Tips, Tricks & Thoughts:

Tips

-

The Loss Of Yacht “Solution”

49 CommentsReading Time: 3 minutesMembersRead more: The Loss Of Yacht “Solution”John’s thoughts on the probable cause of the loss.

-

Group Meeting With John

5 CommentsReading Time: 2 minutesFreeRead more: Group Meeting With JohnGet together over Zoom with John and a like minded group of cruisers.

-

Quick Carpentry Hacks

30 CommentsReading Time: 4 minutesMembersRead more: Quick Carpentry HacksFor those who put done ahead of perfect.

-

The Intrinsic Fragility of Furling Systems

49 CommentsReading Time: 4 minutesMembersRead more: The Intrinsic Fragility of Furling SystemsAfter 40 years of using furlers John has a palm-slap to the forehead moment.

-

The Last Marine Journalist?

22 CommentsReading Time: 2 minutesFreeRead more: The Last Marine Journalist?I have long been concerned about the state of marine journalism, particularly in North America. In my view, most all marine magazines have for decades been little more than extensions of the marketing departments of boat builders and marine gear manufacturers. Heck, it’s been about 20 years since one of my favourite editors, and marine […]

-

Dockside Water Filter Trade Offs

9 CommentsReading Time: 3 minutesMembersRead more: Dockside Water Filter Trade OffsFiltering the water while filling our tanks can be a great idea, particularly for aluminium boats, but there are things to know.

-

New Email System

2 CommentsReading Time: < 1 minuteFreeRead more: New Email SystemDuplicate email mess up apology.

-

The Two Hidden Problems With The Junk Rig

30 CommentsReading Time: 4 minutesMembersRead more: The Two Hidden Problems With The Junk RigThe junk rigged dory-schooner Easy Go that was sadly abandoned in the Atlantic some years ago. The modern junk rig has been used for yachts since Blondie Hasler rigged a Folkboat that way for the first Observer Singlehanded Trans-Atlantic race way back in 19601. Since then the popularity of the rig has waxed and waned, […]

-

Well Done Charlie Dalin

19 CommentsReading Time: 2 minutesMembersRead more: Well Done Charlie DalinSome thoughts on Charlie’s win, and design changes that may have benefits for cruising one day.

-

Safe Water Without a Watermaker

73 CommentsReading Time: 3 minutesMembersRead more: Safe Water Without a WatermakerWatermakers are great…but they are also expensive, use a ton of electricity, take up a lot of space, and are a royal pain in the neck to maintain. Just another damned thing to spend time and money on when we could be sailing our boat or out enjoying the places we sailed to1. Given that, […]

-

More Offshore Sailing New Year’s Resolutions

3 CommentsReading Time: 2 minutesFreeRead more: More Offshore Sailing New Year’s ResolutionsI fear that many of you may be think that Phyllis and I bought the McCurdy and Rhodes 56 back and disappeared over the horizon. Not so, but four factors, two good and two not good, are taking up a lot of our time: So given all that, the relative silence will continue for a […]

-

An Easily Removable Solar Panel

33 CommentsReading Time: 4 minutesMembersRead more: An Easily Removable Solar PanelAn innovative solution for those of us who want to keep our offshore boats uncluttered.

-

An Offshore Sailing New Year’s Resolution

6 CommentsReading Time: < 1 minuteFreeRead more: An Offshore Sailing New Year’s ResolutionFREE Tip. The only six things we really need to think about before we sail offshore.

-

A Great Seamanship Article

6 CommentsReading Time: < 1 minuteFreeRead more: A Great Seamanship ArticleFREE tip: No one who sails offshore, or plans to, should fail to read this article by John Vigor.

-

Why We Suggest Avoiding TeamO and Kru Tethers

9 CommentsReading Time: < 1 minuteFreeRead more: Why We Suggest Avoiding TeamO and Kru TethersFREE tip: We can’t believe that tethers with these clips are still being sold.

-

Happy Holidays

11 CommentsReading Time: 2 minutesFreeRead more: Happy HolidaysAs you can see in the above picture, it looks as if we will have a white holiday season here at AAC World Headquarters, also lovingly known as “The Hovel”. We call the yellow addition that we built some years ago, when we moved ashore, “The Folly” because that’s what adding on to a hovel […]

-

Estimating Distance Hack

9 CommentsReading Time: 2 minutesMembersRead more: Estimating Distance HackTo be good boat handlers we need to develop the ability to estimate distances reasonable accurately by eye.

-

Reducing Boom Dip Risk

13 CommentsReading Time: 3 minutesMembersRead more: Reducing Boom Dip Risk©2024 Bill Greenwood While we were discussing preventers, a couple of members mentioned being worried about the boom end dipping in the water while restrained by the preventer, particularly if the preventer is attached somewhat inboard on the boom to oppose a centre boom mainsheet. Certainly a rational worry. Here’s what to do about it: […]

-

Enabling DSC on Crew Overboard Beacons in Canada

13 CommentsReading Time: < 1 minuteFreeRead more: Enabling DSC on Crew Overboard Beacons in CanadaA month ago I had a good old rant about the DSC feature of Crew Overboard Beacons not being approved by the Canadian authorities. Well, AAC Contributor Matt Marsh went way better than ranting by writing an eloquent and well-researched letter to François-Philippe Champagne, Minister of Innovation, Science, & Economic Development. And, better yet, all […]

-

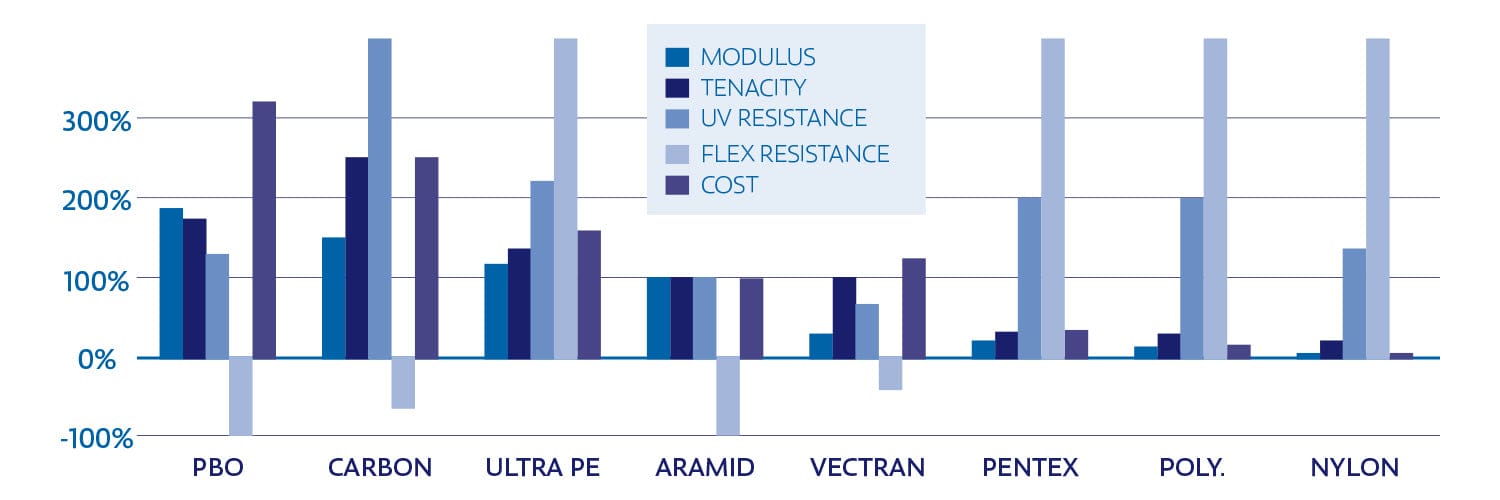

Good Sailcloth Explainer

3 CommentsReading Time: < 1 minuteFreeRead more: Good Sailcloth ExplainerWhile I was researching for my recent tips on buying sails I came across a great page over at North Sails explaining the tradeoffs of pretty much all the fibres used in sailcloth. One quote jumped out at me: Ultra PE fiber [Spectra/Dyneema] is expensive, but very long sail life ensures high value in these […]

-

A Book That Will Help You Afford A Cruising Boat

5 CommentsReading Time: 2 minutesFreeRead more: A Book That Will Help You Afford A Cruising BoatSo is this a book full of refit tips so you can buy an old boat cheap and fix it up to go cruising? No, better than that.

-

Battle Born Smart Batteries Initial Review

15 CommentsReading Time: 4 minutesMembersRead more: Battle Born Smart Batteries Initial ReviewSome initial thoughts about this new offering and whether or not we should put it on our list of lithium batteries to consider for an offshore boat.

-

Q&A How To Run Reef Clew Pennants

22 CommentsReading Time: 2 minutesMembersRead more: Q&A How To Run Reef Clew PennantsQuestion Member Philip asks: …The big problem I keep seeing is that the conventional approach just pulls downward on the sail, without maintaining any outhaul tension, which messes up the sail shape. Do you – or anyone else here – have any proven ideas to address this problem? Answer You are right to be concerned […]

-

Gifting AAC Membership

0 CommentsReading Time: < 1 minuteFreeRead more: Gifting AAC MembershipWith the holiday season coming, don’t forget that you can gift AAC membership.

-

The Off-Axis Weakness of Anchor Swivels

63 CommentsReading Time: 4 minutesMembersRead more: The Off-Axis Weakness of Anchor SwivelsThe effect of an off-axis load on anchor swivels has long worried me, and now we have some solid numbers.