The first time I used a vane self-steering gear in anger was back in the early 1980s, aboard my newly purchased UFO 34 cruiser-racer whilst delivering her home from Scotland through the Irish Sea.

Fitted with a then state-of-the-art Aries vane, we had strong tailwinds for much of the way, which the vane handled fairly well, impressive because the UFO was an early IOR design and a known handful downwind.

But when the wind eased, the vane really began to struggle, failing to respond quickly enough to hold a course, and in the end we had to take over by hand.

Over the next few weeks we tried everything to sort this out, with the aid of the late Nick Franklin, designer and builder of the Aries.

We cleaned all of the bearings, added a lump of plasticine to the counterweight, and even tried attaching elastic cord to help the vane recover, all to no avail.

Finally, during a last despairing chat with Nick the main culprit emerged. “You haven’t by any chance painted the blade?” queried Nick, and immediately the penny dropped—the previous owners had painted the plywood blade with several coats of gloss, and added an attractive logo on both sides at the top—and this was enough to unbalance the blade to the extent that it wouldn’t recover to vertical quickly and smoothly.

So here are 11 more things we have learned about our vane gear over the years:

Hi Colin,

It was an essential article in 2011 and remains an essential article for wind vane users a decade later.

I used a Monitor, but my comments apply to any windvane user. It has been my observation that too many cruisers neglect (and perhaps do not think of or appreciate) the fine tuning that can be had with their traveler and just leave it amidships most of the time.

This capacity for fine tuning can be especially important when trying to get a windvane to behave. A few inches to leeward or windward powering the main up or down can make a nice and easy adjustment to balance the helm and might save the effort of throwing in a reef only to shake it out 30 minutes later.

My best, Dick Stevenson, s/v Alchemy

Hi Dick,

I agree on the traveler and think it’s often one of the most neglected, and yet useful sail controls on the boat. I think it was Bob Perry who said you can always figure out who is a cruiser by the cobwebs on the traveler.

Colin, Dick, John – on a Boreal tiny adjustments to the daggerboards are the secret sauce – we once went 3 full days in a trade wind crossing (Windpilot) only adjusting the daggerboards (usually the leeward one) up or down a few centimeters. I think this speaks to the truism that wind vane gear is most commonly limited by your sail trim expertise with the boat. For us, our Windpilot performance, especially in light air, weird seas, etc… was radically improved overtime on the basis of our ability to properly trim the boat. Seems like most folks name them something magical because when you get’m working it is magic – we called ours “The Wizard”

On our C&C 35, you pretty much have to put the traveller up to windward if you’re close-hauled in light air, and she’ll heel over and fight the helm if you neglect to move it to leeward as the breeze builds or as you turn downwind. (Also, it’s right in the middle of the companionway, so the crew get rather annoyed if you just leave it on centre.)

I haven’t had a chance to use our Hydrovane in a while. It worked OK on our first voyage, but we didn’t really have the feel of the boat’s balance at that point. I’m curious how much better it will perform now that we have some idea how she behaves, and have rigged up a workable main reefing system. The tendency of the boat’s weather helm to overpower the vane if we left too much sail up was my main complaint about it, and that’s really more on the skipper than on the equipment.

Hi All

one of the best things about vanes is that they teach you how to trim your boat at all angles and in all conditions – I, for one, found over time that given the chance I would overshot sails. The vane wouldn’t tolerate this and so I learned better and made faster, more comfortable passages as a result. It’s the same with reefing, selecting the best balance of reefed headsail vs or in conjunction with the main, which will depend on your boat and her sail plan. Robust, quiet, no power drain, what’s not to like?

Hi Dick, Colin & John. A Monitor windvane has done 85% of the steering for over 30,000 nautical Bluewater miles and I agree that sail balance is key. On one of my haul outs I very carefully cantered the rudder and marked the top of the wheel with coloured vinyl tape. I then moved the rudder 6 degrees to port and 6 degrees to starboard and marked these two points on the wheel. A quick glance at the wheel indicates the Monitor is struggling. Before touching the Monitor control lines I first try to re-establish balance usually by dropping the traveller. If that is only partially successful it is usually time to put another reef in the main.

Different boats may respond differently to the various sail adjustments and you have to learn how to achieve a neutral balanced helm on your boat. As others have said this is also faster and more comfortable.

Hi Martin,

Absolutely, in fact your 6 degree marking idea is a great tip whether we have a vane gear or not. For example using the same trick with an autopilot reduces load and electrical use a bunch.

The other trick is to get into the habit of hand steering for 5 minutes every hour or so of a watch. Another good way to check if the trim is wrong, although your way is more definitive.

I would be interested to hear how well the Sailomat performed on Morgan’s Cloud. I found that particular wind vane very difficult to set and unreliable to leave unattended. I have replaced it with a Hydrovane which is wonderfull and a joy to use.

Hi Ian,

Same experience. We got it working eventually, but had to rebuild the damned thing at vast expense. Not recommended.

A big yes to putting a tell tail or two on the air vane. It is amazing how just a little gear stored in the vicinity of the vane gear can change the apparent wind the vane sees. Until I discovered this, getting the set right, used to drive me mad, until I would just give up in frustration. No longer.

The importance of having a balanced helm cannot be under estimated. Using a traveler is something few cruisers hardly ever adjust. If it too hard to adjust, work on changing that. Increase the purchase on the control lines. Change to a ball bearing car if necessary. Make the track as long as possible. Then learn how to use it. You will be glad you did.

Tell tales on the air vane work wonderfully well and don’t alter the essential balance of the vane. Cost nothing, too…

Great article.

2 years ago I was looking for a new windvane for my Luders 33 and I only had a few choices Hydrovane, Cape Horn, Windpilot and Monitor. Unfortunately all out of my budget (all >6K CAD). Unfortunately several makers went out of busines over the last several years, and in this age of electronics, this is a niche market.

But it’s worth mentioning that there is a new kid on the block, and Windy out of Estonia is well built in stainless steel and very fair priced (2K CAD including shipping). I have one installed and I am really happy with it. Another option for anyone looking for a windvane.

Hi Marcelo, thank you for the pointer to Windy (https://windyselfsteering.com). Although I am not (yet) looking to buy a wind vane – still more urgent investments to do on my 22 year old boat – I found they also provide mast steps, at an unbeatable price, and Imre is a very responsive guy and seems quite knowledgable. I am now awaiting my 24 mast steps 😉

Both windvane and mast steps surpisingly cheap and strong. The steps do look quite hard edged. One would probably require protective clothing, shoes and gloves to use them. Also I found with steps that halyards have a nasty habit of wrapping themselves around them, especially at night. I ran light lines down them, both sides of the mast to prevent this. Not pretty but quite effective. With the Windy design you might be able to get the manufacturer to drill holes in the outer profiles to neatly run line through.

Hi Mark,

I agree on the sharp edges on the steps. The other issue with steps is windage, which, I believe, is far more disruptive than many think. And then weight aloft is an issue too.

For these reasons I always liked the ABI aluminium folding mast steps, but it seems they have been discontinued.

All that said, while I can see reasons for mast steps, and had them up to first spreaders on the old mast on our McCurdy and Rhodes, on balance I would not fit them again but instead rely on ascenders for unassisted mast climbing. Matt and I have a couple of articles in the hopper on mast climbing.

Hi John and Matt,

I will be interested in your article on mast climbing. It is my take that many a cruiser neglects work and forgoes inspections, for a wide variety of reasons, when it entails going up the mast.

My best, Dick

Hi John

I am with you both on windage and on folding mast steps. Folding ally steps were going to be my next port of call but maybe I should try out an ascender first. Its got to be cheaper and I hate drilling extra holes in the mast. Has anyone here tried using one while underway ?

Hi Mark,

No, never been up the mast at sea with ascenders and am very happy about that! That said I did some single handing at one time and before that bought a set of ascenders and practiced with them to the point that I was reasonably confident that I could go up with the boat heaved-to. More in future articles.

Hi John, its been a while, but too bad ABI went out of business, they had some very nice stuff. Regarding windage related to the steps, it is not something I noticed on my previous boat, perhaps a bit noisier in the higher wind scales, but its worth the piece of mind. Going up the mast is the single task I cannot do on my boat, and being a singlehander it has caused headeaches before. It more than paid for themselves for the inumerous times I had to climb in a hurry over the years. So I decided to live with it again on this old boat.

I had a heated argument with myself (I always win), and I decided that a radar dome with its brackets and cables weight more than my steps, and these are installed on many masts. Its amazing how we find excuses to ourselves to go ahead with these things, eh?

Hi Ernest, I am glad you got them. I also have bought steps almost exactly as Imre’s but locally and before I knew of Windy’s. I will round the edges before installing, and all 24 of them weight 5 kilos, which makes mine a bit heavier at about 200 grams each. My mast is 40 feet, I’ll place 2 5 feet below the top and one evey 18 inches above the genoa winch, so I am not sure if I’ll use all 24 or them, will install with monel rivets. I will see if I can drill holes on the outside to run a fishing line to prevent snags.

Yup, same here – planning to smoothen the edges before mounting, will install them using 4.8 mm Monel pop rivets. Will be a couple of weeks until I get around to it.

@John, as this article is about wind vanes, and not on getting aloft, where might I post some update (if anyone would be interested)?

Hi Ernest,

Both Matt and I have articles on mast climbing in the works, so probably best to wait for them. Thanks for thinking of it. Real world updates on gear are one of the best parts of AAC.

Hi Marcelo,

Thanks for the heads up on that. How many miles have you got on the gear? The reason I ask is that the concern with less expensive alternatives is always longevity under load offshore. Of course there are also examples of gear where a less expensive alternative is just as good and only costs less because the manufacture is more efficient or has lower costs.

Anyway, please keep us informed on how it’s going with the gear as time and miles pass.

The Windy gear looks neat and it’s good to see one fitted on a smaller boat on their website. The last small boat vane I used was the Navik gear, no longer available as far as I’m aware (I think spares can still be had). Which worked wonderfully well and was ideal for a boat with a small battery bank.

Hi John, good point on the cost/quality. The fact that they use most stock items rather than fabrication was one major decision point, it facilitate repairs if needed. I am still tweaking the vane since I only had it for one season, like trying to determine the best route for the lines, etc. I am satisfied with its simplicity, construction and strength and I am confident it will provide long service. The windvance on my pevious boat (Ratcliffe, from Boston, long gone) was also made with stock pieces and I used for over 30K miles without a hicth, pretty much the same scantlings as the Windy. I did call for references and users were satsified with its offshore performance, also, Imre is a circumnavigator he understands the needs. But time will tell.

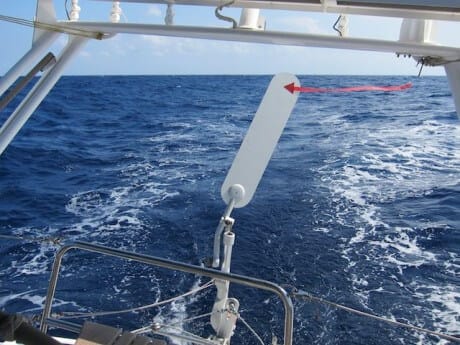

Picture

Hi Marcelo,

Thanks for the fill on that, does indeed sound good.

I installed a Windpilot Pacific on my heavy Koopmans centerboard vessel in 2014. It has not got a lot of use, but saved me when required. (electric generation failure mid ocean – so no normal autopilot). From time to time I have been in contact with Peter Förthmann, either to get advice, or buy a small part.

His customer service is absolutely outstanding beyond anything I have experience in this industry and beyond.

As regards gear on boats, it is not a question if it breaks, it is a question of when. Then it is good to know Peter F is there to help.

No sponsorship – just a happy customer.

Hi

I have been very pleased with my Cape Horn vane gear. It is over 20 years old now and a trouble-free veteran of many thousands of offshore miles. Our 27,000 lb boat is tiller steered so we could dispense with the through-the-transom option and just attach tiller lines to the upright end of the paddle arm and lead them through turning blocks. Maybe this type of set-up will work on the Adventure 40 as well.

Wilson

Hi Wilson,

Can’t have a better endorsement than that, thanks. I’m also a fan of keeping it simple and taking the lines directly to the tiller, rather than the under deck option.

+1 for cap horn. It’s fitted on my 32′ cruiser racer and is used all the time. Had it rebuilt a couple of years ago, it was still functional before the rebuild. The only thing I’ve ever needed to change is bungee cord.

Used it for 20 years before the rebuild 🙂

here is a picture

FWIW 3 comments.

My 33’, 16,000lb steel cutter is fitted with a aux rudder vane gear, a design by Bill Belcher. It was constructed by the PO. The vane controls a trim tab on the trailing edge of the aux rudder pushing it as needed. It seems to work well. It also works well with a tiller pilot. Forces are quite low and you can use the main rudder to help trim. It is also a decent secondary rudder.

Our 44’er, 40,000lb steel CC British/Pape cutter has a wheel AND tiller. I have seen this arrangement in 2 other (French) steel boats of similar size, all fitted fitted with Aries gear. The idea is the boat is steered normally with the wheel and the Aries drives the tiller. It simplifies the Aries set up and assures you have a functional emergency tiller. I am using a PY Pilot control married to a CPT drive unit as AP. Pealigic on the Aries as a second back up.

Finally I have switched to Pealigic tiller pilots due to ram failures with other makes. I don’t have a lot of experience yet but like what I have seen, a lot.

Hi Howard,

Sounds like an interesting and flexible set up. We experimented with using an aux tiller for the vane gear lines on our McCurdy and Rhodes 56, but it never worked well, and eventually we went over to a drum on the wheel. Just shows that these things are very boat specific with no one right way.

Slightly off topic but has anyone tried hooking up their L and S autopilot to a pelagic control system? I think that one day my b&g will just not restart and I will have no autopilot . I love my wind pilot, when I don’t hate it, it sailed us for 3000 miles .

Good to see the Monitor on FC, Colin

Here’s a photo from October 1983, crossing Biscay, a Hydrovane taking the strain on a ketch.

The crew takes the strain. At least it didn’t fall off completely. And it shows you can remove it at sea. Sadly I cannot remember how long or hard we worked to get it aboard.