I have long been a fan of holding-plate refrigeration systems over evaporator systems:

- More efficient.

- When done right, better temperature consistency.

- Can be force-run when there is ample power, say when motoring or a generator is running—can be automated.

- Can be shut down overnight for quiet without the box thawing out or getting too warm—if the plates are big enough and the insulation good enough.

- Don’t cycle on and off every few minutes, which I find irritating.

- With intelligent management a holding plate system reduces required battery bank size.

And no, I’m not talking about engine-driven holding-plate systems, which, based on having owned two, I don’t recommend—hanging a compressor off an engine just about never ends well.

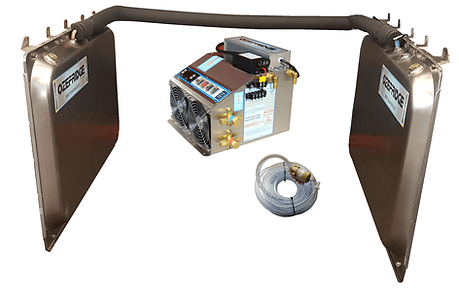

Rather, I like holding-plate systems with a powerful compressor being driven by a big electric motor (1/2 to 3/4 HP) like the Glacier Bay system that gave us great service for nearly 30 years.

The sad thing is that these seem to have pretty much died out.

Probably because holding-plate systems are more expensive, as well as harder to install and maintain than evaporator systems using the ubiquitous Danfoss compressor.

A holding plate is essentially a thermal battery. If refrigeration is a significant part of your house loads, then using holding plates instead of plain evaporators is a great way to make use of excess power when it’s available and to reduce the demands on the house battery when it’s not.

It also buys you a lot more time to fix anything that goes wrong, before your food starts to spoil.

I’m glad to see some manufacturer interest in this technology again.

Hi Matt,

Exactly, in fact having large holding plates was how we got away with just having 450 Ah at 12 volts in our house bank on the M&R 56 for so many years, before we upgraded to 800Ah. We only ran the fridge/freezer when the generator or main engine were running. The other advantage was that the load from the fridge, (almost 1kW) helped load the generator properly.

Hi Matt and John,

I am curious if you are aware of anyone doing a comparison calc of a holding plate system versus having a bigger battery bank? I am thinking things like cost, size, weight, etc. As they are both what engineers call “accumulators”, they can be compared on an energy basis.

The problem with holding plates to me has always been that for boats that have very little energy usage other than the fridge, the high power draw can mean that you have to be running a generator or main engine to turn on the fridge as the batteries will be inefficient at that high C rate and the voltage drop will be too great. Lithium can change this but at the same time it would be interesting to know if people have compared whether simply getting slightly bigger bank and using one of the Danfoss based systems makes more sense?

Eric

Hi Eric,

No, I don’t know of any in-depth testing, or at least not recently. I do know that the Glacier Bay unit blew away all other options on efficiency when tested, but there were several reasons for that, not just holding plates.

Good point on the effect of Peuket constant on efficiency with lead acid batteries. As always these things are usage specific.

On the McCurdy and Rhodes this did not matter much since because our boxes were so well insulated we almost never ran the fridge off the batteries, since before the plates were full thawed, we would almost always need to run the engine or generator.

But with Qzefridge the compressors are the same as for evaporator systems, they just run longer less often, so I can’t see how C factor comes into it?

Talking of usage, I was thinking just last night of how nice an Ozefridge would be on our J/109 because we could run it to freeze the plate(s) before leaving our wharf with shore power and thereby reduce our power usage a whole bunch over our typical 2-3 night cruise. Ditto if we had to motor for a few hours, or visited a wharf with shore power.

Hi John,

I missed that the Ozefridge uses a small compressor so my C factor comment doesn’t apply to it then.

It should be possible to get a good idea of extra batteries vs a holding plate based on specs if they actually publish decent specs. The few times I have looked at specs for refrigeration systems, I have been very annoyed by how useless the published specs are from most manufacturers. I would expect to see a heat transfer rate versus temperature differential graph and information on energy usage such as COP. Instead, they usually just say what size fridge the system is appropriate for which ignores things like insulation and infiltration. It makes it very hard to actually design an appropriate system without any useful information.

Eric

Hi Eric,

I agree that the specs on these systems are not useful to make a decision. That said Ozefridge did do some interesting experiments.

Ozefridge are well known and loved in the community down here in Australia. I’d certainly have them top of the list if you were looking to replace a built in chest style fridge or freezer. I think the thing that is really doing in the holding plate systems is the love of the new integrated drawer systems. It’s certainly got a usability appeal and if you’re never that far away from a dock and have the power to burn they have a great deal of appeal. Happy there is still a very solid DIY option for the rest of us though.

Confirm Nick’s comment below – Ozefridge have a rock solid reputation in this part of the world and are on my shopping list for certain.

The broader question being raised here is the role of refrigeration more generally. It’s my sense that the requirement can be split into two modes – one at anchor or dock which is 90% of the time where an easily accessed 4degC refrigerator is ideal – a modern pull out being popular . Great for keeping fresh food and drinks safe and convenient as we normally in land based kitchens. In this scenario there is usually plenty of power available either through dock power or extra solar that can be deployed, so efficiency is likely less of a concern.

By contrast the 10% of time on passage leans to an emphasis on frozen goods or pre-cooked meals and in this scenario a highly efficient -18degC chest style freezer looks to be more applicable where power is typically less available. And in this the Ozefridge excels.

Also I think many people might overlook the potential use of ice bricks and gel packs – ideal for example to use in simple insulated bin to keep a passage caught fish safe for the day or two before it’s eaten.

My view is there is a role for both forms of refrigeration; each complementing the other in different cruising scenarios.

Hi Philip,

Sure, all these things are usage specific. That said, as a sailor who abhors added windage and clutter, I would not add solar to, in effect, support a less efficient fridge, but would rather celebrate a more efficient unit allowing me to cut the number of panels, even ones deployed temporarily at anchor.

What would your thoughts be on adding eutectic packs to a evaporator based fridge/freezer?

I’ve noticed a large variety of eutectic options for medical transport, not sure how to go about integrating them but if it was possible to reduce overnight running, especially if you had excess power from solar before sunset and could use that to bring temps down a bit more than normal prior to shutting down overnight.

Hi Star,

Sure, you could do that, but I don’t think it will be very efficient since the fridge won’t be set up right—too short run time, and wrong temperature—for a holding plate situation.

I have just installed an Ozefridge system in my S&S 30 boat. The installation was very straight forward and I cannot speak more highly of Louie, their refrigeration engineer, in his assistance with a few minor problems.

We installed an Ozefridge in the icebox on our last boat (a lovely old Tartan 37). Simple installation, great performance and easy on the batteries. Holding plate systems are common on boats in Australia (and surely elsewhere too?). The folk at Ozefridge have a great reputation and provide excellent and timely advice on the right system, its installation and use.

Hi John and all,

I will be interested in this new frig product you report.

I have lived with both a holding plate (HP)and an evaporator plate system. When I bought Alchemy, it had a holding plate in the freezer and a spill-over from freezer to frig to cool the frig. The HP was AC driven alone: generator or shore power. There was always an exquisite balance that needed attention between HP temp in the freezer, the spillover device managing the temp in the frig, the ambient air temp and the sea temp.

I may not have given holding plates enough time, but I was happy to flop Alchemy over to a DC boat (with small AC loads covered by an inverter). And we removed the 5kw AC generator which was shoe-horned into my 40-foot hull. With this, I went with 2 air-cooled evaporator plate units (Sea Frost BD units) one for the freezer (our cruising style really appreciates a big freezer) and one for the fridge: 2 units giving us redundancy to my capacity to keep things cold. I never explored whether I could have gotten a big inverter that could have run the AC holding plate system which would have allowed use while motoring (with a bigger alternator than I had at the time as holding plates demand a lot of power).

For my use, after a day of motoring and settled into a nice anchorage, I needed to run the generator to bring down the holding plate: really not nice to continue to have an engine going. Also, I was daily or twice daily needing to determine the amount of time the HPs needed to be drawn down: not always easy to determine and easier on shore power but we were mostly at anchor and interested in short generator run times.

The impressively large holding plate was removed freeing up lots of freezer space and the BD units found a nook to live in taking up much less space with the evaporator plates (EPs) situated where they were most efficient and took up little space in the frig/freezer.

I greatly underestimated (or did not consider at all), how really very nice it would be not to think about the frig/freezer: with EPs they operated just like a home unit turning themselves off and on as needed and as set by the thermostat. With the BD units, I just set the thermostat (like a home frig). The older I get the less I like to fuss with decisions: so, I relished (and after a couple of decades still do), not have to think about the frig and freezer.

Thinking still needs to be done as the battery bank needs monitoring: but that is something I would have to do anyway. If batteries are adequately charged, the frig/freezer takes care of themselves and all I have to concern myself with is to ensure the battery bank is adequately charged, something that would concern me anyway.

I did add to my battery bank when I turned Alchemy into a DC boat, which I would have done anyway as we lived at anchor for long periods. We also went with a DC generator to keep the batteries topped off which worked (with much effort) for us for 15+ years.

So, from my point of view, EPs have a lot to offer. I relish their independent operation, their far smaller footprint in the cooling areas and also smaller out-of-the-box machinery. Air-cooled simplifies installation and maintenance quite a bit and has proved workable even when living in 85-degree F water and hot temps. Another plus to air-cooled is that when living aboard on the hard which regularly occurred for us and often for a week or two at a time, we had refrigeration.

An alternative view.

My best, Dick Stevenson, s/v Alchemy

Hi Dick,

I have never had holding plate units, only evaporation plate fridges/freezers, so judge my input in that context. From quite a few different installations, I can conclude that the commercially available alternatives I’ve experienced, including the “premium brands”, have one common essential flaw: (Very) poor insulation.

If my assumption is correct, most holding plate systems are not bought as a complete box, but rather a cooling package that the builder will install in a separately made insulated box. This insulation is probably waaaaay better than the standard industrially made evaporation type fridge boxes. Since energy is constant, (Einstein), I must conclude that the main difference in efficiency between holding plate systems and evaporation systems has to be found in this box insulation topic. Maybe I overlook something?

I’ve mentioned earlier how I made our fancy pancy 1800 Euro German stainless Isotherm fridge use about one third the power by putting 19 mm of insulation on the outside of the box. It now uses negligible energy. It runs on average 5 minutes every 30 minutes, in the summer. It draws insignificant power and it’s not possible to hear it unless the door is open or your ear is actually touching the fridge. That means:

1. The original box insulation is worthless, garbage. So expect to improve it, no matter who made it.

2. It’s really easy to improve dramatically, with minimal cost. We used Armaflex, ironically also made in Germany.

3. The wiggle room for efficiency improvement with another cooling method, like holding plates, is minimal. It’s still there, but noticeable improvements are an illusion.

4. We can pick any of the two solutions, based on what fits us.

As an aside, expect significant tech improvements in the not too far future. I don’t know which tech will be the one coming first, but there seems to be several contenders. (Perhaps heat pumps?) Should you wait for it? Nope! When it comes, whoever knows when, it’ll be expensive and probably unreliable.

Conclusion: Right now, evaporation type systems are the standard. Ubiquitous. It’s totally fine. Just expect to insulate the box better. No need to struggle more than that.

Hi Stein,

While I agree that insulation is vital, and a well insulated box with an evaporator system works fine too, it’s not true to say that’s the only difference between holding and evaporator.

The decision is, as always, usage based, but even assuming good insulation a well thought out and installed holding plate system is intrinsically more efficient than evaporator and better still it augments the battery bank by being an energy storage unit, see Matt’s comment and the links in the tip.

A heat pump is just like any other vapour-compression refrigeration loop, except that it has a reversing valve so you can run it in either direction. Not applicable here.

Insulation is *so critical* for refrigeration. The effect of variations in insulation quality overwhelms all other effects so dramatically that head-to-head comparisons of different refrigeration systems, unless the insulation is *completely* identical, are worse than useless.

What new tech improvements do you think are on the way? We’re already running up against the law of diminishing returns; there simply isn’t much more efficiency to be gained from vapour-compression cycles or from brushless DC motors before fundamental thermodynamic limits start rearing their heads. The main change that I see in the near future is the switch to 48 V DC compressors, which the car industry is planning to mass-produce for EV and PHEV heat pumps, and which the boat industry will quickly borrow for refrigeration.

A simple calculation of cycle efficiency doesn’t tell the whole picture, and even then, the thermodynamic cycle efficiency is roughly the same between an evaporator and a eutectic system of similar quality. Evaporator systems that cycle every few minutes must draw power from batteries when the engine isn’t running. Eutectic holding plate systems with DC compressors have the option to draw tremendous power during periods when power is free, and to draw no power during periods when power is precious. That is definitely worth something.

Hi Dick,

That sounds like a very bad implementation of holding plates.

I had something similar at thirty years ago. In my experience the problems you outline are pretty much all to do with the primitive and poor implementation that was common at the time. Also many of those systems did not use the right holding plate solutions which caused variable box temperatures.

So while I would not say that holding plate systems are always better I would say that using a poor AC implement as a base line to damn all holding plate systems is a pity.

So, for example, if you had a good DC holding plate implementation you could run it when you were running your DC generator (or main engine for propulsion) and the net result would be to reduce the amount off hours you would need to run either since the holding plate system would continue to store energy after the batteries had achieved acceptance and charge rate had fallen off.

And a system like the Ozefridge would give you all of the advantages of your current system (same compressor), with a substantial jump in efficiency.

(I have a Seafrost on the J/109, so have first hand experience of that too).

Interesting and from the sounds of it good, but I can’t take the scientific experiment and claims seriously when the author is confused about the difference between energy (Joules) and power (Watts).

Hi Giles,

Each to his own, but to me that feels like throwing the baby out with the bathwater.

Hi Nick, Philip, and David.

Thanks for the confirmation, good to hear. I think that if the fridge on our J/109 ever dies, Ozefridge would be the first place I would look to.

You might be interested in Nigel Calder’s short but wide ranging refrigeration article in Professional Boatbuilder. https://www.coastalclimatecontrol.com/images/PDF/Nigel%20Calder%20Marine%20Ref%20Part%20Two.PDF

Another interesting article is the June 1995 Cruising World side-by-side comparison bench testing of most of the various refrigeration systems available at that time. It involved an amount of work that I doubt could be done today by any print publication. The link will take you to the last page in the article. Just scroll up to page 54 where the article begins.

https://books.google.bs/books?id=cbA2Sw1wqGQC&pg=RA6-PA62&lpg=RA6-PA62&dq=cruising+world+refrigeration+test&source=bl&ots=ahtN-A5lQT&sig=HMTHtDo_iNw2Sb3kPeFFPZcgQVU&hl=en&sa=X&ved=0ahUKEwjZ56DH_vPaAhXGk1kKHS8FC2QQ6AEIPzAD#v=onepage&q=cruising%20world%20refrigeration%20test&f=false

Hi William,

That was the article that prompted me to buy the Glacier Bay system that served us so well for nearly 30 years.

It was also the last true product comparison CW did, if memory serves. I was writing for them at the time and one of the editors told me that the word came down from publishing that there would be no more articles like this because so many of the companies that did not do so well pulled their advertising.

From there it was all down hill.

Glacier Bay claimed their TSS-5 and TSS-26 propriety solutions to be eutectic solutions like the corrosive calcium chloride solutions used in delivery trucks. Other makers seemed to be using propylene glycol and water solutions. The solution in the plates should be chemically stable with time, non-poisonous, and non-corrosive in a mix of metals perhaps as different as stainless steel, copper, and aluminum. It should have a freezing point 10F or 15F degrees below the box temperature, and it should have both a high latent heat of freezing and a low expansion on freezing. The desired eutectic solution with its one freezing point would be superior to antifreeze solutions like propylene glycol which begin to freeze at one temperature and continues to freeze at lower and lower temperatures as the freezing continues and similarly melt over a range of temperatures.

Glacier Bay left the business, and I have not been able to find the TSS-5 and TSS-26 compositions. Does anyone know why they left and what the compositions were?

Hi William,

I can confirm that the Glacier Bay solution was a true eutectic since the temperature stayed stable as the solution changed state up until all was liquid, on our system. I seem to remember that it was proprietary and non-toxic, but I might be wrong.

Not sure what Ozefridge is using, but I bet if you ask them they will share. They seem very knowledgeable so I bet they are using the right solution.

As to why GB went out of business. As I understand it, the principles were always more into development than focusing on running a business and in the end that caught up with them when they bet the farm on hybrid diesel electric way before the tech was ready to make that work. They built a few systems but the problems put them out of business.

Hi William,

Good article, as we expect from Nigel. Thanks for the link.

I have had an OzeFridge for 8 years. I use it as a refrigerator with a tiny “freezer” unit that makes ice for my wife. I love it. It has performed flawlessly for all those years, including 9 months in the tropics in 2016-2017. It helps that I rebuilt and reduced the size of my box with vacuum panels as well as a protective layer of blue board–estimated 45 R value. But the box is still plenty big. The only thing I have replaced is the water pump–a stupidly broke one of its spigots.

Thank you for all interesting inputs and discussions on holding plates in the fridge. At the end of the day, I guess a certain amount of energy is needed to keep the temperature in the fridge, whether the electric energy is stored in the battery only or in the holding plate + battery (obviously, cold is stored in the food too). I do not know if an extra battery would work as well as a holding plate but it seems nice to store energy in a holding plate when the battery is charged in absorption mode and the full effect of the alternator or shore power is not used. Holding plates or not, the most important is of course to have a well-insulated fridge.

I have good experience of another holding plate system,

the Isotherm ITC 3251 SP made by Isotherm (https://www.indelwebastomarine.com).

It has a holding plate and is sea water-cooled but requires no seawater pump or air fan. The condenser is built into the through-hull fitting for the galley

sink. I do not know how much energy is saved by the absence of pump/fan but it seems clever and one electric device less is always good in a boat. The

pump/fan-less condenser works with the boat on land too, less effectively but

on land I will have shore power and the extra energy consumption is irrelevant.

The system works very well when motoring, on shore power and with solar panels on a sunny day. But as Eric Klem pointed out, my present fridge controller sometimes diverts more energy from solar panels to the fridge and less to the discharged batteries than I would like, especially on a not so sunny day. However, in that case I can turn the fridge controller to manual mode in which it will keep the temperature but will not freeze the holding plates, i.e. work like a fridge without holding plates. Perhaps the new “Isotherm Intelligent Temperature Control (ITC)” can control the compressor in a more effective way? Retro fit of ITC is possible but I have not tried it.

HI Carl,

I have long wondered about the Isotherm and their innovative though hull heat exchanger, so thanks for the real world report.

Selecting a system ‘fit for purpose’ requires some groundwork… (Need cold beers, not tears!)

A: Note your cabinets inner dimensions, insulation thickness and capacity.

B: Establish your cabinets heat load and power consumption in the most extreme situation likely. Use an interactive online estimator like this: https://ozefridge.com/heat-load-calculator/

C: Choose a system type that suits your usage with less than a 50% duty cycle. (50% run time).

D: Each type of system, whether its eutectic, fan forced or a cold plate, has some advantages and disadvantages listed below. Users also have to weigh in on how they want to use their refrigeration system to get the most out of it.

D1: Aluminum cyclic cold-plate.

Positives: Low initial cost. Fast cabinet cool down. Suits weekend cruisers. Can be used for fridge or freezer.

Uses little space in cabinet.

Negatives: Soft aluminum cold plate and refrigeration pipe is easily punctured and subject to pip-hole corrosion.

Very power hungry due to low COP and excessive compressor start-ups. Requires battery supply 24/7.

Best with stainless steel and copper tube cold plate as seen here:

D2: Forced air evaporator:

Positives: Very fast cabinet cool down. Suits weekend cruisers.

Negatives: Very power hungry. Can only be used long term as a fridge. Requires battery supply 24/7.

D3: Eutectic Hold over. (Phase change)

Positives: Suits continuous use. Much more power efficient. Less reliant on battery supply. Stainless steel construction, (not aluminum!)

With ECO2, all or most of the days refrigeration can be automatically achieved using ‘abundant power’ taking the load away from the battery supply.

Eutectic holdover speeds up cooling of warm products added.

Negatives: More costly initially. Uses more cabinet space.

Hi Louie,

A good overview, thanks

I’d like to hear more re “engine-driven holding-plate systems” not being your friend. I’ve had a Seafrost unit for 10 years with no issues and love the performance it gives driving the twin plates cold. The engine driven compressor is mounted on the engine so it’s straightforward to keep the belt tension correct and everything aligned.

I have a Danfoss compressor in parallel with the engine driven unit and the combination has done a nice job plus provides redundancy.

What should I be on the look out for (problem wise) with the engine driven unit?

Best regards,

Ron & Ellen Kraus

S/V Sola Fide

Annapolis, MD

Hi Ronald,

Good to hear you have good service. The main problem with engine driven systems is that vibration and refrigeration are not generally a great combination, so systems of this type are prone to leaks. I also don’t like the clutter added to the engine and the fact that the engine must be started to run the fridge, so in most cases, like yours, there also needs to be a back up system for shorepower use, which adds complication.

For these reasons I prefer the same type of compressor but driven by a big DC motor, which has the added advantage that it can be used off shorepower or off the batteries without starting the engine.

Anyway, if things are working for you, that’s the main thing, but when it dies I would advise looking at alternative options, although sticking with holding plates.

Hi Ron,

Suspect the issues to “look out for” are not with your clearly well set-up refrigeration system, but with your engine (which for many / most is mission critical, to get through calm periods / weather a lee shore etc).

By way of illustration, a friend of mine was preparing for a race start in 25 knots under engine. With sails going up, lots of noise in the cockpit and occupied with timing their Division 1 starting sequence signals, no one heard the engine over-temperature alarm. The first they knew of a problem (as I was told it anyway) was the head of the engine block hitting the cockpit floor.

Over a few years of hard racing, the engine coolant hoses had chafed unseen over steel brackets holding the refrigeration compressor. And one burst at an inopportune time – no one had foreseen such an issue, unique to this boat and custom install.

The engine was a write-off and not covered by their marine insurance policy, deemed a maintenance issue, exacerbated by the owners having modified the engine to non-standard spec.

Fortunately this was a short inshore harbour race and money can fix most things, but an interesting learning opportunity!