Back in 2014 I wrote an article arguing that the only right way to rig a boom preventer was from the boom, near the mainsheet bail, to the bow. (I will call these bow preventers for the balance of this article.)

But I still see a surprising number of boats rigging “preventers” from the boom, directly above the toe rail or a little outboard, to a fitting on deck, directly under the boom (in its running position) or slightly forward of that. (I will call these amidships “preventers”*.)

So I want to revisit this.

When kids say ‘when am I ever going to use trigonometry in the real world?’ this is a perfect example of where a little bit of trig might just save your life one day; you don’t even need to do the numbers, understanding the concept will be enough!

Hi Dan,

That’s a good point and might explain why the very first time I saw an amidships preventer some 45 years ago I understood that it was a bad idea…I loved trig at school. Just wish I had gone further with the math so I could accurately calculate the loads, though.

Hi John, wouldn’t this “bit of trig” depend on whether a substantial, properly rigged and adjusted vang (kicker) was employed? Having said that, cruising yachts with amidships preventers may well also have old handy billy type tackle, usually hanging slack because the owner doesn’t like the creaking noise…. But if you have no vang, there will definitely be a substantial vertical force as you say. But if the boom crashes down into the sea, with the dynamic forces of the boat rolling with an apposing wave providing upward force in a “perfect storm” scenario, the resultant vector (force) on the preventer could be way more than double I would have thought?

Pretty sure we need more than trig to even estimate these forces.

Rob

Hi Rob.

I think this issue is discussed in the previous piece on preventers, (?) but as I see it, a vang makes no substantial improvement, and might sometimes even add salt to the wound. A vang is a good example of difficult angles and leverage producing huge loads. A vang will keep the boom down, as long as no overloads come, in which case the vang, boom or something else must break.

The vang is very far from the aft boom end. Dipping the boom end in the water or getting an unwanted gybe in strong wind can be expected to frequently produce plenty of force to break something substantial, like a boom, since the force is multiplied by the leverage of the boom length and the vang makes that load into a bending load.

With a correctly rigged preventer, close to all of those loads on the boom are compressional, along the boom, which it can handle extremely well. A vang will then probably not see too much load. A vang that is expected to help carrying the loads of a faulty preventer, might just make it worse, by breaking more stuff. I’ve not actually tried this or done any detailed study of the relevant geometry, so this is just what I think…

Hi, good post as always. Just a quick comment on the topic of “preventer or boom can break if it hits a wave”.

Let’s assume a 40ft boat and 8 kt speed. 1 metre of 20cm diameter boom dips on a wave, mainsail is reefed so there’s only boom and some sail. How much actual force we will get to boom end from that wave hit by drag ?

Fd = 1/2 x rho x Cd x A x V² = 1/2 x 1000kg/m3 x 1.0 x 0.2 m2 x 4 m/s ² = 1600N = 160 kilos = 0.16 tons.

And multiplying that by x2, we get 0.32 tons on preventer rope. Your hit angle, speed, area and conditions will vary, but my point is that wave hit is not ‘categorically unmanageable’ event.

For reference, drag force of the whole hull of a slick 40ft boat, at 8 kt is – about 250 kilos.

HI JC,

That makes sense based on my own experience of seeing both booms and spinnaker poles dip without breaking on old IOR boats given to death rolls.

By the way, the best defence against a boom dip is having a sailmaker that knew what they are doing and therefore added adequate rocker to each reef, thereby raising the boom more and more as sail is reduced. https://www.morganscloud.com/2014/11/26/reefs-how-many-and-how-deep/

Hi Rob,

Yes, where and how a vang is rigged is important. That said, I think it’s vital when thinking about these things to simplify as much as possible by solving one issue at a time. To that end, no matter how a vang is rigged, a bow preventer will always increase safety substantially. For example, even if the boom dips in the water, a bow preventer will reduce the chances of it breaking, and if it does break, reduce the chances of the debris hurting anyone, and at the same time make getting the mess under control a lot easier.

Once we have that clear in our minds, and the boat properly rigged for a bow preventer, we can then move on mentally and practically to vangs. By thinking this way, in manageable pieces, we avoid the temptation to do nothing because the issues are too complex.

I will think about an article on vangs.

Hi John, Stein,

My comment was about the effect of having a vang deployed (or not) on the MATHS needed to calculate the resultant force – I was in no way advocating a vang as a replacement for, or mitigation of the risks with, an amidships rigged preventer. But having suggested it John, an article on vangs would be good thanks, especially the ideal rope to use (low stretch vs some stretch) and/or whether to include a fuse in the system – if so, where best to include one safely?

A quick comment on “racers” vs “cruisers”. I have experienced two well versed coastal racing skippers, both surprised and hesitant about using our bow rigged preventer due to the time taken to rig and swap it over in a gybe – ESPECIALLY at night. I wonder if this train of thought is what leads to the muddy thinking on where and how to rig one?

When these same racers have been offshore with us and experience the conditions when cruising shorthanded, ESPECIALLY at night and seen how easily John’s system (which we have exactly copied) is changed over in a gybe, they are quickly convinced of the value.

BR, Rob

Hi John, Stein, how might a vang be of any influence, even if very small, on horizontal boom movement? The lower attachment of the vang is normally exactly in line with the boom rotation axis (more or less the mast) so no force is executed on the boom to stop it from swinging from one side to the other, at least this is how I understood it. Could you please enlighten me?

Hi Ernest,

That’s right, a normal vang rigged from boom to mast only serves to hold the boom down, not out.

Or to put it another way, a vang is a sail trim device to keep the boom down and the leach properly shaped when the boom is to far out for the sheet to do the job.

A preventer is purely a safety device to stop the boom swinging horizontally.

That said, as Wilson states earlier. Some boats have no vang and therefore rely on a vertical (or near) tackle to a point on deck to keep the boom down when reaching or running. There is nothing intrinsically wrong with this, as long as a bow preventer is rigged too. That said, the added tackle does add complications if the boat is caught aback, so I prefer a traditional vang for sail trim, even though the loads are higher than on said tackle.

Hi Ernest.

You’re right, of course, but what I was thinking about was that the loads are quite often not aligned. If dipping the boom in the water at speed, with a correctly rigged preventer, the vang would see a significant load that could in some cases perhaps break the boom? Using only the bow preventer and main sheet to keep the boom down would give enough vertical flex to reduce the load much and no extra purchase on the load on the boom, since the attachments are at or close to its end.

(I dislike arrangements where the main sheet loads are much further in on the boom.)

Hi John,

I’m curious about attaching the preventer to the boom at the mainsheet bail. I have my preventer rigged to the boom end. Looking at it though it seems the opposing forces placed on the boom between the mainsheet bail and the boom end could fold the boom. When I set it up I was concerned with rolling and dipping the boom end in the water and breaking the boom if it was attached at the bail. I would like to hear your opinion.

Hi Ed,

You will find my thoughts on that in the original posts, see further reading. Also see some of the comments to those posts.

Hi John.

This is another example of this site proving its importance. It’s also related to one of my pet peeves. I probably have too many of those, as I admit to being a “besserwisser”, but whatever…. 🙂

Anyway, after several decades on many types of real racing boats, when comparing to cruising boats, I feel there are some fundamental differences in thinking that shouldn’t have been there.

I notice that items on a real racer will be extremely much lighter AND extremely much stronger than the exact same items on a cruiser. I also notice that, quite often, the racing items are simpler and cheaper to make than their weaker cruising siblings, even including high tech materials. This is partly because real professional racing is the frontline of development and these items will get to cruisers in a few decades, (too slow). Still, what i react to isn’t the items but the thinking side of it.

Racers are also often stupid and follow their habits, but at least try to use analysis to understand the problem and solve it smartly by looking at all related issues. That means looking at it just as John does here. Angles, dynamics, unusual situations, failure consequences, etc.

On cruising boats, the norm seems to be something like this:

“Well, I’ve seen this thingy used somewhere around here, so that’s what we’ll do too. To make sure it’s good enough, we’ll beef it up a lot. And the attachment points too. And that area where the attachment points are, need to have triple thickness. Let’s do that for the whole boat. Since our structure is now twice as heavy, all loads are 8 times more, so our boat can take almost half the punishment it would have, if we used our brain first. Oooops.” Actually I think the main reason true racers have way more breakage than real cruisers is that the racers see way more hours sailing hard and that they are intentionally sailed at the limit. So, I actually think that if a real cruiser was built with some of the systems and structural thinking of a real hard core extreme racer, just as a pure cruiser, it would be waaaay more robust than any normal cruiser, and maybe cheaper too.

I’ve discussed the exact topic of this article, and related ones, with several people before. Normally the end conclusion is about like this: “Yeah, but you’re a racer. Our boat doesn’t have as big loads and we don’t sail it hard. Also we have put really strong blocks and ropes there. It can’t break.” That last part is the main problem.

When I tell them some rough calculations of loads, and compare that to the estimated break load of their weakest link, they always believe that I exaggerate. I don’t. If I describe how easy it is to make it better, they may agree and say they’ll change it, sometime, but quite often I notice that logic cannot penetrate the shell of tradition and habit. If the traditionalist circuits of the brain detects a challenge, it seems to shut off the logic circuits, which enables a loop among various denial systems. 🙂

In a big system like the preventer, I don’t understand how one can avoid looking at angles and related loads, but the same issues are just as relevant in any part of a sailing boat, even in small parts like the goose neck and other rigging pieces. When a part or a system breaks, it’s always when:

– The load is high, thus

– The results will have the biggest influence

– The probability of personal danger is high

– The situation can be that one breakage makes it critically dangerous.

Not all items on a cruising boat have important influence on the operations of the boat, of course, but small items tend to show their importance in a new way when they break. Any item that sees large forces, or might in a rare case see it, must be looked at with a critical eye. “What if, in the extreme worst case….?”

I think it’s smart to look at any issue, say the preventer, and answer four questions:

1. If I keep adding load to this system until it fails, WHAT will break first, and HOW?

2. WHY is it that item and that way?

3. Is there any thinkable SCENARIO where the load can occur?

4. When that breaks, what will the worst thinkable CONSEQUENCES be?

5. Are all the answers to the above OK?

Hi Stein,

Lots of good thoughts that totally agree with, thank you. I particularly like your analysis:

A way of thinking we are all prone to and must guard against. And also explains why generally good and seamanlike organizations like the CCA and Sail Canada can still advocate for a fundamentally dangerous practice.

I also agree about the benefits of thinking like a racer when tricking out a cruising boat. One of the first things I did when I bought Morgan’s Cloud was replace a bunch of the heavy old cruising deck fittings with good quality stuff from Harken intended for racing. Not only are these fittings way stronger than the old ones, they also make the boat easier and safer to handle.

Hi John, Any wisdom on using a boom brake vs a preventer?

I purchased a dreamgreen.org preventer a few years ago but have not yet installed or tested it.

To me, logic would seem that allowing the boom to jibe gradually on it’s own would reduce the load quickly and eliminates trying to release the load manually which has it’s own issues.

Hi Mike,

I discuss boom brakes in the original article, see further reading and practicalities links.

We also have a chapter on boom brakes here: https://www.morganscloud.com/2009/08/18/boom-brakes-for-boom-control/

That said, boom brakes are not a substitute for a proper bow preventer, but rather a good addition.

Mike,

Another way to look at is like this:

Boom brake is great for making intentional jibes more controlled, and impart less stress on the gear; the traveler especially.

A bow preventer is an essential safety item to eliminate dangerous unintentional, accidental jibes.

Cheers

Hi Philip,

Exactly.

Having recently completed the International Certificate of Competence, we used the Sail Canada syllabus for Intermediate Skipper cruising certification. I was surprised that they suggested use of the amidship preventer and only mentioned the bow preventer. When I attempted an explanation it was shrugged off and ended with “the midship is so much easier.”

Colin… lets rig this right on my Boreal!!

Hi David,

That’s really scary, and a great disappointment that our national body would be putting convenience ahead of safety, particular since, if we set up properly, a bow preventer is not really any more difficult to set up than amidships. Just shows how difficult it is to change bad practice. Stein has some interesting thinking on why that is, further up the thread.

Assuming the preventer components are rigged in advance, I don’t understand how deploying a midships preventer can be thought to be “easier” than a bow preventer. Either can be deployed from the cockpit or, at worst, by the mast. So there isn’t even “easiness” to encourage the least safe option!

Hi Ian,

I’m 100% with you. And even if a bow preventer were less convenient, that would not be a reason to use an amidships preventer. As I often say, “seamanship is the fine art of doing things right even when it’s a pain in the neck to do so”.

John,

The Maritime New Zealand report of the loss of life aboard Platino is very sobering. It contains a wealth of information about how and why gear (and people) fail that should be taken very seriously. I can hardly contemplate the horror of the events as they unfolded at high speed and great violence. Imagine that 678 kilo boom gybing wildly back and forth with the traveller car sweeping across the cockpit like a wrecking ball on the end of the mainsheet …

Stories like this make me appreciate the old fashioned and very substantial gallows frame that positively protects me from the boom overhead and a mainsheet arrangement that does not sweep the cockpit. We don’t have a boom vang/lift arrangement so I often rig a kicking strap more or less vertically from mid boom to the rail. I have sometimes been lazy in letting this serve as a preventer. No more!

Thanks for your continuous stream of good advice.

Wilson

Hi Wilson,

Yes, I have to say that reading the report scared the heck out of me too, to the point that I didn’t even want to think about it for a while.

And yes, I too am very happy to have a massive boom gallows protecting us from the boom and mainsheet. A feature that seems to have fallen to cost cutting on modern cruising boats, even though once one has a gallows it’s hard to contemplate not having one, not only for safety, but convenience too.

And thanks for the kind words, particularly valued when I consider the source.

Hi John,

while the tragic story of Platino clearly demonstrates that only a properly rigged AND properly sized preventer can actually work as intended even in heavy circumstances the whole story clearly shows that it is preparation and regular maintenance which will help to avoid such disasters from unfolding at all.

Starting with the “refit” where the attachments for the autopilot rams have been found to be inadequate for the loads to be expected, these weak points have been deteriorating slowly up to a point where they would fail in the worst possible moment.

Continue with the probably small leak in one of the rams which finally led to amassment of air in the AP hydraulics which rendered the AP nearly unservicable. Had the owner, or the skipper, regularly checked the AP hydraulics level the crash gybe possibly wouldn’t have occurred at all.

Next these ridicular pad-eyes where the would-be preventer was attached to – you might be able to shear these off with a hammer. No way they would ever be able to withstand the loads of a crash jibe.

I do not accuse the crew of mishandling the situation (although they did), I doubt that anyone might keep a clear head when one of your friends you just had dinner with all of a sudden lies dead across the deck, his head open, I probably wouldn’t know if I’m a boy or a girl in such moments. I accuse the non-seamanlike preparation and boat maintenance that allowed this tragedy to unfold after all.

Depending on the situation even a properly bow-rigged preventer might have failed (though I doubt it), but a well-maintained boat (mainly inspection of rudder and AP installation) might quite well have been handling the situation before the accident a lot better.

It is always the same story (as with MOB and its rescue) – emphasizing disaster prevention over disaster handling would make everything (not only sailing) a lot safer. And this is NOT to advocate that disaster handling shouldn’t be trained.

Hi Ernest,

I agree, as I wrote under further reading, there’s a lot more to learn from the report than just about preventers.

That said, when analyzing a disaster and trying to learn from it, I always try to drill down to the key failure that hurt people. In this case, it was clearly the preventer failure so that’s where we need to put our priority and what I focused on in the article.

Or to put it another way, sure the autopilot could have been better maintained, but even if it was, it could still fail due to an electrical outage or a hundred other small failures and it would be impossible to make sure none of these details could every cause the autopilot to trip out. Therefore, to me, maintenance of the autopilot is a secondary issue that we need to be sure does not obscure the primary cause of death: rigging the preventer wrong.

Another example is the Cheeki Rafiki tragedy where focus on many other details, like the position of the liferaft, obscured the fundamental problem that killed: the construction regulations for keel scantlings are too lax. https://www.morganscloud.com/2015/06/25/cheeki-rafiki-report-misses-an-opportunity-to-make-boats-safer/

Do you know if there exists an up to date list of accidents reports? Would certainly be a valuable resource.

Hi Christopher,

I don’t think so, since they are produced by different authorities. That said, we have put the ones I have written about together:https://www.morganscloud.com/category/safety/lessons-from-losses-at-sea/

Not a substitute for what you are suggesting, but hopefully useful.

You can see a list of UK Marine Accident Investigation Reports at https://www.gov.uk/maib-reports

Hi Ann,

Thanks, great link. The top one certainly confirms Rob’s worry about CO2 fire systems! And I see we have yet another keel failure warning.

I did read your previous article, and after reading this, it may have saved the life of my wife. We were sailing offshore about 15 miles down the Pacific off Baja, pole & preventer rigged. It was about 1am I was in the forepeak due to the rolling caused by 3 wave angles in the Pacific. I heard waves hitting our bow and just as I sat up, I heard my wife say “I don’t know what’s going on up here but we’ve done a 180!!” Our bow rigged preventer held, and we were aback, it took awhile to get things settled down, but no injuries or broken gear. We had a ver tempting pad-eye on the deck just in front of the mast, outboard, I’m so glad I did not use it. Thanks a million.

Hi Tim,

Thanks for the real world report. Really useful in that it once again confirms that getting caught aback is far more common than most sailors think.

Hello John

Just to emphasize your point.

I have for 2 Month been sailing a 47 feet yacht latlely from Tonga to Fiji. When I boarded the yacht the amid preventer system caught my attention based on your previous articles. But I did not change it!!

One week ago night sailing in 25-30 knots we where hit by 2 very large waves that the autopilot did not handle very well. A hard gype , the Traveller slided across , injures one person badly. The preventer had ripped open a 10mm stainless attachment as if it was spaghetti!

We had luck, 2 minutes before the same person had been standing on the traveller- a gype could have had fatal consequences.

I continue blaming myself for not have taken action when I noticed the preventer arrangement.

I hope my story can help others to take action

Thank you for your great writing.

Brgds

Klaus

Hi Klaus,

Thanks so much for sharing your story. Admitting to a mistake publicly takes courage that many of us, myself included, often can’t summon. And yet, sharing stories of our mistakes, are, I think, the most vital thing we can do to make our sport safer.

I hope your crew member is mending well from their injury.

Dear all,

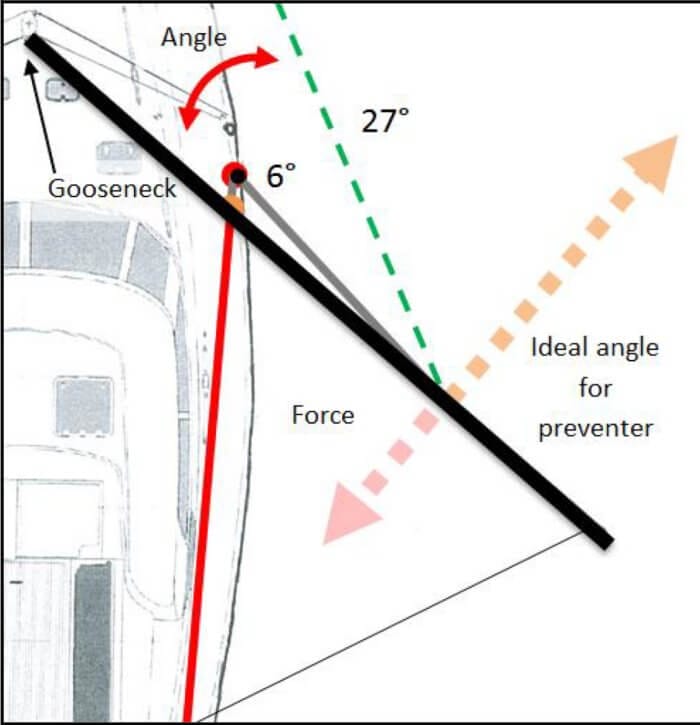

Putting 20 years of structural engineering experience with on- and offshore structures to the test, I would suggest an increase in loading by 1,4 for 45deg vertical angle to 2,0 for 30deg vertical angle. This is simple trigonometry. As you say bad, but not the main effect compared to the very smal angle in the horisontal plane in case of a midship rigged preventer.

When designing lifting appliances or connection points, we usually apply a safety factor of 5, which I frequently use for my boat equiptment too.

To illustrate this in a different way, engineers would almost never (yes I broke that rule, but with very specific intentions, don’t try this at home) design a truss girder with diagonals angled at less than 30deg.

A few weeks ago I did a 180 in 20 – 25 knots with a bow preventer set, worked flawlessly. I am still thinking of other ways to increase the angle of the bow preventer and would suggest to keep the bow preventer tensioned hard on. This to reduce any slack which could decrease the angle under tension and also increase load impact. I also use a dyneema preventer connected to a dyneema racing sheet to minimise stretch, not a polyester line.

I don’t have a vang on my boat and never used one, but suggesting it as part of a gybe preventing system does not directly make sense from an engineering point of view.

Hope this helps

Florian

Hi Florian and Jeff

That’s great, thank you.

So what I’m hearing is that the force multiplier on an amidships preventer is 20 to 25. So a wind force of just 500 pounds when caught aback would exert 10,000 to 12,000 pounds on the preventer. And then if we add in a safety factor of 5, as you use, we get 50,000 to 60,000, way beyond the strength of any fittings available.

Really, if that does not convince people not to use an amidships preventer, I don’t know what will!

And good point about the need to keep the preventer good and tight and make it of low stretch materials. I have mentioned this in the bow preventer how to post, and that it’s particularly important for boats with swept back spreaders, since the boom starts off at a less advantageous angle, even with a bow preventer: https://www.morganscloud.com/2014/03/13/rigging-a-proper-preventer-part-2/

One thought though. I am using a Spectra line on the boom, but polyester on deck. My theory was that since we have straight spreaders and therefore a quite large angle to the boom, that the advantage of having a bit of give in the system, to absorb the shock of being caught aback, outweighed the disadvantage of the stretch reducing the angle. What are your thoughts on that?

Hi All,

Generally speaking, I like a fairly low stretch preventer setup that is pre-loaded some to try to keep the boom rock solid. If you can keep the end of the boom locked in, then the dynamics should be pretty low and the stretch should be low so the angle don’t work about you. You will have some dynamics as things are not zero clearance fits but it shouldn’t require a lot of stretch to deal with. While dipping the end of the boom will cause significant load, designing in enough stretch that the load would go down would be far too much I think, just like why low-stretch is fine with a drogue. Having not actually run the numbers, I would think that a John’s proposed combination of dyneema and polyester is fine.

In theory, it is okay to run a much higher stretch setup and then preload it a lot but I don’t like leaving this much energy built up in the system. For preload, you would want to exceed the expected load on the preventer which is not insignificant. Before we had access to low stretch materials, I used to let the main out a bit further than we wanted, tighten the preventer, then crank back in the main. With a low stretch line, you can get away without the large preload as the displacement of the line will be small limiting dynamics but even with this, some preload is good so that the force comes on immediately. Remember that the preload is working against the mainsheet so both the sheet and the preventer need to have reasonable force/displacement characteristics, a really stretchy sheet would require a large preventer preload.

Eric

Hi Eric,

That’s interesting, and all makes sense to me. One thought that did come to me in reading it was that using very stretchy rope for traveler lines as Drew Frye advocates (climbing rope), and I was thinking of trying, will have an affect of required preload of the preventer. Any thoughts on that?

Hi John,

I haven’t given much thought to your question on traveler line stiffness before from this perspective but it would certainly be possible to have too stretchy of a traveler line both from this perspective and from the perspective of sail trim. Traveler lines tend to be lightly loaded because of the geometry and the multi-part purchases that make them easy to trim, therefore, they tend not to stretch a whole lot either. Eyeballing the angle in the picture from the report, the angle looks to be about 30 degrees so the load on the lines would be 87% of the mainsheet horizontal load. The vertical load and the load fore and aft on the traveler is taken by the car bearings so the line only takes the side to side load. If you have a 4:1 purchase, then the load on each leg is 22% of the horizontal mainsheet load (that will likely have multiple legs too so you need to sum the legs). Practically, we have found that on our boat with a 340 ft^2 main and mid-boom sheeting that 3/8″ nylon double braid in our 3:1 traveler tackles works well. We run very little control line preload usually and in big gusts, we only get a maximum of ~1/2″ of car movement on all points of sail but gybing is so much nicer than with the unknown origin polyester double braid that came on the boat. If you know the geometry and lines used, it would not be particularly hard to calculate the relative stiffness of the preventer and the traveler. Without that, smaller boats that tend to have oversize traveler lines simply for handling convenience are likely fine with nylon double braid but as you get into large boats, if they have long travelers, small diameter control lines, low mechanical purchases or other geometries that results in high loads, then polyester double braid may be a better bet so you don’t require a lot of preload on things.

Since there are a bunch of numbers being thrown around, I took a look at the geometry as detailed in the report. Their graph is a bit tricky to read as they have an interpolation between points and the point they are actually showing is for 5 degrees not 6. If you treat it as a purely rigid body problem where all of the load on the preventer from the sail is in the horizontal, then the load multiplier is 9.6 for the purely horizontal preventer (1/sin(6 degrees)). For the vertical, if we take your diagram of how 60 degrees is measured, we need to assume how far in the boom is. Assuming that the boom is at 50 degrees as measured from 0 being on centerline, then the factor is 15.3 (the reason that you can’t simply multiply is that the way you are measuring 60 degrees is out of plane with the boom load). Adam is correct that going to coordinates is best when trying to solve this type of problem, I simply plugged it into software as I have to do this regularly. It is possible to solve it as 3 successive 2D problems to get the 3D hypotenuse also, not hard math just mind-bending. Regardless of the exact numbers, you should really never work with angles this low, the loads will be high and extremely small displacements can greatly effect the angles in play.

Regarding vangs, it is impossible to actually calculate exactly what is going on without knowing a bunch of info on stiffnesses. Since the preventer is a line, it can only apply tension, not bending so if we assume that we know the angles and the horizontal preventer load, we can then get the vertical preventer load. This ends up being 9.7X the ideal horizontal load with the Platino geometery so you would be pulling down on the end of the boom really hard, at levels likely far greater than any vang is going to provide. With a rigid vang, depending on the stiffness of the preventer, sail, the rig, the boom and the vang, you may actually be pushing down on the vang in a backwind situation with a midships preventer. If you move to a bow preventer, then the vang becomes a major player again.

Eric

Hi Eric,

Thanks very much for your analysis.

Based on that, I think I will give replacing our Dacron traveler lines with nylon, as you have, a go, but not go all the way to dynamic climbing rope as Drew advocates for smaller boats. I guess I should say that we have never really had a problem with excessive jibe shocks, but that’s probably because we tend to reef early, particularly if we know a jibe is on the cards, and because we are really careful about having the mainsheet all the way in before the jibe. That said, one thing I have really had reinforced in all of this is that reducing loads (shock or static), wherever we can is a just good seamanship, and I think that goes double for bigger boats.

Also, thanks to you and Adam (and others) for confirming the load multiplier on the amidships preventer. Based on that, I now feel very comfortable saying 15-16 and will change the post to reflect that. As you say, the key point is that using a bow preventer reduces that to somewhere around 2, a huge difference, so the exact number is not material.

Hi Florian, really valuable point about low-stretch, thanks.

I started the confusion on vangs in this thread – I was just trying to point out that if Platino had a vang rigged (and from the photos it seems so) then there would be no vertical angle component to the resultant force on the boom, as it would be “prevented” by the vang. It is possibly why the vertical component was discounted in the original report.

From a sailing point of view (not an engineering one), if you want to understand how a vang helps prevent un-controlled gybes, I recommend hiring a laser dinghy at a local lake in just 20 knots of breeze and try running square off with no vang set. To abbreviate the learning process – the tight vang helps your downwind control by stopping the leach twisting off which when caught by-the-lee, can drive your boat into a windward roll, which in a laser usually ends in grief – plunging the helms-person into the drink and for me usually a full windward capsize! The exact same components exist on a cruiser, only bigger and more expensive.

Rob

Hi Rob,

The vertical component that I mention, and that is mentioned in the report, is not to do with any vertical component to the wind force on the sail transferred to the boom. Rather, what I, and the report are referring to is the incremental load placed on an amidships preventer that multiplies the horizontal force on the boom from wind pressure on the sail as a result of the disadvantageous downward angle of an amidships preventer.

This is why whether or not a vang is rigged is a bit of a red herring. In fact, if a vang was not present the wind/sail force on the boom that the preventer was subjected to would have a bit of a vertical component and that would actually reduce the load on an amidships preventer because said force angle would, with no vang, be slightly better aligned with the amidships preventer vertical angle, although not enough, or even close, to make it a good idea.

That said, I’m not suggesting sailing without a vang, if for no other reason that so doing results in a lot of chafe on the main from the shrouds and spreaders.

The force multipliers in this case are simple trig relations:

For the fore/aft angles (6 deg vs 27 deg), it is the normal force (force on sail, perpendicular to the sail plane) divided by the sine of the angle of the preventer makes to the boom (Fn / (sine 6 deg) = 12 x multiple over normal force.

The force multiplier for the angle below the plane of the boom attachment point, it is the normal force divided by the Cosine of the angle. Having a preventer at 60 deg from nomal, adds an additional 2x strain to the already 12x.

Hi Jeff,

That’s great, thanks. I will make a note of the equations, as I’m sure they will be of use going forward.

Just to confirm, the two factors should be multiplied to get the total of 24 times wind force on the sail?

Hi John,

I think the vertical force would be as Jeff states above an additional force, to be added to the horizontal force/factor. So a combined force of 14x, and as I tried rather clumsily to say in my comments above, given that Platino seems to have a vang rigged in the photos, there was probably no vertical component to add, so likely to be the 12x, but still fatal.

What I would have thought would be of more significance is where that wind force could be considered to be acting on the boom. On most cruising yachts with little or no roach, the RESULTANT force is probably acting just under half way along the boom, or for a reefed main even less, or a point close to where Platino had her twin preventers rigged.

But for an end rigged boom, the preventer would have had a 2x or perhaps up to 3x (if reefed) mechanical advantage for “preventing” the horizontal component of the force, using the lever arm of the boom. Now this I believe WOULD be a divisor. So, if no vang were deployed, an end boom preventer would have had approximately 1/28th less strain (or even up to 1/42nd less strain if reefed), than the amidships one used by Platino.

Hope I haven’t confused everyone further, including myself.

Rob

Hi Rob,

Hum, I really think the multiplier resulting from the poor vertical angle multiplies that resulting from the poor horizontal angle to the boom, so the answer is 24.

But really, as I say in the post, who cares. 14 or 24 does not change that a midships preventer should never be used.

John,

Yes, the 2X multiplier for one misalignment attachment is applied (multiplied) onto the other misalignment force multiplier (too many uses of “multiple, sorry). (12x) X (2x) = 24x the force. (this assumes it is one line experiencing two components of misalignment)

Jeff

Hi Jeff,

Thanks for confirming that. Much appreciated.

This feels right to me, but the two angles are tricky to measure. To get an accurate loading factor in a three-dimensional case I would recommend measuring Cartesian vectors for the preventer line and wind force (you can assume perpendicular to the boom and horizontal). The loading factor is inversely proportional to the normalized inner product of those vectors. This is effectively looking for the angle between the vertical plane containing the boom, and the preventer, and using that angle in place of the purely “horizontal” angle; intuitively it makes sense since it produces an infinite loading factor whenever the preventer is perpendicular to the wind, and unit loading when they´re parallel.

For example, for a preventer rigged in line with the mast on a 20m boat with an 8m boom and 4m beam and a gooseneck 2m off the deck, with a 1000-N wind measured at the point the preventer is attached, perpendicular to a boom swung 80° to starboard from centerline. I’ll do everything in coordinates centered on the gooseneck with +y toward the boom and +z vertically upward.

Preventer deck attachment position is (2 m, 0 m, -2 m).

Boom attachment position is 8 m * (sin(80°), -cos(80°), 0) = (7.878 m, -1.389 m, 0 m)

Vector from boom attachment point to deck attachment point is = P = (5.878 m, -1.389 m, 2 m); ||P|| = 6.362 m

Wind direction vector = W = (cos(80°), sin(80°), 0) = (0.174, 0.985, 0); ||W|| = 1 m

Loading factor = reciprocal of normalized inner product = ||P|| / |P.W| = (6.362 m) / (0.3854 m) = 16.5.

Now we do the same for the preventer rigged at the bow at position (0 m, 10 m, -2 m).

P = (7.878 m, -11.389 m, 2 m); ||P|| = 13.99 m

W = same as above = (0.174 m, 0.985 m, 0 m)

Loading factor = ||P|| / |P.W| = (13.99 m) / (9.847 m) = 1.4.

Hi Adam,

Yikes, my head hurts! Seriously, I think I followed most of it. Anyway, 16.5 as against 1.4 for a bow preventer should convince anyone that amidships preventers are a very bad idea. Thanks very much for the analysis.

After spending some time reading the report from the “Platino” accident, and digging into it’s very competent info and conclusions, my belief is that there are more conclusions to draw than those mentioned.

As John said, there’s no doubt that the single issue that made this a lethal accident was the flawed preventer. Rigging a good preventer is quite easy, and it seems the boat was prepared for that, so the reason for the flawed solution was either missing competence or missing attention. It seems as the most competent person onboard was the guy who got killed and the then the guy who went overboard. Thus making it even harder to recover from the situation.

I see myself as competent enough, and able to keep the cool even in stressful situations, but I can’t feel confident that I can keep that up, and do the right actions, when the situation gets as bad as this. I think especially the emotional issues will seriously disturb the ability to detect important issues, understand their consequences, make decisions and execute them. That level of emotions could make me, and probably anyone, fairly useless. That seems to have happened in this case too. Most likely they did not turn off the autopilot, which is probably why they could not steer the boat into the wind to get the boom under control and retrieve the MOB.

So, since I accept that I can’t trust myself to be functional in situations when i really need to function better than ever, I must conclude that I need some sort of help. The only type of help I can think of that would be always available is written procedures. It’s been discussed earlier on this site. “Platino” didn’t have any such written procedures. My boat does have some, but FAR from good enough. Lists and procedures seem so unimportant. Like when the flight attendants go through the safety procedures. We stopped paying attention. For a boat theres a lot more detail and several different types of procedures. I’ll put some energy into improving that this winter. I’m convinced this will be more important for safety than most other items on the boat.

So, I’ve mentioned some issues, which are all known to the readers here:

– We need to rig preventers correctly, which is to the bow.

– We need to be competent.

– We need written procedures etc for important topics.

But there’s one more issue that sticks with me after digging into the report. That issue isn’t mentioned in the report as a problem, and it’s normally seen as “just how it is”. I think that’s not OK. What issue is it? The heavy boom and the far too vulnerable systems to control it. It’s a disaster waiting to happen. This is true for the vast majority of sailing boats.

If we attached a loaded machine gun in the same location as the boom, and gave it the same treatment as we do with the boom, knowing that if we lose control over it, it will start shooting, I don’t think we would think one single main sheet, occasionally helped by a preventer, is good enough. We would have several redundant systems to help us. And we’d not be comfortable with the speed and force of a normal planned gybe.

“A loaded machine gun”? What’s the point of that? Have I lost it? Well, if the “Platino” actually had that instead of its boom, and it was also allowed to swipe downwards to the deck, it would maybe have been about the same… The boom and sail was well over 700 kilos, 1500 pounds. It’s a big boat, but not that big. Is this good design? Is it ok to have something like that in such a position? A similar type of potential danger in a car or in a production facility would be prohibited immediately. Most of us have a similarly dangerous contraption attached and ready to deliver its devastation. Maybe it’s called BOOM for a reason…

It’s possible to have boom less mainsails or exotic types of rig. Maybe some of those solutions are good, but in general I think we need to just improve the control systems of the boom. So, if our preventer is rigged correctly and strong enough, plus the same for the main sheet and traveller etc, we’re safe if we do things right, and nothing unforseen happens. I can only speak for myself, but I do occasionally make mistakes. (Don’t tell anybody in my family I said that).

If anybody goes up the mast, I’m extremely careful with the halyard, and then I make sure there is one more person with another halyard being just as careful. When a danger is unacceptable, we need redundancy, a backup. The boom has proven to be just as dangerous. Are ther solutions? A boom brake would most likely have prevented the devastation on “Platino” by dramatically slowing down the boom motion, reducing the dynamic loads and preventing that the main sheet was ripped off.

On our boat, we have no backups to help us with the boom if we make mistakes. That will now change. First, I’ll get a boom brake. I’ll read up on those. I’ll also ponder the issue. And maybe some here have good ideas for making the boom less of a potential hazard? I really think that I needed this wake up call to remember that I’ve just gotten used to that dangerous boom. That doesn’t mean that it’s ok. It isn’t.

Hi Stein,

Your thoughts on the boom are interesting but I have a bit of a different take on what to do about it. I agree completely that booms are large and potentially dangerous and that we should be careful to make sure that they do not pose an unnecessary danger. This means proper triangulation of the outbound in most cases with the wind sometimes providing one of the forces and at others it being a piece of gear.

When I first got out of school, I tended to try to belt and suspenders my designs with redundancy but I have come to believe that it is often not a good idea. Rather than do that, I try to design a single system which is really robust and won’t cause high consequence failures. The reason is that in the belt and suspenders case, the systems rarely load share, are rarely both tested and rarely have the durability of a single well designed system. There are of course exceptions to this but it is usually in a place you know that the main mechanism will fail occasionally and you can’t design around it. Car brakes are a good example of a compromise solution, they know that there could be problems like a blown hose or line and instead of having redundant systems, they split the system in 2 so you only loose half of it and while this could still cause an accident, it greatly reduces the likelihood and represents a good compromise. What we don’t have is 2 pedals (can you imagine that? it would probably decrease safety), 2 reservoirs, 2 master cylinders, 2 sets of lines and hose and 2 sets of rotor/caliper/pads. If you look at your boat, it is full of single point failure design which we accept as the failure rate is low and it is impractical to double things up, your standing rigging is a classic example. To me, the Platino had a marginal mainsheet and traveler system for normal loads which was not designed for any dynamics. Increasing the strength and putting energy absorption in a place that doesn’t affect performance such as the traveler lines would have been good and even better would have been to address the root cause of the dynamics which is mass. Also, having strong hardpoints throughout the boat that they could improvise with in an emergency would have been huge in taming the boom. To properly tame that boom, it really needed to be triangulated so they needed to get 2 lines over it but 1 may have held for long enough to rig the second.

I have sailed on boats with booms that are 3000 lbs + and taming them is definitely tricky bordering on scary at times. There are a few keys to this working, especially when lowering the sail. Having a place to quickly hook tackles onto in a relatively safe way is really key where the person doing that connection is not in an exposed place. Some boats run dual mainsheet systems which really simplifies this but makes general sail handling much harder. The other thing is that the older boats (Baltimore clippers are the classic example) run a lot of rake to the masts which makes the booms tend to swing to centerline so once the wind is out of the sail (say if you are slatting), they are much more predictable and easily controlled.

I guess this is a long way of saying that sometimes a properly built primary system with proper maintenance is far better than 2 redundant systems.

Eric

Hi John,

The bow rigged preventer is a given.

However the next thing that gave way is the traveller controls.

These were held by 6mm bolts that were inadequate as the meat in these is only 5.1mm.

In addition the traveller was centred while the boom was forward. I would expect the acceleration of the boom would have been slowed if the mainsheet take up would have happened earlier. Then with the full length of the traveller the next thing to give way was the endstops . To shear the 2 off 10mm bolts would take a theoretical force of 5t ie 3t each less the thread allowance etc. So the speed at impact would have been 12m per second.

My endstops (LEWMAR ) have a substantial rubber end to absorb and have 3 off 10mm bolts. While the control lines are held by 1off 10mm bolt and 2 off 8mm bolts.

I would look to the turning blocks for a tie off point in this scenario, using the spinnaker brace pulley.

I will also use twin braid control lines.

Hi Bill,

That’s interesting on the force required to break the end stops, and certainly very sobering. Your comment got me thinking that in cases where boats retrofit roller reefing/furling booms that are heavier than the original, other gear like the mainsheet traveler needs to be upgraded too.

Hi Bill and John,

I have long looked at the end stops on my traveler and thought them suspect to failure if the car slammed into them. To give them a better chance, I seized the traveler control lines back on themselves so the seized area came up against the brake leaving the car to stop an inch or so before it reached the end stops. My thinking was that the brake/seized line would drain off some of the impact as the car rushes toward the end stop and might save the system. I extended the “gap” to a couple of inches when I swapped the traveler lines for ones with more stretch. This shortens the athwartships range of the traveler a bit, but this seems like a small price to pay for protecting the gear.

An observation when the sail was wung way out and drawing hard just before reefing when I purposely let off the brake and had the pressure of the sail just sit on the seized area of the control line indicated very little closure of the gap. So, I would hope that a more powerful assault on the traveler end stop would be softened considerably when the seized area hit the brake.

My best, Dick Stevenson, s/v Alchemy

A few thoughts, in part from my own experiences, in part from investigating accidents, and some from an article I published a while back.

1. Midships preventers work fine on multihulls. This is not in conflict with the above, it is simply a result of different geometry.

2. And yet I broke one anyway in strong conditions. Did it serve as a useful “fuse?” Not even on a multihull, since the capsize moment was not that high, but the speed of the boom was, No harm, but it could have been. Which brings us to…

3. Clipper Race fatality Andrew Ashman, the result of an acidental jibe following the failure of a bow-rigged preventer. In this case a stope at the bow failed due in part to improper splicing procedure, but also because they underestimated the load. The reason they under estimated the load is that…

4. Aft-swept spreaders and boat reaching fast with the boom well aft create terrible leverage. For years, boats ran with the boom squared off and the leverage applied by bow preventers was good. If the boom was back, the wind was well to one side and the risk was low. But planning monos and fast multis carry the AW so far forward, that even with the AW 70 degrees off the wind, they are only a bear away and bow stuffed in wave away from a jibe. Been there. And when the boom is angled back, the line led to the bow, and then back to the cockpit…

5. Only a few percent stretch will allow the boom to jibe. Draw the same image with the boom amidships and 45 degrees off, with the line going almost 2x the length of the boat, and you will find the difference in length is not that great.

This is a risk for fast boats and a risk for B&R rigged boats. In my opinion, forget the shock absorption theories with today’s boats. With the boom angled back, with polyester line, they will simply jibe anyway. Use very low stretch line and rig the boom high enough (when reefed) that it won’t go in the water. That is what the math says and that is what experience with back-angled booms is telling us.

Hi Drew,

As you say, I can see how an amidships preventer would be better on a multihull. That said, I think it would still be important to lead it so the deck attachment is well forward of directly under the boom to keep the load multiplier sensible. I guess since the horizontal plane multiplier is minimal, that 45 degrees or less would be good for the vertical angle, when measured as shown in my diagram above.

And yes, I agree about this danger of swept back spreaders—another reason I don’t think they belong on cruising boats—and I have recently added that warning to my preventer how-to chapter:https://www.morganscloud.com/2014/03/13/rigging-a-proper-preventer-part-2/

On the Clipper Race fatality, I too have read the report and, to be blunt, I was amazed that Clipper and their rigger could think that the way they spliced the strop was anything but a very poor idea. Two independent strops with full splices would have been a much better way to go.

Hello,

Very interesting topic and investigation report.

Of course we will check all these items on our HR46.

For the moment we use dyneema 10mm preventer from the end of boom to goosneck dedicated for preventer fixation by selden and 12mm low stretch (prevoious halyard) to bow cleat and back to cockpit winch . I have a question : we use spinaker type wichard spinnaker snap schakle. Would it be better to use dyneema soft loop schackle rated for 2500 kg. Our boom is 5m long and mainsail is maximum 50 sqm. We have in line speaders. I would estimate the weakest element is the extension of preventer to the bow. We use a low friction ring in a dyneema loop at the bow and a spinlock spinaker turning block at the rear end of the boat . Do you think a SS thimble at the splicing add extra strength spreading a little the load at the connexion? Do you think 2500 kg WL is sufficient? I think the bow cleats on the HR46 are very strong as the boom section looks oversized compare to booms of productions boats having similar main sail surface.

Thank s for your knowledgeable advice.

Denis

Hibernia II

Hallberg Rassy 46

Thank s for your advice.

Hi Denis,

You will find a lot of the answers to this in my preventer how-to chapter here: https://www.morganscloud.com/2014/03/13/rigging-a-proper-preventer-part-2/

As to adding a thimble, I would not do that. Recent testing has shown they don’t add much, if any strength.

And, as so to soft shackles. I think, given the importance of this connection that I would use a positive locking snap shackle, see above linked post.

It is sobering to read of such tragedies, because if it happens on my vessel it would be me, my son, or my spouse who suffered the consequences. My condolences to those who lost family members. When my son and I,sailed from Portland to Mexico, then Polynesia and home, I rigged bow preventers as you describe. We mostly sailed on reaches and runs, so it was an essential arrangement. Only once did we backwind the main, but thank god for the preventer. The only difference on my boat from Morgan’s Cloud is how I attach the preventer on the boom. Instead of a padeye, I drilled holes on each side of the boom and placed bushings in the holes. I then passed a high strength high tech line through the holes, with a couple of additional wraps around the boom, put two eyespliced high strength lines around the attachment lines, then tied the ends of the attachment lines together, and whipped the knots to prevent slipping. As you instructed, the boom attached preventer lines then run up the boom to a small cleat on the bottom of the boom, again each end is eye spliced. The two preventer deck lines run up the deck from winches in the stern to turning blocks on the bow and can be easily bowlined to the boom lines. I cannot thank you enough for the advice on how to run preventers. What seemed like a bother became both automatic and easy.

Hi Terry,

Thanks for the real world report after a significant voyage, always the best kind. And, I think, if I were doing it again, I would take a page out of your book and use high tech line wraps on to attach the outboard end of the boom line, rather than pad eyes.

One other question for the group. I always tie my preventer to the boom line using a bowline. I assumed that weakened the line by 40 to 50 percent. The report asserts that would have weakened the line by 70%. Is that correct? Certainly would change my thinking on lots of belays. Thanks for any thoughts on that.

Hi Terry,

The number I have always heard for a bowline was indeed 40%. I can’t be sure, but perhaps the report was taking into account the danger of tying knots in high tech lines like ones with Spectra cores and Dacron sheaths where the drop in strength would indeed be 70% or more since the sheath would take all of the load.

Hi John

My two preventer boom lines are mounted on a fitting on an aluminum track on the bottom of a leisurefurl boom. If I wrap the lines around the boom, they would interfere with the sail, the mainsail cover and mainsail cover track.

Would this fitting be strong enough? Any solutions or recommendations for a leisurefurl boom? It seems there would be a great deal of torque on the track if there ever was a serious backwind.

Thanks

Charles

s/v Dawnpiper

https://www.flickr.com/photos/157134020@N05/shares/33fu51

Hi Charles,

There is no way for me, or anyone else, to opine on whether or not that fitting is strong enough without knowing a lot more including the sail area, position fore and aft on the boom, angles of the bow preventer, and how it’s attached to the boom to stop it sliding in the track, at least.

Perhaps the best bet would be to contact Leisurefurl and ask them what the fitting was intended for, and it’s design strength.

That said, I don’t much like the look of it.

Could you move the preventer to the far outboard end of the boom and use wraps of line around the boom there? Might be a lot of separation from the mainsheet, which is not ideal, but better that than the fitting pulling out.

Thank you John for such a thought-provoking article, and for pointing out the fascinating and sobering Platino report, which read like a nightmare.

As a result of this, I’ve added a “Mainsheet Failure / Uncontrolled Boom” section to my emergency playbook. I also examined my existing boom brake / preventer setup. The brake attaches to the boom where the vang used to be. This gives it a more ideal angle from a midships attachment, but less mechanical advantage. To quantify, I performed static load computations taking into account the line angles in three dimensions. What I found for my vessel is that there’s a 2.8x difference in the load between a vang-to-midships preventer vs. a boom-end-to-bow preventer. This is not great, but also not as bad as I’d feared. Assuming the boom brake line is the weakest part of the system (it may not be), a back-winded full main in 25 knots still leaves a 2.3:1 safety margin. Of course, boom end to bow is best.

Hi Chuck,

That’s very interesting and useful, thank you. As you say the 2.8 disadvantage of the brake is not great, but then again a boom brake will start to slip as soon as the boat is caught aback so the loads will bleed off. That said, I would still rig a bow preventer since I understand from Colin’s article that whether or not the boom brake works perfectly is very dependant on keeping the tension on the line exactly right: https://www.morganscloud.com/2009/08/18/boom-brakes-for-boom-control/

Hi John, a late addition to this topic, but I was provoked by your reference to amidship preventers in the Old Salts Part 2 post. Your analysis, as almost always, is excellent and comprehensive. However, in spite of this, I am a proponent of the amidship “preventer” with the usual caveats. I have both an amidship and an end-boom preventer rigged on my boat (46′ 14 tonne cruising yacht), but I have found the amidship system to be very convenient, effective and reliable. It is far more than a preventer. I do not have a boom gallows and the amidship preventer allows me to lock the boom in any position, particularly in the centre when flaking and securing the main. I was on a 50′ yacht rigged with an end-boom preventer. The line snapped in a wild jybe resulting in an uncontrollable boom swing, not unlike Platina. The light weight Beneteau boom crinkled like a Coke can. No system is perfect. All systems have limitations and we need to understand these and work with them to be safe. Without trying to be facetious, it’s not unlike the seat-belt and air-bag arguments. Both devices have caused deaths, but we all use them in the hope of benefitting from their primary purpose.

Hi Chris,

I entirely agree about the benefit of tackles to control the boom, for example when hoisting and dropping. In fact we do just that on our boat and have for years.

But the key point is that you, and I, still use a end boom preventer. The problems come when people confuse a boom controlling tackle with a preventer.

Note that the piece above is just one of three on preventers. The other two fully explain my position: https://www.morganscloud.com/2014/03/02/rigging-a-proper-preventer-part-1/

https://www.morganscloud.com/2014/03/13/rigging-a-proper-preventer-part-2/

An interesting article John. I’ve only seen “midships preventers” being talked about in north American YouTube channels. On this side of the Atlantic we are taught that all preventers go to the bow and I wonder at some time in the past there was a change in north American thinking that has been past down the generations?

Hi Sandy,

I have no idea, but I have seen amidships preventers in use in the UK and (if memory serves) an earlier comment even mentioned an RYA yacht master instructor advocating from them, and the tragedy above happened with a NZ crew, so I’m fairly sure it’s a world wide problem.

A number of thoughts.

Strength. I too have gone through the math, and even allowing for the boom and some sail dragging in the water, the answers are not huge. If rigged bow to boom, about the same as genoa sheet loads.

Safety factor. A 5:1 safety factor is normal for working loads. However, much safety gear is designed around safety factors as low as 2:1 or 3:1 for worst case loads that will only happen a few times. Climbing gear, for example, is based on about 3:1 safety factor of the worst fall you can take. Of course, the gear must be in nearly new condition and inspected frequently with a jaundice eye. What this means, of course, is that if yous design for a reasonable worst case, some slightly worse variation will still be OK a few times.

Angles. Yes, the failings of a midships preventer are just obvious.

Traveler. Platino did not use the traveler at all. It was still centered and a lot of mainsheet was out. Apparently, the only thing they really use it for is to haul the clew above the centerline when beating. Off the wind, the main sheet and vang are used, because this is physically easier, probably because the traveler tackle was undersized. As a result, boom swing after the preventer failure was maximize. I sail multihulls. You ALWAYS use the traveler off the wind, in part because it is there, in part because most multis do not have a vang, but also because it gives you a lot of control during a jibe. You haul in the excess sheet and control the boom with the traveler. Even when a preventer is not needed, it is common to lock the traveler down to leeward. A simple step that reduces the consequence of an accidental jibe. But Platino did not do this.

Boom Brake. I’ve used boom brakes and don’t care for them. They add clutter and I fond them fussy to adjust. I would rather just use the traveler, and rig a preventer when needed. But I’ve also wondered if the “traditionalist” trap keeps us from looking at another application. They make even more sense on big boats and boats like the Platino with heavy (1500 pounds) booms.

First, a boom brake locked down tight would have served as a preventer backup. It would not have held the boom, but it would have prevented movement fast enough to break the mainsheet tackle.

Second, after the initial accident, further damage, loss of life, and the loss of the boat could have been prevented if there had been a way to get the boom back under control. A boom brake would have done this, stabilizing the motion enough to attach a jury tackle and get the boat back under control.

Finally, even with a preventer, the mainsail can be backed. All it takes is an autopilot failure, as happened on the Platino and has happened to me (I don’t have a dramatic story). You still need to be able to ease the preventer. Yes, if the line is led back to the cockpit it can be put on a winch and eased, but the line will come across the shrouds in a cruel way. If the traveler is to the new windward, that helps. But a boom brake would also take some of the load.

Just thoughts. I find myself thinking that the bigger the boat, the more a wide traveler is needed and must be used. A boom brake may increases safety by dividing up huge loads between tackles and providing a backup. I might find it particularly attractive as a singlehanded racer, since rigging a preventer in wild conditions is a drag and racers these days are more likely to be reaching than running, with the boom not squared off. A contributing error on both the Platino and the Clipper boat was relying on a single system (under strength preventer) when other means were available (traveler).

[None of this is intended to take away from the merits of a proper boom end preventer. Not at all. It is an exploration of what a boom brake may be “for.”]

I just recently came across a story where a boom brake caused the boom to break due to a mishandling of the loads. The chaps were using a Walder brake and tightened it up quite a lot so the brake effectively held the boom in position whatever may have come. Then they used to tighten the main sheet to have a stable rig.

This caused a material fatigue in the boom near the brake attachment until it broke suddenly, without even a lot of force used at this very occasion.

The video where they explain what happened is here: https://youtu.be/tAYzQ0YGRSk?t=233 – unfortunately for most here it is in German but the time code I link to is where they draw the sketches explaining the forces.

This leaves me to believe that even without such mishandling a boom brake may put undue strain to the boom, mainly if pulled tight so the brake takes part of the load the sheet would normally take.

Hi Ernest,

Good point and the same modality that causes broken booms with midships preventers.

Hi Drew,

I think the efficacy of boom brakes is a lot dependant on boat size. I have never seen one that I would trust on my boat, but on the other hand I think they can be reasonable on a 40 footer. That said, I would never trust one as a substitute for a preventer on any sized boat. The other drawback with them is that the lines pose a big time trip risk.

As to travellers. We have a full width of the cabin top one on our boat, but setting it down to leeward does not make a material difference to crash jibe risk, particularly since I would not expect it, and it’s control lines to survive a really bad crash jibe, even though it’s top of the line (Harken) and oversized for our boat. (I replaced the lighter one the boat came with.)

In summary, I always prefer a really good preventer setup that makes it so easy to set that we always do. The other point that cruisers should keep in mind is to always reef at the right time to reduce the loads to manageable and safe levels—neglected far too often downwind because many do not realize that the loads are building exponentially as the breeze increases.

Interesting. Thank you and that is why we post!

The load is actually much greater than a vang, because when locked down and jibed, the vertical load is multiplied by the side load (leverage triangle–my German is too rusty to have noticed if he mentioned this). Additionally, the boom section is designed for the vang (vertical) load and not for an angular load. I did my testing on a cat, with a lot more beam; the attachment point was much farther aft, so probably only half the load and 1/3 the tension requirement. Thus, I did not take this problem seriously enough. My boom is also relatively fat; many racing booms are quite high aspect.

The real problem, though, and a challenge with any boom brake application, is judging the correct tension. An engineer, with tables on the device and specs on the boom, could specify the safe tension reasonably safely, but that’s not going to work in the field or for the broader world of sailors. It would have to be an engineered solution, not an add-on. For example, a system for a mega-yacht could include a brake that had a hub that would release at a pre-set load, something like a prop hub.

Something for super yacht designers to mull over. I still believe there is an idea here. But the current designs are crude and a simple to use, reliable means of limiting the force is vital. Hmm….

Hi Drew,

I agree, the current boom brakes are just to crude to be really safe. Also, as you point out, very often they are added to booms that were not designed to take the loads. Ditto you often see the lines attached to the deck on fittings that are way to flimsy, or worst to a chain plate. Bottom line, to make boom brakes really work right would take some serious engineering. In the mean time I prefer the solution with the lowest loads: an end boom preventer led forward, preferably coupled with straight spreaders so the boom can be let out properly.