As many of you will be aware, Randall Reeves just made a planned stop in Halifax after 227 days at sea circumnavigating Antartica as part of his Figure 8 Voyage.

(Randall’s original planned stop was Saint John’s, but he wisely diverted because of the unusual density of ice bergs off Newfoundland.)

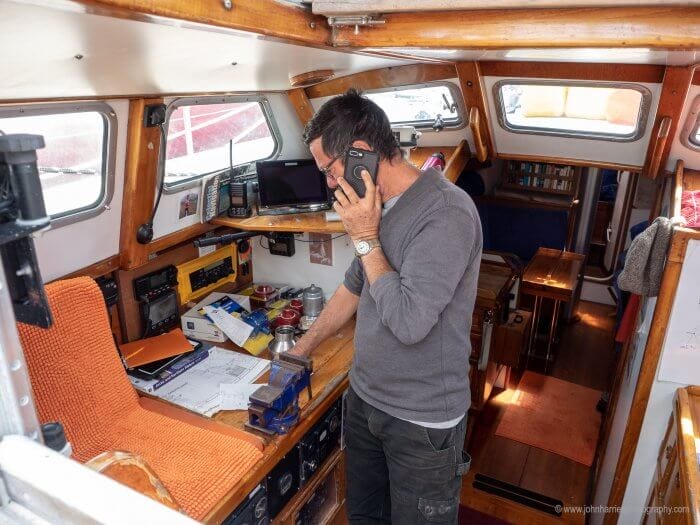

I was lucky enough to spend a couple of hours with Randall on his boat Moli, most of which we spent discussing his experiences with series drogues designed by Don Jordan.

I’m working on an in-depth article on everything I learned from Randall (not a trivial task because there was a lot), but in the mean time I thought it would be fun to post a short video clip from our chat.

I have only lightly edited it because I want to preserve the reality of two sailors figuring stuff out.

Update June 2025

We now know that my idea of using loops spliced into the drogue line won’t work but have a way better solution.

John, great interview, thank you. I’m interested in the Makita unit you have used to “power” a winch – pls advise the model.

Hi Steve,

Full information here: https://www.morganscloud.com/2013/06/01/jordan-series-drogue-retrieval/

Thank you…but that link talks about a Milwaukee drill whereas your recent chat talk about Makita. Is this just an error?

Hi Steven, John made this error while talking. If you check the video again you’ll see the insert John has put in, correcting “Makita” to “Milwaukee”.

Hi Steven,

Yes, I got it wrong in the video, the post is right.

Have a JSD yet to be deployed in anger. Have Outbound 46’ which weighs 30k fully loaded so Jordan added an extension. We are two. Wife weighs 100lbs so for stuff like this she can tail but do little else. Our JSD is not on dyneema so it’s heavy.

Was thinking of setting up a double block at bow and single with becket on free end using dyneema. Put clip or shackle at bitter end. Use that with powered primary and additional loops in jsd line to retrieve.

Any thoughts?

Please give link on splice you guys referenced

Thanks

B

Lee,

Just for information I came to the exact same conclusion for my dyneema JSD after listening to this interview : an added loop on the rode every boat length made of different color dyneema line with a snap hook to the winch. A large block at the bow. Use my high torque Makita with a “winch bit”.

Unfortunately I have the same question you do : how to add a loop to an existing dyneema rode?

Yannick

Hi Lee and Yannick.

The splice I referenced is a brummel splice. If you put that into google you will find any number of pages of instruction. I have not tried this and, as I say in the video, I’m far from the the greatest splicer so I can’t give you detailed instructions on how to do it.

That said, making a loop in the end of the short piece would be a simple brummel splice and I’m thinking that then attaching the short piece with the loop in it to the main line should be doable using the same techniques.

If it were me faced with this, and given how important it is, I would probably take it to a good rigger and let him or her figure it out.

I believe it might be a huge improvement to the JSD if they came with a sort of “inline retrieval eye splices” out of the factory. At least if it were for me I’d be willing to pay some more for such a feature when ordering a JSD from Ocean Brake.

Hi Ernest,

Angus at Ocean Brake is very open to suggestions, so I’m sure he would do that for you on request.

I think we all as users and subscribers of this resource really appreciate the effort being put into gathering all possible real world information and experience of the use of the JSD, where information from the field is generally scarce. I suspect we will all be the better for the pooling of the specific details on this evidently imortant safety equipment. Great to see Randall talk about his use of the drogue, I’ve been following his blog since just after his departure. Looking forward to further discussion on what was talked about on Moli

Couple additional thoughts:

1. It would be worth experimenting with rolling hitches/prusik knots of various line types to see if one grabs where the others don’t. I used a long, old #2 sheet as my retrieval line, running that from the main cockpit winch, up through a block at the bow and back to the drogue with two rolling hitches in series to the drogue line. This #2 sheet was roughly the diameter of the main dyneema immediately following the bridle. The hitches would not grab. Then I tried using 1/4″ covered dyneema and a prusik knot. This also slipped. If a different line or knot combo could be found to work (e.g. rolling hitches of a much reduced line diameter, which I did not try), it would save the expense of the brummel splice solution.

2. One would need to be careful with the brummel splice solution in that the eye must be small enough not to snag *any* deck gear as the drouge is being deployed.

Hi Randall,

That’s true. When using shore fasts I have managed to get a double rolling hitch to stick using lighter line, when changing cleats on the boat, but then again the load might have been lower, so I don’t think I would trust that data point.

Having thought about this quite a bit since our chat I’m pretty sure I will add the loops if we change to a Dyneema first section.

I’m not too worried about the loops snagging when running out given that we deploy from a bag which can be placed with its mouth close to the toe rail where there are no obstructions. I seem to remember that you have enough room aft of the cockpit to do the same?

Hello Randall and John

I too would like to change to a Dyneema JDS for all the obvious reasons – it is lighter, more compact and has minimal weight increase when wet. And of course I have thought about the retrieval issue. I considered the Brummel splice solution and rejected it on two grounds – the problem of snagging during deployment and because I do not want anything that could adversely affect the integrity of the main rode.

The solution I propose to try is to put a cut splice in the rode at each retrieval step – in Iron Bark’s case every 7 or 8 metres – using shoemaker splices. The cut spice is made with a short length of dyneema spliced into the main rode at each end. The main rode is NOT cut in the manner normal for a cut splice. The splice needs to be fairly short to fit in the 0.5 metre gap between the cones.

This should be snag resistant and leaves the main rode undisturbed. The splice can be shorter than recommended as it does not take much load and the load it does take is only for a short time during retrieval – it has no effect on the rode when the drogue is doing its job. If a splice should pull, the only result is that you lose 7 or 8 metres of retrieved line without affecting the integrity of the rode.

Any thoughts?

Hi Trevor,

Sounds good. Not sure what a cut splice is, but I will look it up. Also, I was not in any way suggesting that main rode be broken by a brummel splice. Rather that a loop be made in the added line and that then be worked into the main rode in much the same way as a brummel splice is finished off. However, as I said in the video, I’m a not any kind of a rope work expert and in fact not very good at it. Still I’m pretty sure that someone like you, or our rigger (Jay Maloney), could come up with an answer that will not compromise the main rode.

Hi Trevor,

I just did a search and came up with the cut splice, but only for three strand robe, not Dyneema plat. That said, assuming that there is a way to securely work the added line into the main rode (and I’m assuming there is) I like your idea a lot better than having a loop flopping around as I originally suggested.

As you say, there might be a problem getting enough bury in both ends between the cones, but in the case of a new build that could be solved by just leaving a bigger gap where the splices need to go and then making the drogue a little longer to get the requisite number of cones.

Hi Trevor,

I did a bit of research on splicing Dyneema and also talked to Andy Schell who has done a lot of it. The upshot is that I’m pretty sure a cut splice is not going to work. The problem is that all splices in Dyneema plat rely on the splice being under load to compress the outer part of the splice over the buried part. But in this case the line between the boat and the splice will not be loaded so the splice closest to the boat will pull out.

The good news is that if we just make a loop in a short piece of line with a brummel splice and then simply bury the other end for 72 rope diameters (the standard guideline) and secure it with a couple of seizings it should be plenty strong enough. In fact Andy tells me that high end race boats often dispense with brummel splice and just use this bury method, even on highly loaded lines.

Of course that leaves a loose loop but I’m not sure that will be a big snag risk given how slippery Dyneema is.

Hi Randall and John

No experience of using a drogue to date, but since you suggest trying different hitches/line sizes, have you tried using an Icicle Hitch?

https://www.animatedknots.com/icicle-hitch-knot-end-method

(in case you are unfamiliar)

Hi Henry,

Based on my experience with Dyneema shore fasts I would not trust any constrictor knot to hold reliably. The other problem is that an Icicle hitch is difficult to tie and difficult to remember, particularly for a tired crew who has just been through a nasty blow.

Hi Randall and John

Has anyone tried a climbers ascender on dyneema? If still to slippery might 2 in tandem work?

Any thoughts on how to protect self steering gear from JSD damage?

Hi Carter,

Interesting idea, and way cool if it worked. Certainly worth testing.

That said, ascenders are made to work on climbing rope which is quite rough so I don’t think I would trust one in this application. The point being that I’m near certain that the spliced in loops will work, but all other solutions (other knots for example) are far less likely to work, and if they don’t work its going to be a big problem. So my thinking is better to stick with the loops since the downside of failure is high and practical experience has shown that trying to get anything to stick to Dyneema under load does not work well.

And yes, Randall and I discussed ways to to solve the self steering problem and a method suggested by Stein in an earlier comment. I will be writing about that in the full article on our chat. Spoiler: I think it’s a solved problem.

Hi John

The first thought that comes to mind when trying to devise a method to attach load to the middle of a slippery high-tech line is: Why not start from a proven design that we know works? Something like a Spinlock line clutch is quite compact and could be rubber armored so it could be hauled along the deck without damage. It would seem that a hinged side housing using the same internal components could be designed that would allow the fixture to be clamped anywhere on the JSD drogue line. It should be faster than tying and untying to loops, have more position alternatives, and not risk weakening the drogue with splices or fouling the loops during retrieval. It might be necessary to use covered line for the JSD instead of bare Dyneema, but I can’t think of any other challenges.

Hi Richard,

That’s an interesting idea, however I’m not aware of any clutch type device that does not require threading the line in from the end so, as you say, a new device would need to be built and I can’t see that any manufacturer is going to take this on given that the market would be so small.

Also, I really don’t think there is much, if any, downside risk with adding loops since I can’t see that a simple bury splice will weaken the line and given that we already have a bunch of cones, the added foul risk from a few loops is, I think, fairly easily managed.

A cam cleat attached to the haul-in line might work.

i guess i am the only one not able to break through the muffled audio here…muffled beyond hearing most of the words…oh well…hi tech strikes again ?

Hi Richard,

Hum, I think somethings off in your set up. There are a couple of places with a little wind noise, but generally the sound is reasonable considering it was just recorded on my phone.

Regarding “brummel”:

When I first heard of it, it was referred to as “brummel lock”. As I understand it “brummel” just refers to the way the two parts of the line forming the loop are locked to prevent the inside part of the splice slipping out of the outside part when not under load.

I would guess you will get a splice performing to near breaking strength of single braid dyneema by just sticking the end into the core for 72 times line diameter. Probably slightly more still when tailing the end inside (cutting strands randomly to make it thinner towards the end). But clearly this will work only under lab conditions. In real life, that kind of splice would slip out when *not* under load almost immediately.

So it needs to be locked. I would see 3 ways to do that: a normal whipping, a seizing using stiches and a “brummel”.

The brummel part is not intended to take any load, just to prevent the actual splice to come undone by slipping out.

Because of the way the strands are forced inside out in a brummel lock, I would suspect breaking strength is slightly reduced, similar to but maybe less than by a knot. As a normal whipping on a slippery line is probably also suspect, of the three I would vote for a stitched seizing.

Much of the dyneema sold these days is treated with polyurethane which makes it a lot less slippery than untreated dyneema to the point of it having more grip than e.g. standard polyester double braid. Not sure how long the coating will hold up when exposed to the weather.

Hi Henning,

That all makes sense. I too would not want to add the Brummel lock to the JSD line in case there was a decrease in strength.

Hi John

To retrieve the jsd, if lengths of line or loops cannot be spliced stably into dyneema, why not use two equal lengths of dyneema for the whole jsd. Then there is automatically a loop to grab for retrieval in between each cone. If the dyneema were doubled with two equal length legs, it would do away with a slice or knot at the boat end and could be attached by a cow hitch. That would eliminate the one fail now documented at the boat end. Each cone would have to be securely attached to both legs. And the jsd would be that much stronger.

Best wishes,

Charles

Charles L Starke MD

s/v Dawnpiper

At first glance this has a lot of appeal. I wonder if you couldn’t just interleave the two strands at alternating intervals, say 150 mm buried, 150 mm separate, and then sew the cones on at a point where the two strands are together.

Hi Charles,

Interesting idea, but as I have said earlier in this thread, based on a conversation with Andy, I really don’t think that adding the loops is going to be much of a problem.

Also, with your idea, are you suggesting that the cone attachments would take the load? If so they would need to be way stronger than they are now which would involve, I think, some kind of bury splice, so nothing would really be gained over loops.

I disagree on the JSD retrieval…not the method but the act itself. Deploying JSD’s offshore is something I teach as part of Club Nautique’s Offshore Passage Making program (a week-long offshore course). What I use to retrieve the JSD is a polyproline attached to the end (pre-measured out to the length of the JSD when fully deployed). We just haul it in in reverse, end first. But that’s because we’re practicing in less than a John Kretschmer’s average blow.

BTW, we would never deploy a JSD in heavy weather with a retrieval line as it would twist down and around the rode and collapse the cones. We only do it in practice.

In reality, however, most cruisers will be too exhausted after a prolonged storm to entertain the thought of hauling in a JSD even under partial load in aftermath-seas and the associated winds of a lessening tropical blow, say 25-35 knots. I tell my students “forget it and cut loose. You just used your insurance policy.” There’s no sense straining yourself, damaging the boat, or risking injury to haul in such an ungainly beast.

The way I figure it, it’s very unlikely you’d ever need to deploy a JSD. You could deploy warps or a cone and remain “active” while spinning out of the storm. If one chooses to go with the JSD they’ve made the decision to go “passive” and sit it out…because it’s that bad! In my book, that doesn’t happen very often. But then again, I sail across oceans in the right season.

Hi Mustad,

You are, of course, entitled to your own opinion. And I do agree that retrieval can be hard. However, scores, probably hundreds of sailors have successfully retrieved JSDs, and many of them have done it multiple times.

As to staying active, We have a whole online book on why we don’t recommend that: https://www.morganscloud.com/category/storm-tactics/online-book-heavy-weather/ Said online book is based on both good science and the realworld experience of several of the most experienced offshore sailors of our time.

I guess on the science side the most important quote is:

Bottom line, both science and experence show that even a F8 gale at sea can produce a wave that will capsize the average cruising boat and the JSD is the best solution to that risk.

Hi John,

This post reminded me that I have wanted to ask a basic question about the JSD.

If you only sail between 40 degrees N and 40 degrees south, short of being caught in a tropical cyclone, do you still recommend the JSD be included in on-board safety gear? My wife and I have no extreme latitude ambitions.

Thank you,

David

Hi David,

Good question. Unfortunately the answer is not really straight forward and each of needs to make it for ourselves based on our own risk tolerance. This may help with that: https://www.morganscloud.com/2018/10/26/11-things-we-do-to-stay-rational-about-safety/

I would also suggest this chapter and the next which cover capsize risk: https://www.morganscloud.com/2018/09/16/there-are-no-rogue-waves/

One tip I can give you: Four of the five worst canings I have taken offshore happened south of 40N, albeit in the spring and fall, not summer. But then summer is, in many places, a bad time due to tropical nasties.

John,

Thanks for the reply! I’ll certainly reread those chapters.

All the best,

David

Hi John,

I have been thinking about the issue you discuss above with Randall which has been well commented on here by yourself and others. I find myself confused as to the solutions being discussed, as I’m not sure I understand the problem(s) faced. So apologies in advance for being slow, or if I have missed something, but I want to make sure I’m not making any false assumptions for our own JSD retrieval process.

Is Randall’s need for retrieval loops in the Dyneema JSD, so he can use a powered windlass for retrieval, using a lazy line running forward, rather than directly use the manual sheet winches? So he can get longer hauls? Because he finds the cones snag with the Dyneema rode on his sheet winches? Because his cones are made of nylon and damage too easily if JSD retrieved around a sheet winch? Or because the Dyneema line slips on the sheet winch and is therefore dangerous? Or ineffective? All of the above? Any other issue I may not have considered please John?

br. Rob

p.s. We have an ACE hybrid JSD with the front section made from Dyneema.

Hi Rob,

Good questions.

I’m just working on a full article on that and some other issues. In the mean time, Randall is referring to the same retrieval technique that Trevor uses: https://www.morganscloud.com/2017/05/19/battle-testing-a-jordan-designed-series-drogue/

Thanks John – just re-read Trevor’s article. I hadn’t considered the possibility of the boat broaching side on if using the sheet winches to retrieve the JSD. I need to consider how to create a lead that is strong enough to retain the JSD line at the stern during retrieval, whilst being open enough to allow the cones to pass through. Look forward to your article.

Br. Rob

John,

I’ve been pondering the JSD problems for some time.

What I’m considering is a captive reel in the transom, much like those seen for anchor winches on vessels in the PNW.

This would have several advantages:

1) if the JSD was connected periodically with eye splices, only a portion of the line could be deployed, allowing continued progress with more directional stability. The eye splices would provide attachment points for the harness, so the load wouldn’t be born by the winch drum except for the few moments while the harness was rigged.

2) The full length of the JSD could be used for its intended purpose. Again the captive drum would only bear the load as long as it took to deploy the harness.

3) Additional lengths of line could be stored on the drum, so if sea room was an issue, they could be deployed and the JSD would function more as a sea anchor. Depending on how long the lengths between eyes, this could be fine tuned by selecting different eyes to attach the harness to.

4) Retrieval would simply require reeling in as the boat motored astern.

Problems that I can foresee are. 1) serious modification of my transom and cockpit lockers. 2) weight in the end of the boat. 3) ensuring the winch was strong enough to temporarily bear the weight of the JSD while the harnesses were being made fast.

Has anyone attempted anything like this?

Regards,

Thomas Braun

S/V Nomad (little sister to Randals boat)

Hi Thomas,

All interesting ideas, but I really wouldn’t go to all that trouble, particularly since I really don’t like the idea of reversing down on the drogue. The way I see it, is that the JSD is simply not broken, so don’t fix it. Bottom line, we know it works in its basic configuration so any changes to the fundamentals just increase the chances of unintended consequences.

Also, no matter how long you make it, it will never act like a see anchor, and nor would I ever want it to since sea anchors have a poor track record in comparison to the JSD.

As an experienced mountaineer I’d like to add my two cents. While a prusic knot may not grab the dyneema a jumar certainly would. The benefits being easy placement and removal anywhere on the line. It can be moved, slid or removed under load. The largest line it could handle would be 12mm but that is plenty for most boats.

Hi Alan,

That’s interesting. I have a jumar on the boat and will do a bit of experimenting.

I’ve read through some of your earlier comments and thought more about. You mentioned the roughness of a climbing rope being better suited to the jumar and that is not the case. It would positively work on dyneema. In fact the problem may be the opposite. Under design loads the jumar would shred the dyneema. Simple retrieval would suffice but a broach during retrieval may destroy the dyneema.

Hi Alan,

Yes, I wondered about the chances of damaging the Dyneema too. Particularly since the plat is loose so I can see the Jumar pulling that apart. Bottom line, I’m still liking the spliced loops. More in an upcoming post.