How To Select The Best Power and Propeller Settings For Your Engine

84 CommentsReading Time: 8 minutes

More Articles From Online Book: Engines For Cruising Boats:

- Better Powertrains For Auxiliary Sailboats and Motorboats

- Understanding An Engine Fuel Map

- What Marine Engine Duty Ratings Mean To You

- Understanding Power and Torque

- Applying Power and Torque

- Propeller Efficiency

- How To Stop Killing Your Engine With Kindness

- How To Select The Best Power and Propeller Settings For Your Engine

- Controllable Pitch Propellers (CPPs)

- Selection Criteria For The New Engine For “Morgan’s Cloud”

- New Engine For “Morgan’s Cloud”—What We Chose

- Engine Installation—The Devil Is In The Details

- Perkins M92B, Initial Report Card

- New Engine, The Proof is in The Voyage

- 10 Tips To Save Your Engine From Overheating

- Is Your Engine Properly Fused?

Hi John,

Very useful information again, and thank you for bringing this subject up to a higher level. This understanding can save us money but it also gives many frustrations on how to do it right.

Also frustration regarding propellers, feathering propellers has very low drag, but when you see the flat surface of the blades you don´t need to be a rocket scientist to see that the prop is not the most efficient, but that is maybe another discussion since you put load on the engine with this propeller also.

Bore glazing occurs at low speed and light load operation and if you are lucky you can get rid of it as you did. With a correct run-in engine I think it´s not so easy to get bore glazing, -if you don´t change the routine you had the first (50-100?) hours.

Cylinder bore polishing is worse and you can get it after wrong run-in and long-term under-loading with incomplete fuel combustion and loss of lubrication. Then the microscopic peaks and valleys in the cylinder are gone.

Hi Odde Arne,

We were lucky in that we had already run our engine in at good high loads before we had the glazing problem due to running at very low RPM for long periods on our Greenland trip, so I’m pretty sure we did not do any permeant damage, particularly since WOT returned to it’s original level very quickly as soon as our return south to the land of readily available fuel allowed us to run hard for a while.

Having said all that, I think you are right: many yacht engines are permanently compromised by under-loading in the first few hundred hours.

Hi john,

This has been a very interesting series of articles on engine/propeller installation and optimization.

Over the years I have reached much the same conclusions as your articles as to what constitutes an efficient engine installation and have installed a Perkins M65 (45Kw @2600 rpm) engine driving a 23 inch feathering prop through a 3:1 reduction gearbox on our current 15 meter 17 tonne cruising yacht.

At commissioning I set the propeller pitch to the manufacturers recommendation and sea trials gave 9 knots at 2600 rpm (wide open throttle) which was a little better than expected top speed.

With these settings we were running at about 2000 rpm to achieve a cruising sped of 7 knots but noise levels were a bit on the high side . A couple of years ago I increased the propeller pitch to a level which only allows the engine to achieve 2450 rpm at wide open throttle. This has brought the cruising speed revs down to 1800 rpm and resulted in a much quieter installation. Fuel use has improved a little to 5 l/hr at 7 knots.

I have noticed two minor changes to the operational characteristics of the boat which may be significant if substantial over pitching were to be contemplated:

The boat speed at idle is now 3.5 knots which requires frequent shifts to neutral in slow speed maneuvers in marinas.

The prop walk in reverse has increased and definitely needs to be allowed for.

Another aspect of engine installation which needs to be considered if substantial over pitching is contemplated, is the strength of the drive train .

On a previous boat I changed from a fixed three blade prop to a controlled pitch prop after several thousand hours of problem free motoring and soon ran into problems with the gearbox clutch packs slipping. The extra power that the CPP was capable of adsorbing was more than the gearbox could transmit.

I suspect that some engine manufactures size their gearboxes to suit a typical propeller curve ie they can easily transmit the power that a typical propeller can adsorb but can only transmit full engine power at the seldom used wide open throttle revs.

From an engineering perspective a far more demanding criteria is to size the gearbox or prop shaft to transmit full engine power at the revs where the engine puts out maximum torque . This closely corresponds to the bulls eye in Matt’s fuel mapping diagram so any changes which we make to the engine/propeller system to move towards this ideal, will result in increased loads on the drive train.

Regards

Jim Clifford Wonambi 2

Hi Jim,

Great real world information, very useful, thank you.

Good point on the gear. One thing I would say though, is if one has problems after over-propping, or installing a CPP, it shows that the gear is undersized with or without those changes since even without said changes the gear should be able to handle the full output of the engine.

My point being that sooner or later an undersized gear (distressingly common) is going to give trouble, and therefore that should be fixed with a larger gear, regardless of prop changes.

Of course that’s easy to say, and hard to do in confined space of a yacht engine room. Having said that, in our case, by going down in HP from 120 to 87 we were able to fit a robust commercial gear to replace our older recreational one, so a win/win.

John, note the modern generation of folding propellors, eg Varifold (as fitted to my yacht) and Flexofold have twisted blades and their performance is typically as good, if not better than a conventional fixed blade prop,. Also plenty of thrust going astern.

Hi Alan,

Yes, some yacht folding props do have curved blades, but I fairly sure that does not make them as efficient as a properly specified fixed propeller because the former have larger bosses than optimal and the blades are not at tapered enough or twisted enough to be optimal.

Bottom line, I’m pretty sure that a fixed propeller will always be the most efficient if properly matched to the engine output.

Having said all that, it doesn’t much matter for this discussion since neither the Varifold or the Flexofold solve the propeller matching problem that this post is about.

Hi John,

A very nice article and well, thought out. You have brought together and balanced an impressive confluence of inter-dependent variables. A question and a comment.

What lead you to determine that you had glazing in the first year of your new engine?

You asked about others experience over-propping. We did so on our last engine/drive train in roughly the way you describe: conservatively, and were very pleased with the results which were in line with what you experienced. It was hard to parse out exact results as we were looking for more “punch” in adverse conditions and had gone from a 17 inch 3 blade Max Prop to a 19 inch 4 blade. We now have 2 years on a new engine and to date have stayed within the warranty limits of the engine. I just re-pitched one degree which should be about a 200 rpm decrease at WOT.

My best, Dick Stevenson, s/v Alchemy

Hi Dick,

As detailed in the last post, the thing to look for is a sheen on the water from the exhaust and/or a drop in max RPM without anything being changed. We had both after our Greenland trip in 2011.

Sounds like a great change to your boat. Particularly since, as long as tip clearance is OK, more diameter will always, in and of itself, result in better efficiency.

On the other hand, adding a blade results in a slight drop in efficiency, but this is often offset by a better diameter to pitch ratio.

Hi John

With respect to fitting a larger diameter prop: most recommendations for prop to hull clearance figures (such as the ones in Dave Gerr’s excellent prop book) are overly conservative. At least they were in my case. I believe they tend to give clearances based on the prop being below a flat hull bottom, such as found on many/most power boats. Sailboats generally have a significant “V” in the hull configuration above their prop which minimizes the exposed hull to the forces from the prop and its wash. It also helps to have a good prop guy backing you up such as Chris at Darglow in the UK. He was prepared to shave my Max Prop blades and re-balance (not really a big deal as I understand it) were there any problems.

My best, Dick Stevenson, s/v Alchemy

Hi Dick,

That’s interesting, and makes sense.

Hi again,

People may be interested to hear that a Yanmar 4jh5e (a 3000p rpm engine) has a running in (breaking in) sked as follows: first 10 hours = moderate usage, nothing extreme. 10 to 50 hrs. = full power range with most time spent at 70% duty and every ½ hour a 10 minute period at 80% and a 4-5 minute period of WOT. No light duty for more than 30 minutes. We felt fortunate that we were in “delivery” mode and doing a lot of motoring, but even so the above regimen was still a pain. I suspect most sailboat usage (in and out of marinas/anchorages) would make the honoring of the above quite difficult and that many owners do not bother for that reason as well as it may feel “abusive” to the engine to push it hard in this way.

My best, Dick

Hi Dick,

That’s interesting and, as you say, I suspect very few owners actually honour that.

Also begs a question. In the manual do they specify an RPM setting to achieve 70% duty? If not, I suspect that may owners get tripped up by thinking that 75% duty equates to 75% of max RPM.

Hi John,

Yes, they specify an RPM level to run at (interestingly, by directing the user to run not at a specific RPM but at a certain number of RPMs below WOT) and then they say what approximate duty they are aiming toward.

Dick

Hi John,

I think your recommendation is very reasonable. In my opinion, people get way too hung up on the max rpm rating of their engine and base way too much off of that. Engine designers are typically limited by cylinder pressure over most of the operating speed range and they determine their fuel map based on that. Therefore, displacement will essentially give an engine’s torque rating and then taking the max rpm, you can estimate the power rating. As a designer, the easiest variable to tweak in order to increase power output without changing displacement is max rpm. This isn’t entirely free power as the efficiency typically falls off at the high rpm range but it doesn’t require any physical design changes, just governor changes until you run into things like inadequate cooling, valve float, etc.

Since the cylinder pressure at full throttle is the same at max rpm or a few hundred revs short, I have no problem at all increasing prop pitch to do this. For that matter, if you look at a lot of engine’s available, the only difference is the governor setting. As an example, the Beta 38 (3600rpm, 38hp) is simply a faster running Beta 35 (2800rpm, 35hp). By increasing the rev limiter by 29%, they got an extra 9% power. There is absolutely no reason why an owner of the 38 shouldn’t “overprop” so that they max out at 2800rpm where the engine makes 35hp if they never need more than 35hp. Note: at some point you can definitely overdo it and it depends engine to engine how much the designers have made the engine protect itself versus how much they rely on the user. Journal bearings rely on a film of oil to keep the shaft “floating” and speed is very important to this so if you drop the speed enough and keep the same torque/loads, you will eventually damage these. For the same amount of power, your engine is pumping a lot less air at lower rpm so your EGT’s are higher for the same power output.

One of the variables that has been alluded to many times is power density which can mean many things. An engine running at high power/displacement will generally run warmer although in some cases, torque/displacement is a better indicator as it is more independent of rpm. For example, your Perkins is about 19.5hp/L at wide open while the Beta 38 I mentioned is closer to 25.3 hp/L which is a significant difference caused by the higher speed of the Beta, the Perkins actually has a higher torque/displacement value. The other thing that matters is the surface area to volume ratio of the cylinders. Larger engines have a lower ratio meaning that they lose less heat to the cylinder walls per unit time, an important factor when determining cylinder temps.

Finally, one note on EGT’s. The probe location is very important to the reading, the closer to the cylinder, the more accurate it is. This is especially true with turbos which are thermodynamic devices so they lower the exhaust temps often by ~200F. For accuracy, a pre-turbo measurement is best but many prefer post turbo for higher reliability in the case of a broken probe or a leaky attachment and then apply a correction factor.

Eric

Hi Erik,

Thanks very much for the conformation and further clarification, much appreciated. Even though I researched the hell out of these two posts, and read Matt’s theory chapters about five times each, I’m always concerned that I may have missed something fundamental when I get into an area where I have no formal training. The great thing is with members like you around I know that if I do make a mistake it will get corrected before it can do any damage and become another of the many myths surrounding our sport.

hi folks-

Anyone have a good suggestion for a source for an EGT unit? I’d like to fit one to my ol’ Perkins and see what’s going on in there at various rpm. Seems to be simple enough that it’s a no-brainer… but it’s not something you see ‘on the shelf’, so to speak. I’ve done a little surfing on it – lots of options for the offroad and competition truck modders. I suppose there’s no reason those units won’t work on my wee 65hp 4 banger – temp is temp, right? just need to make sure there’s clearance for the probe in the exhaust manifold where the hole is drilled I presume. Anyone done this?

thanks-

Hi Ben,

We just used a EGT gauge from VDO that fits nicely in our panel, as seen in the photo above. I don’t remember having any trouble getting it from a VDO marine dealer. Most of them are built so the penetration depth can be adjusted.

You will have to have a threaded collar welded to the exhaust exit assembly, but that’s no big deal.

Hi Ben,

I have installed a few from Isspro and never had a problem with one. I have not done any real research on this so I can’t speak to what is actually best.

How you install it can be a bit of a trick. One way as John mentions is to have a collar welded onto your exhaust. Some exhaust manifolds actually have thick enough walls to drill and tap. Either way, it is definitely a bit nerve wracking as you do it. If you do a pre turbo install, it is best to remove the turbo so you can clean the pipe properly as otherwise the metal shavings will go through it when you start up. It probably wouldn’t be a bad idea to carry the appropriate size pipe plug to replace the sensor in case you ever have a problem.

As you search for an EGT gauge, it may help to change the term to pyrometer, that is what I have heard it called more commonly in the performance diesel world.

Eric

Hi Ben,

A pyrometer is also on our list for this year for our Ford Lehman SP90 engine. [This will help us apply the lessons from this excellent series from John…]

While I prefer analog gauges for such readouts [like our tach- reducing the need to think/interpret the reading…] I am intrigued by the various digital gauge offerings from CruzPro. [NZ] http://www.cruzpro.com/

Most of their gauges have internal, user settable alarms, and integrate to a NMEA 0183 network- if desired, and will fit well into our existing instrument cluster.

I don’t yet have first-hand experience with their offerings, but my research so far reveals solid, positive reviews- for years. [18 years in business…]

Therefore, several of their offerings will find a home in our instrument cluster as new capabilities are added [e.g., pyrometer] and existing gauges are replaced. [e.g., fuel gauge that you calibrate to calculate live consumption data, etc.]

Here is the link to their pyrometer offerings in case this is of interest:

http://www.cruzpro.com/py60.html

Cheers! Bill

Hi Bill,

Looks like some really useful kit, thanks for a great link.

John

There is a lot of re hash on this motoring issue…Gee I thought this was a website devoted to sailing rather then motoring…. Just kidding, I think every cruiser motors more then they would like, and the engine is an important part of almost every sailboat.

You aksed in your original post about examples of over propping. Well here is my experience.

I have a 35 ft IP. With a modified full keel, that is nameplated at 17500 lb.

The prop is a three blade Michigan wheel fixed prop 17×15″

The engine is a yanmar HM 35F nameplated at 30 hp (no not 35hp)

The gearbox is a Kanzaki KBW10, ratio 2.83

The prop and engine are original from 1990

There is 4400 hrs on the engine

It burns no oil, none.

Yes, there is a spotty stain on the transom

I cruise all day at 2400 rpm making 6.0 knots and my maximum rpm in gear WOT is 2800 rpm. The labeled redline , and owners manual show 3400 rpm redline, which I cannot reproduce.

My fuel consumption is 3 liters per hour, 2KM per liter.

Their is only one factory thermostat available for this engine , and the glycol coolant runs at 145 F , no higher. I dont know what the exhaust gas temperature is.

Its a great little engine, no excesive vibration, minimal noise, burns just a little fuel, and no lube oil at all, I love it!

I give it a little hug every time I see it!

It seems to me based on your verbage about engines that it is over popped..

And should suffer all those things ” that the flesh is ‘er to”

But you can’t argue with success, 25 seasons and still working fine.

Moving on, I think the engine is well past its prime, but its working great, albeit a little over propped for my boat. I think I’m going to let it run to failure….as I am disinclined to spend any serious money on repairing a 26 yr old engine.

Most operators, and even some Engineers say, ” dont fix it if its not broken” .

That is usually a good policy.

If / when I have to replace the engine, then I think I would keep the same fixed 3 blade prop, but increase the horsepower to a 35hp Beta or that 39 hp Yanmar mentioned above. I think ypu reviewed both those engines for the AT 40. Funny, I previously researched both those engines, and thought either would be a good choice for me.

Thanks

Ed

Finnback

Hi Ed,

Sounds like you are using your engine exactly right. You are over-propped by a lot, but then again since you only run at 2200 you are no where near lugging, so all is good.

The only thing I would say, is that it will not make any sense to go up in HP when re-powering since with your present engine you are not using even 30HP, so if you go up in power, you will have to over-prop even more. (If you go up in HP and keep your current prop you will then be chronically under-loading.)

By the way, when Erik did the drag study on the A40, we found that the 30 HP Beta was plenty, so that would be the best replacement option for you too, and even then you will probably need to over-prop by 200 RPM or so.

John

Why would you prefer the British Marinized Beta ( Kabota)

over one of Yanmars. The 3 ym ae. Making 30 hp at 3200 rpm

Or the Yanmar 3jhme? Making 39 hp and a lot of torque and redlining at 3000 rpm

Am I detecting an anti Yanmar bias here?

If you dont like Yanmar then its OK, Anyone can have there preferences, and you are entitled to them, I am just asking why you feel this way….

Regards

Ed

John

Forgot to mention

At 2400 rpm I am using close to all the torque available.

Ed

Hi Ed,

Yup, that’s the whole point of over-wheeling. One way to define max torque is (thank you Eric Klem) maximum amount of work done for fuel burnt.

Hi Ed,

No anti Yanmar bias, (I used to own one) however there are a bunch of good reasons to use Beta in the A40, which I will detail in a future post.

All this is very helpful, given that we are still in our Beta 60 break-in period and we have a feathering prop (a Variprop D-107) for which we can change the pitch in the water should we discover the issues described here.

Speaking of which, the issue of gearbox wear we decided to address with a hydraulic ZF 25 A with a reduction ratio of 1.93, which I certainly hope is sufficient, and an AquaDrive CV joint on a welded thrust bearing to mitigate both wear and noise. So far, so good, but I’m going to take notes this season to confirm that. The EGT installation, though fraught, makes a great deal of sense to me.

Thanks for the links folks – very useful. And a great discussion!

…I’m going to take the leap and put in a pyrometer. first thing is to see if I can get an accurate wall thickness reading on the exhaust manifold of my old perkins 4-154 using my audiogage. If there’s enough wall there I’ll drill and tap… holding my breath the whole time!

bg

Hi John,

Both articles great and very informative.

I do understand that a continuous duty engine should be loaded at 75% since it is permitted (by manufacturer) to go as far as 100% load factor for unlimited hours. But typical sailboat engines such as Nanni diesels are sold under M4 rating and on their brochures they limit the load factor to 40% of rated horsepower i.e the cruising speed should be such that the engine is not loaded more than 40% and this is reflected in their warranty given for a new engine. Limitations on hours under full load exist.

So in this case how do you think the engine should be run for maximum longevity and without voiding the warranty?

Nikolas

Hi Nikolas,

That’s the the catch 22. Many manufactures will void the warranty if you can make full revs at WOT, but if you can, particularly on sprint engine, you will be underloaded at cruise. Bottom line, a turbo charged M4 Nanni is an inappropriate engine for a displacement boat since the top end power is essentially useless and it forces into too small a prop. More in part 1: https://www.morganscloud.com/2016/04/12/how-to-stop-killing-your-engine-with-kindness/

If it were me, I would over-prop and with the goal of, in effect, derating the engine with the prop. For example the N4.60 Nanni is the same block as the Beta 43 HP engine. So what I would do is over-prop the Nanni to, in effect bring it down to about 50 HP WOT (difference from Beta because the Nanni is turbo).

If we assume they mean 40% of 60HP that would be a load of 24HP and that would yield a cruise RPM of about 2150 reading from the prop curve.

So, if I over-propped to bring WOT to say 2400-2500 and then cruised at about 1900 I would still be at or below Nanni’s required 40% load at cruise, but I would have moved cruise speed to max torque and decreased propeller mismatching, so fuel consumption would be lot better. (I eyeballed the changes to the prop curve, so I might be tad off on the exact RPM.

Ironically, what the above little exercise shows is that for a displacement sailboat the Beta 43 HP is a effectively a more powerful engine than the Nanni 60HP since Beta are happy to let you run it WOT for as long as you like. (I have that directly from the CEO at Beta, who I was talking to about the A40 engine.) And 80% load would be 34 HP load at which it would run at very comfortably as a standard cruise setting.

Hi John,

From an engineering standpoint, in general (I know, quite a contradiction!), turbochargers are almost an clear benefit. They take what is otherwise waste [exhaust] heat and turn it in to useful work [air density increase]. I don’t know about the specifics of the Nanni and Beta engine controls, but at least *in theory* adding a turbo to a steady-state engine will only improve it’s efficiency. That’s why every tractor and gen-set made in modern times has one, and they are typically continuous duty engines. It can be a problem though if you put the *wrong* turbo on the engine. you can end up with a turbo that doesn’t help at your operating point, i.e. the big one on a passenger car that only spools up at high RPM. It’s very possible that the Nanni is in that regime, but I can’t say for certain. My gut says that on the kind of low RPM, mid throttle that sailboats IMVHO operate at, you’d like a much smaller turbo than the equivalent (for the displacement) automobile.

Hi James,

Yes, I realize a turbo adds efficiency, but that does not change my recommendation above, which has nothing to do with the presence of a turbocharger, but rather the fact that the Nanni is an M5 engine and the Beta an M2. The result is that that the Nanni is, at any efficient point in the prop power curve, way too powerful for the boat in question. And worse, since its an M5 engine the manual forbids running it at an appropriate place in the power curve for long enough to do a displacement boat any good.

The issue here, when comparing the two engines, is prop matching and engine rating, not the presence, or not, of a turbocharger.

Although, generally in the small engine marine space, turbo engines tend to be lightly built high revving M4-5 engines, so not appropriate for displacement boats. However, a M2 rated turbo engine would be fine.

All that said, the advantage of naturally aspirated engines is less to go wrong.

Hi Nikolas,

My take on this is that it is a function of putting many different output ratings on the same block which is the reason why I struggle with absolute rules of thumb around % load. Our concern is over cylinder temperature which in turn effects several other things including oil temperature. An engine manufacturer can take the same engine block that output 100hp and had ideal temperatures at 80hp and make it a 200hp engine by changing the governor and the fuel plate/map. If gearing is equivalent, the engine will still run those ideal temperatures at 80hp but that is now only 40% load because we changed the denominator is a somewhat arbitrary way. I think that the best thing you can do is watch things carefully and monitor temps if possible. In general, I would not try to exceed the engine ratings unless you are monitoring EGT, oil and coolant temps carefully. The ratings are necessarily conservative but typically not overly so.

Eric

So, I’m wondering what two alternators and engine driven refrigeration adds to the the total loading? I’m guessing that it’s akin to de-pitching the prop. So, if I wanted to work the engine a little harder, it would be with the refrigeration engaged at something less than WOT. Sabre 38 MKI at 15,600 displacement, Westerbeke 38B with only 975 hrs on it, Max Prop at some PO determined pitch. My fuel consumption is .78 gal/hr at 2800 rpm. No smoke, no oil burning. This is not empirical, but I’m feeling like it’s a pretty solid setup.

Hi David,

Yes, I would think that all of that stuff would add quite a bit of load, although, of course one must account for the state of charge of the batteries. Having said that, if you can reach rated WOT with the fridge on and the batteries low, the situation may be even worse, not better. Because with the fridge off and the batteries charged you would be substantially under-propped and therefore at low cruise speeds glazing could be even worse, not better.

So in summary, having those parasitic loads does not necessarily fix the problem, and could actually make it worse. On the other hand, if with the all the parasitic loads off you can only just make rated RPM at WOT, or a little under. And then you are at cruise and turn them on, they could indeed be improving things.

The great thing in all of this, is that at 37 HP, you are not horribly overpowered, like so many boats, particularly with all that parasitic load, so that’s a good thing.

Hi John,

Without getting too technical, I feel like my setup is good. I do have an infrared temp gun, so at some point, I’ll check engine oil temps. The great thing about this discussion is now I’m AWARE that running the engine at anchor, or at low rpms for long periods is not good. On our 22 month trip (10 days sailing followed by 2 months back in Texas working and so on) from New Jersey to Texas, we brought aboard one of the worst things a cruiser can have in many people’s minds, a schedule. One thing the schedule did was to force me to keep the rpms higher when we were motoring and needing to get to a certain place by a certain time. So, unbeknownst to me, I was giving the engine what it really wanted! Thanks again.

Hi David,

We have the same engine but in a CS36T. Yes, alternators and refrigeration can add significant load. For example, a 70A alternator will require a maximum of around 2.7 hp (this is using the old 50% efficiency rule of thumb that includes belt efficiency, I have not checked recently to make sure it is still valid). Personally, I like to set my prop like these loads are not there and then know how to disconnect the loads without ruining alternator diodes should you ever need that max power. This is the way we are set up and while I have run a few minutes at close to max power here and there, I have never had to disconnect the load although it is quite easy. Some very conservative people don’t like to set pitch this way as it doesn’t use worst case assumptions but I feel it is the best overall compromise as I have never actually needed full power.

Eric

Hi Eric,

I do have the data that gives me the MaxProp details. I should give that a good look and maybe talk to them as well. As John says, at 37hp and 38 ft, I’m not really over powered, so I feel pretty good about my setup.

John

Your comments of April 18th are confusing me.

Here they are again,

“”Also begs a question. In the manual do they specify an RPM setting to achieve 70% duty? If not, I suspect that may owners get tripped up by thinking that 75% duty equates to 75% of max RPM”

Well, What do you mean when you use the term ‘power’ or 75% power??

Wikipidia, and other texts define power as

Work over time, and units of measure of power are

Watts, kilowatts, and ‘ horsepower ‘ . So it seems ot me that

horsepower hp os synonomous with ‘power’

I think I understand your meaning of duty cycle and 75% power to be

75% of maximum ‘ torque’. Or perhaps I’m really confused.

So, Can you explain (or tell me where you covered it previously)

Power , 75% power, duty cycle, and torque

Perhaps some of our engineering support team , can help me out?

Thanks

PS , overppropped and lugging, are well up there on my list of fuzzy terms too!

Hi Ed,

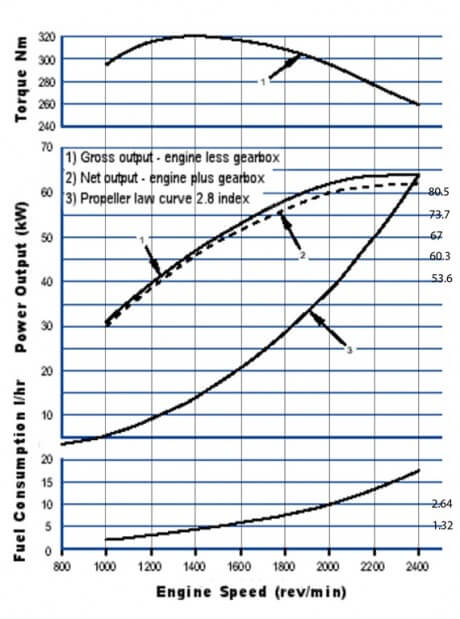

Yup it’s confusing. HP is a measure of power, the rate work is done. KW is the same. But there is a further wrinkle here. There is the power available at the crank shaft of the engine but that is different than the load placed on the engine by the propeller. Example: if you look at the graph at the top of the post and take say 1800 RPM you can see that the engine is at about 75 HP or about 88% of full rated 85 HP. And if we had a CPP that 75HP would be the full load we could put in the engine before the RPM would start to drop and that would be lugging or over-loading.

But we don’t have a CPP, so we use the prop factor curve which tells us that at 1800 the prop is only loading the engine at about 29kw or 38 HP or just 44% of max.

Having said all that, all I’m doing in this comment is rewriting what I already covered above.

And no, the 75% that Steve D mentions is of max HP not max torque.

As to duty cycle, we have a post from Matt coming soon that explains that and relates it to ratings.

I cover all of this in the last two posts and Matt covers the whole prop matching earlier in the book. The bottom line is that if you are really going to get this, you will have to go back, as I did, and read it all again really carefully. For example I clearly define over-propping above (see third para under the Run Hard heading), so there’s not a lot of point in doing that again here. And Matt clearly defines lugging in the chapter on the fuel map.

Heck, I even provided links at the bottom of the post for the base reading required to understand this post.

Interesting discussion about overpropping. We bought our Tayana 47 and the Yanmar 4JH2-DTE had been grossly overpropped to the point where it would only turn 2400RPM at WOT, about 1000RPM less than specified and the prior owner had run it that way for years. At this speed the turbo wasn’t even operating. It also had other problems so to regain confidence in it, I sent it off to Mack Boring to be remanufactured. After consulting with PYI, we set the Max-Prop so that it now turns 3500RPM as it’s supposed to be able to. This engine is an 88hp turbo diesel and our boat actually weighs 46,000lb, but we can still cruise at 7+ knots at about 2600RPM so I am running into the problem that’s already been discussed here where I’m tempted to accept that “comfortable” cruise RPM rather than pushing it up to 2800-3000RPM. If I do that for even a portion of the day, I run it at higher RPM for awhile before shutting it down. I’ve thought of increasing the prop pitch slightly but worry that with a turbo engine, the lower RPM’s might mean the turbo doesn’t hardly ever get used and will get dirty and gummed up.

Also, ever since the remanufacture (and possibly before), only about 150 hours ago, there seems to be more black smoke than normal and whenever it gets up over about 3000RPM, it’s very noticeable. It’s certainly not overpropped and since it has done this regularly even during the break-in period, I don’t understand what could be causing it. I realize this is slightly off topic but I’d love to know what’s going on with it if anyone has seen this before.

But my primary question is in regards to how deliberately slightly overpropping by about 200RPM’s might affect the health of my turbo. Is there a different consideration for turbo engines as opposed to normally aspirated ones?

Hi Jeff,

If it were me, given those numbers, I would over-prop by about 200 RPM, at least if the engine was running well all the way to rated WOT.

However, I would also want to fix the black smoke problem before changing anything. I think the first thing you need to do is get with the rebuilder and insist that they fix the black smoke while you are still in warranty, even if the engine must be returned to them. I know this is really terrible news but a rebuilt engine should run clean just like a new one. If it does not it indicates that the rebuilder made an error and that needs to be fixed. The good news is that it could just be an in injector or fuel pump problem, both of which can be fixed in the boat.

Bottom line, don’t let Mack Boring off the hook until the engine runs clean at rated WOT, even if you have to get a lawyer involved.

Sadly I am seeing these kinds of problems in about 70% of small engine rebuilds, which is why I don’t recommend them.

Great article series, worth subscription for next year!

– love the pic of your engine panel, that’s what they should all look like (though I’d add a bilge pump ‘running’ indicator too )

Norm

Hi Norm,

Thanks for the kind words. As to a bilge pump indicator, we take it a step further and have a load audio alarm as well as monitoring bilge pump runs via a iphone app. More here:https://www.morganscloud.com/2014/06/13/the-worlds-best-bilge-pump-switch-really/

In light of the propeller discussion to date, I would like to query the collective wisdom, as I’ve obtained some real-world numbers.

We have a four-bladed VariProp of dimensions 19″ and a (factory) pitch of 15″. We have a Beta 60 naturally aspirated four-cylinder diesel with a 2,700 RPM full load limit with a 1.97:1 ZF25 hydraulic transmission. The boat is currently light load at 29,000 lbs. in the slings and a waterline of 31 feet on a modified full (box-type) keel.

Yesterday, in very light winds and near-flat seas, I drove around 7.2 knots at 2,100 RPM. I had about an inch of throttle left but could not raise the RPM. Engine temperatures and pressures were normal (the temperature was slightly below 180F, but the lake was cold!)

Now, 7.1-7.2 is faster than I would usually care to go for reasons of fuel economy. I would be happy with “motor all day at 5 knots” if I could do it at under one gallon per hour fuel burn. So it strikes me that I am overpropped and should flatten out to a pitch of 13 or 14. My prop allows different reverse and forward pitches, and I am well-pleased with the stopping and backing down power at 15, so this would simply be a change to the forward pitch to get the RPM up to avoid damage to the engine. My fuel map indicates that at 2,100 RPM, I am at about 42 BHP out of a theoretical 56 BHP at 2,700. That’s actually not bad having re-read Matt’s “fuel map” piece, but I’m trying to cover all my bases. Certainly if I drop to 1,600 to 1,700 RPM, the fuel map suggest my consumption lowers considerably to under three litres/hour…and I’m still doing 5 knots.

Does this appear to be the right strategy? I’m still in the break-in period and intend on running the engine properly. An additional wrinkle is that the boat will shortly have about a ton of batteries, additional tankage and gear added to it. Any suggestions would be helpful, given the variables.

Hi Marc,

The base issue, is that the engine is too big for the boat (as so often happens) since you are reaching hull speed (speed to length of 1.3) at such a low RPM setting. So then the question comes what to do about that. As I explain in the post above, your best efficiency and engine loading is going to come from being well over-wheeled, as you are, but if you do decide to stay that way you will have to be very careful not to damage the engine by lugging it. So if you decide to stay over-wheeled fitting an EGT gauge would be a good plan.

I guess if it were me, I would fit an EGT and then take a bit of pitch out (as you say) to achieve say 2400 RPM at WOT and see how that goes, but I would also be very careful about chronic under-loading. I’m near certain that if you motor all day at 5 knots with this engine you will glaze it up. But again, an EGT will warn you of that.

Finally, note that the water temperature tells you almost nothing about engine loading.

Good comments, John. The problem may in fact resolve itself when a) the boat is fully loaded with water tanks, a third fuel (day) tank, its imminently arriving six L-16s batteries, and whatever gear we choose to load. B) would be a slight depitching, and C) would be that EGT to determine we are in the zone for an adequate load. I’m not convinced that 60 horses (read: 56 BHP) is ultimately going to prove too big, given I have yet to put in a right-sized alternator (it’s just the small-case stock one at the moment) and we are well off our lines to the point we have lead ingots for trim in the bow. I did, however, want to start off on the right foot, and a slight depitch and an EGT is a good place to start, especially as I am modifying the exhaust system to a port and starboard “North Sea” type this summer. Thanks for the comments: the greatest value of this site is the exchange of ideas and the filling in of the blanks of knowledge that can arise from self-study.

Hi John

I read this post a week or so ago and it set alarm bells ringing in my mind.

I have only been sailing for three months so forgive me if some of the things I say are ill informed.

I have a 1985 45ft Gulfstar CC factory fitted with a Perkins 4.108 which was fully reconditioned by the previous owner and had 400 hrs on when I bought the boat and now has 750. It burns no oil (but annoyingly leaks a bit but the engine access is so bad I cannot see the other side of the engine and thus cannot yet identify the source of the leak) and runs very sweetly.

Until your article I had no idea I was killing her with kindness- I have racked up most of those 350 hrs over the 3 months cruising here in the Med, at about 1800 rpm at a speed of about 5kts. At this usage she uses 2.4 l/hr which I think is pretty low consumption.

After reading your article I took her out on a calm-ish sea and did a bit of testing.

To measure the oil temp I fixed a digital thermometer probe to the outside bottom of the sump (best I could think of). The boat has a water temp guage on the dash (which I suspect is under reading dramatically, as you will see).

Appt wind of 10kts off the port bow.

At 2500rpm, water temp read 56c and oil 76c (after 30 mins of running). Speed 6.5kts

At 2800 water read 66c, oil 79c, speed 6.8kts

At 3000, water 70c, oil 82c (yay!), speed 7.3kts (I think the slightly non-linearness of the speed figures would be accounted for by changing wind conditions).

Truthfully I chickened out at about 3300 as it sounded super loud and as if she would blow up at any minute (no thank you!) But I blipped her to 3500 and she eould have gone further if I had had the balls to push her but I didn’t.

So, my take on this is I am under propped. Do you think so?

I have no idea of the spec of the prop but will swim down there today if I knew what I should be measuring, although in my mind I picture measuring the diameter as very difficult with rudder, propshaft etc stopping me putting a tape measure squarely across the prop. Also, with a three bladed prop, how does one actually measure the dia in situ?

A related point is that this boat has a pretty fearsome propkick. To moor stern to, you have to start a long way away as the stern heads off hard to port for a long time, no matter how you treat the wheel. Shameful as it is, I have now started tweaking the bow with the bow thruster as this is the only way I have found of getting her on target in less than about 100m….

As an aside, I have, distressingly, had to give up on the idea of a Spade anchor for now…the S140 steel here in Greece is….€1287. I just ain’t got it!

Cheers

Paddy

Hi Paddy,

Yes, definitely sounds like you were underloading the engine. Having said that, this does not mean that you are necessarily under propped. First off you need to check if the engine will reach full rated RPM at wide open throttle. I think I’m right in saying that rated RPM is 4000—the 4.108 is a real screamer. If the answer is yes, you may or may not be underwheeled, since the governor will kick in at rated RPM and or within about 100 rpm over.

That said, given the cold oil, I’m guessing you are underpropped.

The other issue is that the very often the reduction gear ratio is wrong for these high revving engines and worse still the prop installation may not let you swing a big enough prop for efficiency.

Sorry, this is getting complicated, but then it’s a complicated subject. The key point to take home is that running a 4000 RPM engine a lot at 1800 rpm is not going to end well, even if the prop and gear are right.

Unfortunately the best solution to all of this is going to cost big bucks. That is to fit a three blade adjustable feathering prop, like a maxprop, and then experiment with pitch to get things optimal within the limitations of the installation using the information in this Online Book.

If that’s not on the cards, the next best solution is just to run the engine harder.

Paddy,

Whats the max rpm rating of that old Perkins?

Id run her at a comfortable 2500 to 2800rpm.

With my existing prop, and not worry to much about the theory and

Efficiency.

The Perkins is an oldie but a goodie.

Ed

Well thank you both John and Dave for your replies.

I’ll research the costs of repropping as John suggests and see if I can afford it or not….but I imagine it ain’t going to be peanuts..

I just checked and yes, the wot is 4000!!

For an old school diesel, that is truly a screamer…and honestly not something I am very keen on.

For obvious reasons the last thing I want is this engine to blow up and she sure purrs happily at 1800…but I guess for the most part those days are over then!

I’ll start using her at 2500 to 3000 for now and get busy researching the prop options.

Btw, if the wot is 4000, to load her to 85%, should I be running her at 3400?

Hi Paddy,

See this chapter and the last for the answer to you last question. Short answer: no.

And if you want to run a 4108 slower (I get that) I don’t think you will have any problems over-wheeling to bring WOT down to say 3600. Just keep an eye on the exhaust and back off if you get any black smoke at normal cruise. Doing this will both heat the oil better and improve you fuel economy.

Oh, and I forgot to ask, how do I identify the prop dimensions of my current prop?

Paddy

To measure the diameter of a three blade prob…

You can only measure the radius on one blade , then double it to get the

Diameter. So measure from the center hub/ center of the drive shaft to the outside edge ofone blade, if that number is 9″ then your diameter is 18″ …simple

The pitch is not as easy, perhaps you will find it written on the hub of the prop…

Do you know what rpm rthe previous owner ran her at? Id take that into consideration, even though the motor has been rebuilt…

And I think I’d be comfortable running her at 2500 rpm, and expect my fuel consumption to almost double…

Ed

Once it warms up a bit today, I’m going to take a wire brush and a tape measure (guess I’ll be writing that off!) then dive down to the prop to measure the radius and see if the pitch is stamped on it sonewhere.

I looked at the Maxprop site- wow, they make some sexy props- and I’ll get in touch with the Greek dealer as soon as I know what to ask for. I am also interested in the fact they say with one of their folding props I can say goodbye to propwalk…as I said before, this boat has savage propwalk that I would be thrilled to eliminate.

Almost €1300 for a Spade anchor, god-alone-knows how much for a Maxprop….this is a capital intensive way of life!

Cheers

Paddy

Hi Paddy,

You will not get rid of prop walk, but you will tame it considerably with a Max prop. I personally like a bit of prop walk as it helps in marina maneuvers. You are new to your boat and sailing, so give yourself some time to make some of these bigger decisions work well for you. For ex. Max props also come in 4 blade and 5 blade varieties as well as the more common 3 blade. These might be nice if you motor sail a lot or if the size prop you can swing is limited. By the way, (to avoid unnecessary confusion) I believe that if you are talking Max prop, you are looking at a feathering prop rather than the folding prop you mentioned. Similar results, but they work differently and have different capacities.

Good luck and keep us posted, Dick Stevenson, s/v Alchemy

Thanks for your info Dick, much appreciated. I can see the advantage of propwalk for turning on a dime in a marina but mine is so severe that when mooring stern to, as is pretty well universal here in the Northern Ionian, I have the following proceedure to contend with:

No lazy lines and often depths of around 10 metres so we have to drop the anchor about 50 m distant from the quay. I usually ask my wife to start off with,say, 30m of catenery then I begin to back up. No matter how gently I do it and of course with a straight rudder to begin with, the stern resolutely heads off to port and I cannot get here to respond to the helm until we have covered around 25m so by now I am way off course…then before making the final approach we have to know for sure that the anchor has set. If it does set we are now at a standstill so as my wife pays out more rode I have to get the beast back on course to snuck into the available slip, which is damn near impossible…and naturally there are always half a dozen people standing on the quay watching and you feel such a twit because your boat is basically uncontrollable, given the need to set the anchor. One cannot, either, start the whole process further downstream to starboard, as it were, to compensate for the propwalk as you would then be dropping your anchor over your future neighbour’s chain.

And we have had it several times where we have needed 3 or 4 attempts before the anchor sets…and my wife, being Italian, is not the most naturally patient woman in the world…then throw a 15kt wind on the sb beam into the mix as well and you will understand why quite often we just give up and head off to find a quiet bay to simply anchor!

A lot of these difficulties stem from the crap abilities of my cqr anchor. I have been discussing this issue with John and know well that I need a Spade S140 but the Greek dealer wants almost €1300 for one and we are under-capitalised live abords so for now I’ll have to put up with the cqr, it seems.

Re the prop, I probably used the wrong adjective. I believe a folding prop is the sort that kind folds up when not being driven so as to reduce drag, and a feathering prop has some form of adjustable pitch, no? I thought I read somewhere on the Maxprop site that with their prop you can kiss propwalk goodbye…but I can’t that bit looking again this morning so I think I must have imagined it.

What I don’t understand though, is just how does one of their props even reduce propwalk if the pitch cannot be altered when actually in use, but only by diving down to the prop with a few Allen keys etc in hand?

In truth, I don’t even understand what causes propwalk at all except I am guessing it is some sort of torque reaction to the thrust of the prop ie one of Newtons laws perhaps?

Anyway, enough of my prattling for now..

Cheers

Paddy

I just dived down to the prop and the radius is 210mm which equates to a diameter of 16 1/2 inches…do they come in half inch increments?

But I couldn’t see anything about pitch stamped anywhere, even though to be completely truthful I didn’t hang around very long as I find it pretty dark and spooky down there.

In general terms with a Perkins 4.108, and 45 ft Gulfstar, is a 16.5 inch prop in the ballpark or a bit small? The only thing I can say about the pitch is it is very obvious, the blades aren’t remotely flat, as it were…

Hi Paddy,

I wouldn’t fixate too much on the specs of the existing prop, at least in isolation. The reason being that there is no way for me, or anyone else, to tell you whether or not the prop is right without knowing much more—reduction gear ratio, torque curve of the engine, pitch, tip clearance, drag characteristics of the boat. And even after all that is known, a substantial number of complex calculations are required to come up with an idea prop for a given boat. If you are interested in how to do this, I can recommend Dave Gerr’s Propeller Hand Book: https://www.amazon.ca/Propeller-Handbook-Installing-Understanding-Propellers/dp/0071381767

Given the above, the first test you need to do, before spending any money, is see what RPM the engine reaches at wide open throttle. But even here there’s a catch. Most yacht RPM gauges are not accurate and some are wildly off. So step one is to get a mechanic with a laser RMP counter to check the accuracy of your tachometer, or you could even do this yourself with one of these: https://www.amazon.ca/Neiko-20713A-Tachometer-Non-Contact-Accuracy/dp/B000I5LDVC/ref=sr_1_fkmr1_1?ie=UTF8&qid=1474544834&sr=8-1-fkmr1&keywords=laser+RPM+Counter

If you can’t reach 4000 RPM, you are not under-propped, end of story (assuming engine is working properly). If you can reach 4000 RPM, or a little over, you may or may not be underpropped, as I explained in last comment.

All of this uncertainty is why, often, the best course of action, and in the end the cheapest, is to simply buy a max prop. You can then arrive at the best settings by experimentation and you get better sailing performance and less prop-walk into the bargain. Given the information I list above, your max prop dealer should be able to recommend the right diameter and number of blades.

Hi Dick,

I agree, a reasonable amount of prop-walk really helps. Thanks for the help on this.

Paddy

Please allow me to give some more input…

Reflecting back on your temp and pressure recordings above…

Those temps looks funny, they should be constant, throughout the entire operating range, thats the purpose of the thermostat.

Did you check your thermostat? Are you sure you have a thermostat? Perhaps it got left aside at the rebuild…

Can you get a thermostat that opens – functions- at a higher temperature ?

That would get your engine water – glycol coolant- and your base oil temperature up. But Im not even sure that is necessary.

Moving on, I think if there is something wrong with your engine , you cant really fix the engine by spending several thousands of dollars or Euros on buying and installing a fancy prop. You still have the same old 35 year old engine.

Paddy

Perhaps you step back and let the dust settle on this one.

Run the engine at 2500 and see how things work out. That in itself is a big change, and actually could cause engine failure!,

Actually your safest bet is to do nothing, run it at 1800.

The engine is 35 years old , and recently rebuilt, thats a dicy proposition at best. And you have been running it sucessfully , idling along at 1800rpm.

Buying a new prop and considerable expense, then loading up that old engine to close to max power, torque, rpm or hp. (whatever) can exceed what that old engine is actually capable of. I wouldnt expect and old engine to function as a new engine, and a new prop.

The engine is not new from the factory, its rebuilt, its 35 years old. It may be just a good as a new engine, and maybe – probably – not.

Now, I’m not suggesting that the theory of diesel engines props, effciency,

And all that technology is bogus, its certainly not. But I would be reluctant to try to make an old engine perform like new…

Some figures of speech that come to mind:

If its not broken don’t fix it.

Stop throwing good money after bad.

You cant make a silk purse out of a sow’ s ear.

In closing , Please know that my intent here is to help and not ridicule or belittle anyone. I just feel that if I were in your position, I wouldn’t spend a lot of money trying to fix an apparent problem that I didnt know I had until I read about it on the internet a few days ago , regardless of the source, or how technically sound the info.

……I appologize in advance if this is not what someone wants to hear..

Regards

Ed Finn

Hi Ed,

Just to clarify, the readings of temperature that were of concern were for the sump oil and therefore the thermostat is not relevant. And further, such cold oil will cause problems over time. Having said that, I agree that the simplest answer maybe just to run the engine harder, as I said in an earlier comment.

Thank you all. I have much to mull over…

Paddy, unfortunately the best answers come from a holistic appreciation of not only the entire drivetrain from engine to prop, but aspects of how you yourself drive, rudder size and angle and hull shape. Fortunately, all these things are knowable and technique comes with time.

I agree with the sentiment that an old rebuilt diesel such as you have should be throughly explored as it stands before getting into the esoterica of a potentially better prop. If you can find a quiet place off a beach to practice anchor drops and backing down, you may hit on a less entertaining (for the observers) method of getting into that Med mooring situation. It could be as simple as more throttle to back down straighter, and then going to neutral to coast back in a straight line, allowing for contrary winds and currents. Prop walk in my experience is most noticeable at low RPMs; we tend to coast in and give a brief blast in reverse to kick the stern into the dockside and to (nearly) stop, as rudders don’t work at zero knots, anyway. When we re-engined and re-propped, I did a lot of close quarters maneuvering next to a buoy first and then against a 100 foot stretch of sea wall. The peculiarities were made manifest before we had to dock for real.

So I will bring this thread back to life as I just joined AAC. We recently repowered our classic Tartan 40 with a Beta 50. Definitely overpowered. But since the engine box protrudes into cabin, noise reduction was a big objective so I wanted a low revving cruise speed. The 43 and the 50 are same block and dimensions.

So I overpropped with a flexofold. I meant to go 200 RPM lower than 2800, but it ended up topping out at 2550 light, and 2450 with full cruising load. So reading this makes me feel better about not getting a lower pitched set of blades for my flexofold to satisfy “warranty”. Essentially I now have a 43 hp 2400 redline engine. Cruise at 7.1 knots at 1800 RPMs which is really smooth and quiet. I’ve calculated HP needed to drive hull (theoretical) and then modeled 5 and 10% gear losses, alternator loads to see if engine is theoretically overloaded based on prop curve.

It looks like with 5% gear losses and 1-2 hp for alternator (usual light charging) I always stay below the power curve (using conservative industrial ISO 8665 rating). Only if I model the worst case- 10% gear and bearing losses, and 4 hp for alternator- do I find that at 1950 RPM my hp needed to make speed starts to exceed theoretical engine output.

2 questions for John and others:

1. Is this method of calculating safe overprop engine loads based on theoretical HP valid?

2. You had mentioned fuel pump and fuel mapping earlier. Other than that my engine is not governed at 2400 RPM, is there something else that would be changed if my engine were actually detuned in a shop to 2400 RPM/43 hp? Ie is there different fuel timing/delivery/etc?

If anyone is interested I can post my spreadsheet with calculations of HP/RPM/Speed compared with actual speed and RPM

Hi Mike,

Your theory sounds right.

If the engine we actually set up to run at 2400 the fuel pump settings would be a bit different, not just the governor. This is how the same block is produced at different duty ratings: https://www.morganscloud.com/2016/10/20/what-marine-engine-duty-ratings-mean-to-you/

All that said, see “Be Safe” above for the best way to be really sure you are not lugging.

The other quick and dirty method is to keep an eye on the exhaust and cut back if you any signs of smoke—sure sign of lugging.

In summary, the Beta is pretty rugged, so I doubt you will hurt it with your set up, and in fact will probably keep it healthier by not under-loading.

Hi Mike,

Regarding your first question, you started in the right place by doing the analysis and then you move to checking the results once everything is put together. For a given rpm, if the torque required to turn the propeller is greater than the torque that the engine can produce, you will have a torque mismatch which leads to an angular acceleration meaning that the engine speed will decrease. This decrease continues until you reach an rpm where the engine output torque is equal to the torque required to turn the propeller and then things will stabilize there. If you are really punching into heavy weather, the propeller required torque versus rpm is not constant so the rpm of the system will not stay constant but rather hunt around a bit as the load changes. This is also somewhat dependent on how your governor is setup, whether for amount of fuel or rpm with boats being designed to hold an rpm and vehicles being fuel delivery based. In your case, the rpm where the torques are equal is 2450 on the engine. I highly doubt that in the real world you have any points below this rotational speed where your load exceeds your possible output as you wouldn’t be able to get beyond that speed. Since you found that you had that from a theoretical standpoint, I would take a look at the hull drag numbers you used which should be roughly exponential and is the biggest reason why available torque and required torque only actually coincide at one point.

People talk a lot about overloading engines and I think that it kind of misses the point. For example the one thing that I really didn’t like about Nigel Calder’s video was when he talked about matching the propeller load and engine at the governed rpm and then said that if you added alternator load the engine would be overloaded and damaged. This assumes that magically the engine would start producing more power/torque at that rpm which it couldn’t, your rpm would drop until torques were balanced again. What you really want to know is what rpm range can your run the engine at wide open throttle without shortening its life unacceptably. The people that designed the engine will have looked at cylinder pressure (this determines mechanical loads), exhaust gas temperature (don’t melt those pistons and valves), plain bearing film thickness (low speed can’t handle as much load), emissions, etc. Once they have determined what they deem safe, they put that into the engine through a fuel map, fuel plate, AFC, etc. The question then becomes whether they limit the output so that wide open throttle is safe at all rpm or not and unfortunately I can’t speak for what the different manufacturers do. At the very least, most of them give an rpm range around the governed rpm that they say is acceptable to operate to the duty cycle related to their M rating. For engines where there is another version that is just governed down, I would have no problem propping the engine as if it were the other version.

In addition to the post that John linked to on your second question, if you are really curious and if you can get ahold of the parts diagrams, you can compare key parts such as the fuel limiter in the injection pump (guessing it is a fuel plate in this engine but not sure), the injector nozzles and the cam. You can also look at the workshop manual and see what they have you set the timing too as I suspect that they are not running different timing gears with different timing marks. If I had to guess with the 2 power levels being not that different is it is likely they changed the governed rpm and the timing but nothing else.

Eric

Hi Eric,

Thanks for the fill on that.

Hi Mike,

One other thing that may make you feel better. My friend Steve Dashew did a bunch of experimentation with his Sundeer boats which had quite powerful (way too big for the boat) high rev Yanmars in them. If I recall right he ended up over-propping by as much as 600 RPM and found that as long as they never ran the engines hard enough to cause visible smoke in the exhaust all was good.

Bottom line, I’m pretty sure I can say that for boats that have engines that are really too big for them (most modern yachts) thoughtful over-propping (as you have done) is a hell of a lot better for them than chronic under-loading. My own experience confirms this too.

Eric and John- this is such helpful information. It validates my approach and I will look into the parts approach to see how this engine is detuned. I am pretty sure I’d have to search industrial equipment- this very Kubota block is in a lot of Bobcat skid steers, ironically including the one that our marina owns.

But it sounds like an exhaust pyrometer is about the only way to use data to figure this out if I want to be precise about knowing where engine is optimally loaded vs under/overloaded. Also when conditions such as payload and bottom growth, wind and sea state change the load for speed. For now I am quite confident my slower speed cruise isn’t overloading engine in the 1850 RPM and even upwind in 15 knots I still get >6 knots. But I probably would like to know what happens above 2000-2100 RPM which would be a fast cruise or get out of trouble speed….

I think I read that you have to tap into manifold for a transducer placement, and can’t get by in the first part of exhaust elbow possibly before the water is injected? Also is there a general temp range for small diesels or is it really manufacturer specific?

Mike

Hi John,

Thanks for this series. I know that this is an old article, but it has me wondering:

You have made a very compelling argument for not buying excessive hp. The conclusion then seems to be find an engine that will just get you to hull speed, or with a bit left over and overpropping a bit. (I’ve inferred)

I’m wondering if you’d consider an article or reply that explains why underpowering is not ideal.

For example. My boat takes 28 hp to reach a hull speed of 7.34. At half that horsepower, it can still reach 5.9 in windless, flat water. What would be the harm in using a 14hp without overpropping (so that the engine does not bog into wind/waves) or using an AutoProp. Would that not keep the engine more properly loaded and be more fuel efficient in general, especially compared with boats that are regularly run at half-throttle to conserve fuel?

If beating into a chop, you’ve already argued that everyone should be motorsailing. So what circumstances are there where you absolutely need maximum hull speed in the absence of the wind to use your sails? Are there comcenrs of damaging or overloading a smaller wngine if you’ve decreased the pitch to compensate?

I ask because I will need to repower within a few years. Although the cost does not increase dramatically as engine power increases if purchased from a dealer, and the installation will cost approximately the same, there seems to be new but second hand engines available regularly on Kijiji from boat building projects that are abandoned, but they are usually in the 13-25 hp range, ?because of the typical size of amateur projects. If there is a good reason to not go that route, I’d like to know, but if it is perfectly viable so long as the system takes into consideration the limitations, it could be a way to manage the cost of a repowering.

Thanks,

Philip

Hi Philip,

There’s no fundamental reason not to under power. Back in the day sailboats often had very small engines that could not get them to hull speed. And, as long as the prop is set right, there is no reason that a small engine will be damaged.

That said, there have been a few times in my boating career when having a bit (not a lot) of extra grunt in the engine has saved a situation. This is particularly true when manoeuvring in tight places, so I would not install an engine that was not able to drive the boat at a speed to length ratio of about 1.3. On the other hand, power to exceed a speed to length ratio of about 1.4 to 1.5 is wasted.

Also, I would be careful about buying one of those “new” second had engines. The problem is that they have probably been sitting for years and often the seals and gaskets will have dried out. I had just this problem with the first engine in Morgan’s Cloud. It had been sitting for six years while the boat was built.

Hi everyone-

Bumping this thread 1 week into a cruise with my new EGT installed on my Beta 50 on a Tartan 40. Very validating that I overpropped deliberately. The 50 is same size as the 43 but by overpropping I can now extract the power I need at lower RPMs which are much quieter. I give up top HP which is too much for my boat anyway. So I have given up about 350 rpm of top end power and now have 2450 redline. At 1800 rpm which is 7 knots I barely get to 500F on EGT. 1900 gets me 7.2-7.3 and digs a nice wake and gets me to 550-600. I had never dared go to 2000 rpm but I get nearly 7.5 knots and about 650 on EGT. Going above 2200 and the EGT starts to approach 850-900. And that’s super overpowered. So I have a good cruise setting at 1850-1900 which seems to just load the engine enough. I was worried I had overpropped too much but in fact the engine is more lightly loaded than I thought. So the pyrometer is a great addition and didn’t cost that much. Great thread- I bet lots of folks out there would be shocked to know how much they are underloading their engines. In fact I think that’s why my old Yanmar 4JHE which came with boat smoked and left a fuel sheen in the water- I think I the old owner liked to run it at 2000rpm (of 3600 redline) and 6 knots which I think never really loaded the engine.

Mike

Hi Michael,

Sounds like a good setup. And yes, I agree, it’s amazing how many people are under-loading their engines. Just heard from a manufacturer of a displacement motor boat beating on me for taking the boat to task for having a M1 sprint engine. So if the manufacturer does not understand why that’s wrong, what chance do the customers have!

John,

Love the website! Your article on “Power and Propeller Settings For Your Engine” is one of the most concise well written articles we’ve read about the issues with sailboat diesel auxiliaries. We recently purchased a Pearson 530 engined with the same engine you are currently using, a Perkins M92. The boat currently has a 2 bladed fixed prop 23×14 and we are worried about the engine issues you describe in the article. Through reading your article and doing some research we are looking at purchasing a H6 Autoprop (566mm). To us the Autoprop is a hybrid. It attempts to address the below issues:

1) Propeller feathers reducing drag while sailing.

2) Blades have twist reducing tip loss at higher RPM’s.

3) Substantially reduced prop walk in reverse due to unique design (blades use same leading edge in forward and reverse).

4) Automatically varies pitch depending on operating conditions, maintaining maximum efficiency at all times resulting in higher speeds and greater range with reduced RPM and fuel burn.

Three questions for you John,

1) What is the make and size of your prop with your current pitch setting?

2) Curious your thoughts if you have them on the Autoprop?

3) What is the make and where did you get your engine instrument panel?

Our boat – 1981 Pearson 530

Engine – Perkins M92 with 2600 hours

Transmission – Borg Warner Velvet Drive (1.91:1 reduction ratio)

Driveshaft – 1.75”

Thanks in advance for your response,

Per & Merissa Lovfald

S/V Sojourner

Hi Per & Merissa,

Thanks for the kind words on the article.

Yes there’s a lot to like about the Autoprop. That said, there is one huge drawback: with your Velvet Drive you will need a shaft lock to stop the shaft spinning when sailing. And shaft locks are a huge pain in the neck with big potential for a screw up.

There have also been questions about the durability of the Autoprop in the past. Not sure if they have that sorted.

We have a 21″ Maxprop: https://www.morganscloud.com/2010/04/27/selection-criteria-for-new-marine-diesel-engine/

I can’t remember the pitch off hand, but it will not be of use since we have a different reduction ratio.

And our engine panel is custom bezel and then I built it from there using much of the parts from the standard Perkins panel, but added an exhaust temp gauge and gear oil pressure.

I am qute pleased with our four-bladed VariProp. another feathering prop that has (to us) the advantage of setting different pitch settings in forward and reverse. Using John’s sound logic, we flattened the pitch in forward in order to reach very close to our diesel’s rated RPM in forward, which put us in the desired fuel economy zone at 75% of maximum RPM. Keeping a coarser pitch in reverse, however, gave us stopping and maneuvering power for the few seconds we typical use reverse on a heavy displacement vessel with no bow thruster. I also favour John’s use of an exhaust temperature sensor and may have to alter our helm panel to have one to confirm that our pitch settings are as good as we can get them for fuel economy and engine efficiency.