Update 7th October: In light of things I learned in the comments, I made a few changes to this Tip including reducing the level of charge to 70% (from 80%) and sharing Emile’s experience with the Bluetooth in Victron Smart Lithium batteries.

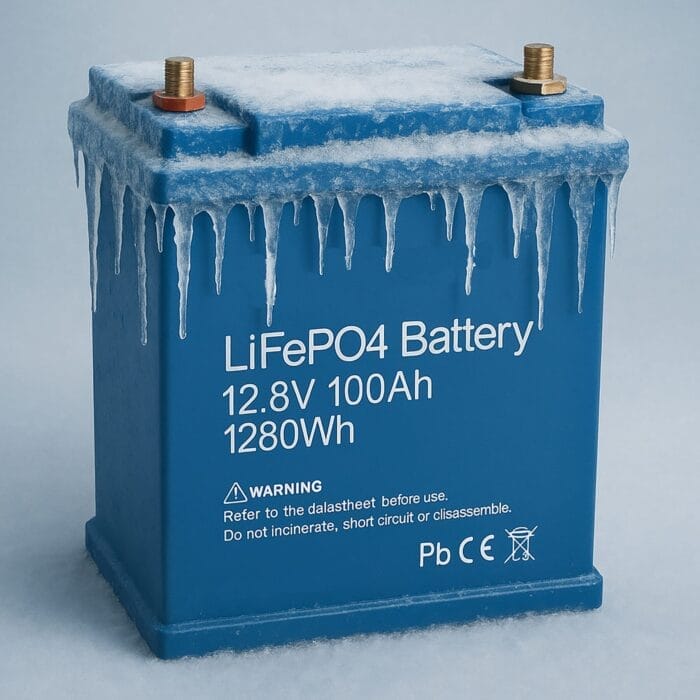

A couple of weeks ago I read a particularly interesting article over at Pambo about the risk of trashing lithium batteries over a winter when the boat is stored in a cold location.

I highly recommend reading the original article in its entirety, but the key things I took away were:

- LiFePO4 batteries do self discharge over time. 2-3% a month is a good estimate.

- Parasitic loads that remain connected to the batteries can dramatically increase that discharge rate to the point that the batteries, if not regularly recharged, can be toast in just a month or two.

- Most lithium batteries will be damaged if charged with the temperature below about 5C (41F), not very cold, making things doubly difficult to manage while the boat is stored in a cold place.

- However, lithium batteries can be stored at much colder temperatures without damage; for example, Victron Smart Lithium can be stored down to -45C (-49F), which should work in most places.

Clearly the problem here, at least over say a six-month period, is not self discharge. For example, the battery could be charged to say 70% in the fall and six months later would be still a bit over 50%, assuming 3% (worst case).

Rather the real culprit is parasitic loads from the BMS as well as any connected monitoring systems, which can flatten the battery to destruction in a month or so.

Login to continue reading (scroll down). Paid membership required:

John: I agree entirely with the suggestion to consider disconnecting everything from a lithium bank. Several winters ago I disconnected the load bus from the lithium bank but I left connected an external BMS and some other components that were directly wired to the bank. I set a recurring calendar appointment to remember to check on the state of charge monthly. You guessed it, I missed one check and after 60 days the cells were trashed. The parasitic loads included a WiFi module for broadcasting info from the BMS, the BMS itself, and the microcontroller in a charge controller that was separate from the BMS (plus god knows whatever else i missed). Those loads killed the bank. Great lesson. Luckily it was not too expensive a blunder because the bank had been assembled from bare cells and all the cost+labour of the battery box, contactors, BMS, wiring, fusing, backup lead acid (your system for this is fab!) was preserved. That said, I am not at all sure about the upside in leaving the batteries for six months, starting at 80% SOC. Somewhere I have read (Eric Bretscher perhaps) never to store for the long term above 50% SOC. Even a 20% self discharge over 6 months would leave your batteries at a very healthy 30% in the Spring. I have done this 3 winters and my bank still shows the 99% State of Health with which they came, new, and the same internal resistances as when new. So it has worked fine for me in Toronto Canada winters.

Hi Andrew,

Thanks for that very good first hand information, although sorry it cost you a bunch of cells and time to confirm my idea! On the 50%, you may indeed be right although I would be a bit nervous of getting that close to the 20% SOC where things go wrong quickly. Maybe split the difference and say start at 65% SOC?

The general rule of thumb for retaining maximum useful capacity for any of the lithium battery types is that they should be stored at 40-60% SoC. The lower end of that range is slightly better than the upper end, but not enough to make much difference. Staying above 20% is also the typical recommendation. Of course, a manufacturer’s recommendation for their specific battery is more useful than a rule of thumb.

The major caveat with these recommendations, though, is that the storage temperature is presumed to be moderate. With very low temperatures, 40-60% SoC is already getting into the region of higher self-discharge — more of a modest ramping down than falling off a cliff, but not nearly as self-stable for long times as a warmer lithium battery is. The conclusion is that maintaining a lithium battery in an optimal SoC for long-term storage requires much more diligent monitoring and readiness to recharge as storage temperatures decrease.

Hi Mark,

That’s interesting, but not what I found in the bit of research I did (see the linked paper in the tip). Sure, discharge capacity drops with temperature, but everything I found indicated that self discharge rate also drops with temperature. This would also seem logical because I’m thinking self discharge is a chemical reaction and most (all?) chemical reactions slow as temperature drops. Therefore I don’t think it’s true to say that batteries stored at low temperature require more diligent monitoring.

All that said, do you have good sources to refute that?

Yeah, this is getting into terminological sloppiness again, to which I’ll plead guilty. If we define self-discharge as just what happens to a battery cell of a particular chemistry with no external circuit connected, then self-discharge does decrease for lithium batteries with decreasing temperature. I think that remains true even for very low temperatures, but I’m not 100% certain of the behavior in extreme conditions — lithium batteries behave quite differently from our usual experience when they get really cold.

However, if self-discharge is defined as what happens to a particular disconnected lithium battery product (i.e. several cells packaged in some kind of case and potentially with an internal BMS, monitoring circuits, bluetooth interface, etc.), then we’re dealing with not just the inherent properties of the battery chemistry, but also with the parasitic loads of all the internal add-ons. The self-discharge from the chemistry goes down with temperature, but the power draw from the internal parasitic loads doesn’t change appreciably with lower temperature. Meanwhile, the battery capacity or the amount that battery voltage must drop to produce a given amount of energy does drop with temperature. The shape of the discharge curve starts to change appreciably at cold temperatures that are not extreme (around 0-degrees C), and changes dramatically at extremely cold temperatures. That means that those parasitic loads can much more quickly exhaust the reduced battery capacity and thereby drop battery voltage to damaging or difficult to recover from levels. So, when a battery manufacturer tells you to expect their battery with internal add-ons to discharge 5% of the battery’s capacity per month when no external loads are applied, roughly half of that is due to battery chemistry and half to internal parasitic loads — under moderate temperature conditions. If the storage temperature is very high, then at least the part attributable to battery chemistry will go up. If the storage temperature is very low, battery capacity can go down by a lot, and the near-constant internal parasitic loads can be consuming a greater percentage of that reduced capacity. That demands more diligent monitoring and potential remedial action to preclude battery damage.

So, it all depends on how you define self-discharge for a battery with internal add-ons. I don’t think we are understanding things much if at all differently. For example, given deep cold storage conditions, I’d be much more comfortable storing a lithium battery with a disconnected external BMS than one with an internal BMS, active Bluetooth interface, etc.

Ugh… correcting more of my sloppiness:

Of course, I mean that capacity drops with decreased temperature, but the amount that battery voltage must decrease to produce a given amount of energy increases at lower temperatures.

Hi Mark,

Sure, I agree with all of that. Seems like we are on the same page that if we can get rid of parasitic loads cold storage is fine. In the Tip I deliberately differentiated self discharge and parasitic load discharge for just this reason.

Sure, but not all battery manufacturers make that distinction. Some give just one figure for loss of capacity (e.g. 5% per month, and may even call that “self discharge”), others specify a self discharge figure and another for things like communication load, and some specify all of these in ways that don’t add up consistently (e.g. if you calculate how much their specified communication drain works out to in amp hours per month and add that percentage of battery capacity loss to their specified self discharge figure, then you end up with a total monthly loss of capacity that is much different from their separate monthly loss claim.)

Without actual measured data of how particular batteries behave in storage, I’d only be comfortable with a very large margin of error and/or frequent checks on the health of the batteries in storage. And even then, you need to be aware that an extended period of colder temperatures than expected can also produce greater capacity losses than expected.

Hi Mark,

I think we are making this more complicated than it needs to be. My point was simply to differentiate parasitic loss from self discharge which I did in the tip, and to suggest that it might be easier to deal with winter storage with a battery with separate BMS, which seems well substantiated. Let’s leave it there.

Hi Andrew, John,

No cold climate issues for us, but a comment on storing LiFePO4 batteries above 50% charge for extended periods.

We winter our boat on our marina and I like to keep the batteries charged for bilge pumps, monitoring and convenience. We don’t use the boat a lot over the four winter months and sometimes not at all.

I consulted our marine electricians (Enertec) early on in our ownership cycle who consulted with MasterVolt and they said not to worry, only if we were leaving the boat for say 6 months or more.

So our three Mastervolt 180AHr LiFePO4 batteries have remained connected and between 95 and 100% charge since new. 10 years on we still have only used just over 200 cycles and seem to reach 100% of charge without any problems.

So with our battery setup, I would start at 80 or even 100% charge and not worry.

Hi Rob,

There seems to be pretty good consensus in all the research I did that storing lithium batteries fully charged reduces life. Where is gets a bit muddy is what range of discharge is optimal but it does seem that at 80% or less life gets better with marginal gains on that down to 50%.

Also keep in mind that the fact that your batteries will take full charge does not tell us anything about whether or not they have deteriorated. As far as I know, the only accurate way to determine battery capacity (regardless of chemistry) is a discharge test at constant current. Here’s some more on that: https://techfinepv.com/how-to-test-lithium-ion-battery/

Hi Rob and John,

It’s a well tested fact that LFP cells do age quicker when stored at a high state of charge (SoC). The mentioned levels are indeed what the makers and researchers report. However, the rate of degradation increase when done wrong is still fairly low.

My impression, after a lot of reading and experience over many years, is that keeping the cells completely full at all times, both in periods of use and during storage, seems to increase cycle degradation by over 50%. A dramatic effect, of course.

The flaw in that observation is that these cells can take many thousand cycles without losing much capacity. Even if we halve that number of cycles, we’re still looking at decades of use. That brings in another problem:

Calendar degradation. If we do absolutely nothing wrong with the cells, just plain time will still kill them. Moderate mistreatment will barely register. It seems unlikely if even great cells can keep a good capacity much more than 20 years in a realistic environment, no matter what treatment. If we reduce our cycles from 6000 to 3000, will we ever get there? Full time cruisers often stay below 200 cycles per year. That gives 15 years of use with bad charge degradation. For most of us, at least double that. The calendar comes to get us before the charge mistreatment does.

Am I saying that it doesn’t matter how we charge and otherwise treat the LFP cells? No, absolutely not. My point is only that we might relax a bit about some of the details, like charge levels, and perhaps look more at some others that get less attention, in spite of being more important.

At least 99% of LFP batteries die because of overcharge or over discharge. The former much more than the latter. The only way either of those can happen is if our system is poorly designed. Thus, understanding the logic of our complete system, and the different levels of protection it gives our cells, or far more frequently, doesn’t give, should be our primary focus.

When that’s good, before we nerd out too much about charge levels, we should think about the previously mentioned calendar degradation. From test data, keeping the cells cool is the most important factor to ensure longevity. Calendar degradation accelerates much from 30C (86F), and is dramatic from 50C (122F).

If we keep our LFP cells in the engine room, the cells will 100% certainly die from heat accelerated age degradation, long before the charge levels or number of cycles makes any difference. Lead acid batteries also suffer from this, but far less. LFP cells thrive at room temperature when in use, and prefers properly cold storage. Freezing is no problem, it even seems to almost stop age degradation.

I know of 60 large LFP cells from a trashed car that were stored in a barn in Northern Norway for 9 years without any care. In other words, always cold and half the year frozen. The owner died. His grandson asked me if they were just junk. I haven’t tested them, but they were all at 3,21 V, which indicates perhaps 60% SoC. He put them in a boat and some in a mini car for the farm. These were still working well last time I heard about it. If absolutely nothing is connected, self discharge is very low.

As is the point in this article, most LFP “batteries” on the market contain more than the cells. The conclusion, that an external BMS is better, is in my opinion indisputable truth, for many more reasons than what is discussed here. For me it’s the only acceptable option. An internal BMS gives the market what it’s used to, a self contained complete box. And more importantly: A BMS is internal predominantly to keep it out of your control, to hide its deeply flawed design, to make sure you have to buy a whole new battery as soon as possible. Internal BMS = Scam! If it wasn’t intentional scam, why is it internal, when external is better in every thinkable way?

Hi Stein,

All makes sense to me, and I really like the overall point that we should chill about some of this SoC stuff because the years will get ’em first…kinda like humans!

Also, thanks for the confirmation that storing cold is good, not bad. All the papers I found said that, and so does basic chemistry, but still there seems to be a lot of push back.

Although I might not go as far as to call internal BMSs a “scam” I too much prefer the idea of external for a whole bunch of reasons, many of which I have written about in other places. I guess one of the primary ones is that as an electronics tech by trade I find systems that are broken into separate pieces, each with a function, a lot easier to deal with, and generally more robust, than those that have single boxes full of multiple things. One thing I would call a scam is “drop in batteries” and I think that scam contributed a lot to the situation we are in today where internal BMSs are so popular.

Not sure why functional internal BMS LiFePO4 batteries would be any harder to manage than externally managed ones, John?

In the unlikely event of us ever cold winter storing our boat, our user battery manual shows a setting in the MasterView terminal for battery storage up to 6 months, with instructions on isolating from the supply bus, load bus and comms (MasterBus).

The manual refers to “up to 4% discharge per month” so I would start with say 60->70% state of charge. Am I missing something here? Thanks.

The beginning of the Storage section of the current User Manual for Mastervolt MLI Ultra batteries (emphasis added):

Hi Rob,

No you are not missing anything. In fact I say in the tip that this could be managed in software.

That said, given that the penalty for missing any parasitic load (monitoring comes to mind) is potential destruction of the entire bank, coupled with the complexity of modern battery systems, I prefer the low ambiguity and easy visual verification inherent in total physical disconnection, and that’s not possible with an internal BMS.

One thing I learned a long time ago as a computer tech is that if you can do something in a physical way it’s almost always a more reliable and harder to screw up than a software solution.

Let’s also keep in mind that the guy who wrote the article worked in battery support and saw a lot of batteries destroyed this way, and I bet in most cases the owners though they had all bases covered.

I don’t have lithium on my large boat, though that one’s in Florida, so freezing temps are not ever going to be a problem for very long, once I do replace the batteries.

On my little boat, here in Iowa, I drag the lithium battery, with the built-in BMS, home for the winter, and let it sit in the basement about half charged for the winter season. I suppose, if I had a bank of six or seven of the things, this would be a bigger pain, but still, I would expect that most of us have things that we already don’t leave on the boat all winter, like sails, or bedding, or even some electronics.

H i Karl,

Sure, that’s another option, that said, if the battery has an internal BMS I would want to be checking its state of charge every month or so.

This is what I did last winter; completely disconnected my Victron LiFePO4 bank at about 70% charge. No issues in NC, where temperatures dip occasionally below freezing but not for any extended time.

I left the lead acid bank connected to a solar panel, which kept it at 100% and allowed me to run the remote monitoring system for peace of mind.

Hi Raj,

Thanks for the confirmation, always good to have real world experience to back these things up. Do you by any chance know what the state of charge on the batteries was at the end of the winter?

I don’t, precisely. They did not seem to have experienced significant self discharge because they reached full around the same time the BMS SoC (still synced to the SoC in the fall) indicated they should.

I am about to lay up the boat again (this time in Portugal, so a bit warmer). I’ll write down the cell voltages and compare in the spring, and share what I find here.

Hi Raj,

Actualy, now I think about it, the fact that they reached full SoC in the same time tells us all we need to know: they did not self discharge much. Thanks

I did a battery upgrade this spring and this will be my first winter storage with lithium. I have 2 300AH Victron Lithium NG batteries and I store my boat outside, covered, in Michigan. My plan is bring them down to about 50%, completely remove them from the boat, and store them in my basement. They’re not that heavy, so my thought is to just remove them and avoid the temperature issue altogether.

Hi Daniel,

Sounds like a plan, particularly in Michigan! The great thing is that by totally disconnecting you are removing any change of an unnoticed parasitic load.

One thought, I would check the state of charge via Bluetooth once a month or so. My guess is it won’t be a problem, but given the cost of the things and that at 3% a month they might get to say 30%, which would start to make me nervous, its probably worth the 5 minutes work, particularly for your first winter.

I would be really interested to hear what their SoC is at the end of the winter.

Good idea, I’ll check throughout the winter and let you know what I find out.

I have some first-hand experience to share on this: my first lithium battery was trashed over the winter due to a faulty BMS, but it wasn’t self-discharge: The BMS got stuck thinking it was -5 degrees and refused to connect the contactors, even in June when it was actually 25+. To their credit, the manufacturer honored the warranty and actually gave me a full refund (which I had asked for).

I replaced it with a Victron battery but I needed a ton of additional gear to make it work properly so it was still an expensive upgrade even with the refund. That battery is now about to start its second winter; last time I just shut off the big “master switch” I installed on the positive cable and everything went smoothly.

I just have one correction for the article: the Bluetooth controller in Victron batteries shuts down after a while if there hasn’t been any activity on the battery. When I got mine there were some instructions on how to turn it on because it was shut down while in the warehouse and in shipping. I think you’d have to check it at least once a week to keep it awake, or just let it shut down and not have any parasitic loads at all until you reconnect everything in the spring.

Hi Emile,

Thanks for the first hand information and correction. I will change the tip to reflect it. Actually I think that’s good news since if the Bluetooth shuts down the parasitic load with the batteries disconnected will, I’m pretty sure, be zero, just leaving the self discharge to worry about, which should be fine over a winter, particularly since self discharge rate goes down with temperature.

As far as just switching off the master switch, I personally would still consider disconnection of the batteries to make absolutely sure a parasitic load does not discharge them, particularly given how expensive they are!

My understanding is that LiFePO4 batteries can still be charged below 40F, but that the rate of charging must be very slow, below 0.01C. Put another way, impractically slow for use, but not zero. I’ve been planning to limit charging to 0.02C this winter, which is simple enough.

From ReLion:

“When temps fall between 32 degrees and 14 degrees Fahrenheit, batteries cannot be charged at higher than .1C. When temps fall between 14 degrees and -4 degrees Fahrenheit, batteries cannot be charged at higher than .05C….”

True? Not true? I do sail all year, so disconnection strategies are not very practical. Not impossible, just difficult. Since I don’t draw them down much (no more than 5% SOC, only a few times, and practically always on above freezing days) in the winter, even a very low charge rate will get it done in a day or a few, which is fine. The batteries do have a no-charge-below freezing feature for extreme cold.

Hi Drew ,

That’s interesting, I thought it was zero, but looks like not. I guess this is one of those issues where we can’t know for sure genericly but can probably trust the manual for a given battery because most manufactures are conservative in these things to avoid warranty blow back. Sorry, that’s all I got.

Anyone else have solid information on this?

Hi Drew and John,

What I say below must be seen as probably true, but definitely not absolute facts, of course. It will also vary with cell details we cannot relate to, and it develops non stop. Anyway, according to what I’ve been able to find through the years, as a general idea:

LFP cells can be charged at any temperature, also far below freezing, but the colder it gets, the lower the charging speed (Amps) must be, if we don’t want damage. When below freezing, the safe charging speed is so minimal that it is mostly useless. It can’t keep up with any real life consumption. Discharge isn’t limited by cold.

It’s possible to charge faster, but as always, the further we push, the more it will limit the life of the cells. There are some thresholds, one is often mentioned around -5C, where the vulnerability rises rapidly. Yttrium was used to improve this some years ago. Some claim they have improved cold charge properties a lot. I would not trust that. However, cell temperature often isn’t the same as outdoors temperature. Especially in the cold, it’s quite easy to keep them warmer.

I like using temperature zones, with “traffic lights”:

– GREEN: Cell temperature 10-25C (50-77F). In that range, we can disregard temperature. The cells are happy.

– YELLOW: Out of the above range is also just fine, but the further we go, the closer we get to problems. We need to monitor this region. It’s perhaps smart to have a warning light pop up, so we can start adapting before we need to.

– RED: At freezing we should stop charging, but can still draw power. Above 30C (86F) the cells degrade, especially if we charge or draw. No immediate destruction. They work fine, but a new bank may jump years closer.

Just for perspective: In about one month CATL, the World’s largest maker of Lithium batteries, will start industrial deliveries of Sodium batteries. Compared to LFP, these have initially about the same power density (Wh/Kg), are not sensitive to temperature, cannot possibly burn, have more than twice the expected life time, use no lithium or rare earth minerals and are about 10% cheaper. Salt is NaCl, Natrium Chloride. Natrium = Sodium. The sea could deliver all we need of that forever, if this was the final chemistry. The price is expected to drop a lot and the energy density will increase. I’d guess it’ll take years until it’s available for normal customers, but perhaps not? I wouldn’t wait… This is just one of many interesting developments these days, but this one will certainly and quickly be economically disruptive in that business.

Thanks!

In my case days below freezing in the battery compartment (boat in water) are not that common, I have a means of limiting charging, and the batteries have a low temperature cut-off anyway. As you say, 0.02C is pretty useless for most purposes. For me, it is just for simplicity, since I don’t winterize and I do day sail. Not that unusual. We pick our nice days! A slow rate is enough to replace the autopilot amps before my next visit 5-10 days later.

The honest reason I switched to lithuim.

My battery is located in an ergonomically horrible place (boat yoga and a weird twisting pull) and I wrenched my rotator cuff getting it out. Lithium is physically easier when bulling is unavoidable. The only other solution would be renting a young strong guy.

Very interesting and timely, just winterizing our Victron lithium (New England). Wish I could explain why, I can’t—but we previously had Mastervolt lithium on a prior boat. They recommended winterizing at 100%, annd follow a “shutdown” all systems disconnected including the Masterview (monitor ). This was 2-3 years ago. End of winter was in low 90’s. I had to look around a lot to find Victron materials also asked the boat manufacturer from Denmark that regularly winterizes boats there own boats and customers with the same batteries, conclusion is 60% SOC for Victron and everything disconnected. Maybe you or someone smarter than me can explain why they are different but passing along in case helpful.

Hi Marc,

Thanks that is indeed very useful.

I think the difference is that the Mastervolts have internal BMS and so, as described in the article over at Pambo, have at least some parasitic load over the winter, even if in some kind of sleep mode. Clearly Mastervolt know this and so want to start the winter with as much capacity as they can.

Whereas, the Victrons, when disconnected, and after about a week when the BlueTooth shuts down (thanks Emile), will only need to deal with normal self discharge, which is very low, particularly at low temperatures.

These supports my theory that if we will do a lot of winter layups it’s better to select batteries with an external BMS.