boat’s speed is too low for the rudder to be effective in overcoming the drag of all that rope and over a hundred cones. I lashed the tiller and left it at that. Although at times I had the tiller lashed off-centre in an attempt to bring the old sea on to the quarter, I believe that slightly shortening the appropriate leg of the drogue’s bridle had more effect on the course . As in all cases I shortened the bridle leg and lashed the tiller off centre simultaneously, I cannot be certain of what was more effective. I am a practicing coward and find working on deck in those conditions difficult enough to deter experimentation beyond the most essential so will probably never know the answer to that question.

Yours

Trevor

Thanks for these insights, Trevor. A bit of back-of-the-envelope math suggests that your system of steering by adjusting the bridle legs is doing most of the work, and the rudder’s barely contributing at all when the bridle legs are offset. Designing a good way to handle that offset into both the boat and the bridle seems like a very prudent step.

I’d find it very hard to believe that there is no material that can withstand the punishment these cones see. More likely, the market’s so small that the best material just hasn’t been found yet. One candidate that comes to mind is the high-tenacity polyamide(6,6) that Invista makes for car air bags. Or whatever that fibre is that’s used to make the braided wrapping on fire truck hoses.

Hi Matt,

Thanks for the input about the relatively small effect the rudder has on steering compared to having asymmetrical bridle legs. It is always comforting to have one’s crude first impression confirmed by a more rigorous analysis.

Some method of shortening one or other bridle leg is a valuable addition to any Jordan drogue installation. How to do so is going to be different in every installation. Those with the bridle attached to the vessel by way of chainplates on the quarters may be able to do it by running the steering line through a block on the chainplate. There are a number of obvious problems that will need to be dealt with in such an installation, but a failure of the block should not be catastrophic. If the block or steering line fails, the ability to steer across the wind is lost when the bridle leg again takes up the strain, but the drogue continues to work as designed.

I am sure you are correct that there is a better material available for making the cones for a Jordan drogue but I have no idea what that material is. I believe the cones fails because repeated stress reversals cause them to loose the binder upon which the cloth depends for much of its strength. After being subject to 100 hours or so of cyclic wave action, the strength of the cloth is reduced to the point where the cones burst. This is despite the fact that the strain on a 5inch (125mm) diameter cone is small.

I know too little about the characteristics of modern fabrics to comment on which one(s) are worth investigating further. The critical characteristic is going to be the ability to withstand repeated stress reversals without loosing a significant amount of strength. I imagine it being as similar to the having a sail flogging for long periods without the fabric disintegrating, though this may be an oversimplification. If I am correct, this precludes Dacron with a high amount of filler as well as most high-strength sail laminates because they end up looking like a wet tea towel or delaminate and tear to ribbons if flogged for long enough.

Any suggestions from anyone who knows more about modern cloths will be valuable.

Cheers

Trevor

I wonder whether the cones could be made out of webbing rather like mini Galeriders.

Dick Stevenson, sv Alchemy

It would be interesting to test how cones made out of Kevlar worked. Despite the hefty price tag it might be viable to have the most-stressed cones (those near the boat) made from a different/better material.

Hi Trevor

There are several interesting questions here, and I assume you, and maybe even more, Angus of oceanbrake.com, have been pondering these and other questions for years.

From reading here and other descriptions and storeys of use, I get the impression that fibre strength might not be the only critical issue here. Loads are apparently not close to breaking points of fibres, and repetitions also seem to be too few to explain the degree of the observed failures.

Flogging sails have been mentioned. A flag is another example. The fibres do get punished by the flogging, of course, but what seems to be the mechanism of the destruction is that the fabric gets loose and falls apart. Much like most knots on a rope will also come loose if they get enough shaking.

So, if we assume that good fibres are chosen, we’d look for a way to keep the weave stable when exposed to lots of flogging. Melting the edge and sewing it too was already done with these cones. The only way to get more stability seems to be either to partially melt the cloth, laminate it somehow, impregnate it somehow or to use some weave method that has locking knots as part of the weave. I have no idea if that exists.

One more possibility is to make the cones from more rigid materials than cloth. Some sort of PEHD maybe? That might prevent flogging. On the other hand, it seems quite unpractical, probably impossible in actual use, but maybe they could be stored stacked in eachother or such. I just wanted to mention it. Maybe it triggers somebody’s imagination. 🙂

Perhaps some intermediate method could have merit. What about having a few battens in the cones? Battened sails withstand flogging much better.

Thank you for the further elucidation, Trevor. Good points, all.

Hi Trevor,

Thanks for the excellent accounts of the use of your drogue. The durability problems seem unfortunate but if it makes such a big improvement in comfort and safety, occasional maintenance may be what is required as you suggest. Hopefully the ACE cones hold up better. This also makes me wonder how well normal drogues such as the Delta would hold up.

I am curious as to why nylon double braid was used instead of something stiffer such as dacron or even dyneema? If I understand the design correctly, the give in the system comes from the cones pulling through the water and not stretch but that any stretch results in potential energy being stored in the system which can pull the boat backwards when the load eases causing the drogue to react more slowly on the next wave.

Thanks.

Eric

Hi Eric,

Until I try them, I have no way of knowing if the ACE cones will last any better than the Ocean Brake cones, but my first guess is that there will be little difference in longevity – I will let you know if/when I have had a chance to find out.

OceanBrake uses nylon double braid rode because that is what Dan Jordan specified. I believe the reason for using nylon because it handles shock loads better than dacron, and the shock loads on the drogue in a storm are considerable. Dyneema was not generally available when Dan Jordan designed the system so he did not experiment with it, but may work. I have considered replacing the 14mm nylon tail section with dyneema to reduce the weight and bulk of the drogue but am reluctant to take the step. It is not cheap, but more importantly there is no going back on the decision in the middle of a severe storm if it does not work.

I have no experience with single-element drogues, but over the past 20 years, whenever I have met anyone who has used a single-element drogue in the Southern Ocean, I have quizzed them on its performance. Some worked better than others but none seem to have lasted more than 12 hours in storm conditions (force 10 and above) before failing completely. That leaves us with some sort of series-element drogue system, and the Jordan-type seems to be the best of them.

Yours

Trevor

Hi Trevor and Eric,

I understand from Dave Pelissier at Ace that he discussed spectra as an alternative with Don Jordan towards the end of his life and that Jordan had no problem, based on his research, with that substitution. I also understand that Dave has made quite a few JSDs with at least some spectra and had good results.

That said, I have not talked to anyone who has used a JSD made from spectra.

Hi Trevor,

Thanks for the reply, lots of good information.

The combination of your, John and Angus’ comments on line material are interesting. I certainly would not want to be the first person to try a major design change in southern ocean conditions. It would be very interesting to examine the dynamic effects of stretch in the system. With a low-stretch line such as dyneema, the shock absorption capability would be lower. With high stretch, the load would ramp up more slowly and it might allow the boat to accelerate to a significantly higher speed before being pulled through the wave. I don’t have a handle on what the numbers are for this so can’t say anything more than that. Given that Jordan saw no issue with spectra, it is definitely intriguing although I hear Angus’ concern over cost.

For several years, I have been somewhat bothered by how we try to do shock absorption on boats. We are pretty good at putting in springs such as nylon line but we are poor at putting in dampers. Watching a lot of boats anchored on long nylon rodes, it often looks to me like a car hitting a bump with worn out shocks where it keeps bouncing for a while due to underdamping. In the case of a JSD, the drogue itself represents a decent one way damper and the question is how to tune the spring.

Eric

Hi Trevor,

Thank you for the detailed and informative chronicle of your experiences using the JSD. Since you mentioned you now intend to carry spare cones on passage, could you speak a bit more on the time required to replace damaged cones along the drogue? Is it a matter of splicing them into the line, or is there sewing involved? Much thanks!

Hi Scott

I have not yet replaced any cones so am speculating here, but I think it will involve sewing each cone up in place. I think (but do not know) that it will be better to carry the spare cones as flat arcs of cloth, The arcs hemmed with the tapes sewn on, but without the final seam to form a cone from the arc of cloth. The cloth elements can then be wrapped around the warp and the cone formed in place by sewing up the final seam. Lastly the tapes are hooked through the warp and knotted.

My replacement cones have only just arrived in New Zealand and are at the opposite end of the country to me – a common problem with an itinerant life. I will post a comment once I have replaced some cones, but it may be a while before that happens.

Regards

Trevor

Trevor, thanks for your reply. I look forward to hearing about how the repair goes, so as to get the full picture of the life cycle of this type of equipment. Perhaps your experiences here will inspire further R&D in what fabrics can be used in the making of a JSD.

Hi Trevor

I read your report on your website a little while back. The best description of the use of a JSD anywhere. We built our JSD from scratch, and after threading 120 cones onto the line, I wonder why your replacement cones couldn’t be similarly threaded. I would have thought that hand-sewing each cone after wrapping it round the line would be difficult, time consuming, and would not achieve the security of a machine-stitched cone. I guess the problem might be that pulling a replacement cone over line plus existing cones is impossible. I’ll test my theory this evening.

?

Yours aye,

Bill

Hi Bill,

I hope you are right and the replacement cones can be threaded on to the warp. I will be very interested to hear the result of your experiment. I am impressed with your with the patience, tenacity and skill to make and assemble a Jordan-type drogue. I looked at the option and immediately ordered a ready-made one from OceanBrake.

Threading new cones on from one end of the warp, as you suggest, is the first option I will try when rebuilding my drogue, for the reasons you outline. For a major refurbishment such as I need to do, I think it will be worth pulling or even cutting the splice at one end of each warp if that is necessary to let ready-made, machine sewn cones to slide over the warp end.

Threading replacement cones on a spectra or dyneema warp should be comparatively easy as it will be over a much thinner line than a nylon warp. This is another argument for using a long-polymer warp in place of nylon.

If replacing just a few cones at sea, it may be easier to unpick and resew the cones in place, but I have no experience with any of this. Until I get into the job, all I can do is speculate.

Cheers

Trevor

Hi Trevor

Great story and invaluable education! I have insignificant experience with drag devices and none with JSDs, but for some time I’ve considered the latter as essential gear. Your story has strengthened my conviction and made me more prepared to use it right. Thanks!

About the fouling of the Aries vane or any other structure in the vicinity of the drogue legs, do you think covering them would be a solution? A canvas or other cover made to fit? Alternatively, maybe just a piece of rope or shock cord from the tip of the exposed item to som other points to stop the rope from coming around it? Spinnaker sheets have a maybe similar ability to jam anywhere and then destroy things when load comes on. On racing boats I’ve found shock cord works well. Any thoughts?

Hi Stein

Using rope or shock cord to deflect the drogue warp from projections around the stern may work. As always, it will depend on the details of each installation. I gave something similar some thought and decided it would not work on Iron Bark, but it may be effective on your boat. The difficulty of rigging lines over the stern in heavy weather also needs considering.

I cannot imagine any installation where a canvas cover would work, but that does not mean it does not exist. Again the difficulty and danger of rigging covers is winds of force 10 (with seas to match) needs considering. The drogue is only going to be used in conditions that make doing any unnecessary work on deck is dangerous. The simpler the system the better.

Cheers

Trevor

Hi Trevor

Thanks for a valuable analysis of a piece of kit I’ve been considering for a while.

Would a (anchor type) trip line make retrieval easier . . or am I missing something obvious ?

Cordialement

Neil

Hi Neil,

I cannot see any way of rigging a trip line on a Jordan-type drogue that will help retrieving it, other than a short line to the junction of the bridle and leader warp to get things started.

A trip line to the weighted end of the drogue system will need to be at least as long as the total warp system, which means there will be at least 100 metres of rope streaming parallel to the drogue. This will inevitably tangle with the drogue warp. If by some miraculous chance it does not, hauling the drogue by its bitter end means dragging a huge bight of warp and cones through the water, requiring a far more effort than pulling it in from one end.

Despite being neither particularly strong nor young, I found recovering the drogue took only about 3 hours of steady, but not exhausting, work. It is probably easier to retrieve the drogue in a seaway than in quiet water because the surge as each wave passes allows me to haul in half a metre or so of warp without undue effort.

Regards

Trevor

Hi Trevor,

The test was successful. The JSD line is 20mm and 16mm double braid polyester, “20-fach geflochten”. Sorry but I can´t think of the right english words, but it is relatively loosely braided. I find the tightly braided lines impossible to splice. The lines are well above the breaking strain requirements for our boat, a Rustler 36, plus 1,500 Kg load. The lines have hard eyes at the front and back ends, and soft eyes for the join between (cow-hitched). I was quite surprised that the cones slid easily over the smaller hard eye, and of course, over the soft eyes. I didn´t try them over the hard eye where the bridle is attached, as that would be the wrong end anyway. The drogues are standard as defined by Don Jordan.

The construction of the JSD was time-consuming but not difficult. Imke and I split the work between us. I made a template for the cones out of thin ply. It was important to make notches on the two perimeters where the tapes were to be sewn, and then to join up these marks before cutting them out. The Nylon came free as offcuts from our sailmaker. I marked them out with a felt-tip, then cut them with a hot-knife on plate glass. Imke sewed them on our Sailrite, using Prittstick to attach the tapes before sewing them. They were not hemmed. To my surprise, the most time-consuming step was the threading of the cones onto the lines. We made a record of the time involved in each step for our friendly sailmaker (he decided, unsurprisingly, that it would not be an economic business for him to offer the JSD). If anyone is interested I can look out these times.

For the majority of sailors, the JSD would be seen as vastly too expensive, for those who need them, as your passage demonstrates, probably cheap at twice the price.

It has occurred to me that the problem you experienced of the JSD fouling the self-steering because of the enormous waves might be eliminated if the weight at the end of the drogue was increased. Our JSD bridle is permanently attached to two chainplates, so we can´t play with the bridle lengths to adjust the boat´s aspect to the seas.

Thanks again for your passage report.

Yours aye,

Bill

Hi Bill,

Thanks for taking the effort to give us that valuable input on drogue maintenance. It is reassuring to think I will not have to hand sew 124 cones to the warp. I am currently beating slowly south along the east coat of New Zealand towards where my new cones are being held, so will soon have a chance to find out for myself how to slide the new cones on to my warp.

Thanks also for the offering the information on built times for the Jordan drogue. If anyone wants it, this is the obvious place to exchange that data.

I think your suggestion that adding extra weight to prevent (or at least reduce) the slackness in the warp leader is sound. After demolishing the Aries paddle, I added 5 kg extra weight to the end in the form of a bit more chain. It was hard to tell how effective it was. The warp never fouled again, but of course there was no longer a servo-paddle to foul. It looked to me as if the bridle had less slack in the worst troughs, but that may have been because the seas in the next gale were not so large.

Thanks

Trevor

Another suggestion for a cloth that might be better than ripstop is Hydranet from the German company Dimension Polyant. It’s not so easy to describe, but it uses two different PE strands woven on a special machine, one very fine and the other thicker, and works in a similar way to ripstop. Friends who use it as sailcloth are delighted, as it is extremely robust and holds its shape well. I have some offcuts and will sew up a couple of cones to see how easy it is to handle. But I have no idea how one might test it. It may be the case, as someone suggested in an earlier comment, that the JSD should be seen, at least in part, as a consumable.

Regards

Bill

Dear All,

First, full disclosure, I made the drogue which Trevor talks about in his article.

I’ll try and answer any points raised there, but also those here in the comments.

Before all that I’d like to say that we offer a lifetime guarantee on our cones. If you have any issues, we will replace them free of charge.

Bill and Trevor, the way we build our drogues means that it is actually fairly facile to thread new cones on. We do not put a splice in the end of each section, instead we have a figure of eight knot on a bight, which is then seized. Once this is removed, you can slide old cones off and new cones on with no difficulty. It is then fairly simple to replace the seizing and knot. Cone replacement need take no longer than 5 minutes per cone.

Eric, we subscribe to the same approach Don had: If it isn’t broke, don’t fix it. As has been mentioned, dyneema wasn’t as readily available back then, and double braid nylon worked well in the system he designed. We offer dyneema drogues to those who ask for it, but given the price differential, roughly twice the price, we prioritise the double braid. When Jordan encouraged us to start making drogues, his aim was to ensure that they were available to all sailors who needed them, and unfortunately, dyneema drogues are incredibly expensive to produce.

Marc, we are constantly looking for new and better fabric to build our cones out of. The current material has proven to be the best under the conditions we’ve tested it in. Going forward, we are looking at other polyester fabrics (un-resinated dacron).

We have sold many drogues and had much feedback, and I have to say that Trevor is the exception rather than the norm. However, for all those who plan on sailing the southern oceans, we will be happy to work together to create a solution that will last.

If anyone has any questions, please feel free to either reply to my comment or email me on I’m always happy to discuss storm survival issues, no purchase necessary.

Angus

Thank you for posting this. It’s a token of your investment in the rather unusual product you make.

Just a few thoughts on the cone design. As I recall, Don considered his research into materials and construction far from complete.

No resins or coatings. We all know that resinated cloth resists stretch better, but that the resin does not hold up to flogging. Additionally, when the resin begins to fail it is abrasive to the fibers. I would select a heavy, non-resinated cloth.

Polyester has a MUCH (5x) longer fatigue life than nylon. Although there are impacts, they are minor, and it is fatigue over 100,000 cycles that matters. There are also high modulous fibers, but I don’t know enough about them to comment.

What about 4 webbing straps? That would reduce the stress and flexing on the fabric by nearly 50% (it’s not linear). I don’t think there is anything magical about 3 straps.

A JSD could be made with ~ 6-8 cones of developmental constructions. They could even be “extras” so that failure would not matter, although realistically, the selection of cone number is empirical anyway. Alternatively, build a substantial cyclical loading test rig, such as Jordan did. That was a smart thing, but he did not finish the research. This would be my natural inclination. I have built such rigs for chafe testing. Just a gear motor, a trough, some pulleys, and a weight.

Hi Drew,

As I’ve mentioned above, I’m looking into different polyesters, without any resins, for future cone construction. I’ve been trialing 4 straps vs 3, but haven’t seen any conclusive evidence either way. (yet!)

A cyclical test rig is all well and good, but unfortunately no simulation ever covers all the eventualities suffered by cones in heavy weather usage.

Any thoughts you might have on the matter are definitely appreciated.

Kind regards,

Angus

Hi Drew and Angus.

On the topic of 3 straps. There might actually be a bit of “magic” about that number. 3 straps will be perfectly balanced in load. Like a chair with 3 legs, which will always have all legs on the floor, even if it’s very uneven. I don’t know if this is relevant in this context, though.

The reason 4 straps give lower loads on the fabric is, of course, that the loads are better spread so local peak loads get much lower. That could maybe be done other ways too. Maybe in how the webbings are attached? Maybe a reinforcement, like in sails?

And thanks to Angus for participating here! It gives the discussion another level of usefulness. In my book, it also gives lots of cred. A maker who has an interest and keeps looking for improvement, is one I trust.

As I check data, the fatigue life of polyester fabrics is actually many thousands of times better than nylon. You only use nylon when you really need stretch, and then you don’t expect it to last forever unless considerably (over 20x) over strength.

https://2.bp.blogspot.com/-Fi_lgsXSs2U/UEkwMS4htAI/AAAAAAAABEo/8niFADj6Q6c/s400/rope+fatigue+life.png

It also strikes me that the cloth weave was rather loose, dependent on the coating for structure.

I don’t know if the rubber coated cloth was nylon or polyester, but those materials are generally nylon, because nylon stretches and moves better with the coating. But I am guessing.

This is a tough problem, blending difficult engineering and a tiny market, with the need for compactness and reasonably simple construction to control cost. No criticism is intended, and it is clear that the vendors really care.

Hi Drew,

The cloth we currently use, and in fact, the previous few iterations as well, is made from polyester.

Angus

Before I go into the below, yes, John, definitely agree with your below post that this use-case is extraordinarily rare, and likely the existing construction for the cones is just fine.

500×1000 denier unresinated sailcloth is probably the best bet for use-cases similar to Trevor’s. In fact, there is ‘Tall Ships’ 1000×1000 denier filament yarn polyester sailcloth available as well, but might be overkill. Anyways, any sort of coating or finish that causes the cloth to be firm in hand at all will reduce the tearing strength and also the tenacity of the yarns in the weave and should be avoided unless necessary to keep the ‘mouth’ of the cone open. Suspect the webbing binding at the ‘mouth’ is good enough for this, though.

I have met Dave from Ace Sails and spoken at length about the drogues he makes. He did not say that the 6.5oz sailcloth had tearing or other problems. However, that cloth is only a 250 x 400 denier cloth, and it does have a fairly firm finish (generally about 8-9 hundreths of an inch stretch at 10lbs force on an industry standard sailcloth test), so I suspect it may have similar problems to the coated version.

Hi Nate,

Yes, I can see that high denier cloth might me an improvement. That said, I wonder what the price effect might be? Perhaps not that much given that much of the total cost of a series drogue is labour.

Higher denier is important for sure, but there are also higher tenacity yarns available now as well. This means you get more ‘strength’ for the given weight of the cloth. The fibers in that 6.5oz cloth are probably 4-5 gram/denier tenacity on the warp, whereas I have recently seen affordable 500d yarns that are 6-6.5g/d. This is a huge difference. Thread or stitch holding ability for high tenacity yarns is much greater, and it appears from the photos that increasing strength of this one aspect would help a lot. To gain maximum benefit, I would think the cones should be cut so that the 1000 denier fill (or weft) yarns form the circular ‘mouth’direction of the cones. Price differential for yarn like this, and resulting cloth, is pennies per kilogram more. Unnoticeable when compared to labor, as you suggest. Downside is cloth useage is so small for something like this that the cloth supplier would make extremely little money on it and would not likely be worth the time and effort of any even tiny company but were it someone that personally cared for these types of endeavours.

Hi All,

One thing that has struck me in reading the excellent comments to Trevor’s story, and particularly those suggesting ways to improve the longevity of the cones, is that we must be careful not to forget that Trevor’s level of use is extremely rare.

Most of us will not in our lifetimes put as much wear and tear on a series drogue as he did in two voyages and therefore the present state of the art at both Ocean Brake and Ace will be fine for us.

And further, let’s not forget that historically, and still to at least some extent today, the biggest barrier standing in the way of wide adoption of this boat and life saving gear is the expense, and/or extreme tedium involved in building it.

Or to put it another way, let’s not let perfect get in the way of very good.

John and all,

I would like to reinforce John’s comment. The Jordan drogue is a valuable tool for safely managing small vessels in heavy weather and almost all my experience with it has been positive. The relatively minor issue of cones failing after something in excess of 100 hours use should not be allowed to obscure this. I brought up the issues of fouling the servo paddle and the failure of some cones after extensive use as relatively unimportant addenda to the positive aspects of the Jordan drogue.

Although many of the drogue cones were quite badly damaged after 138 hours of use on Iron Bark, the drogue was still functioning nearly as well as when new. The failure was gradual and not catastrophic. At a guess from the effort it took to retrieve it, the drogue system still had at least 80% of its initial drag. Even badly damaged cones provide a lot of resistance.

Except in the Southern Ocean, few vessels are like to encounter conditions so severe or prolonged that the drogue, at least as supplied by OceanBrake, will sustain significant damage. It seems hard to justify any large increase in price or complexity to extend the life of a drogue system beyond that which will be required by most yachts. A spare set of cones is probably a good idea for vessels making a long Southern Ocean voyage but not necessary on any other passage commonly made by yachts.

As far as construction and service goes, I thought my drogue as supplied by OceanBrake to be extremely well made using excellent quality materials. Its maker, Angus Coleman, has done everything that could be expected to sort out the relatively minor problem concerning the longevity of the cones. My dealings with OceanBrake have been entirely positive.

My dealings with Ace Sailmakers have been less extensive than with OceanBrake. As far as they have gone, they have also been positive. I do not (yet) know how the cones supplied by Ace Sailmakers compare to those from OceanBrake.

The fact that the cones have a shorter life than other elements of the system is no reason to reject using a series drogue. It may be that the cones can be made of some material that has a longer life, but so far I have seen no conclusive evidence for any such material. If a longer-lasting material is found, I will embrace it gladly. Until then I will make whatever effort is required to keep my drogue in good shape.

Regards

Trevor

Hi John and Trevor

Your comments describe well what is already my take on the issue of series drogues as described by Don Jordan. They’re essential gear for an ocean going yacht. No improvement of the product is needed for this to remain true.

Still, I’m an incurable nerd trying to understand the details of all sides of sailing. Important items trigger the interest and creativity the most. Looking for perfection isn’t always useful, but it’s still fun.

I guess the above partially fits others here too. A group of people like this, might even find some idea worth looking further into, as a pure bonus. 🙂

Hi Trevor

One last comment from me on the JSD, replacing damaged cones. To fit my cones I used a homemade “splicing wand”. The tapes need to be inserted between inner and outer braid. The wand is a piece of s/s welding rod, bent around a nail to give a hairpin shape, with the two ends epoxied into a block of wood as a handle. Built to ease splicing single braid Dyneema, it worked really well for threading the cones. Hope this helps.

Yours aye,

Bill

Thanks Bill. I will make such a tool.

Trevor

Just for those who might want to play around a bit and build their own cones: I found a nifty online program (although in german) to construct the shape for a cone: https://www.rmc-sachsen.de/?nav=konus

For the original JSD dimensions enter:

Durchmesser 1: 127

Durchmesser 2: 38

Seitenlänge/Höhe: 153

Berechnungsgrundlage: select “Höhe”

The dimensions of the resulting template converted to inches:

Radius 1: 2.68″

Radius 2: 8.95″

Winkel (angle): 100.5°

Sounds like an amazing piece of gear!

If anybody would like to see actual deployment of a JSD, atomvoyager has made this very good video of setting the drouge and retriving it in addition to adding some useful commentary

https://www.youtube.com/watch?v=IUfHUGHwdaw

Greetings!

Trevor mentions that after 100 days the bottom was heavily fouled.

I wonder to what extent the “fouling” imposed additional loads on the drogue. Perhaps there needs to be an additional “fouling factor” added to the calculations, if the drogue is used on boats with heavily fouled bottoms, since the drogue may have a harder time slowing the boat down due to the greater friction and fouling “attachment” to the water?

IE: Isn’t a clean bottomed boat easier to slow down?

IE: If there aren’t enough cones, each existing cone is subject to greater loading and wear? (I do not know if this is true.)

Of course a heavily fouled bottom will slow the boat down itself.

Hi Frederick,

Actually I think that the fouled bottom will decrease the load on the drogue, not increase. The reason is that the mechanism of a broach is partly that the boat accelerates down the face of the wave due to gravity, in much the same way a car with no brakes accelerates down a hill: https://www.jordanseriesdrogue.com/D_9.htm. Therefor the breaking of the foul bottom should assist the JSD.

(There is also the the forward motion of the wave to take into account, but since the entire wave is moving forward (see link) the state of the bottom will make little difference.)

I had not read the “feather” principles on the Jordan website.

http://jordanseriesdrogue.com/D_14.htm and the logic for stern to anchoring in a storm/hurricane which solves the “sailing” problem.

Quote from the web page:

“These engineering data clearly show that, in storm conditions, a sailing yacht should be moored or anchored from the stern with a bridle, not the bow. If moored from the stern, the boat will lie quietly and will weathercock with changes in the wind direction.”

Conversely, what are the results when a JSD is deployed from the bow? Is there a significant difference?

Hi Frederic,

The JSD should never be used from the bow for the reasons stated in the page you link to. Bottom line we want the minimum amount of veering back and forth while on the JSD. (The veering back and forth problem is one of the huge weaknesses of sea anchors off the bow.)

If you would like a more detailed answer: https://www.jordanseriesdrogue.com/pdf/droguecoastguardreport.pdf

Hi John and AAC community,

Trevor mentions an issue for those of us planning retrieval of their JSD directly to a primary sheet winch (powered or manual).

Trevor writes: “the drogue streamed out almost abeam as I hauled it in, leaving Iron Bark rolling and lurching beam on to the old sea. Worse, I was trying to haul the boat sideways into the wind to get the drogue back—an impossibility”.

I suspect this will mostly occur in big left-over seas, as the stern is thrown around. And the further the winches are forward, the bigger the issue will be and the larger the side forces created.

Has anyone devised and better still tested a solution please? Fairlead needs to be strong enough to retain the JSD streaming over the stern, but be gentle enough not to tear or snag the cones, as they come in over the stern?

Thanks, Rob

Hi Rob,

We have custom large enclosed fairleads and I think that you are right that without them direct to winch retreaval will not work.

You will find all the details of our winch based recovery method here: https://www.morganscloud.com/2013/06/01/jordan-series-drogue-retrieval/