In the last two chapters in this Online Book, I wrote a lot about the huge benefits of having an aft spring running from the boat at her balance point.

But what to do if you are not blessed with the required cleat and/or fairlead (most boats are not)? That’s what this post is about.

Truth and Consequences

But first, let’s pause for a moment for a reality check. I know many of you will say installing a new fairlead and/or cleat is just way more aggravation than it’s worth.

I totally get that and so will have some alternatives in a moment.

But first, to help you in your decision-making, here’s the consequence of not making the change:

Spring Not at Balance Point

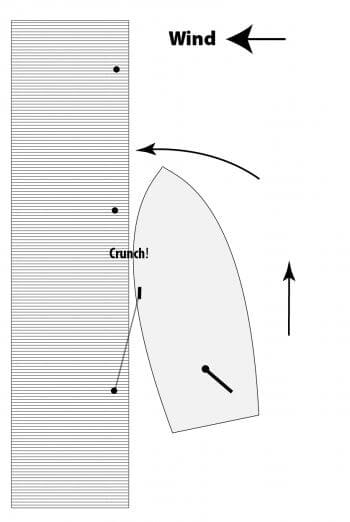

A boat that does not have a fairlead at the balance point will, in many circumstances, need to get two lines, instead of one, onto the dock, adjusted for length and secured, before the docking situation stabilizes.

The reason is that on some (most?) boats, going ahead and loading an aft spring led from the more common amidships fairlead or cleat, will result in the bow swinging in and hitting the dock, perhaps quite violently, while the stern swings out, regardless of rudder position.

This might be manageable when coming alongside a floating dock with a bunch of fenders hung forward, particularly on a smaller boat, but cruisers who venture further afield will be faced with fixed wharfs and/or coming alongside other boats, and sooner or later damage will be done with this method.

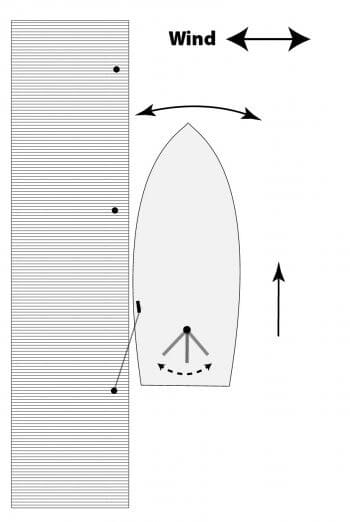

Spring at Balance Point

And, anyway, a balance-point fairlead just makes the whole docking process easier and more elegant, with no need for pulling on lines to get the boat straightened out—particularly important when the breeze is up and/or the crew are not quite as spry and strong as they once were.

I want to emphasize that last point. If our standard docking procedure requires the crew to pull the boat into position using brute strength, said procedure is fundamentally flawed and should be fixed. Otherwise, except with very small boats, sooner or later there will be a disaster and that may include someone getting hurt.

And one final plug: Although Morgan’s Cloud was designed and built with a fairlead in just the right place—Jim McCurdy was a smart guy—now that Phyllis and I have experienced the joys of the aft-running spring at the balance point, we would not live without it and would modify any boat we might own in the future to suit, pretty much no matter the cost and hassle involved.

Two Alternatives

All that said, if you do decide that the balance-point fairlead improvement is not for you, here are some work-arounds:

Hi John

Very interesting and simple (now you have told us) way to find the balance point. It occurs to me that fender positioning might have a marked affect – do you try to always place them at the same points on your rail?

Having a central cleat, up until now we have been your 2nd alternative as our go-to manoeuvre, altering which side we tie up depending on the wind. So if the wind was offshore we would set-up port side to, benefiting from the prop-walk in astern. It seems this must be a balance point for us in reverse as we do not need the bow line to be secure alongside. But we have always set up our fenders differently to try and anticipate where the likely contact points will be.

Rob

Hi Rob,

Yes, prop walk is important and generally our friend if understood and used. I will be tackling that in one of the approach chapters. And yes, I think fender positioning is important, I will be dealing with that in the next chapter.

I doubt that your midships cleat is on the balance point—the test above will tell you for sure—but it may easily be close enough to make a single spring docking practical, and that’s all that really matters. That said, as we will see in future chapters, the closer a spring is to the balance point the more options it gives us in tricky situations. Also, having used both, we have found an aft running spring is generally more use in tricky situations than a forward running one, but that’s not a huge issue and both will work.

Hi John, you’ve sailed in Norway, so you know that many docks there don’t have cleats or bollards – they have rings with which you thread your lines. During the off-season, there’s nobody around to take your line to thread it through the ring. Your post assumes that you have/can get a deckhand ashore. We’ve had problems getting the “deckhand” (in our case, the husband or the wife) onto the dock in the following situation: strong winds and/or current pushing us away from the dock. As soon as the boat gets close enough to safely step off, it immediately slides away again. After about 15 tries we finally manage but do you have any tips? We are both 55 and have never competed in long jump! Perhaps you’ll address “couple’s situations” in a future chapter?

Hi Kathy,

I have one more chapter coming on set up tips, and then I will tackle the approach and getting a deckhand ashore in several situations, including the one you mention.

Would something like this help out?

https://www.amazon.com/s/?ie=UTF8&keywords=hook+%26+moor+boat+hook&tag=googhydr-20&index=aps&hvadid=178143573061&hvpos=1t2&hvnetw=g&hvrand=6848274105770059821&hvpone=&hvptwo=&hvqmt=b&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9012391&hvtargid=kwd-76571501775&ref=pd_sl_1fu3fpawwp_b

I have a ‘Hook and Moor’, it jammed after a couple of uses – sitting on the side deck with the aft spring jammed in the end of a pole as you rapidly approach a tight finger berth is not a good look 🙂

Hi Karlj,

Yikes, that sounds pretty damming.

Great and timely insights. I have a article in the April Sail Magazine about a not-so-funny at the time docking mishap. What kind of fairlead are you recommending?

Talking about this http://www.sailmagazine.com/cruising/opinion/voe-docking-goes-awry/ ? I had wetted my trousers…

Yep, sadly, that’s me. John’s magic docking system makes a lot of sense. I’m all in. Just need an idea of the hardware recommendation. Happy landings!

Hi Karl,

I just read your piece. That was a bad day! Anyway, good on you for sharing it. We all make mistakes and we can all learn from them.

It’s good of you to relate that, and the Blue Jacket 40 is a beautiful boat with sound design ideas. I agree you would have benefitted from casting even a breast line to the dockhand forward preferably, but that would demand a good arm or a willingness to point the bow at the dock while in neutral, or from the aft cockpit to the dockhand as the boat passes the end of the dock midway between midships and stern. Looping that line over the stern bollard on the dock gets you at least stopped and close to where you want to be…it would take some seconds to blow off.

I customarily assume it’s better to approach the dock in neutral having aimed as wind conditions allow. Once a midship line is off the boat and secured, I will use reverse and prop walk to stop dead and to walk off or cast another line to the dock. Thanks again for your educational tale!

Hi Marc,

Throwing lines is definitely an underappreciated skill and I find many people are shocked by what is possible with a good line throw. I prefer to throw 2 coils (like https://www.youtube.com/watch?v=1DFLYCRVRPw) although I know others prefer to throw a single butterfly coil or even a single straight coil. When I was working commercially, at the beginning of each season I would get the crew together on a few different occasions when things were light and we were underway and practice. We would line up along the rail with heaving lines and just throw them for 20 minutes or so and the improvements were remarkable. I found that most deckhands could reliably throw a 1″ dockline 20’+ (the limitation here was often hand size) and a heaving line 40′ with the really good ones doing closer to 75′ on the heaving line.

Eric

Good point. I often drive the club workboat in conjunction with a crane barge to reset our moorings (ballasted with former rail car wheels). The barge is self-propelled, but steers poorly by any measure. So we all have to coil and throw line to and from the work boat to stay on station in any sort of wind or even to tie off to opposing moorings. We use much the same methods as in that excellent video. Practice does make as close to perfect as is useable! Same with MOB drill with your least-favourite floating hat! Or, as the RYA does it, with a line-weighted fender pushed off the boat at seven knots.

Hi Eric,

The split coil two handed throw has always worked best for me too.

Hi Karl,

That turned out to be a surprisingly difficult question to answer. The best alternative I could find was this one from Schaefer: https://hardware.schaefermarine.com/index.php?main_page=advanced_search_result&search_in_description=1&keyword=60-60

They also make a smaller one.

That said, I generally prefer a closed fairlead because there is no chance of the line jumping out when the dock is higher than the boat, but despite spending 30 minutes searching I could not come up with one.

Anyone else have a recommendation?

Thanks for the effort John. This is a good start. Cheers.

Hi John,

One good option for people who like the bronze look is Spartan Marine Hardware in Georgetown, Maine. They have a few closed fairleads that are well built and look great such as these https://www.spartanmarine.com/chocks-cleats. They are not suitable for really large boats but they work for most.

Eric

That locking chock is interesting. Obvious in retrospect, but I’ve never seen its like before.

Hi Eric,

They do look good, although with a max fastener size of 1/4″, boat size will be limited, as you say. I was shocked how few really good options there were when I went looking this morning. Lot’s of junk, very little quality, particularly for larger boats.

We have been using a midships cleat but I think, from reading this post, it is too far forward as our bow can end up coming in hard against the dock. We have Tartan 37 and luckily for us, we have both an inner and outer (on the rail) Genoa track. They are through bolted and we have two cleats on cars that we put on the outer rail as we use the inner one for the Genoa. This makes it ideal for experimenting and finding that sweet spot. We will have to work on this when we go back in the water. Great subject!

Hi Steve,

Sounds great. That said, I think that, if it were me, after finding the balance point, I would install a purpose built fairlead there both because that would allow taking the spring to a winch and because genoa track is not really designed to take loads that are off the vertical axes.

Hi John,

Thanks for the great articles, and this one especially. I changed marinas last year, and the new marina docking situation had me flumoxed…but no more!. I am fortunate enough (evidently) to have a stout cleat at the proper balance point on my Endeavour 35. I tried out your method and it worked like a charm. I was singlehanding, and had I set up my stern spring beforehand to what I thought would be an appropriate length. I brought the boat close to the finger, stepped off the boat and got the line onto the dockcleat. I had expected that I would have to run to put on the bow line to prevent a crash into the dock, but with the engine in forward at low idle, the boat took up a position parallel to the finger, bow slightly in and stayed there! I experimented with a different approach, and also experienced a major windshift which required a different rudder angle, but it still work great! Thanks!!

Jo John,

Great, glad it’s working for you. Sounds like you have it cracked.

The next step might be to figure out a way to drop the loop over the cleat without having to get off the boat, perhaps using a boat hook. Although I have done it myself, when there was no other alternative, getting off the boat when she is in gear really scares me.

Hi John and John,

Agreed on finding a way to get the line aboard without leaving the boat with it in gear. I have found that if there are horn cleats, with a bit of practice you can throw a loop on the dock and pull it around a cleat with something like 95% reliability provided the cleat is within 10′. As long as you have room to deal with a miss, then this works quite well and you end up with a doubled spring line that makes leaving easy if you won’t be there for long.

Eric

Hi Eric,

Wow, 95% You are way better than I am! Seriously, a very good way to go about it, I think.

The guy across from me invented this and fabricates them. I can see how to easily make something similar appropriate for your deck height. https://www.youtube.com/watch?v=n6kp5wIj5zc

Hi Marc,

Looks like a useful gadget and clever idea, although suspiciously like a piece of PVC pipe. Also it’s fun to note the location he has the line tied!

Hi John,

While I see the merits of your cleat at the balance point, I do not think it is necessary to have one. I sail single handed with a 34 foot yacht, so I do appreciate the right docking equipment. But I find that when using the back cleat and positioning two fenders, one slightly at the back of the cleat and one a little aft of midships (and an additional one more upfront for later in the docking process), the two fenders form a line that makes a balance point non-existing.

Using this setup, once the back line is attached and the prop pushing us forward, Dutch Rose will align quite nicely to the dock. Leaving the prop in gear I than step on the dock and attach the other lines.

In Holland we have quite a lot of locks that inexperienced sailors abhor. There is usually a bit or a lot of current due to salt/fresh water mixing and sometimes lot’s of other yachts competing for the same spots in the lock. I find my docking system works in these challenging circumstances equally well, even when sailing solo.

Hi Erik,

Sure, that will work, particularly with a smaller boat. As I say in the post, I’m not saying that a balance point cleat is a required for all, but what I do say, and stick by, is that said cleat does make things easier in multiple situations, particularly in some of the really tricky ones I will be getting into in future chapters.

I found these guys who sell chocks and such, get two and you should have spent enough for free shipping. That’s a plus especially for the heavy 8″ ones!

http://www.greenboatstuff.com/dacobrclfa.html

They have more chocks, cleats and fairleads as well.

http://www.greenboatstuff.com/cleatschocks.html

Hi Ronnie,

Great find! One thing I did notice is that the fastenings are a bit light on the smaller ones, so, as you say, probably good to go for the bigger ones.

Those of us whose rudder(s) is(are) not aft of the prop, whether keel hung or twin rudder, cannot easily pivot the boat on the spring line using power and rudder. So, to keep the boat parallel to the dock after coming to a stop we usually try to secure two lines – a spring plus a bow or stern line, depending on the wind direction – as rapidly as possible. Sometimes it’s a real fire drill!

In short, for our twin-ruddered boat, John’s “best alternative” (spring and bow line in rapid succession) is the only solution we’ve found thus far.

Hi Colin,

Good point that without a centre line rudder docking will be more difficult. That said, I would think that if you were able to install a fairlead on exactly the pivot point of the boat, things would get easier.

Of course the test above will not work for you as described, but I think that if you moved the fairlead forward and back to find a point where neither the bow or stern tended to swing in when the engine is in forward gear, you would then be able to come in on one spring.

As a final test before securing said fairlead permanently, I think I would wait for a calm day, put out plenty of fenders, and then come in at about 1/2 a knot and arrest the boat with the aft spring to make sure that the bow does not swing in hard when the boat has way on on. In other words, if in doubt, bias the position of the aft spring fairlead further aft, rather than forward.

Hi John

Pat and I have tested for the pivot point on our boat and are totally convinced of the effectiveness

We have six of these cleats on our boat (a Paul Whiting 40) and have just purchased two more to install at the pivot point.

It was interesting to note (after we tested for the pivot point and then tied up) how secure the boat looked with springs tied to separate cleats

Hi Peter,

Great that it’s working for you. And yes, you are right, not only does the pivot point cleat make it easier to get alongside, it also gives you more and better options to stay that way.

Hi John

Since apparently so few boats are equipped with cleats at the balance point, I was wondering if the precise the location of the balance point is something that can easily be determined at the design stage? You mention that Morgan’s Cloud was designed and built with a fairlead in just the right place. Was this a stroke of luck or is this the mark of an experienced and attentive designer?

Hi Philippe,

Yes, I think that any competent naval architect should be able to calculate the balance point for a cleat or fairlead.

As to our boat, I don’t know for sure, but I would guess that Jim McCurdy did exactly that since this is just one of the many practical details that he got right on the design.

Hi John,

First of all, thanks for the best chapter I have ever read in a sailing book.

I’m rigging my Dufour 32 Classic for single-handed sailing. I have been pondering how to rig a fairlead at the “magic” point. As a standard production boat with an aluminium toe rail and integrated fairleads, it’s a messy (and expensive), job to introduce a new fairlead at the correct point.

Then it struck me: surely a simple swivel block shackled to the toe rail would work?

The force exerted on the block would be dissipated along the toe rail and the block is only under strain for a few minutes until the other lines are deployed.

While I agree with your comment regarding spliced loops on mooring lines, it is an issue that the cleats on “fair weather”, production yachts are usually too small and the cleats are easily overloaded, so using the loop is a compromise to ease this problem.

Another issue I often see in my sailing club, is that many skippers use the wrong type and size of mooring lines (old, hard, three strand and sized to hold the Titanic). I size my lines to be the thinnest that will support the anticipated load and that are as soft as possible to correctly cleat off.

Finally, in line with many skippers, I love the “toys” and, at that wonderland of the Dusseldorf Boat Show, I bought, not one, but two types of mooring aids. On reflection, they are very cumbersome for the single handed sailor to use. So I intend to practise my steer wrangling skills.

Many thanks for your inspiration, clarity and commonsense.

Denis

Hi John, great articles which have proven very useful for me.

I have a 44′ sloop and seem to frequently encounter the situation when I am “short slipped” into a berth where the finger dock is perhaps 2/3 the length of the boat. Running the aft spring line isn’t really feasible. Any thoughts on how you would rig and approach in that situation?

Hi Kevin,

Glad they have been useful.

In that case it’s often best to back in, so that you can use an aft running spring. See the later chapters for backing in techniques.

The other option, if you must, for some reason, go in forward, is a fore spring and bow line, as described in the chapter above.

John… I have a short dock with the prevailing winds blowing off. I’ve been using a heavy snatch block clipped to the toe rail at the balance point. It this safe ?

Bob Haig

Hi Robert,

I really don’t know, too many variables here: boat size, snatch block size, toe rail fastenings…

One thing I would say is make very sure that the snatch block never gets caught on something in such a way that it, or it’s snap shackle, take an off access load.

Also, we careful that no one stands in the bight of the line running through the block.

I guess, in summary, now you know where the balance point is, I would install a good big fair lead for the purpose.

I’m a few years late to the discussion, but I have an interesting setup that’s going to take some more testing. I’ve got a new-to-me Tartan 3700 with a left handed prop on a sail drive, and I’m currently backed in to the slip, port tie. I was having a bit of trouble trying to find the balance point at the dock, and I kept moving the line further aft, but was still having an issue bringing the stern in with the wheel turned away from the dock (wheel to starboard). Starting at step 7 above, the stern would move toward the dock, but as it got closer and required more “traction”, it would stall and swing out again, then back in, repeating the process. I finally noticed that the prop wash wasn’t visibly as deflected with the wheel to starboard as it was with the wheel to port, jogging my memory that the engine (and so the sail drive) is offset to port.

So while the balance point may be the same on both sides based on the shape of the hull, the location of the line and behavior will likely be a different to counterbalance the variation in prop wash, and I don’t think I can find any position for the line when docked to port that I’ll be able to bring the stern in all the way. I’m not sure it’s much of an issue because with the prop walk to starboard, I’ll likely be trying to dock to starboard, but I’ll have to make a decision tree to figure out the best option!

Great series on docking though.

Hi Brian,

Is your spring pretty close to parallel to the face of the dock? If so, the way to make the stern come in is to introduce some angle to it so that it has something like 20-30 degrees of angle. If tying to a dock that is only a few feet wide, when we initially tie up, we typically run the spring across the dock to the far side while docking then move it back once we have the rest of the lines on. If you get it perfectly where the thrust is effectively straight ahead allowing you to change the angle of the boat either way, then the only force pulling the boat into the dock is actually the line as the thrust isn’t moving it in. Boats with wide sterns have made this a bigger issue, boats with lots of shape have their boat attachment end well in from the widest point of beam so you naturally have an angle but with wide boats, you need to reintroduce this angle and it is usually easier on the dock end than the boat end. Of course, once you are tied up, the breast lines keep the boat against the dock and the spring can once again be parallel.

Eric

Ah, interesting, thanks Eric. This boat does have a wide stern…max beam is 12’8″ and the transom width is 11′. The angle was probably a max of 20 degrees and that was as I was moving it back further for testing, in the area I expect the balanced attachment point is, the angle was probably 15 or less. Were I to move it across the dock, I’d probably be in the 30 degree range (these piers are maybe 4 feet wide). That may make it more difficult to rely on as a default if I’m also relying on a cleat being available on the other side of a narrow-ish dock. Right now we usually use a midship breast line as the first line on, but I don’t like as much it because it requires very little margin of error to get it on tight (close) enough to be effective and it’s not very flexible in general. Thanks for the ideas. More testing ahead!

Have you considered making that midship line a loop thrown over the bollard? You might find it easier to adjust and to pull yourself in to get other lines on. It’s the same technique as lassoing a mooring ball.

Definitely will be considering that once I figure out where I want the line.

Hi Brian,

Yes, getting the angle can be a bit of a trick, ideally it points somewhere not too far away from the center of mass of the boat. If you don’t do it on the dock end, I can only think of 2 other ways to do it. The first is to move the attachment point inboard on the boat but fairleads are uncommon here and you usually have to watch out for stanchions, winches, etc. The second is to shorten the spring line which can be okay if you are good at controlling the boat speed under power and surging the line to prevent very high loads stopping the boat. Of course, you can also flip the whole thing around and back against a springline that now comes from 1/3 back from the bow where it is usually narrower but this has its own issues and I have only used it when backing in somewhere, I haven’t tried it where I need to change directions.

Incidentally, the biggest mistake that I witness of people trying to spring off the dock is to get this angle wrong but this time the problem is opposite. Since the boat is expected to rotate, pretty much the only way to get the angle right is to lead it from close to the bow back to a cleat on the near side of the dock.

You can also get yourself in trouble if the spring line is attached too far aft when docking. The trouble is that the stern wants to pull in which then means that you try to correct by vectoring thrust which pushes the stern (and the whole boat) out. If you move it forwards to a point near midships, you will be vectoring thrust to push the boat hard against the dock in order to stay parallel so both the line and the prop wash push you in. The problem with this is that when the spring line initially comes tight, it imparts a yaw torque on the boat which makes the bow come in too quickly. So the right balance is as John describes where the line is from approximately 2/3 of the way aft but you do need to get enough angle so that the line points at approximately the boat’s center of mass.

Eric

Thanks again, you’ve definitely thought this out!

Starting from the step 7 position, the spring about 2/3 of the way back (where it “feels” like it should be), with the stern line taught and wheel toward the dock, the angle of the spring against the dock *is* actually about 45 degrees, which then makes sense that the stern would come in at that point as the wheel is turned away from the dock, and that goes quite smoothly. As it comes closer, the angle reduces to 15-20 or under, and that’s when I see the loss of traction. I’m thinking moving the line across the dock will allow for the larger angle all the way until the boat is parallel, and I’ll avoid having to use more than idle forward to do it (I’m not going to do that, not comfortable using a lot of power to force the stern in, just seems like a setup for a problem.)

After a couple days of docking and testing variations, here’s where I ended up. Because of the starboard prop walk, my preferred tie, and what I picked for our home slip, is bow in starboard. Two-thirds back is a little too far forward for starboard tie because the prop is offset to port and it creates a bit of a rotational force, so I had to move the line further back to keep better control of the bow (port tie, while not preferred because of the direction of prop walk, the balance point is almost at 2/3 back). The resulting line for starboard tie is about 5-6 feet long when the transom is aligned with the back of the slip, so a little shorter than this recommends, but I’m able to be pretty light on it as we come in and I’m using 3 strand line so it’s pretty stretchy. It’s balanced enough to pivot either direction in idle once it’s “settled”.

The attached picture is about how it ends up…so not perfectly aligned with the dock, but totally manageable (I can step off at the lifeline gate normally). If I use the cleat across the dock I do end up more parallel with the dock, but the neighbor has so many lines on that cleat I wouldn’t risk using it. In any case, I’m pretty happy with this as a starting point.

Thanks for the comments back and forth on this, it’s been really helpful.

Here’s the image, deleted it and couldn’t re-add it to the last post. It’s probably slightly more parallel than is depicted, like I said I can step off normally, this makes it look like that would be difficult…

Hi Brian,

That looks good. As you have found, we often have to modify things a bit to the specific circumstances, but the principles are the same.

Thanks John. This book is easily the most detailed and helpful info on the topic I’ve seen anywhere, thanks for putting it all together.

Hi Brian,

Thanks very much for the kind words.

Hi John,

I tried this on my Fast Passage 39 (double ender) with no luck. I knew that the mid-ship cleat was way too far forward, as every time I have tried to dock using a spring line the bow always dove into the dock regardless of the rudder position. The mid-ship cleat is positioned ahead of the midpoint of the hull.

I tied the spring line to the closest stanchion about 3 feet behind the existing mid-ship cleat. The bow still headed for the dock regardless of rudder position when I went ahead slow. I then tied the spring line about 4-5 feet back with the same results.

I continued to move the spring line aft a foot or so at a time until I was about 10-12′ behind the current mid-ship cleat position. By that time I had it tied about 7 feet from the stern. Pretty far back. No matter where I tied the spring line I had the same result of the bow moving toward the dock regardless of rudder position.

Am I doing something wrong here? I have a good understanding of the process and what should happen as I move the spring line attachment position further aft, but these results were unexpected. Any thoughts on what is going on or what I’m doing wrong?

Thanks,

Bruce

Hi Bruce,

That is strange. I have to admit that I just don’t know.

Have you tried both both sides to see if that makes a difference? If not that might get us closer to understanding what’s going on here.

Another thought is how much throttle did you try to get the bow to swing out?

Also, is there any chance there was a current running in under the dock that was pushing the bow in?

And one final thought, does the boat by any chance have an offset propeller shaft?

I will give it more thought and see if anything else comes to mind.

Hi Bruce,

In addition to John’s suggestions, there is one other thing I would suggest looking at and that is the angle of your spring line. If it is too parallel to the boat, your bow will always want to go in because of the moment created between the line and either engine thrust or inertia of the boat and it will also take a lot of throttle to suck the boat in if the wind is pushing you off. If it is too perpendicular, the bow will always want to go out. The ideal for the way I rig our spring is somewhere around 30 degrees from the centerline of the boat with it aimed at approximately the CoM of the boat. Excluding a home berth, each situation is different so the boat won’t end up perfectly parallel at first but a little steering of prop wash and careful fender placement make it close enough that it gets you tied up well each time.

If your angle is indeed too shallow, there are a few things you can do to change it. The first thing to do is to change the lateral offset. Often the easiest to do is to tie across a dock when landing and then move lines later to not present a tripping hazard. You can also move the attachment inboard on the boat end but watch out for the line going and bearing up against something you don’t want. You can also change the longitudinal offset just by line length, a shorter line gives a steeper angle. Too short and you will have to watch shock loading if you are not really good at slipping the line a bit. To get a better idea of how to change the angle, I recommend drawing a top down view and drawing different versions of the spring on it and it should be clear. If you really want to understand it, dredge up your high school physics knowledge and turn it into a free body diagram (and don’t forget that the fenders provide a force otherwise you will have a force imbalance).

By the way, this is very related to the reason why many have trouble springing off a dock. In that case, the line should be as parallel to the face of the dock as possible and lead as far forward or aft as possible as then it provides the least resistance to the boat pivoting out. It sounds like John was thinking of doing an article on this and I for one think that would be great.

Eric

Hi Eric,

Thanks for coming up on that. That makes sense, although I have to admit I had to draw it out to get it clear in my mind. I guess that’s because I have never had to move the aft running spring around to get the desired effect, but then it seems that’s boat specific.

John and Eric,

Thank you both for the replies and feedback. Much appreciated!

I started with the engine in gear at idle speed and then slowly upped it to 1200 to 1500 rpm at various attachment points. We are in a slip with no current but there was a breeze blowing perpendicular to the boat. The breeze should have been pushing the bow away from the dock, but it wasn’t. Could have been due to possibly more wind pressure on the stern.

At this point I’m going to wait for a totally calm day and give it another try, as I couldn’t tell how much affect the breeze had on the outcome.

Regarding angle of the line, that makes a lot of sense, and of course complicates the process a bit as it becomes yet another variable. The spring line was attached to the forward cleat on the dock, so it ran quite parallel to the dock. When i give it a try again with no wind I’ll try different angles to see if I can see a difference. I’ll report back when I know more.

I certainly would second the motion for more articles on this subject, as I truly believe that having a balanced spring line is a major key to control while docking and leaving the dock. Having it unbalanced on my boat as causes so many issues that I have gone away from using a spring line to dock. I either attach a bow or stern line depending on current and wind. Then make fast the other end of the boat. The spring lines go on last to keep the boat from riding forward or astern in a slip.

Thanks again,

Bruce

Hi Bruce,

Wait, you wrote “The spring line was attached to the forward cleat on the dock”.

You are not by any chance trying this with a forward running spring (from the boat)?

Note that this only works with an aft running spring.

Please take another look at the post above, particularly the diagrams, to make sure we are talking about the same thing.

Probably not that, but worth clarifying.

The other thing you could do would be to upload a photo of your set up.

Also note that even if your boat won’t pivot on an aft running spring, I explain an alternative using a bow line and forward running spring that works for any boat, and is much better than two breast ropes, in the above article.

Bottom line, given those two alternatives I don’t have a lot more to say for another article. What Eric was referring to was a piece on getting off the dock, which we published yesterday.

John,

Sorry, that was my bad. I stated forward cleat on the dock, but meant to say aft cleat on the dock. At all times I was propelling the boat forward on an aft spring line. Sorry for the confusion.

Ah, I guess I was misunderstanding Eric’s comment regarding another article. I read the getting off the dock article. It was very good!

More experiments to come on a windless day. Thanks!

Hi Bruce,

Thanks for the clarification. When you are experimenting, if you have a chance, please take a couple of photos and add them to a comment. I would really like to figure out what’s going on.

Eric,

I was finally able to perform the experiment you suggested and attached the spring line across the dock to get a wider angle. This certainly solved my problem. I was able to determine a much better location (farther aft) for the mid cleat that allowed me to rotate the bow port or starboard with just a slight adjustment of the rudder.

My slip has finger docks on each side of my boat with very little room to move the boat sideways away from the dock with the spring line, so increasing the angle by attaching the spring line to a cleat on the far side of the dock provided enough angle to find the best location for my mid cleat.

Thanks so much for the advice. It certainly paid off. I’m looking forward to my next docking using my new mid cleat location.

John, sorry, I forgot to take pictures. 🙁 Hopefully you can imagine my situation by my description of my dock having a finger on each side of my boat. Not much opportunity to move my boat very far from the dock (3′ max), so the spring angle was almost parallel to my boat.

Bruce

Hi Bruce,

Great to hear, and I add my thanks to Eric for coming up with the fix.

Hi Bruce,

I am glad to hear that the angle fixed it.

Eric

John,

I just wanted to say a huge thanks for sharing the balance point spring technique. I don’t think I ever would have just discovered it by chance. I was forced to put it into practice last week when I found myself aboard without a crew. After a bit of experimentation to find the right spot on the toe rail (fairly easy as my boat has holes all the way along the toe rail through which to feed a mooring line), it worked perfectly for several comings and goings from an alongside berth, albeit in very little wind. Being able to park a 53ft boat by casually wandering around and tying up or removing lines with no rushing or panicking was a real treat. The docking-alone part has previously been a perceived barrier to single handed sailing for me. I was able to do my first proper single handed sail last week, largely as a consequence of using this technique and it was incredibly liberating.

Cheers!

Hi Peter,

Great that it works for you. As you say, we have the magic spring working it changes everything.

Thanks for the thanks, it means a lot.

Hey, John. So I have been practicing the magic line lately and have a problem. Each time the bow collides with the dock pretty hard. Now of course I assumed the cleat was not in the right balance point so I did your test and as far as I can tell it is in the right place. The bow goes in and out nicely . So then I suspect a POBKAC (or PEBKAC if you like) and assume that in this last seconds I am giving it too much throttle and steering too hard toward the dock. So today I went real easy on both l but got the same result. It doesn’t seem to make a difference where the wind is coming from either. Today it was on the bow but so slight it made little difference. Anything you can think of that might be causing this?

Hi Michael,

I would still guess that the attachment point is too far forward, even though the bow will come out when loading the line and steering away from the wharf. A boat with a big rudder and prop can still move the bow out even if the line is too far forward.

The other thought is you are going ahead with a lot of slack in the line, so she comes up hard against it. A better way is to pull the slack out of the line and then go ahead. That said, even with slack, the fact the bow comes in hard says to me that the attachment point is too far forward.

What kind of boat is it?

Thanks, John. It is a Sweden Yachts 41. Had another go today and positioned the cleat on the dock around the stern of the boat because I was thinking that maybe I wasn’t getting it far back enough. There wasn’t any slack in the line. I was far easier on the wheel and power and I thought that we came in softer but my daughter insists it was the same and the fender positioned very far forward stopped a bigger whack. She was on the dock so I trust her judgment better than mine behind the wheel. So I am thinking you are right. Next month I am going to do some tests with your temporary solutions to move the cleat further back and see how we go.

Hi Michael,

There are 2 distinct phases where the magic spring helps: stopping the boat and then holding the boat while fine tuning. It sounds like your issues are while stopping the boat and not while fine tuning. When stopping the boat, you need the magic spring to be aimed at the center of mass of the boat in the horizontal plane. Most boats have a COM that is near or slightly aft from the aft end of the keel. Look along the spring line and see whether it is aimed at this point. My guess is that it is aimed at a point much further forward on the boat which will pull harder on the bow than the stern so the bow will swing in. You can think of it like a weight swinging on the end of a line until it hits a soft wall (fenders).

Usually when there is a problem like you describe, either the spring is attached to the boat too far forward or the angle of the spring is at too small of an angle to the centerline, it usually needs to be something like 30°.

If you look a few comments up, you can see Bruce struggled with the fine tuning portion once he was stopped and the solution in his case was to run the line across the finger dock to get more angle. While you are struggling with a different portion of docking, I suspect that the solution will be quite similar. The fine tuning portion does have slightly different needs but for most of our boat shapes and mass distributions, the 2 solutions are close enough that a single spring works great.

It took me a long time to realize to do this but we basically always use a line to get on the dock which we later remove and a line to get off which wasn’t one of our docklines. By doing this, you can set it up in a way that might block the dock or something which wouldn’t be acceptable for any period of time but works great for the time you are docking.

Eric

Hi Michael,

Yes, I think that’s the best way to get to the bottom of this. Also see Eric’s comment on changing the line angle which may help.

I can’t thank John enough for this insight.

Our bearth is tight and we are generally blown off the dock. We started using a balance point spring line a few years ago when we decided that leaping to the dock was no longer an option. The balance point is conveniently at our main winches. We use this with a “Dockingstick” (https://youtu.be/_G4kIyvxJS8) which means I can, for the first time, confidently dock the boat solo.

Hi Bob,

Great to hear it’s working well for you. And the Dockingstick does indeed look like a useful gadget.

Thank you to you all for the great suggestions. I will get to these next month and report back.

So, I have tied up alongside quite a few times since I wrote the above and all fairly successfully. I have more or less concluded that the cleat is indeed too far back but I don’t have time to correct it this year. So what I am doing is being very careful about how much juice I give it (if the wind is in front…none if it is behind), and how much I steer in. This seems to work ok most of the time if I remember to control myself while also instructing the crew on what to do. But I am also putting a large (round) fender right at the front of the boat just in case I come in too hard (which happens for sure). Next year, I will fix the problem properly. Thanks for all your help.

Hi Michael,

That sounds like a good interim solution. I too make sure I have a fender way forward on the 109 in case the bow swings in fast, which it is prone to do on shallow hull boats when the wind is blowing toward the wharf.

Thanks, John. One of the occasions deserves a mention. It was in Bergen harbor (Vagen) where the dock is high and the tide was out and the wind was blowing off. My wife (not tall) had to quickly scramble up the tires and run a long way back to the only bollard available (about 15 feet behind our stern). But it worked perfectly (the tires did help with any bow crash). But the “experienced” sailors standing on the dock waiting to take bow and stern lines looked perplexed as we performed this maneuver and the fact that I wasn’t in a hurry to throw them the other lines. I had all the time in the world to get everything else sorted out calmly. Loving it.

Hi Michael,

We had the same experience in Bergen.

I’m very late to the discussion, but I hope I have something useful to add for those, like me, who read late into the night for answers.

The spring line is an indispensable arrow in the quiver, but I have not found it helpful in the situation I often find at my (floating) home slip: stern to, current or wind blowing me off the finger into my neighbor.

My balance point is at a winch, convenient but irrelevant; once I get my loop over the dock cleat the whole boat is moving off, often the bow moreso. The boat can theoretically move off the dock by the length of the spring at the balance point, which is about 8’ for me. Putting the boat in forward does not make the spring instantly taut; I am still drifting off. Accelerating quickly is not an answer with a 30,000 lb boat.

What I have found helpful is getting a line on the dock cleat from the aft cleat on the boat. Get my butt stopped at a cleat or abort. I have already run the line through the middle of my aft cleat so it doesn’t flop around and get out of place. I pull it tight and tie it off.

I hesitate to say this in this forum, but, then I pop the bow to the dock with the thruster, step off, already out of gear and tie up. .

Hi Scott,

If the boat won’t come in when going ahead on the magic spring then I’m pretty sure something is wrong. What happens after you have drifted off a bit and you go ahead on the spring? If the spring is on the balance point the boat should just slowly move closer to the dock while staying pretty much parallel to it. This worked for me for years with a 50,000 lbs boat and works fine with the J/109 too, so boat weight is not the issue. That said we do have to be careful to take the slack out of the line before going forward on it, but that’s easy if it leads to a winch.

One thought, since it’s you home slip why not leave the spring on the dock, and then you can just pick it up with the boat hook and take a couple of turns on the winch, which is usually way quicker than the other way around. That’s how I have our wharf set up. I also have a small set of boarding steps on the wharf and so leave the magic spring draped over it which makes it easier to pick up with a boat hook.

All that said, sure, if you have a bow thruster your method is fine.