Ever tried to get the bellows perfectly compressed to specification on a dripless shaft seal, while at full-arm stretch in the bilge, and then get the little set-screws tight before the stainless steel rotor slips back?

Sucks, right? But if we don’t get this adjustment right think sunk boat.

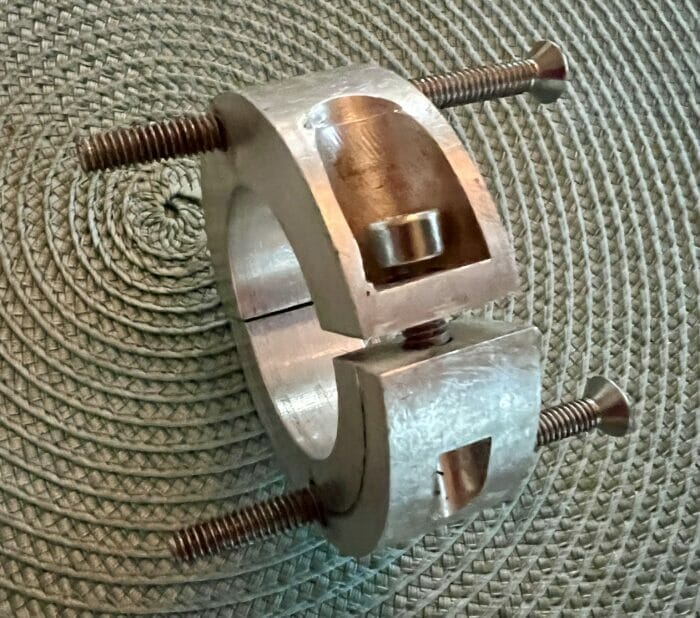

Our friend Phil, he of the amazing salvage, made this gadget up for our friend Hans, he of the great in-boom furling tutorial.

Very simple, very clever, and easy for a machine shop to make.

And, after getting the bellows adjusted right, we could even take the jacking screws out and leave the tool clamped down against the rotor for added security against slippage.

Thank you for the tip. PYI should add a couple of 1/4-20 threaded holes to their shaft safety clamp.

Hi Torsten,

Good point.

We’re getting ready to change the bellows on our pss shaft seal as part of routine maintenance. We’re also changing the engine mounts. We’ll do a rough engine alignment before assembling the shaft seal with the new bellows, but I’m wondering how to check the alignment once the bellows is compressed, the stainless steel collar is locked on, and the boat is back in the water. Can you compress the bellows a little more at this point to allow the use of feeler gauges to check engine alignment?

Hi Michael,

If you mean to move the coupling back a bit to check alignment, then I can’t see that being a problem. After all, you only need more it back a frew thou to get a feeler gauge in.