Tips, Tricks & Thoughts:

Maintenance

-

PropSpeed Antifouling Report

13 CommentsReading Time: 2 minutesMembers

-

The Sinking of “Gunga Din”

17 CommentsReading Time: 3 minutesMembers

-

Fender Washers Are Useless

29 CommentsReading Time: 5 minutesMembers

-

The Relationship Between Stiffness and Thickness

10 CommentsReading Time: 2 minutesMembers

-

Backing Plates Must Be Parallel

19 CommentsReading Time: 5 minutesMembers

-

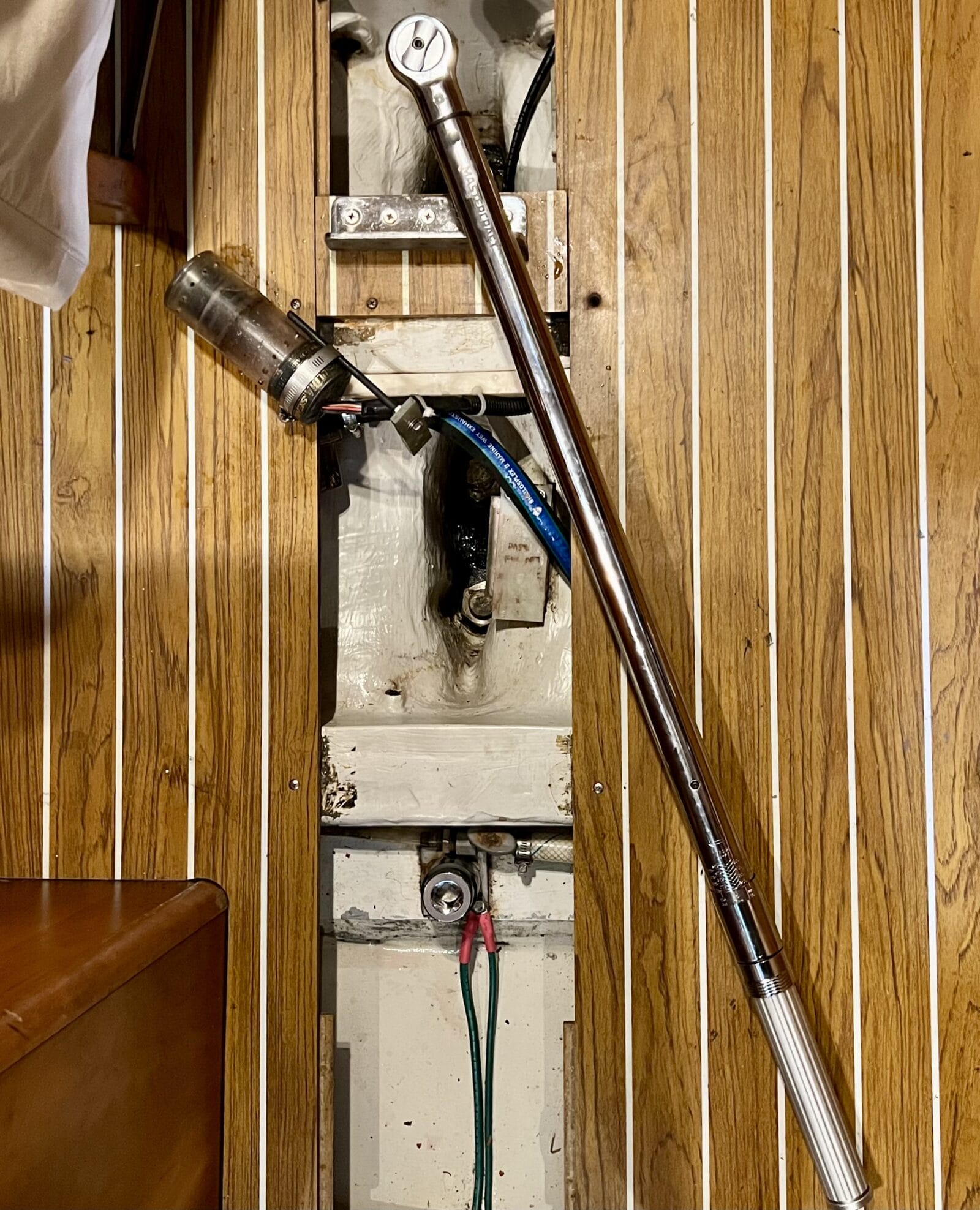

Time To Torque The Keel Bolts

46 CommentsReading Time: 2 minutesMembers